Preparation method and application for sodium aluminum hydride hydrogen storage material doped with titanate manganese

A technology of sodium aluminum hydride and hydrogen storage material, which is applied in chemical instruments and methods, manganese compounds, hydrogen and other directions, can solve the problems of simplicity of preparation process and the price of raw materials needs to be reduced, and achieves low price, fast hydrogen release speed, and high source of hydrogen. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

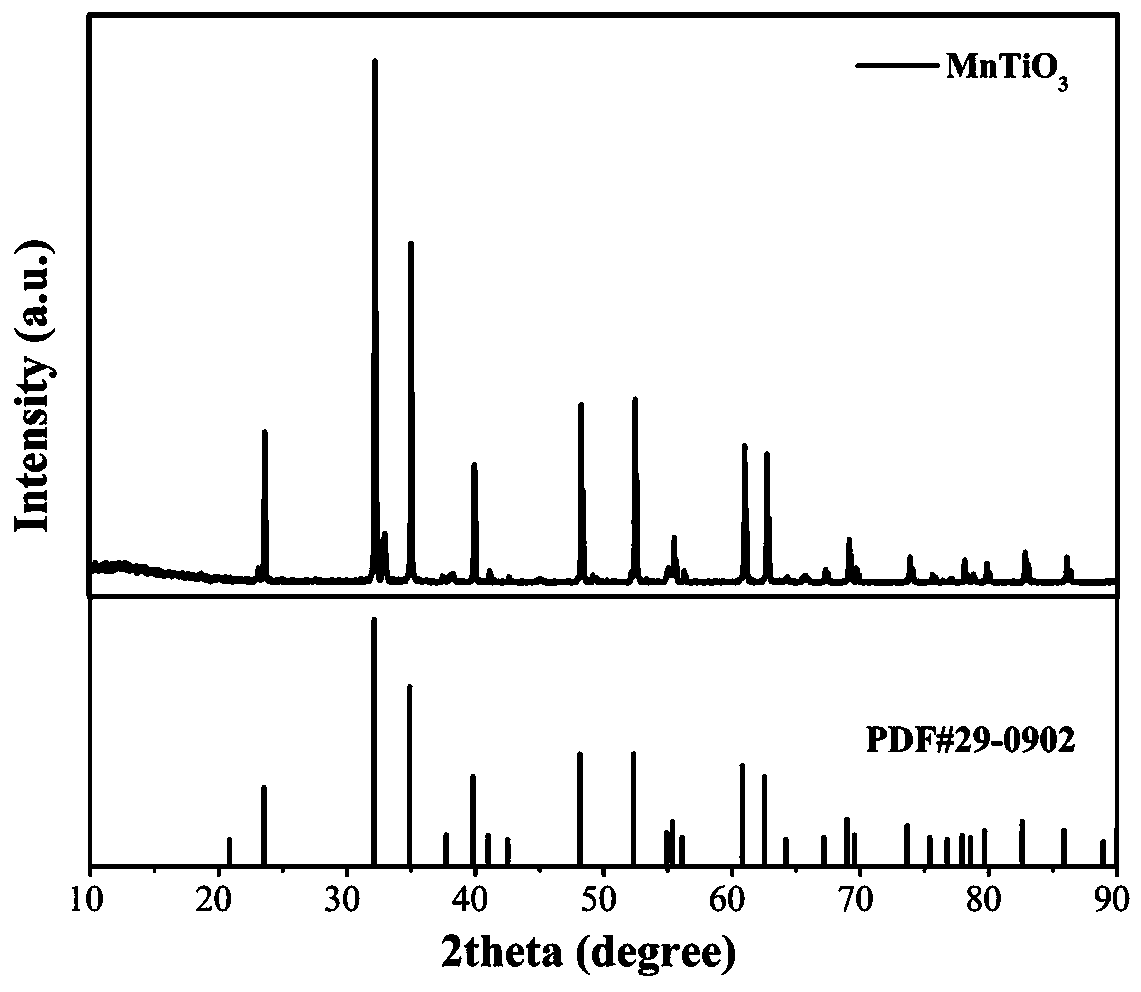

[0022] Preparation of hydrogen storage material of sodium aluminum hydride doped with manganese titanate

