A kind of al-biocl aluminum-based composite hydrogen production material and preparation method thereof

An aluminum-based composite and aluminum powder technology is applied in the field of Al-BiOCl aluminum-based composite hydrogen production material and its preparation, which can solve the problems of inability to continuously release hydrogen in time, long reaction time, etc., and achieve non-toxic price cost and short start-up time. , the effect of fast hydrogen release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

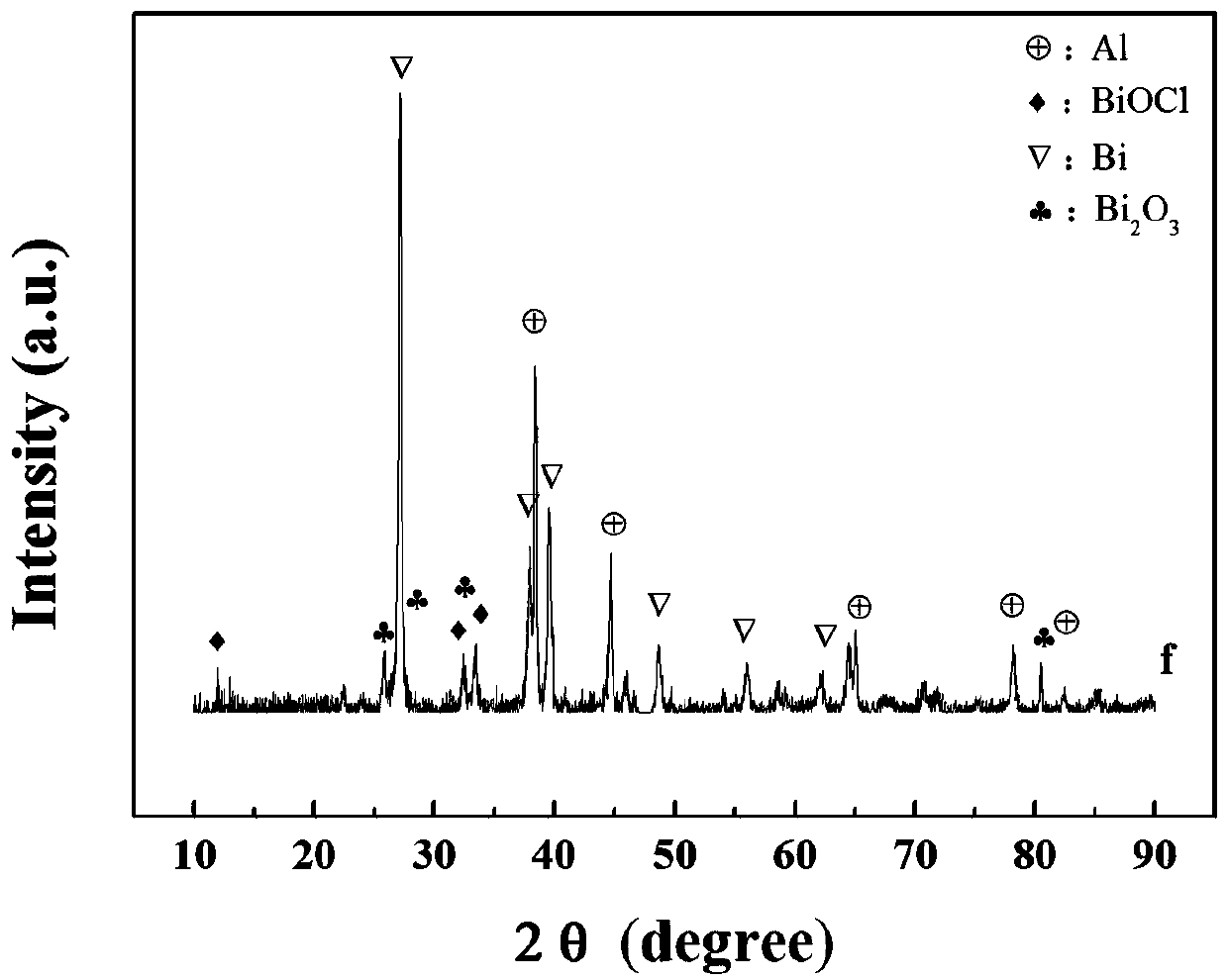

[0027] Adopt the high-energy mechanical ball milling method, under the protection of argon environment, weigh the mixed powder according to the mass ratio m(Al):m(BiOCl) = 0.5:0.5, respectively weigh a total of 1g, add it to the ball mill tank, and then press the ball-to-material ratio to be 60: 1 Add 15 small steel balls (about 60g) to seal the ball milling tank; put the ball milling tank on a Retsch PM400 planetary ball mill for high-energy ball milling. Aluminum matrix composite hydrogen production material. The samples obtained after ball milling were subjected to XRD diffraction. The experimental conditions were: diffracted beam CuKa, power 50KV×200 mA, tube pressure 40 kV, tube flow 40 mA, and the scanning range was 10°-90°. The results of diffraction data processing are as follows: figure 1 shown.

[0028] X-ray diffractometer (XRD) is used to analyze the diffraction pattern of the material, which is necessary to verify the composition of the material and analyze the ...

Embodiment 2

[0030] The high-energy mechanical ball milling method is adopted, the raw material used is powder, the particle size is in the micron level, the ball-to-material ratio is selected to be 60:1, and the mass ratio is m(Al):m(BiOCl) = 0.95 under argon environment protection: 0.05 Weigh 1g of the mixed powder and add it to the ball mill jar, then add 15 small steel balls (about 60g), seal it, put the ball mill jar on a Retsch PM400 planetary ball mill for high-energy ball milling, the ball milling speed is 250 rpm, and the ball milling time is After 5 h, a highly active aluminum-based composite hydrogen production material with uniform composition was finally obtained.

