Preparation method of surface microporous nickel-plating hydrogen-storage alloy

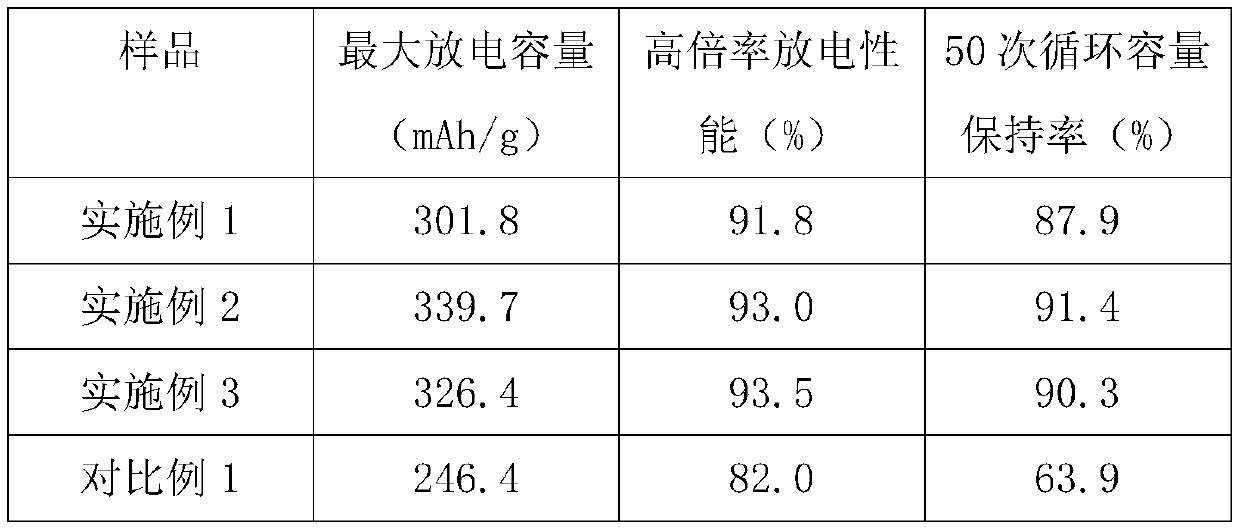

A technology of hydrogen storage alloys and surface micropores, which is applied in liquid chemical plating, metal material coating technology, coatings, etc., can solve the problem of improving the electrochemical performance of hydrogen storage alloys, and the combination of coatings and hydrogen storage alloy surfaces Limited power, easy to fall off and other problems, to achieve the effect of increasing high-rate discharge performance, improving cycle stability, and good anti-plating peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing a surface microporous nickel-plated hydrogen storage alloy, comprising the following steps:

[0028] (1) Smelting: La according to chemical composition 0.75 Mg 0.25 Ni 2.2 co 0.8 Prepare the La-Mg-Ni-based hydrogen storage alloy metal raw material with a purity of more than 99%. After crushing, grinding and screening the metal raw material, induction melting is carried out under the protection of an inert gas or under vacuum conditions. The temperature is 1400°C, the melting time is 5min, and then annealing treatment is carried out under the protection of inert gas. The temperature of annealing treatment is 600°C, the annealing time is 5h, and the La-Mg-Ni based hydrogen storage alloy ingot is obtained after cooling with the furnace;

[0029] (2) Preparation of hydrogen storage alloy strips: the La-Mg-Ni based hydrogen storage alloy ingot obtained in step (1) is placed in a high-purity quartz tube with a slit at the bottom, heated until the hyd...

Embodiment 2

[0034] A method for preparing a surface microporous nickel-plated hydrogen storage alloy, comprising the following steps:

[0035] (1) Smelting: La according to chemical composition 0.75 Mg 0.25 Ni 2.2 co 0.8 Prepare the La-Mg-Ni-based hydrogen storage alloy metal raw material with a purity of more than 99%. After crushing, grinding and screening the metal raw material, induction melting is carried out under the protection of an inert gas or under vacuum conditions. The temperature is 1460°C, the melting time is 10min, and then annealing treatment is carried out under the protection of inert gas. The temperature of annealing treatment is 750°C, the annealing time is 8h, and the La-Mg-Ni based hydrogen storage alloy ingot is obtained after cooling with the furnace;

[0036] (2) Preparation of hydrogen storage alloy strips: the La-Mg-Ni based hydrogen storage alloy ingot obtained in step (1) is placed in a high-purity quartz tube with a slit at the bottom, heated until the hydr...

Embodiment 3

[0041] A method for preparing a surface microporous nickel-plated hydrogen storage alloy, comprising the following steps:

[0042] (1) Smelting: La according to chemical composition 0.75 Mg 0.25 Ni 2.2 co 0.8 Prepare the La-Mg-Ni-based hydrogen storage alloy metal raw material with a purity of more than 99%. After crushing, grinding and screening the metal raw material, induction melting is carried out under the protection of an inert gas or under vacuum conditions. The temperature is 1500°C, the melting time is 15min, and then annealing treatment is carried out under the protection of inert gas. The temperature of annealing treatment is 800°C, the annealing time is 10h, and the La-Mg-Ni based hydrogen storage alloy ingot is obtained after cooling with the furnace;

[0043] (2) Preparation of hydrogen storage alloy strips: the La-Mg-Ni based hydrogen storage alloy ingot obtained in step (1) is placed in a high-purity quartz tube with a slit at the bottom, heated until the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com