Lithium-magnesium-nitrogen-hydrogen composite hydrogen storing material

A hydrogen storage material, nitrogen and hydrogen technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of slow hydrogen release rate, high hydrogen release temperature, difficult to meet practical application requirements, etc., and achieve faster hydrogen release rate and performance. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

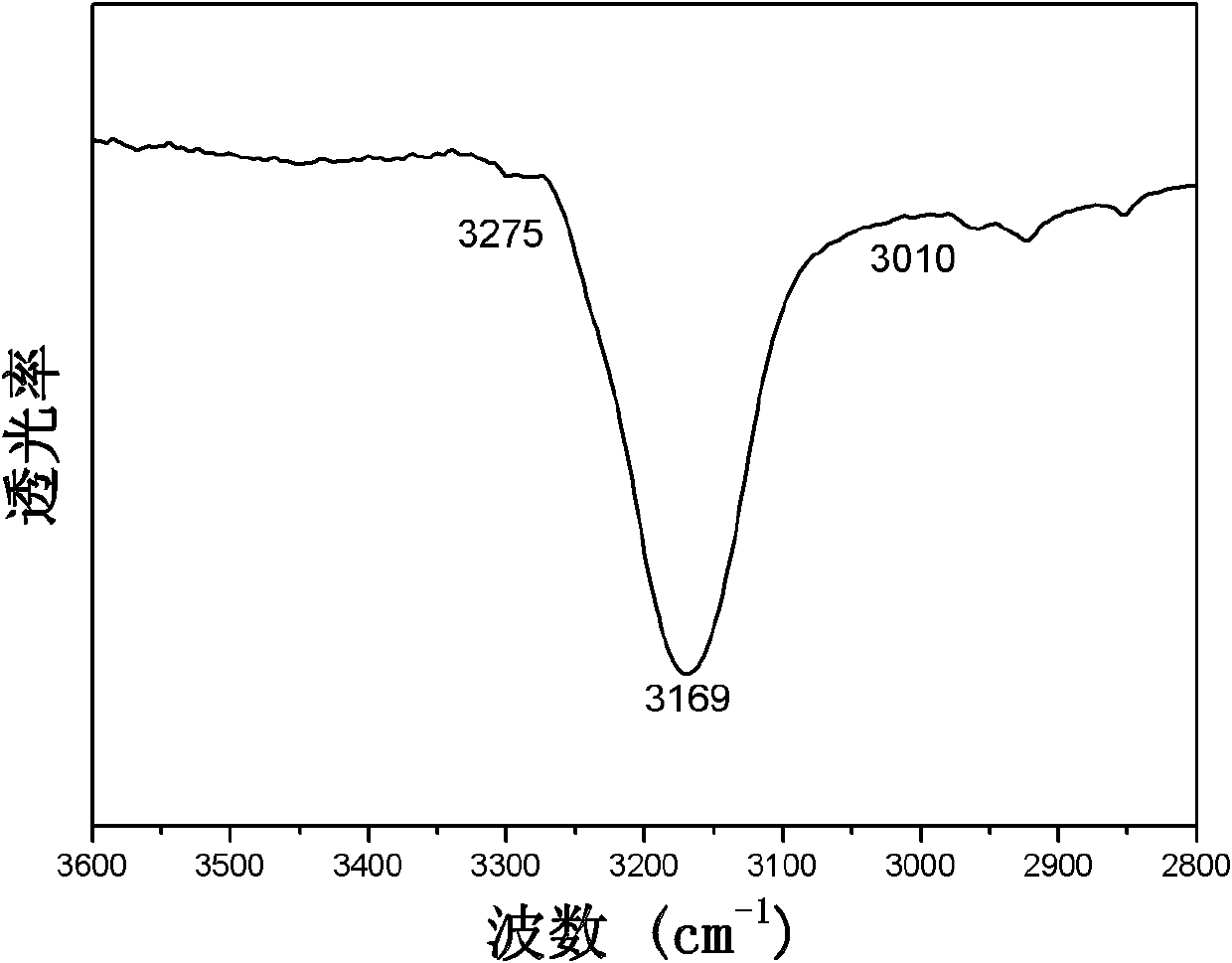

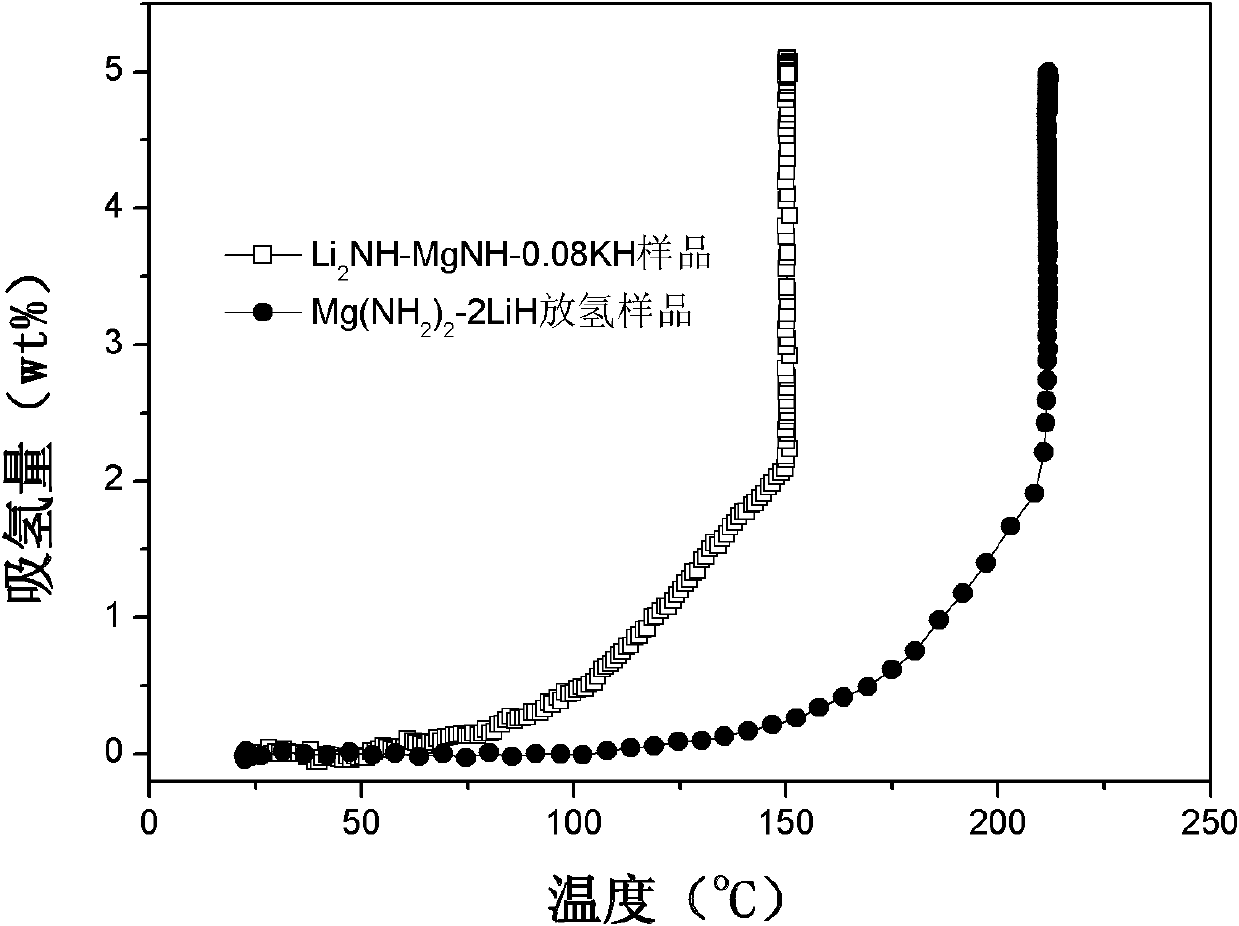

[0019] In a glove box filled with Ar gas, Li 2 NH and MgNH were mixed with 0.01, 0.03, 0.05, 0.08, 0.1 and 0.15 moles of KH respectively, put into a sealable stainless steel tank, protected by argon, and ball milled on a planetary ball mill with a ball-to-material ratio of 60:1 , the speed is 500rpm. The samples after ball milling were first analyzed by FTIR. figure 1 Shown as Li 2 FTIR spectrum of NH-1.2MgNH-0.15KH sample. It can be seen from the figure that the sample is at 3010-3275cm after ball milling -1 In the range of wave numbers, there is an asymmetrical broad peak, and the peak wave number of the absorption peak is at 3169cm -1 or so, which is mainly determined by Li 2 It is caused by the superposition of NH and MgNH infrared absorption peaks. Subsequently, the samples after ball milling were tested for hydrogen absorption performance, the initial hydrogen pressure for hydrogen absorption was 100 atm, and the heating rate was 1°C / min. Table 1 lists the hydroge...

