Amorphous magnesium-yttrium-transition metal hydrogen storage material and preparation method thereof

A technology of transition metals and hydrogen storage materials, which is applied in the field of hydrogen storage materials, and achieves the effects of simple preparation process, reduced cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

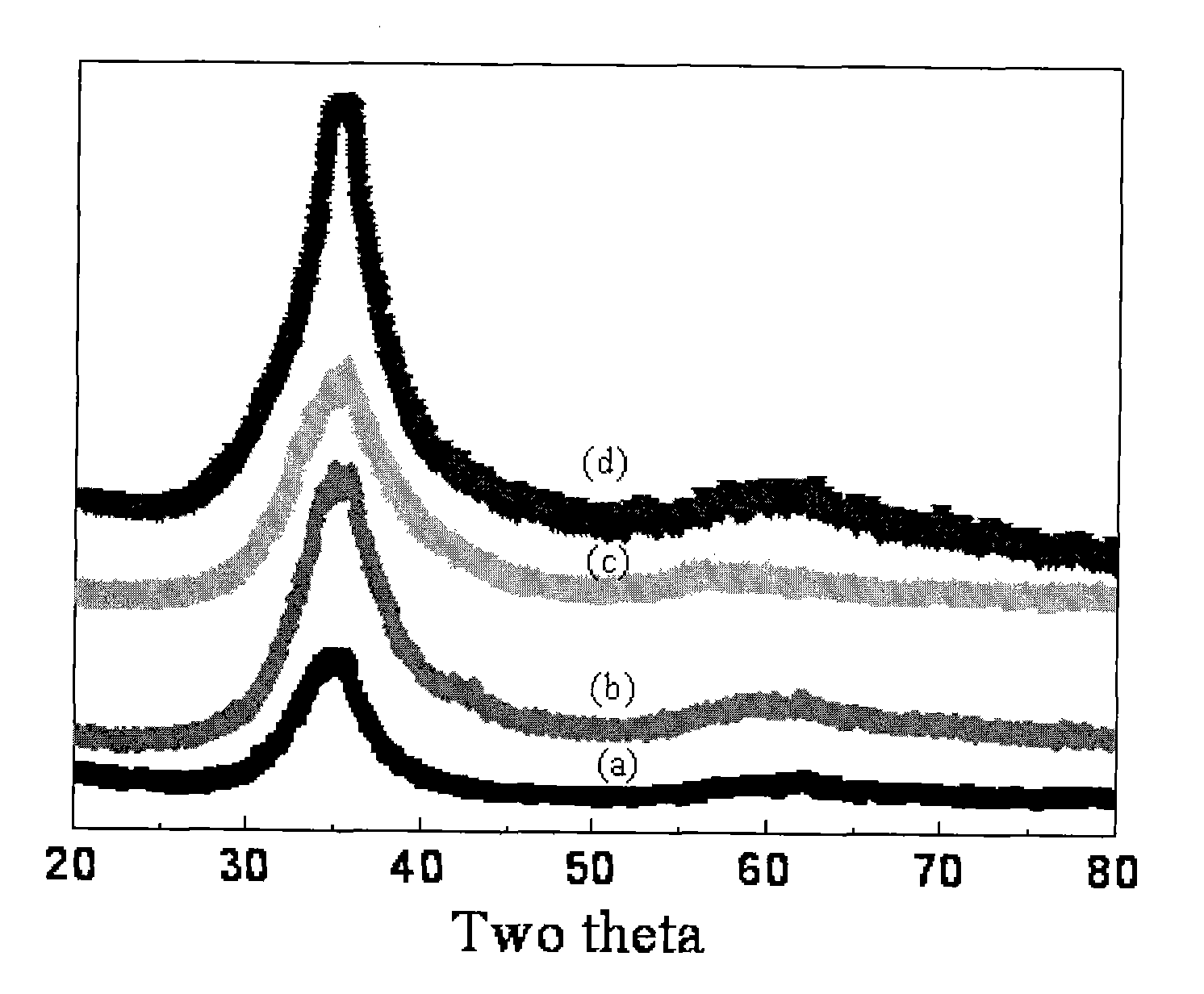

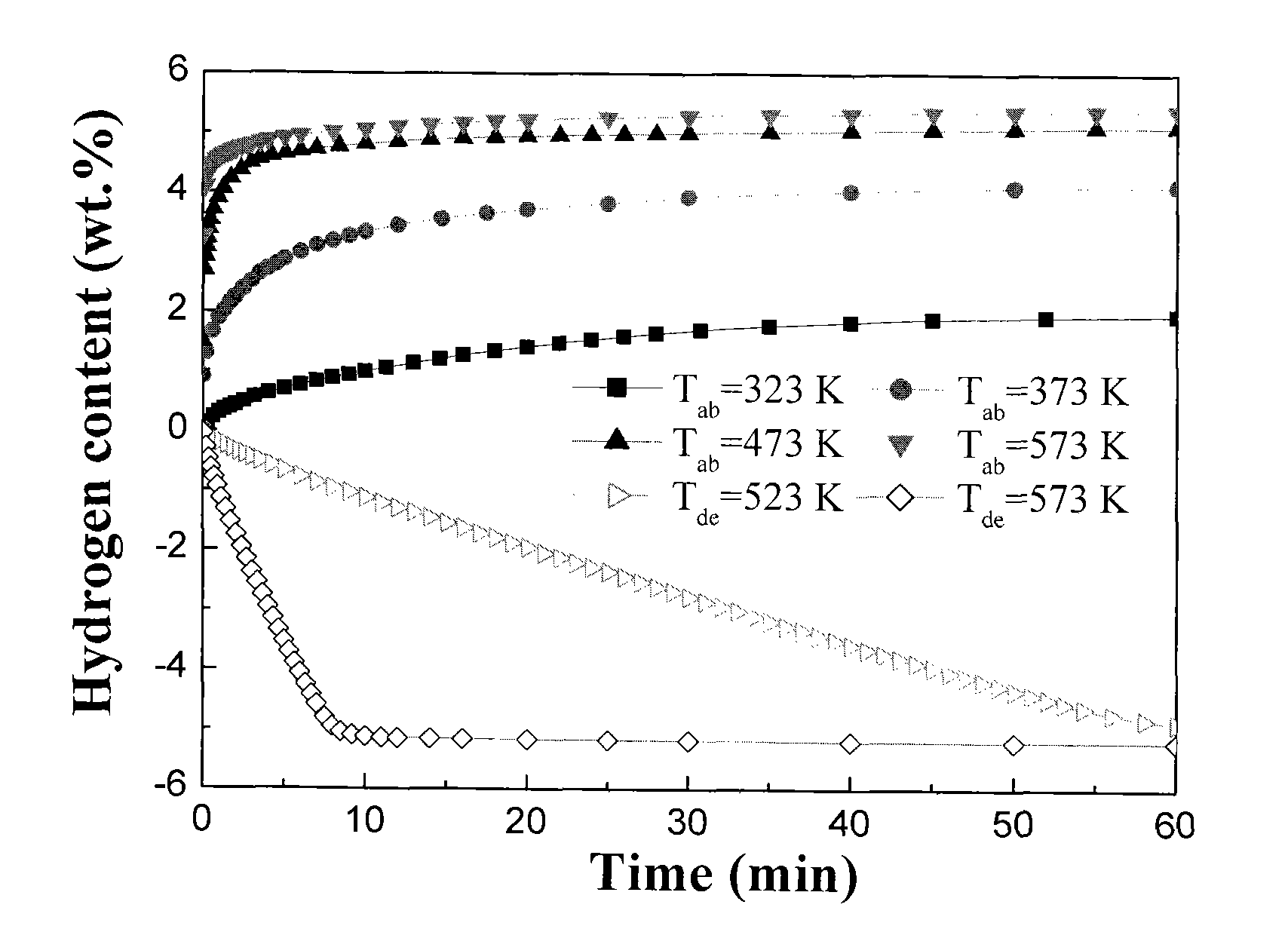

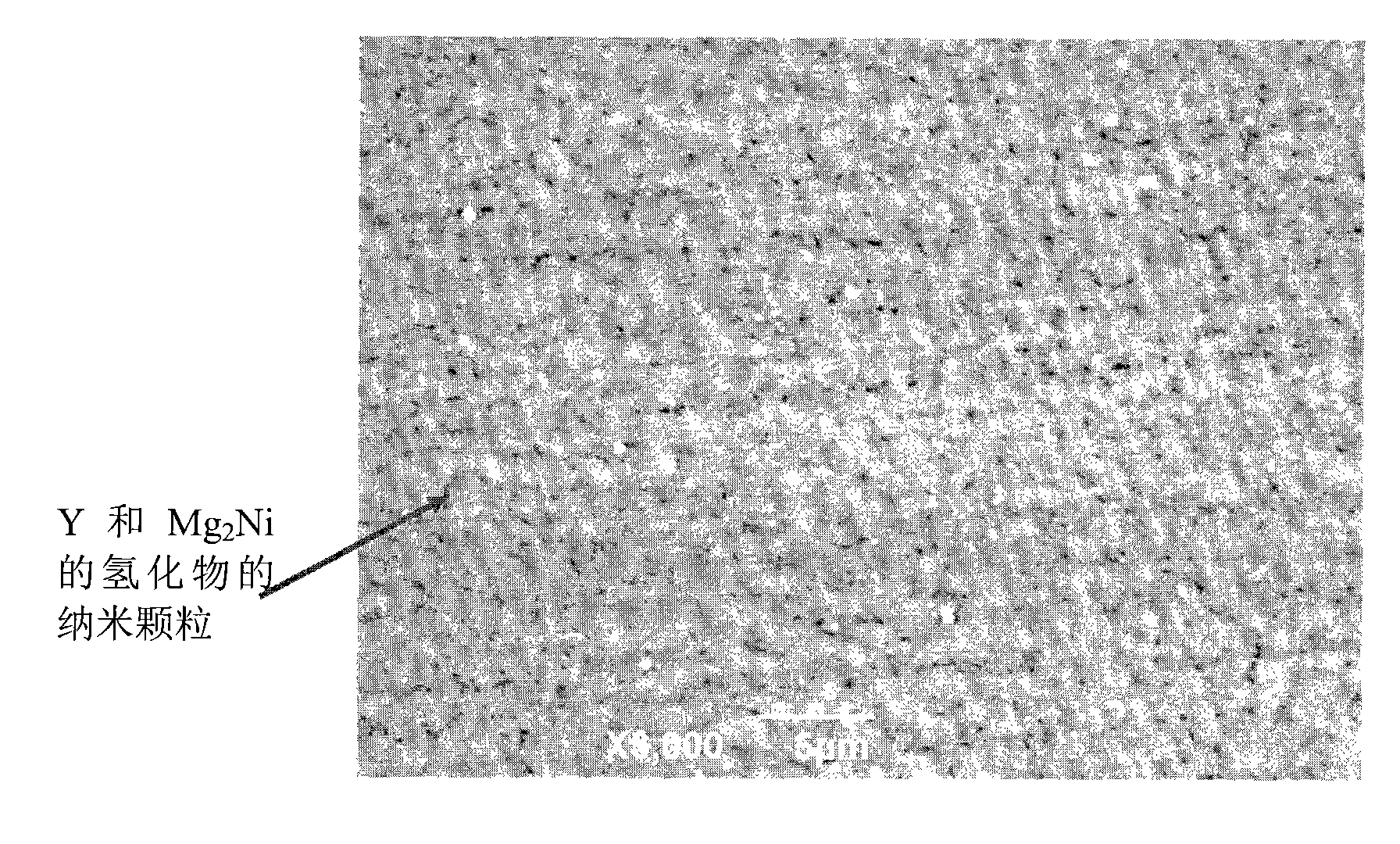

[0021] The metal Y block has a purity of 99.5%; the metal Ni sheet has a purity of 99.9%. According to the YNi alloy molar ratio of 1:1, a certain amount of raw metal (2wt.% burning loss is added to Y) was weighed and smelted under a power of 15KW to obtain a YNi master alloy. by Mg 12 The molar ratio of Mg and YNi in the YNi alloy is 12: 1. Weigh a certain amount of metal Mg block (purity 99.7%) and YNi master alloy (18wt.% burning loss is added to Mg), and then in ZK-10TIII protected by argon Remelting and rapid quenching in a vacuum single-roll melt quenching furnace. The surface speed of the copper roll is 40m / s to obtain amorphous Mg with a width of 3mm and a thickness of 30-50μm 12 