Metal amino borane composite hydrogen storage material

An aminoborane, hydrogen storage material technology, applied in non-metallic elements, hydrogen, inorganic chemistry and other directions, can solve the problems of high hydrogen desorption temperature, slow hydrogen desorption kinetics, and decreased hydrogen storage density, and achieves simple process and preparation. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Using a planetary ball mill equipped with a remote temperature-pressure monitoring system, the raw materials LiH, NH 3 BH 3 Put it into the ball mill tank at a ratio of 1.01:1, the ball-to-material ratio is 50:1, fill with hydrogen to 4bar, set the upper temperature limit of the ball mill tank to 30°C, and the ball mill speed to 400r / min. The temperature and pressure changes in the ball milling tank were monitored and regulated in real time, and the cumulative ball milling time was 10 hours.

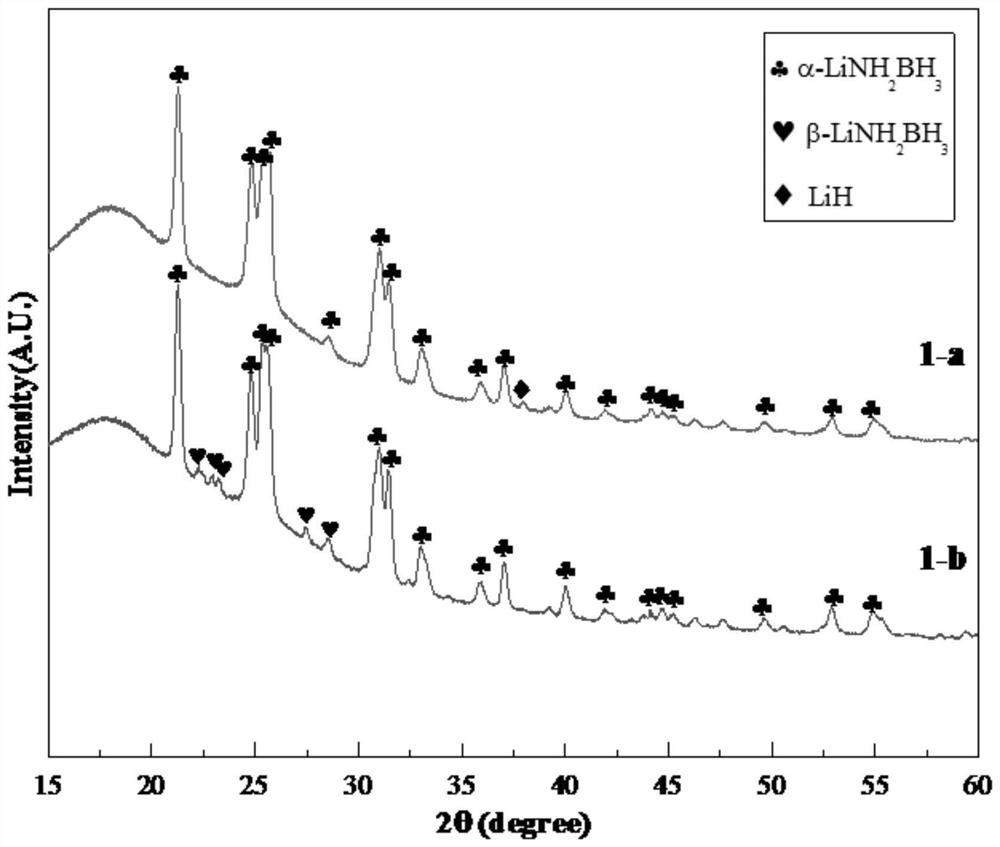

[0024] Take the product after ball milling in the glove box, and carry out XRD structure analysis after sealing the sample preparation, such as figure 1 In the 1-a data line, the product is α-LiNH 2 BH 3 and LiH complexes.