Embodiment 2

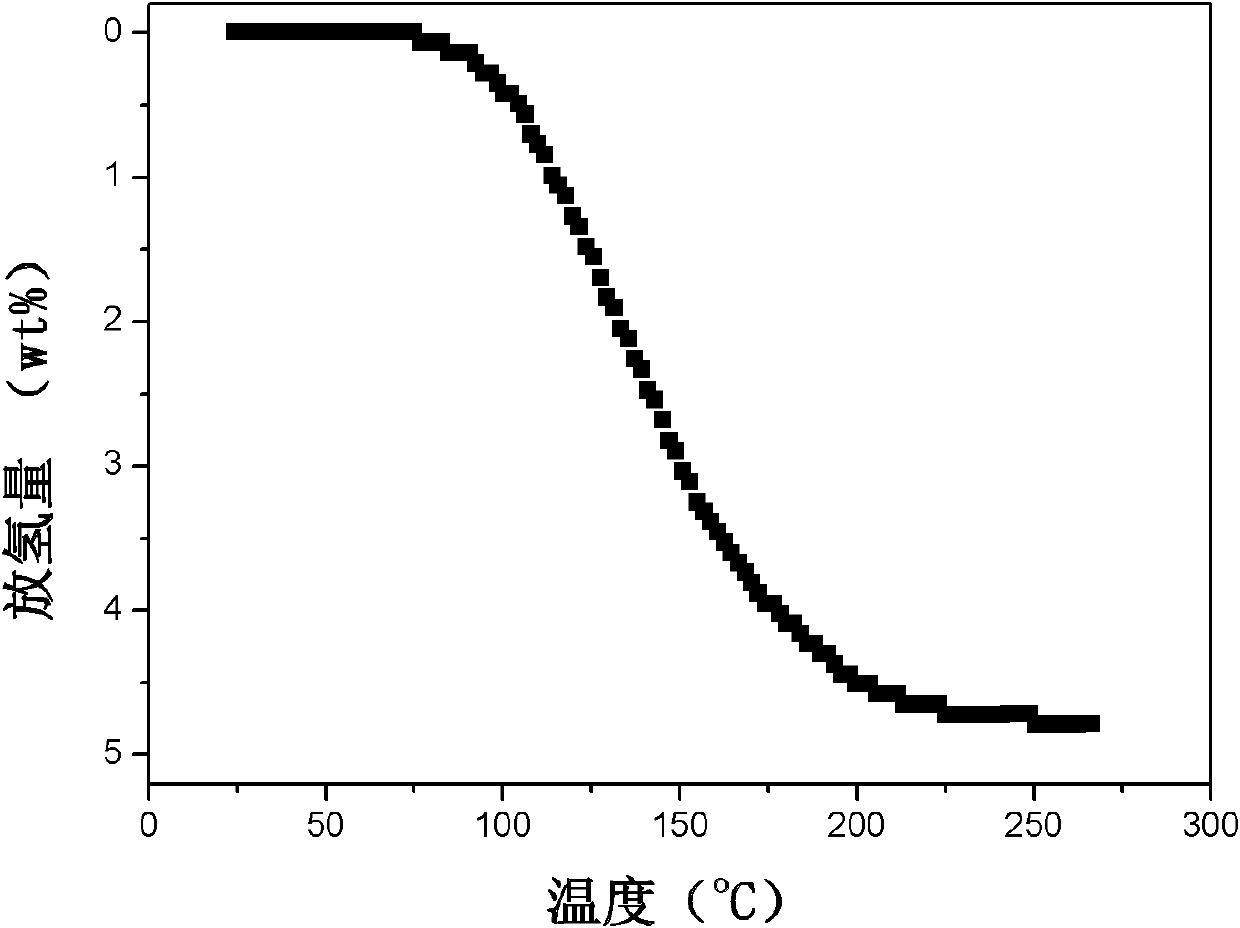

[0027] filled with N 2 In a glove box with gas, the molar ratios of Li 2 NH and MgNH with 0.02, 0.04, 0.06, 0.08, 0.1, 0.12 and 0.14 moles of K, respectively 2 O or KOH were mixed, put into a sealable stainless steel tank, protected by nitrogen, and ball milled on a vibrating ball mill with a ball-to-material ratio of 30:1. The obtained samples were first subjected to hydrogen absorption under the conditions of 80atm and 150°C, and then the hydrogen desorption performance test was performed on the hydrogen absorption samples. Table 2 lists the dehydrogenation starting temperature and dehydrogenation amount of the mixed samples after hydrogen absorption. It was found that the starting temperature of hydrogen desorption of all samples was below 100°C, and the hydrogen desorption amount was above 4wt%. image 3 Shows Li 2 Hydrogen desorption curve of NH-0.5MgNH-0.12KOH hydrogen absorption sample. It can be seen from the figure that the initial hydrogen desorption temperature...

Embodiment 3

[0032] In a glove box filled with Ar gas, Li 2 NH and MgNH are mixed with 0.1 and 0.15 moles of KF and KI, respectively, and put into a ball mill tank with a switch valve. After the ball mill tank is pre-evacuated, the ball mill is mixed on a planetary ball mill, and the ball-to-material ratio is 80:1. , the speed is 300rpm. The obtained samples are first subjected to hydrogen absorption under the conditions of 90atm and 180°C, and the hydrogen absorption samples are then subjected to a hydrogen desorption performance test. Table 3 lists the dehydrogenation temperature and dehydrogenation amount of all the above samples after hydrogen absorption. It was found that the initial hydrogen desorption temperature of all samples was below 100° C., and the total hydrogen desorption amount was between 4-5 wt%. Figure 4 Shown as Li 2 Hydrogen desorption curve of NH-0.75MgNH-0.1KF hydrogen absorption sample. Obviously, the initial hydrogen desorption temperature of the sample is about...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com