YNi alloy strip ( figure 1 (a) Amorphous Mg 12 X-ray diffraction pattern of YNi alloy sample). Amorphous Mg 12 The YNi alloy strip was ground into a 300-mesh powder in a glove box and found to have good hydrogen storage performance ( figure 2 Amorphous Mg 12 Hydrogen absorption and de...

Embodiment 2

[0023] Same as in Example 1, first prepare a YNi master alloy. by Mg 11 Y 2 Ni 2 The molar ratio of Mg and YNi in the alloy is 11:2. Weigh a certain amount of metal Mg block and YNi master alloy (18wt.% burning loss is added to Mg), and then melt it quickly in the ZK-10TIII type vacuum single roll protected by argon. Re-dissolved and rapidly quenched in a quenching furnace. The surface speed of the copper roller is 30m / s to obtain amorphous Mg with a width of 3mm and a thickness of 30-50μm 11 Y 2 Ni 2 Alloy strip ( figure 1 (b) Amorphous Mg 11 Y 2 Ni 2 X-ray diffraction patterns of alloy samples). Amorphous Mg 12 YNi alloy strips were ground into 300-mesh powder in a glove box, and the hydrogen storage properties were tested as follows: the hydrogen absorption and desorption capacities reached 5.1 and 4.3wt.% respectively; the hydrogen absorption and desorption temperatures were respectively lower than those of pure Mg by 277 and 77K; The hydrogen speed is greatly ...

Embodiment 3

[0025] In the same manner as in Example 1, a YCu master alloy (the purity of metal Cu flakes is 99.7%) was first prepared. by Mg 10 The molar ratio of Mg and YCu in the YCu alloy is 10: 1. Weigh a certain amount of metal Mg block and YCu master alloy (18wt.% burning loss is added to Mg), and then melt them in the ZK-10TIII type vacuum single-roller protected by argon. Redissolved and quenched in a rapid quenching furnace. The surface speed of the copper roller is 35m / s to obtain amorphous Mg with a width of 3mm and a thickness of 30-50μm 10 YCu alloy thin strip ( figure 1 (c) Amorphous Mg 10 X-ray diffraction pattern of YCu alloy sample). Amorphous Mg 10 YCu alloy thin strips were ground into 300-mesh powder in a glove box, and the hydrogen storage properties were tested as follows: the hydrogen absorption and desorption capacities reached 5.2 and 4.5wt.% respectively; The hydrogen speed is greatly improved, and when it is higher than 373K, it can absorb hydrogen and abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com