Preparation method for Mg-based hydrogen storage nanowire

A nanowire and hydrogen storage technology, which is applied in the field of preparation of Mg-based hydrogen storage nanowires, can solve problems such as unsafe thermal insulation materials and low-temperature devices, and achieves improved hydrogen storage capacity, a large amount of hydrogen storage, and hydrogen absorption and desorption. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

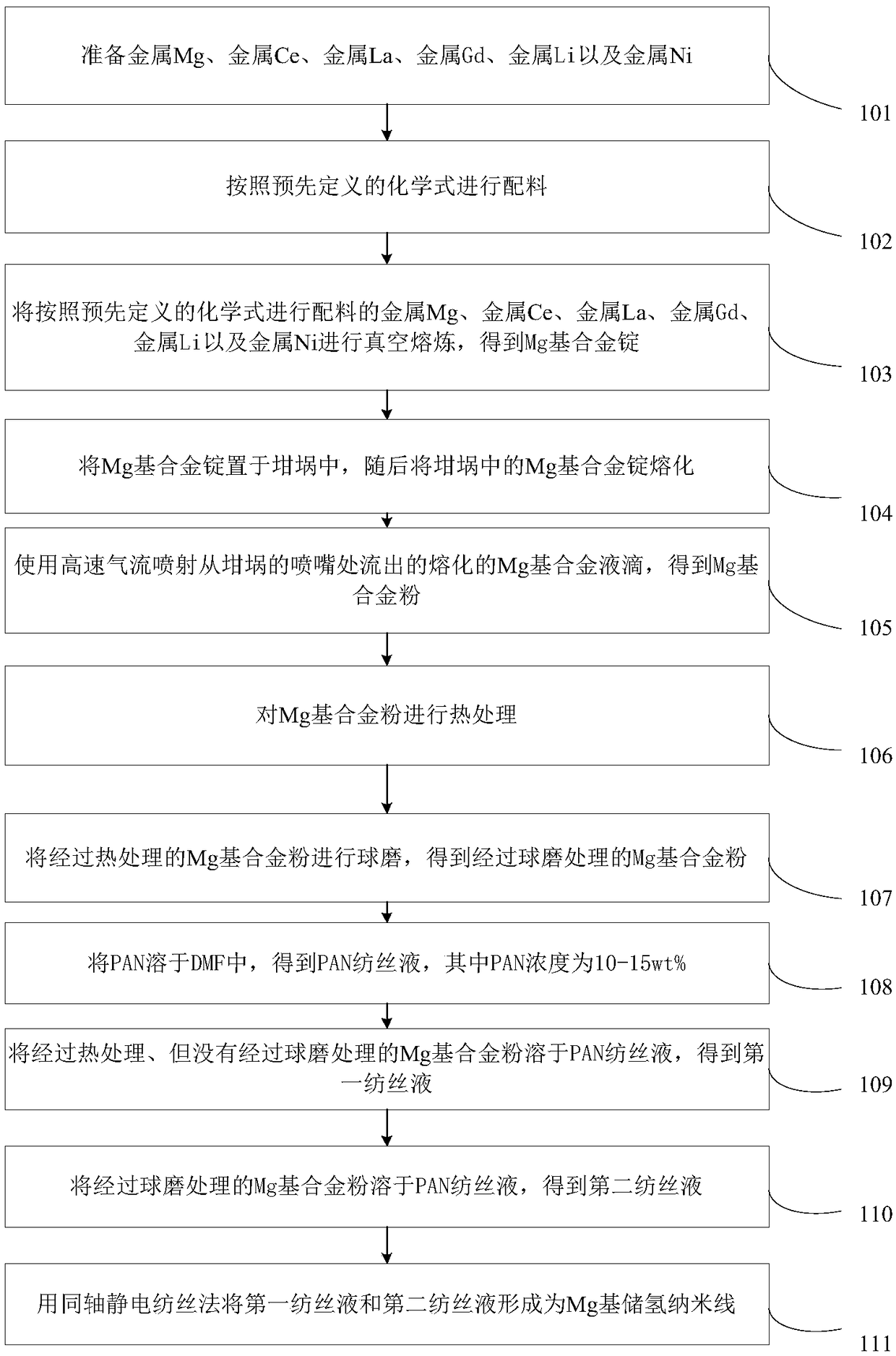

[0018] figure 1 It is a flow chart of the preparation method of the Mg-based hydrogen storage nanowire according to the embodiment of the present invention. As shown in the figure, the preparation method of Mg-based hydrogen storage nanowires includes the following steps:

[0019] Step 101: preparing metal Mg, metal Ce, metal La, metal Gd, metal Li and metal Ni;

[0020] Step 102: batching according to a predefined chemical formula;

[0021] Step 103: Vacuum smelting metal Mg, metal Ce, metal La, metal Gd, metal Li and metal Ni prepared according to a predefined chemical formula to obtain a Mg-based alloy ingot;

[0022] Step 104: placing the Mg-based alloy ingot in the crucible, and then melting the Mg-based alloy ingot in the crucible;

[0023] Step 105: using a high-speed airflow to spray the molten Mg-based alloy droplets flowing from the nozzle of the crucible to obtain Mg-based alloy powder;

[0024] Step 106: performing heat treatment on the Mg-based alloy powder; ...

Embodiment 1

[0031] The preparation method of the Mg-based hydrogen storage nanowire of the present invention comprises the following steps: preparing metal Mg, metal Ce, metal La, metal Gd, metal Li and metal Ni; carrying out batching according to a predefined chemical formula; carrying out the preparation according to the predefined chemical formula The metal Mg, metal Ce, metal La, metal Gd, metal Li and metal Ni of the ingredients are vacuum smelted to obtain a Mg-based alloy ingot; the Mg-based alloy ingot is placed in a crucible, and then the Mg-based alloy ingot in the crucible is melted; Using high-speed airflow to spray the molten Mg-based alloy droplets flowing out from the nozzle of the crucible to obtain Mg-based alloy powder; heat-treating the Mg-based alloy powder; ball milling the heat-treated Mg-based alloy powder to obtain ball-milled Mg Dissolve PAN in DMF to obtain a PAN spinning solution, wherein the PAN concentration is 10wt%; dissolve the Mg-based alloy powder that has...

Embodiment 2

[0033] The preparation method of the Mg-based hydrogen storage nanowire of the present invention comprises the following steps: preparing metal Mg, metal Ce, metal La, metal Gd, metal Li and metal Ni; carrying out batching according to a predefined chemical formula; carrying out the preparation according to the predefined chemical formula The metal Mg, metal Ce, metal La, metal Gd, metal Li and metal Ni of the ingredients are vacuum smelted to obtain a Mg-based alloy ingot; the Mg-based alloy ingot is placed in a crucible, and then the Mg-based alloy ingot in the crucible is melted; Using high-speed airflow to spray the molten Mg-based alloy droplets flowing out from the nozzle of the crucible to obtain Mg-based alloy powder; heat-treating the Mg-based alloy powder; ball milling the heat-treated Mg-based alloy powder to obtain ball-milled Mg-based alloy powder Dissolve PAN in DMF to obtain a PAN spinning solution, wherein the PAN concentration is 15wt%; dissolve the Mg-based al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com