Light-metal composite hydrogen storage material and preparation method thereof

A hydrogen storage material and metal composite technology, which is applied in the production of various metal hydrides and hydrogen, can solve the problems of harsh reaction conditions, difficult hydrogen absorption and desorption activation of materials, etc., and achieves simple process, reduced thermal stability, high Effect of hydrogen storage capacity characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

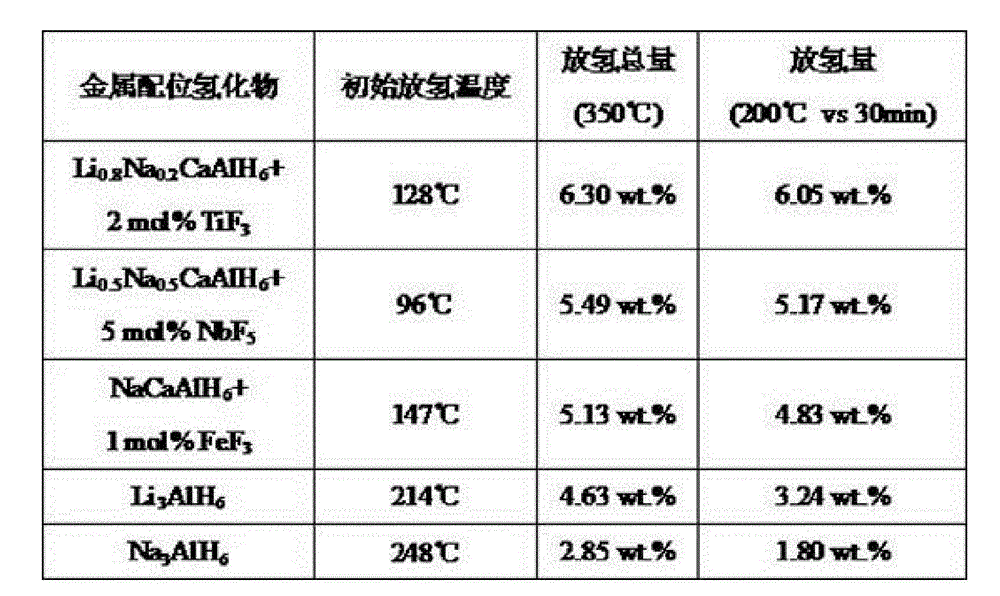

[0018] Light metal composite hydrogen storage material, its chemical formula is Li 1-x Na x CaAlH 6 For metal hydride, take x=0.2; choose catalyst as 2 mol% TiF 3 , which constitutes Li 0.8 Na 0.2 CaAlH 6 + 2 mol% TiF 3 Metal coordination hydride composite hydrogen storage materials.

[0019] The preparation method of the above-mentioned light metal composite hydrogen storage material is as follows:

[0020] First, with LiH (purity 95%), NaH (purity 95%) and Al (purity 99%) as raw materials, under the protection of inert gas, according to LiH : NaH : Al =2.8 : 0.2 : 1 (molar ratio ) to mix evenly, then put the mixed powder in the ball mill tank of the ball mill and seal and vacuum the ball mill tank; then use a syringe to inject 20ml of tetrahydrofuran into the ball mill tank, fill it with 2MPa pressure hydrogen, and then ball mill on the ball mill for 12h. (the ball-to-material ratio in the ball milling process is 40:1, and the ball mill speed is 480 rpm), Li 2.8 Na...

Embodiment 2

[0025] Light metal composite hydrogen storage material, its chemical formula is Li 1-x Na x CaAlH 6 For metal hydrides, take x=0.5; select the catalyst as 5 mol% NbF 5 , which constitutes Li 0.5 Na 0.5 CaAlH 6 + 5 mol% NbF 5 Metal coordination hydride composite hydrogen storage materials.

[0026] The preparation method of the above-mentioned light metal composite hydrogen storage material is as follows:

[0027] First, with LiH (purity 95%), NaH (purity 95%) and Al (purity 99%) as raw materials, under the protection of inert gas, according to LiH : NaH : Al =2.5 : 0.5 : 1 (molar ratio ) uniformly mixed, the mixed powder is placed in a ball mill tank and the addition amount and method of injecting tetrahydrofuran are the same as in Example 1, and then filled with 5MPa pressure of hydrogen and ball milled on the ball mill for 20h (the ball-to-material ratio in the ball mill process is 20:1, the ball mill at 300 rpm), Li 2.5 Na 0.5 H 6 intermediate hydride;

[0028]...

Embodiment 3

[0032] Light metal composite hydrogen storage material, its chemical formula is Li 1-x Na x CaAlH 6 For metal hydrides, take x=1; select the catalyst as 1 mol% FeF 3 , which constitutes NaCaAlH 6 + 1 mol% FeF 3 Metal coordination hydride composite hydrogen storage materials.

[0033] The preparation method of the above-mentioned light metal composite hydrogen storage material is as follows:

[0034] First, with LiH (purity 95%), NaH (purity 95%) and Al (purity 99%) as raw materials, under the protection of inert gas, according to LiH : NaH : Al =2 : 1 : 1 (molar ratio ) uniformly mixed, the mixed powder is placed in a ball mill tank and the addition amount and method of injecting ether are the same as in Example 1, and then ball milled on a ball mill for 10 hours after filling with hydrogen at a pressure of 1MPa (the ball-to-material ratio in the ball mill process is 30:1, The speed of the ball mill is 450 rpm), Li 2 NaAlH 6 intermediate hydride;

[0035] Second, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com