Method for preparing Li-Mg-N-H hydrogen-storing material

A technology of hydrogen storage materials and nitrides, which is applied in the production of hydrogen and various metal hydrides, can solve the problems of high cost, high dehydrogenation temperature of Li-Mg-N-H hydrogen storage materials, and poor cycle stability. Achieve the effects of low cost, improved cycle stability, and accelerated hydrogen absorption and desorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

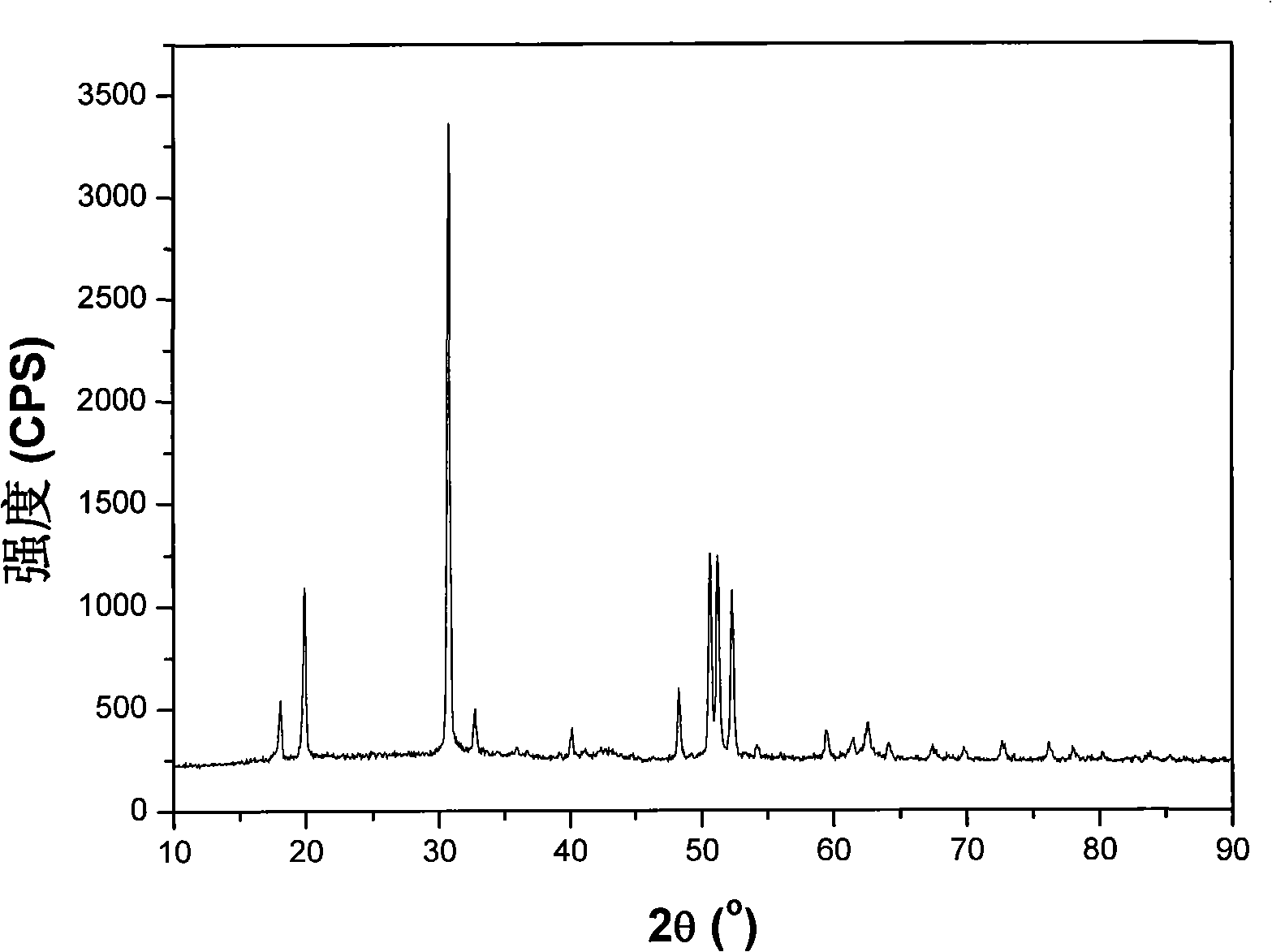

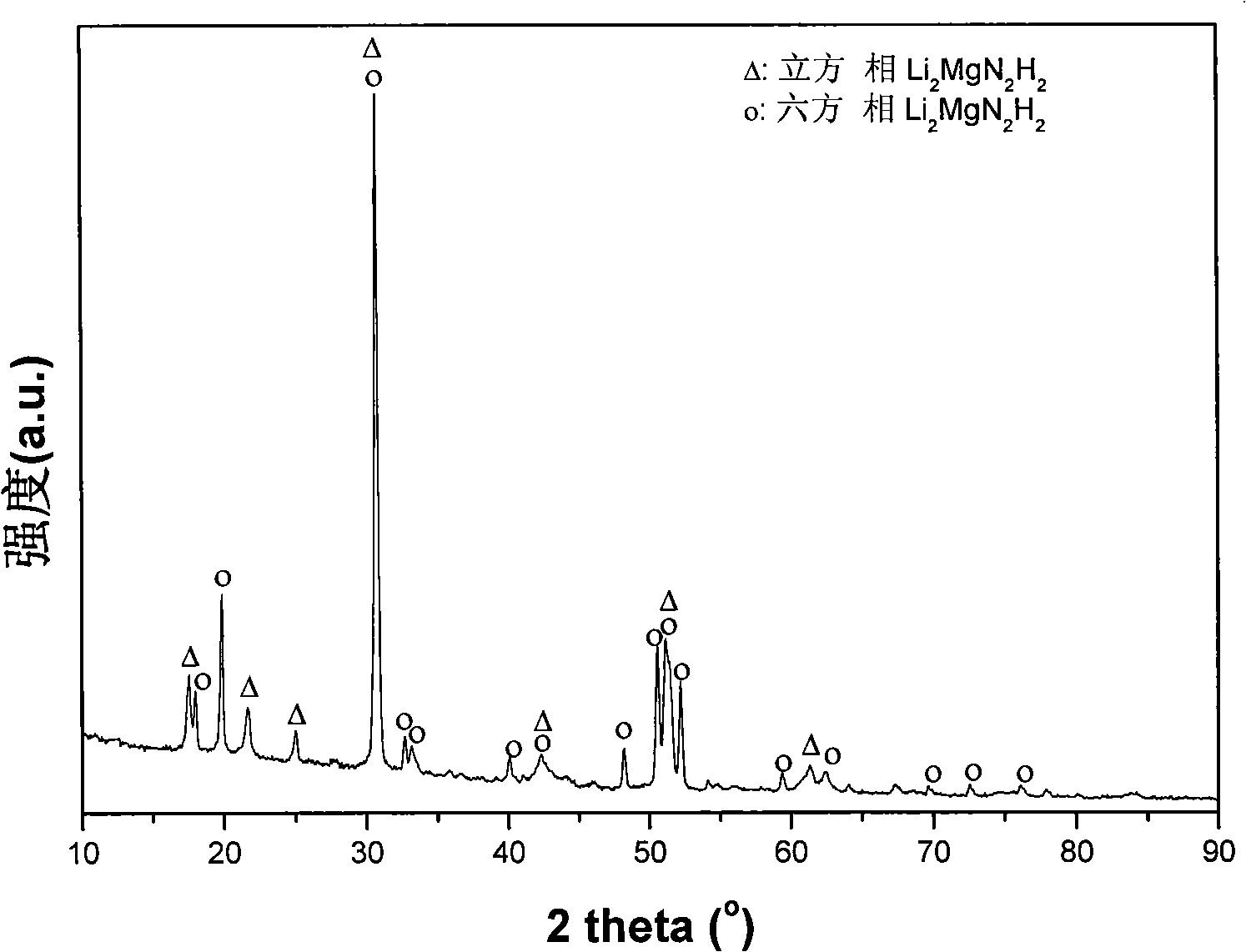

[0033] In a glove box filled with Ar gas, the Li 3 N and Mg(NH 2 ) 2 , LiNH 2 and Mg, LiNH 2 and Mg(NH 2 ) 2 , LiNH 2 , Mg and Mg(NH 2 ) 2 Mix according to the molar ratio of 2:3, 1.95:1, 2:1 and 2.5:0.5:0.5 respectively, put them into a sealable stainless steel tank, use argon protection, and carry out mechanical mixing on an automatic mechanical powder mixer. 40:1, rotating speed 90rpm, mixing time 8h. Put the uniformly mixed mixture into the atmosphere type sintering furnace under the condition of isolating the air, protect it with nitrogen flow, nitrogen pressure 2atm, flow rate 100mL / min, sample sintering temperature 250℃, holding time 36h, sintering to prepare Li-Mg -N-H hydrogen storage materials. The molar ratios of the mixed samples and their mixing and sintering preparation conditions are listed in Table 1. The X-ray diffraction test of the samples prepared by sintering found that the samples showed Li 2 MgN 2 h 2 The diffraction pattern. figure 1 As a...

Embodiment 2

[0035] In a glove box filled with Ar gas, LiNH with a molar ratio of 2.05:1 2 and Mg(NH 2 ) 2 The mixture was put into a ball milling tank with an on-off valve. After the ball milling tank was pre-evacuated, it was ball milled and mixed on a planetary ball mill with a ball-to-material ratio of 55:1, a rotating speed of 550 rpm, and a ball milling time of 6 hours. Then, the mixture was placed in an atmosphere sintering furnace under the condition of isolating the air, protected by nitrogen flow, nitrogen pressure 1.6atm, flow rate 70mL / min, sample sintering temperature 280°C, holding time 30h, sintering to prepare Li-Mg-N-H Hydrogen storage material. The mixed sintering preparation parameters of the samples are also listed in Table 1. The X-ray diffraction test of the samples prepared by sintering showed that the product mainly contained Li 2 MgN 2 h 2 Mutually.

