Lithium-boron-nitrogen-hydrogen hydrogen storage material

A hydrogen storage material, nitrogen-hydrogen technology, applied in the direction of borane/diborane hydride, other chemical processes, chemical instruments and methods, etc., can solve the problem of difficulty in meeting practical application requirements, slow hydrogen depletion speed, and hydrogen depletion temperature Advanced problems, to achieve the effect of excellent performance, fast hydrogen release speed, and low hydrogen release temperature

Inactive Publication Date: 2010-12-01

ZHEJIANG UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

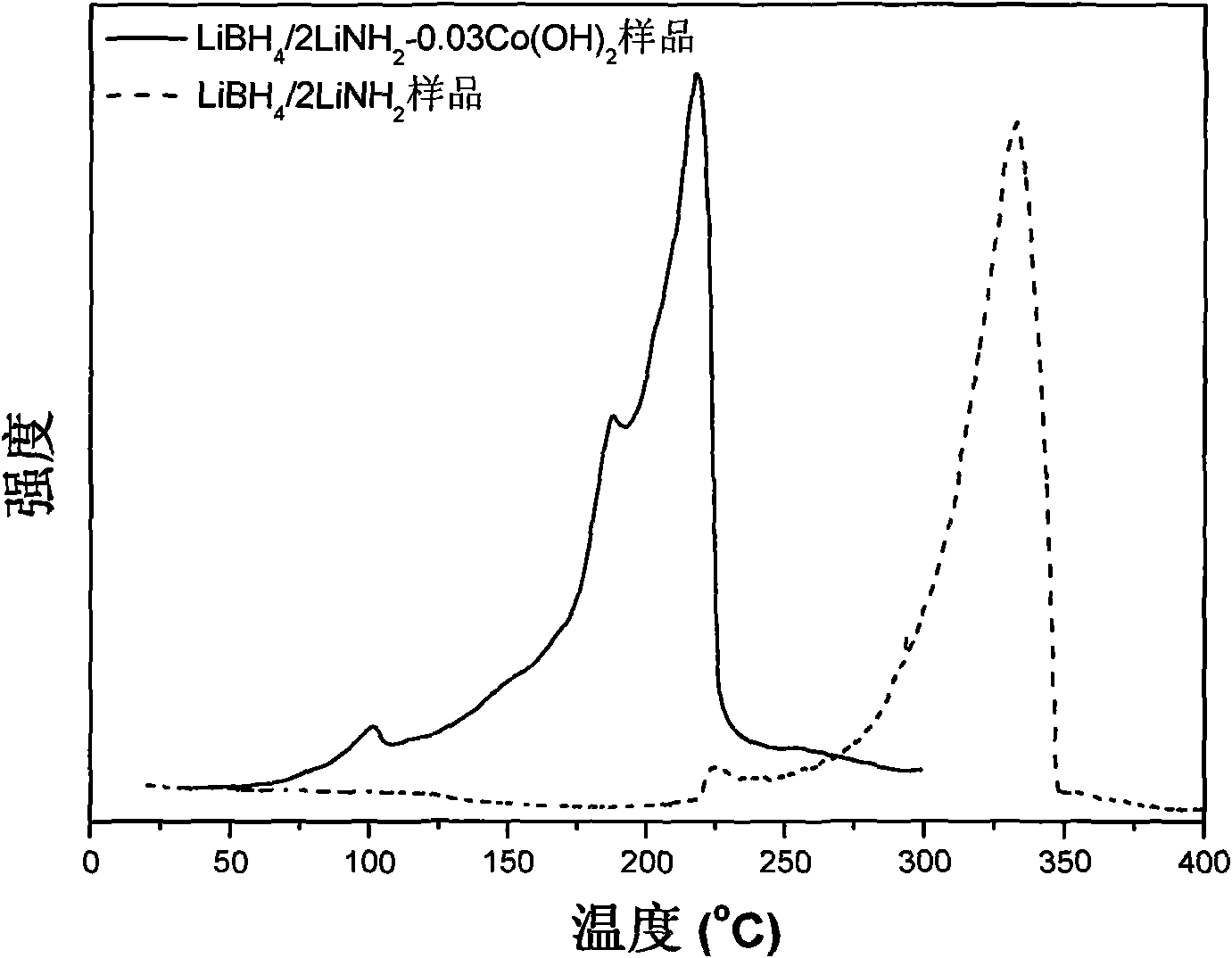

However, the dehydrogenation temperature of the lithium-boron-nitrogen-hydrogen composite hydrogen storage materials currently developed is generally high, the hydrogen desorption starting temperature is above 200°C, and the hydrogen desorption rate is slow, which is difficult to meet the requirements of practical applications.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