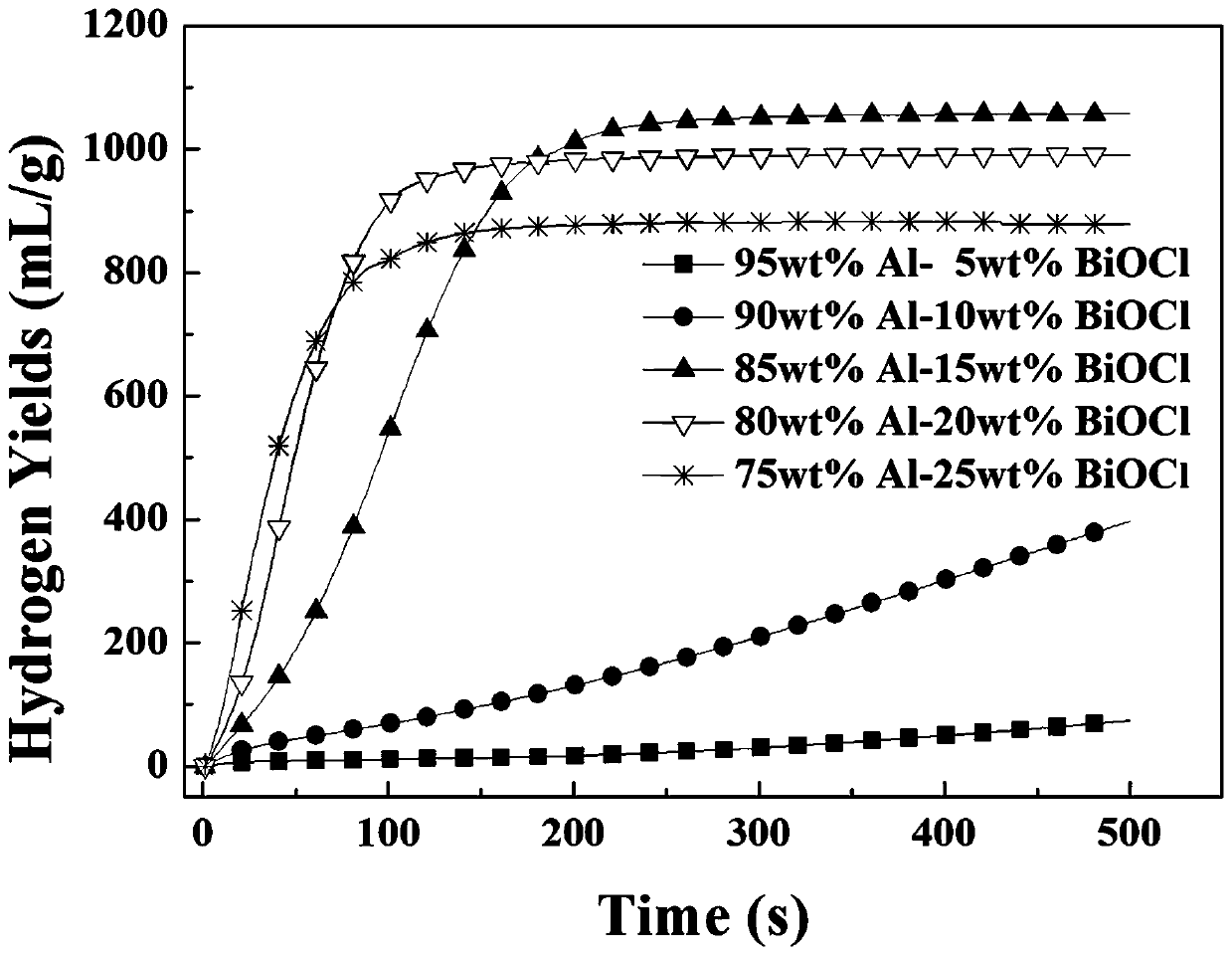

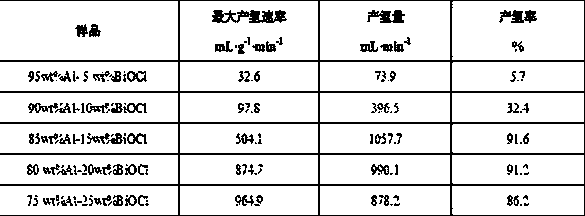

[0031] Weigh 0.01 g of the ball-milled sample into a 200 mL reaction bottle, seal the bottle mouth with sealing glue, put the reaction bottle into a water bath set at 25°C, keep a constant reaction temperature, and add 10 mL deionized water. The hydrogen gas produced in the experiment is cooled by the condensing t...

Embodiment 3

[0033] The high-energy mechanical ball milling method is adopted, the raw material used is powder, the particle size is in the micron level, the ball-to-material ratio is selected to be 60:1, and the mass ratio is m(Al):m(BiOCl) = 0.9 under argon environment protection: 0.1 Weigh 1g of the mixed powder and add it to the ball mill jar, then add 15 small steel balls (about 60g), seal it, put the ball mill jar on a Retsch PM400 planetary ball mill for high-energy ball milling, the ball milling speed is 250 rpm, and the ball milling time is After 5 h, a highly active aluminum-based composite hydrogen production material with uniform composition was finally obtained.

[0034] Weigh 0.01 g of the ball-milled sample into a 200 mL reaction bottle, seal the bottle mouth with sealing glue, put the reaction bottle into a water bath set at 25°C, keep a constant reaction temperature, and add 10 mL deionized water. The hydrogen gas produced in the experiment is cooled by the condensing tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com