Embodiment 3

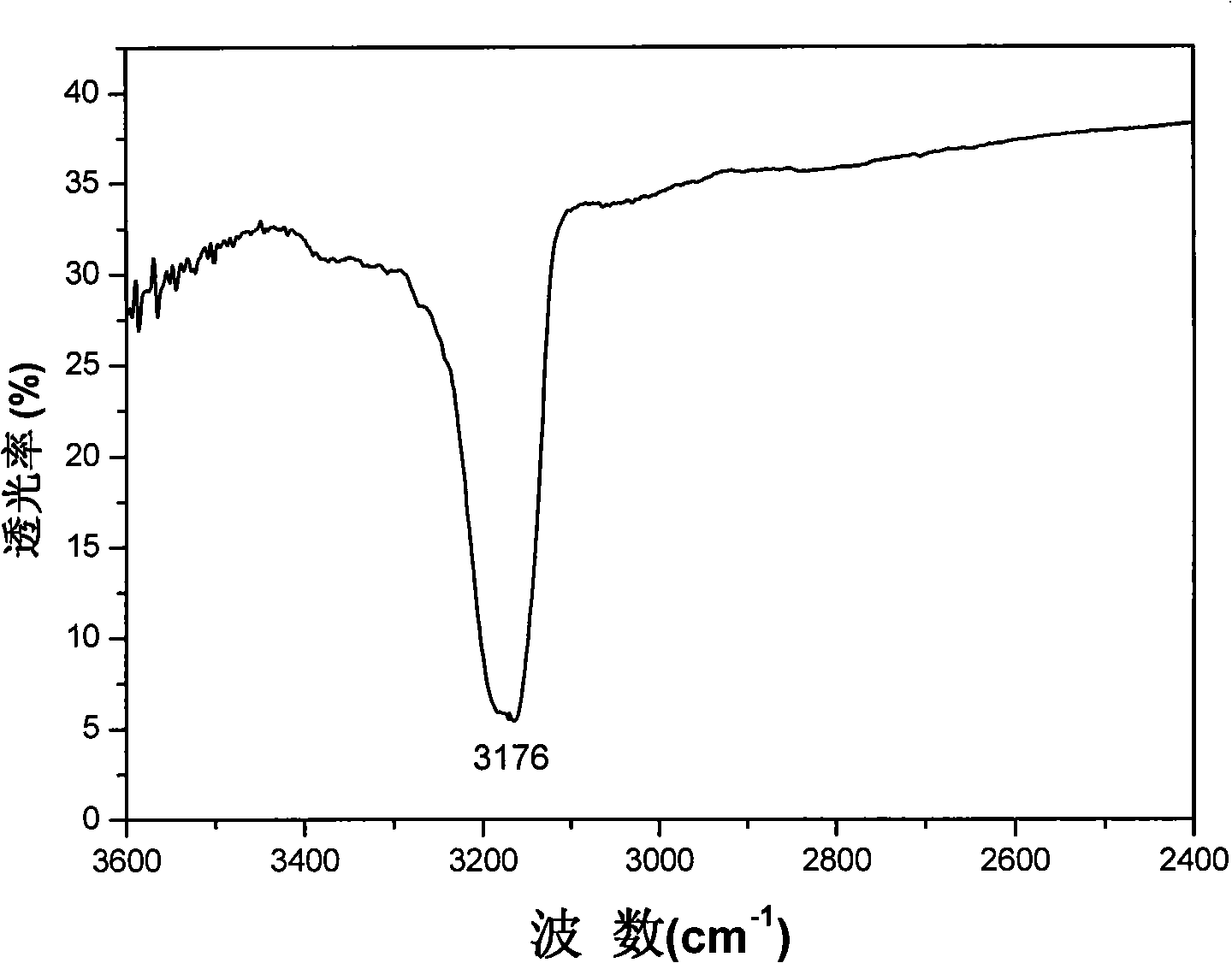

[0037] In a nitrogen-filled glove box, LiNH with a molar ratio of 2:0.1:0.7 2 and Mg 3 N 2 and Mg(NH 2 ) 2 The mixture was put into a sealable stainless steel tank, protected by nitrogen, and mechanically mixed on an automatic mechanical powder mixer with a ball-to-material ratio of 80:1, a rotating speed of 60 rpm, and a mixing time of 12 hours. Then, the homogeneous mixture is transferred to a vacuum sintering furnace without being exposed to the air, and the vacuum protection is adopted, and the vacuum degree is 10 -2 -10 -6 Atm, the sintering temperature of the sample is 300°C, the holding time is 24h, and the Li-Mg-N-H hydrogen storage material is prepared by sintering. The mixing and sintering preparation conditions of the samples are also listed in Table 1. Infrared spectroscopy tests were carried out on the sintered samples, figure 2 shown as LiNH 2 -Mg 3 N 2 -Mg(NH 2 ) 2 Infrared spectra of Li-Mg-N-H samples prepared as raw materials. It can be seen from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com