A lightweight solid-state hydrogen storage power system for fuel cell exhaust water reuse

A fuel cell and power system technology, applied in fuel cells, electrical components, circuits, etc., can solve the problems of low hydrogen storage capacity of ammonia borane and affect hydrogen storage performance, so as to improve safety, improve heat exchange efficiency and Productivity of cooling water, effect of volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

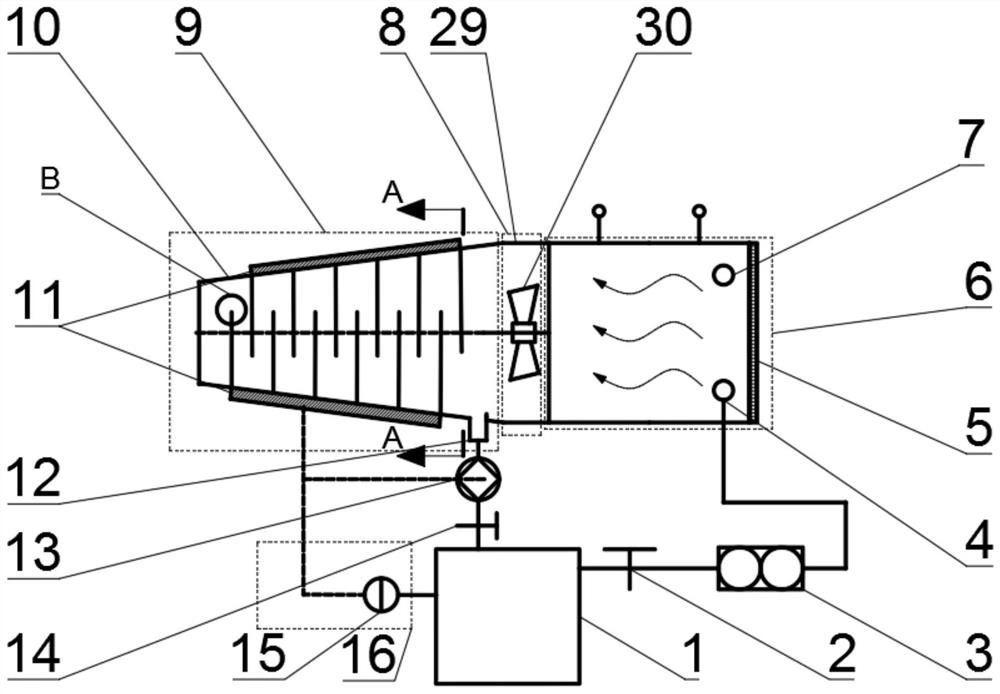

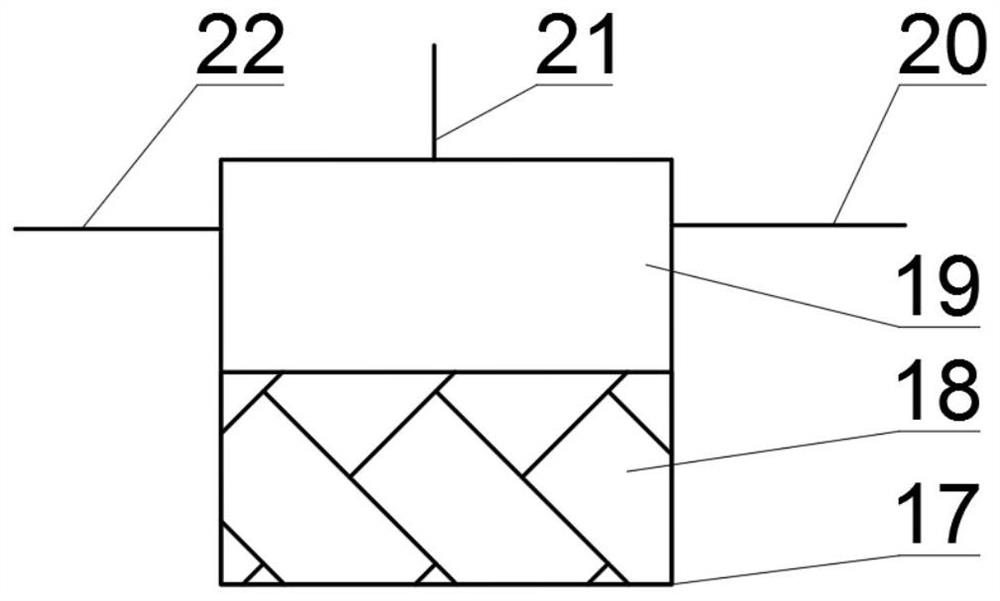

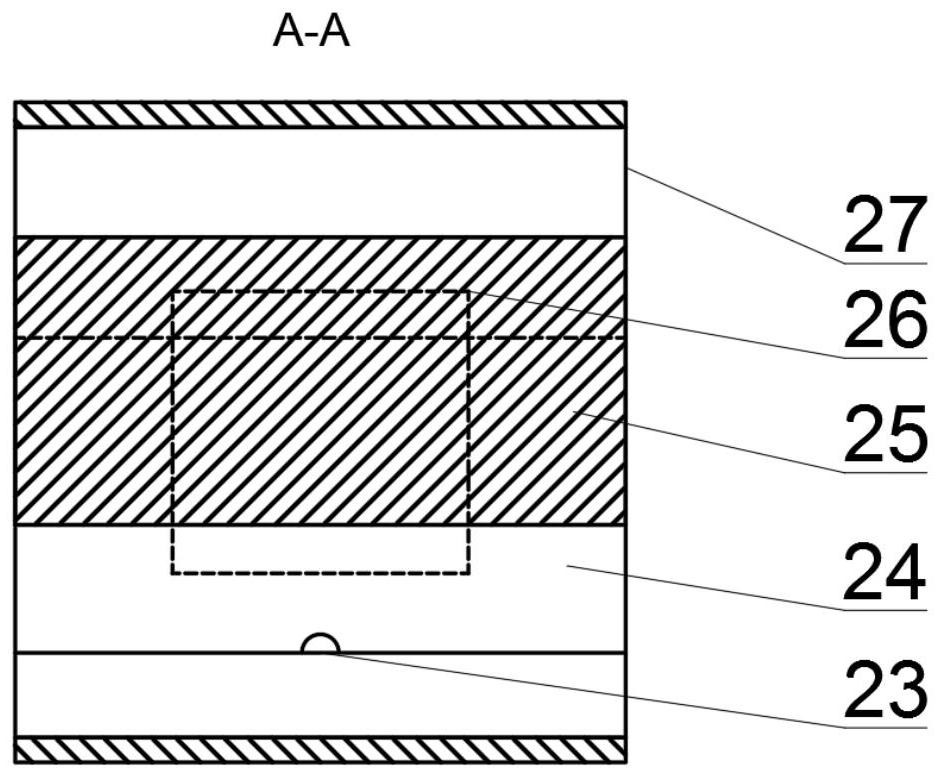

[0042] The hydrogen supply pipeline 20 is connected to the anode inlet 4 of the proton exchange membrane fuel cell, and from the hydrogen supply pipeline 20 to the anode inlet 4 of the hydrogen fuel cell, the hydrogen supply pipeline 20 is sequentially provided with a first valve 2 and a flow controller 3; The water inlet pipeline 21 is connected to the water outlet pipeline 12 of the water vapor cooling device 9, from the water inlet pipeline 21 to the water outlet pipeline 12, a check valve 14 and a pump 13 are arranged in sequence on the water inlet pipeline 21; There is a pressure switch 15, the pressure measuring pipeline 22 communicates with the gas buffer zone 19, so that the pressure switch 15 can measure the pressure in the gas buffer zone 19 in real time, and the pressure switch 15 transmits the pressure signal to the semiconductor refrigeration chip 11 and the pump 13, forming Dehydrogenation control device 16: control the pumping rate of pump 13 through pressure swi...

Embodiment 2

[0054] see Figure 5, compared to the proton exchange membrane fuel cell water is generated at the fuel cell cathode, the alkaline fuel cell water is generated at the fuel cell anode 32, and its anode reaction equation is shown in formula (3). The rear end of the anode 32 is the cathode 31, and the exhaust gas output end of the cathode 31 is fixedly connected with the first end surface of the exhaust device 8, and the exhaust device 8 allows air to flow from the anode 32 to the cathode to supply oxygen to the cathode 31 , can push the air discharged from the cathode 31 into the water vapor cooling device 9 at the same time; in order to reclaim the moisture in the anode tail gas, it is necessary to introduce the fuel cell anode tail gas into the water vapor cooling device 9, so the anode outlet 7 of the fuel cell and the water vapor cooling device 9 An anode exhaust pipeline 33 is added in the middle, the anode exhaust pipeline 33 is fixedly connected with the upper wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com