A kind of manufacturing method of metal hydride hydrogen storage tank

A manufacturing method and technology of hydrogen storage tanks, applied in the field of hydrogen storage, can solve the problems of low space utilization of hydrogen storage tanks, insufficient flow rate of hydrogen charging and discharging, and inability to realize assembly line production, etc., and achieve excellent heat and mass transfer performance , easy to implement, and simple in structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

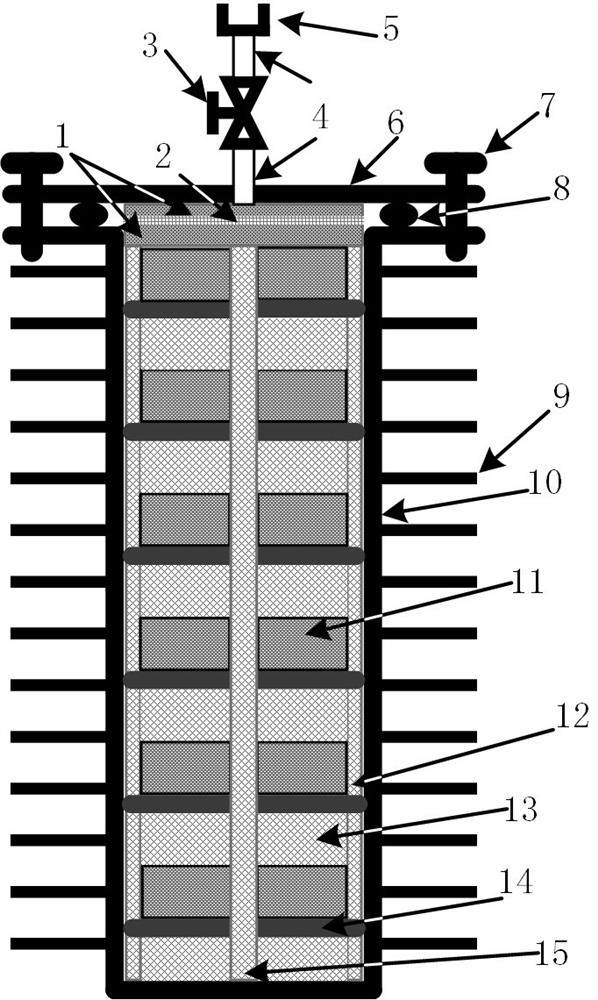

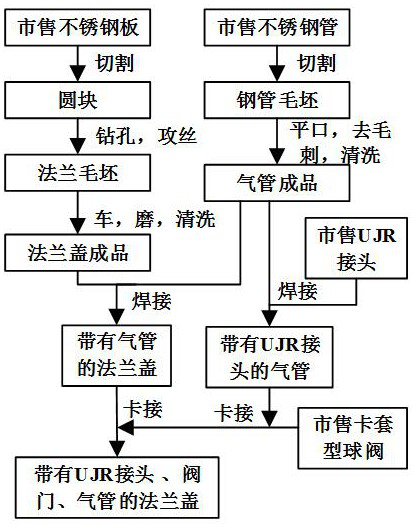

[0070] Such as figure 1 As shown, a metal hydride hydrogen storage tank, including: foam copper round cover 1, mat type copper mesh 2, ferrule type ball valve 3, gas pipe 4, UJR joint 5, flange cover 6, bolt 7, O-shaped seal Ring 8, cooling fins 9, tank body 10, hydrogen storage alloy powder 11, copper foam cylinder 12, copper foam disc 13, copper-water heat pipe 14, copper foam cylinder 15. The manufacturing process mainly includes the processing of the tank body, the processing of the flange cover, the processing of the foamed copper components, the preparation of the hydrogen storage alloy powder, and the assembly and production of the hydrogen storage tank.

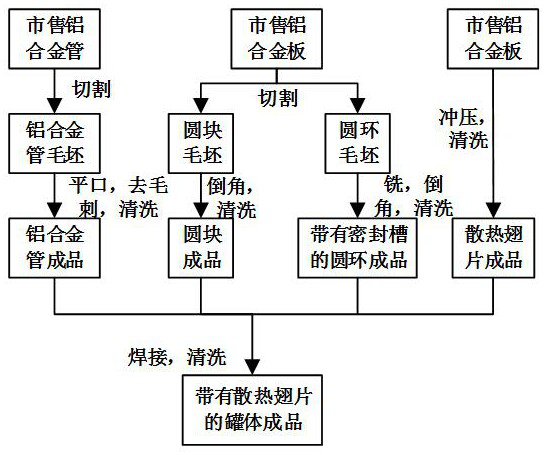

[0071] Among them, such as figure 2As shown, the main process of processing the tank body 10 is as follows: ① cutting the commercially avail...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com