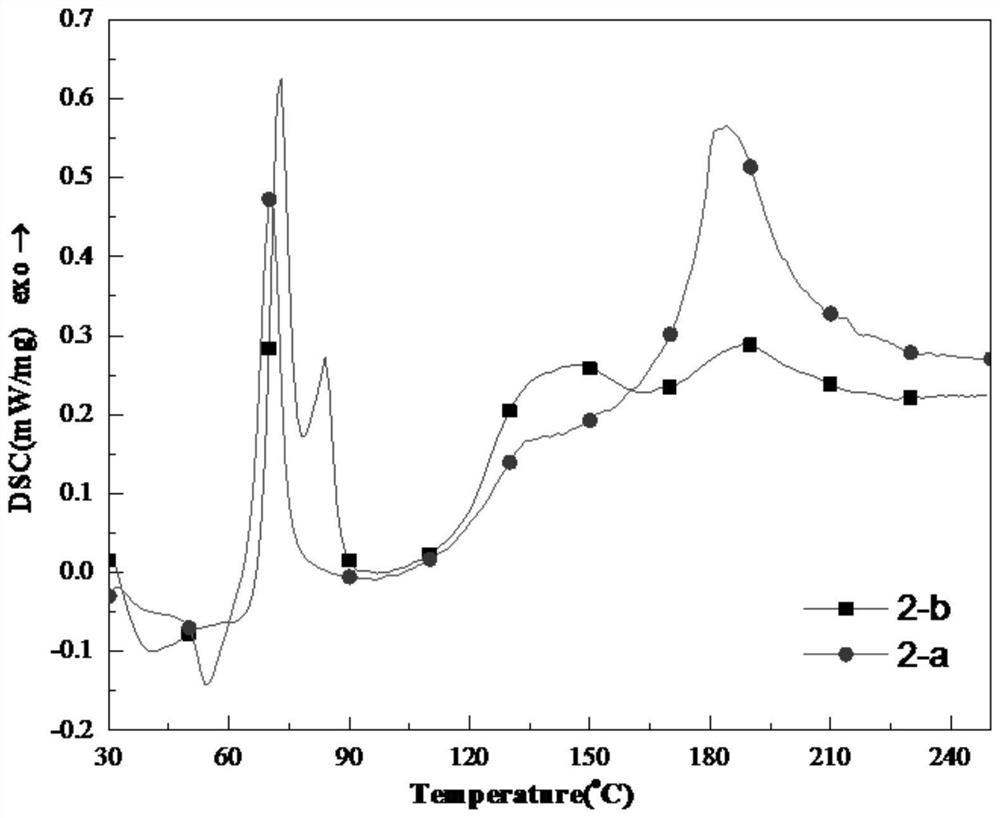

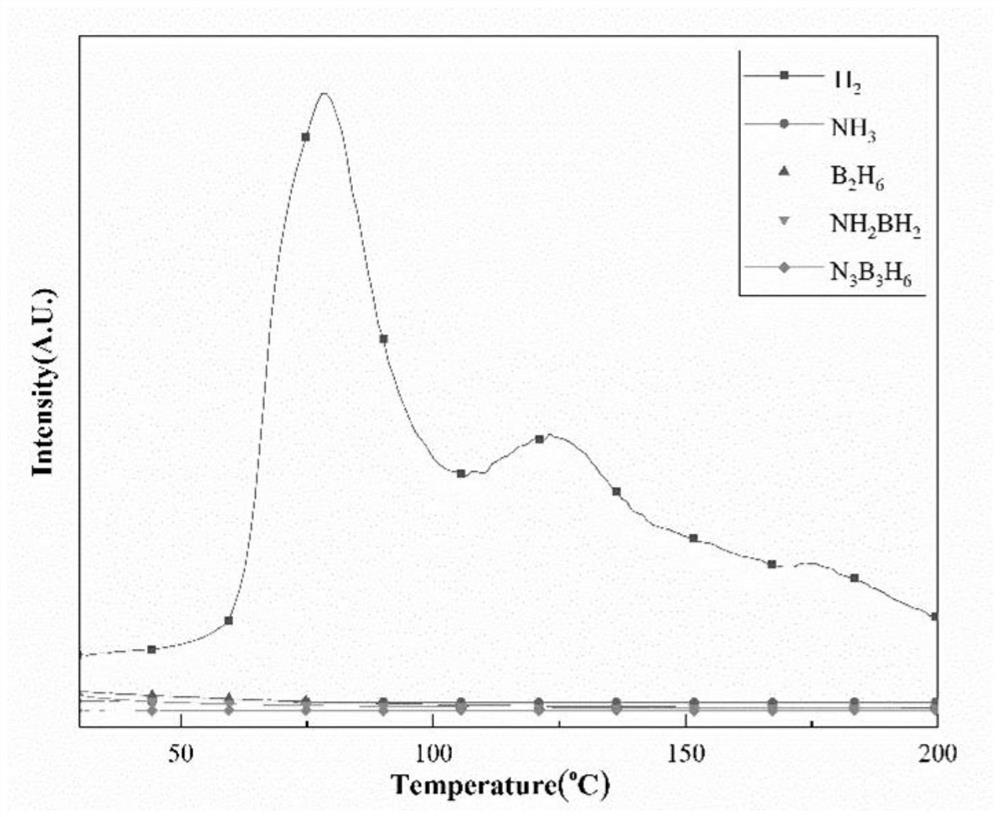

[0025] Take 5-10 mg of the prepared product, conduct DSC analysis at a heating rate of 2K / min, and perform mass spectrometry analysis on the emitted gas, the results are as follows: figure 2 2-a data line and Figure 3-a As shown, the initial hydrogen d...

Embodiment 2

[0031] Using a planetary ball mill equipped with a remote temperature-pressure monitoring system, the raw materials LiH, NH 3 BH 3 , The V-Ti-Cr alloy is loaded into the ball mill tank at a ratio of 1.01:1:0.1, the ball-to-material ratio is 50:1, filled with hydrogen to 10bar, the upper limit of the ball mill temperature is set to 30°C, and the ball mill speed is 400r / min. The temperature and pressure changes in the ball milling tank were monitored and regulated in real time, and the cumulative ball milling time was 8 hours.

[0032]The analysis method of sample structure, hydrogen desorption temperature and kinetics is the same as that of Example 1, and the XRD analysis results of the ball milled product show that, as shown in Figure 3, after adding V-Ti-Cr, α-LiNH is removed from the product 2 BH 3 And LiH phase, appear (V-Ti-Cr)H x phase, which shows that the hydrogen storage alloy has been hydrogenated during the ball milling process.

[0033] Take 0.5g of the compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com