Nickel-containing catalyst and method for removing H2 in CO raw material

A nickel catalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, carbon monoxide, etc., can solve the problem of high hydrogen content, reduce production costs, avoid explosion risks, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

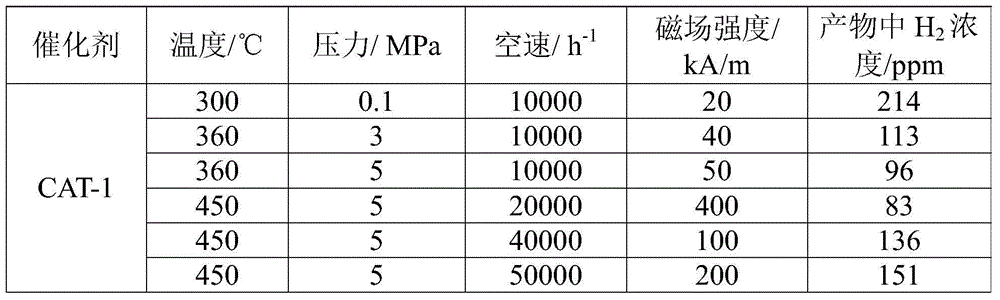

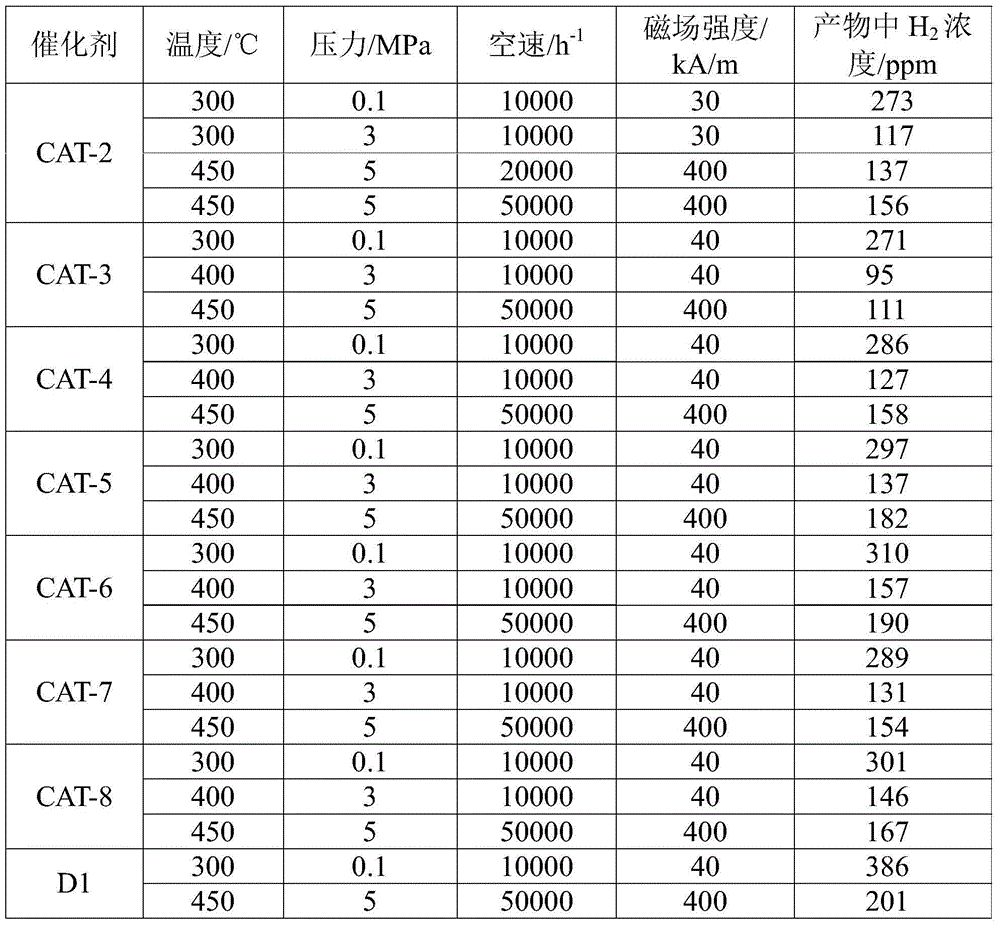

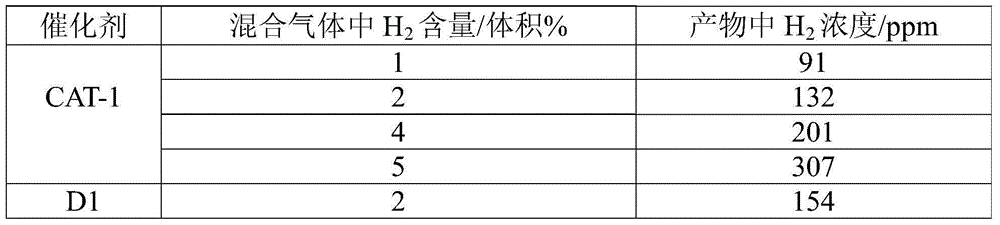

Examples

Embodiment 1

[0048] (1) Preparation of magnetic particles

[0049] 189g Na 2 SiO 3 9H 2 O was dissolved in 1000 mL of distilled water, and 3 mol / L HCl solution was slowly added dropwise under stirring condition to adjust the pH value of the solution to 13, and filtered for later use.

[0050] Add 42.2 g of FeCl to a 3 L stirred tank with 1200 mL of distilled water 3 ·6H 2 O and 20.6gFeCl 2 4H 2 O, heat up to 85°C, add 60mL of 25% NH during high-speed stirring 3 ·H 2 O solution, after stirring at high speed for 3 minutes, use a magnetic separator to separate the black Fe 3 o 4 Particles (particle size 3-30nm). The cleaned black Fe 3 o 4 Particles were ultrasonically dispersed in the above pretreated Na 2 SiO 3 solution, then moved it into a 3L stirred tank, raised the temperature to 85°C, and added dropwise HCl solution with a concentration of 2mol / L to the solution under the condition of nitrogen protection and stirring, within 3 hours, the pH value of the solution was reduce...

Embodiment 2

[0060] (1) Preparation of magnetic particles

[0061] 28.4g Na 2 SiO 3 9H 2 O was dissolved in 600 mL of distilled water, and 3 mol / L HCl solution was slowly added dropwise under stirring condition to adjust the pH value of the solution to 13, and it was filtered for later use.