[0023] Step 1) Preparation of manganese titanate. Weigh 5.75 g of manganese carbonate and 4.0 g of titanium dioxide, grind and mix manganese carbonate and titanium dioxide powder to obtain a mixture, and then place the mixture in a muffle furnace at a heating rate of 10 ℃ / min. Raise the room temperature to 900 ℃ for calcination and keep it for 6 hours to obtain manganese titanate;

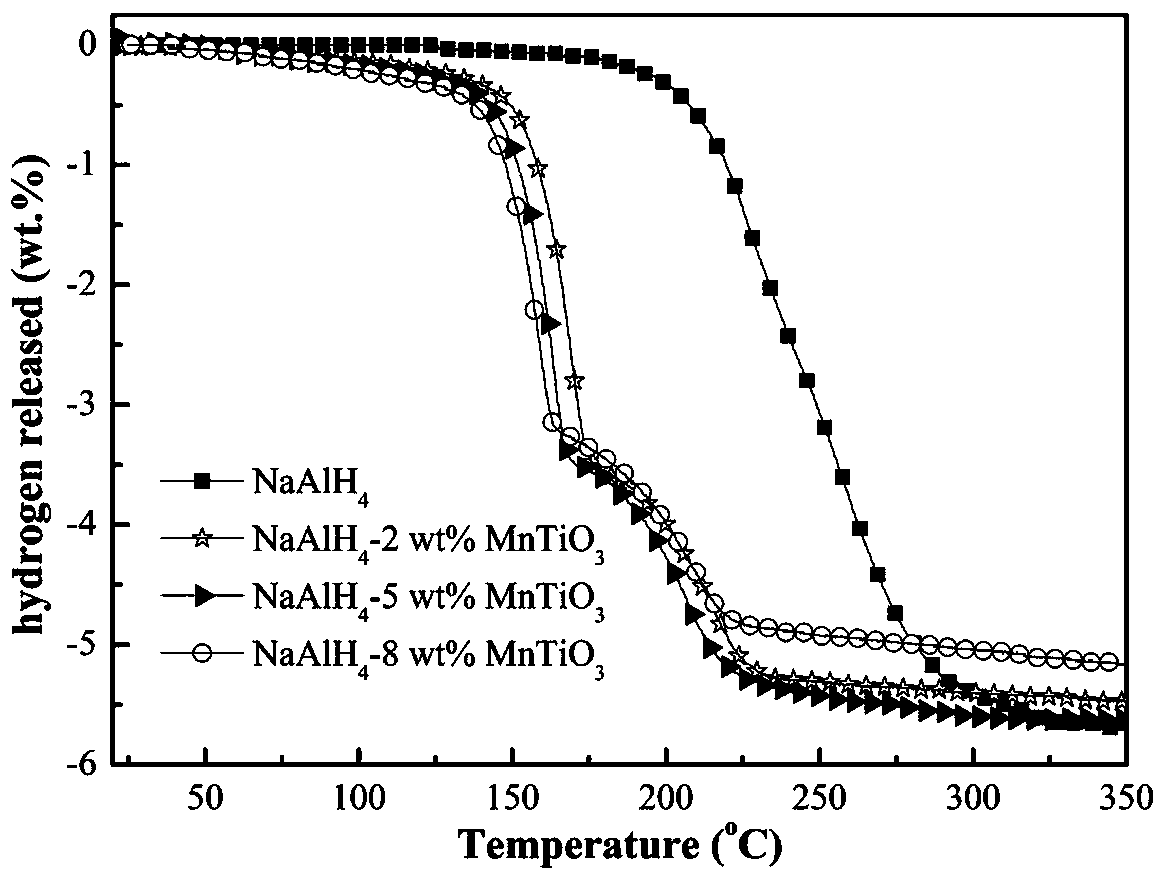

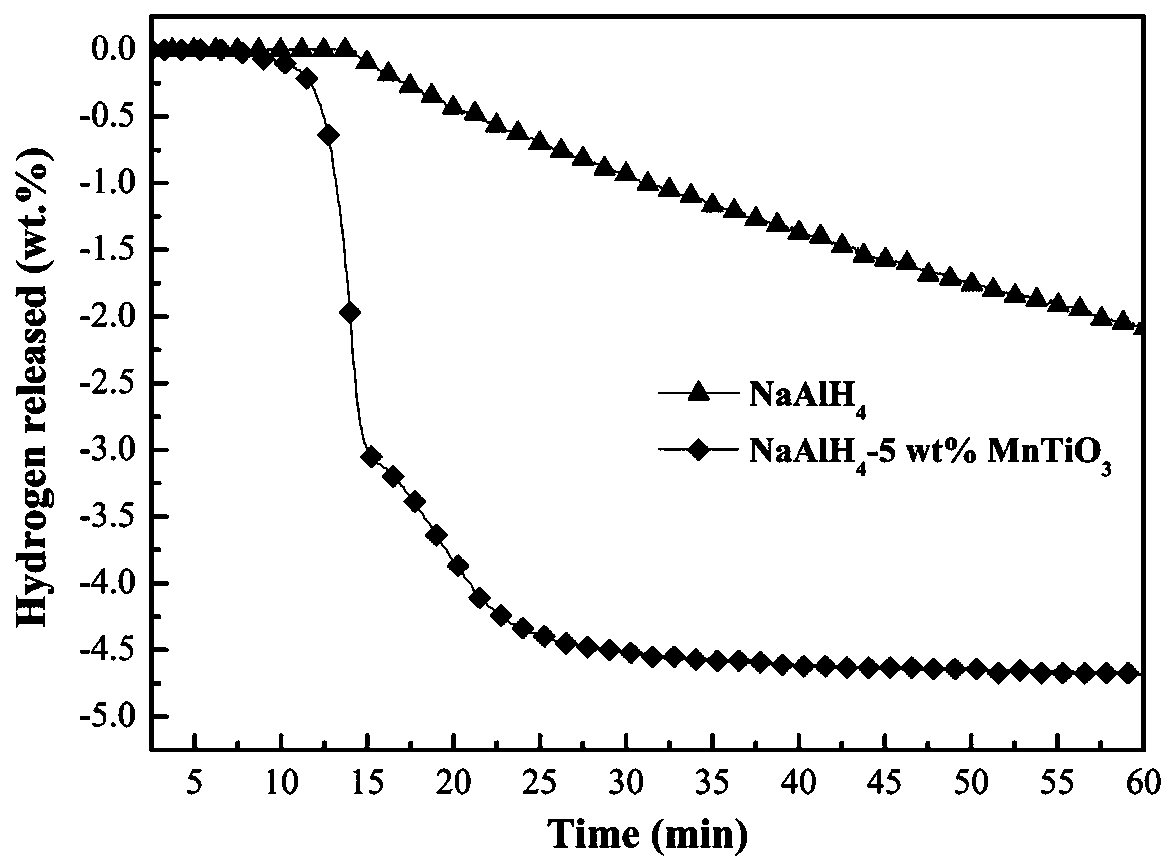

[0024] Step 2) Under the protection of argon, weigh 0.4275 g sodium aluminum hydride and 0.0225 g manganese titanate into the ball mill tank, put 45 g steel balls, and seal, then put the ball mill tank into the ball mill and set the ball mill Rotation speed is 250r / min, ball milling time is 3 hours, ball milling is carried out, and then the ball milled product is taken out under argon conditions, and NaAlH is obtained 4 -5 wt%MnTiO 3 Hydrogen storage materials.

[0025] The manganese titanate in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com