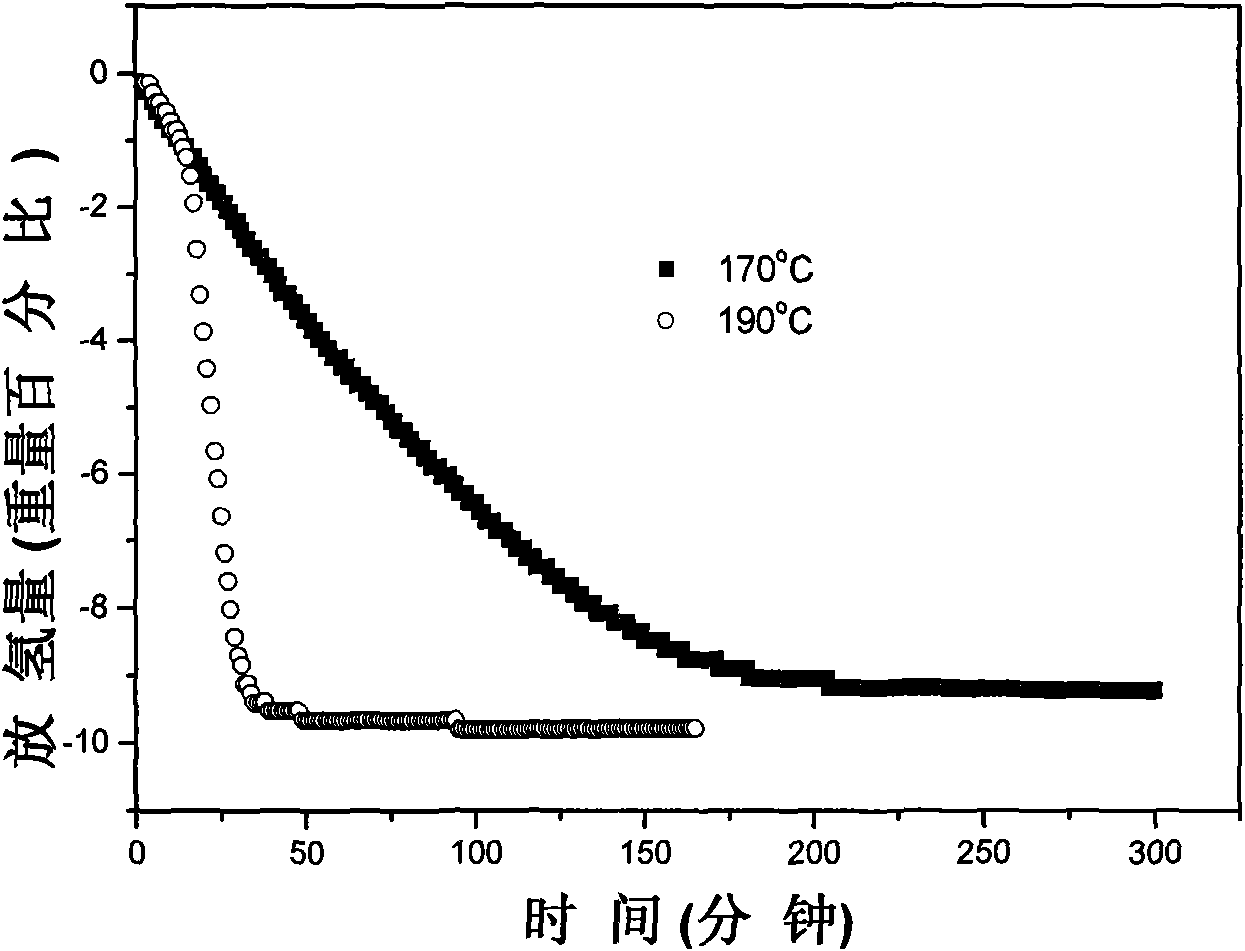

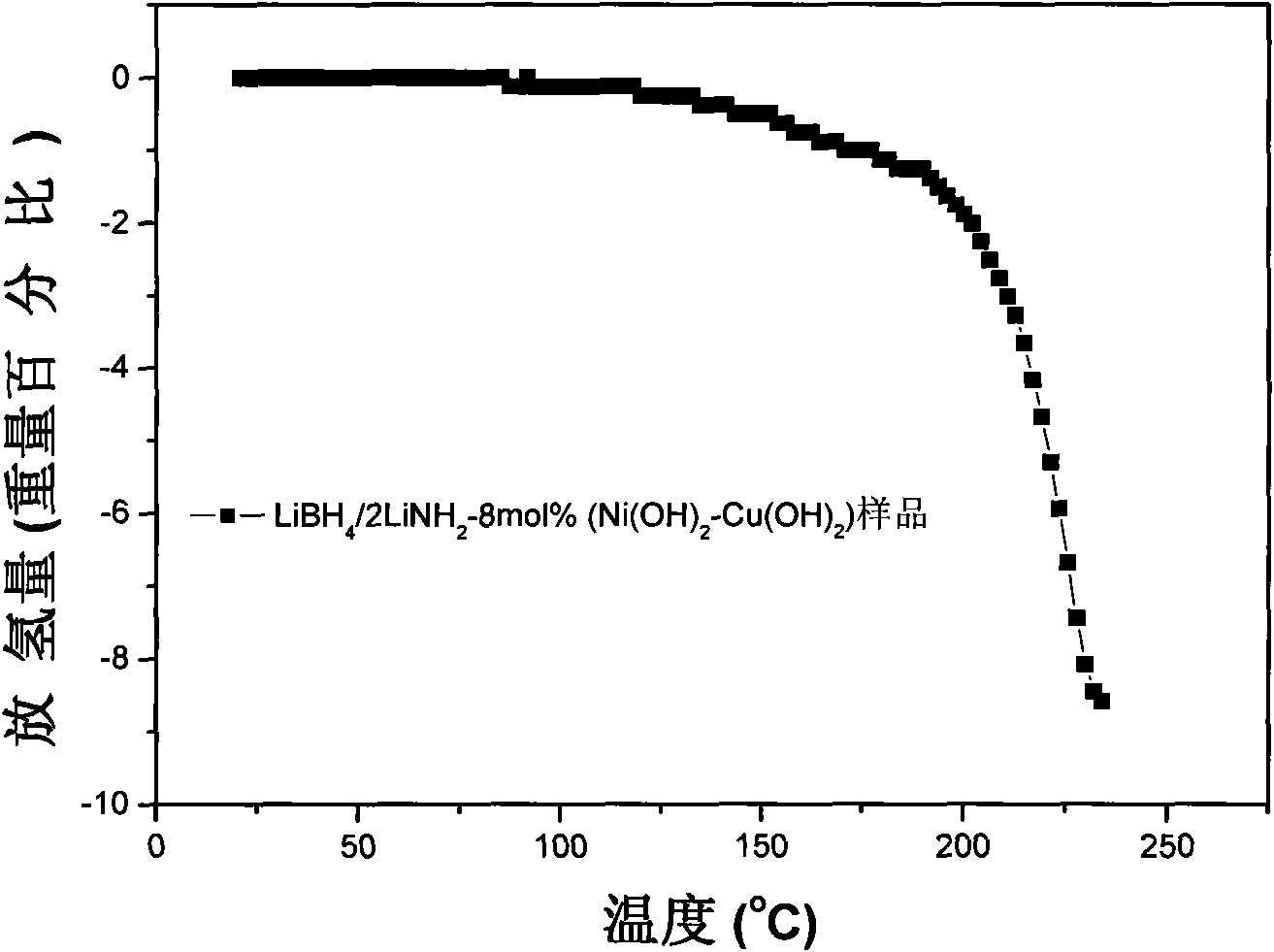

The invention discloses a lithium-boron-nitrogen-hydrogen hydrogen storage material, which has a component of LiaBNbHc-xM(OH)n, wherein M is a metal element in transition group, a is not more than 4 and not less than 2, b is not more than 3 and not less than 1, c is not more than 10 and not less than 6, x equals to 0.01-0.2, and n is the valence state of M. When air is isolated, the mixture of metal hydroxides M(OH)n, LiBH4 and LiNH2 is put in a stainless steel pot. In the condition of vacuum, inert atmosphere and hydrogen atmosphere, the mixture is evenly mixed by using a mechanical mixing method. The lithium-boron-nitrogen-hydrogen hydrogen storage material has over 8 percent by weight of hydrogen storage capacity, low hydrogen release temperature (the initial hydrogen release temperature is about 70 DEG C) and fast hydrogen release speed (over 9.0 percent by weight of hydrogen can be released within 30 min at the temperature of 190 DEG C) and is a hydrogen storage material with goodperformance.

Description

A lithium boron nitrogen hydrogen storage material technical field The invention relates to a hydrogen storage material for a fuel cell, in particular to a lithium boron nitrogen hydrogen storage material. Background technique With the development of technology and economy, people's demand for energy is increasing day by day, leading to the depletion of traditional energy sources such as oil, and the energy crisis is becoming increasingly severe. On the other hand, environmental pollution caused by traditional fossil fuels is increasingly threatening people's lives, and the emission of greenhouse gases and the formation of acid rain are all closely related to it. The development of green alternative fuels can not only solve energy problems, but also reduce environmental pollution. Hydrogen is regarded as the most ideal energy carrier in the future due to its high efficiency, cleanness and non-pollution, and ease of production and transportation. The use of hydrogen as a ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C01B6/21B01J20/04

Inventor 刘永锋潘洪革骆昆高明霞

Owner ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com