[0062] Add 46.7 g of FeCl to a 2 L stirred tank with 1000 mL of distilled water 3 ·6H 2 O and 17.2 g FeCl 2 4H 2 O, heat up to 90°C, add 160mL of 6mol / L NaOH solution during high-speed stirring, and after 3 minutes of high-speed stirring, use a magnetic separator to separate the black Fe 3 o 4 Particles (particle size 3-30nm). The cleaned black Fe 3 o 4 Particles were ultrasonically dispersed in the above pretreated Na 2 SiO 3 solution, then moved it into a 2L stirred tank, raised the temperature to 90°C, and added dropwise HCl solution with a concentration of 2mol / L to the solution under the condition of nitrogen protection and stirring, within 3 hours, the pH value of the solution was re...

Embodiment 3

[0072] (1) Preparation of magnetic particles

[0073] 189g Na 2 SiO 3 9H 2 O was dissolved in 1000 mL of distilled water, and 3 mol / L HCl solution was slowly added dropwise under stirring condition to adjust the pH value of the solution to 13, and filtered for later use.

[0074] Ultrasonic dispersion of 14.54g of black iron powder (particle size 3-30nm) particles in the above pretreated Na 2 SiO 3 solution, and then moved into a 3L stirred tank, heated to 95°C, under nitrogen protection and stirring conditions, added dropwise HCl solution with a concentration of 2mol / L to the solution, within 3 hours, the pH value of the solution was reduced from 13 to 6. Filter to get 60g white SiO 2 Magnetic particles coated with iron powder particles (wherein, the iron powder weighs about 20g, and the SiO coated on the surface of the iron powder particles 2 About 40g, the weight ratio of silicon dioxide to iron powder is 2:1). The magnetic hysteresis loop detected by the vibrating s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com