High-entropy hydrogen storage alloy and preparation method thereof

A hydrogen storage alloy, high-entropy technology, applied to chemical instruments and methods, hydrogen, non-metallic elements, etc., can solve the problems of poor activation performance, high hydrogen absorption and desorption temperature, and small hydrogen absorption and desorption, and achieve simple process , fast hydrogen absorption and desorption, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

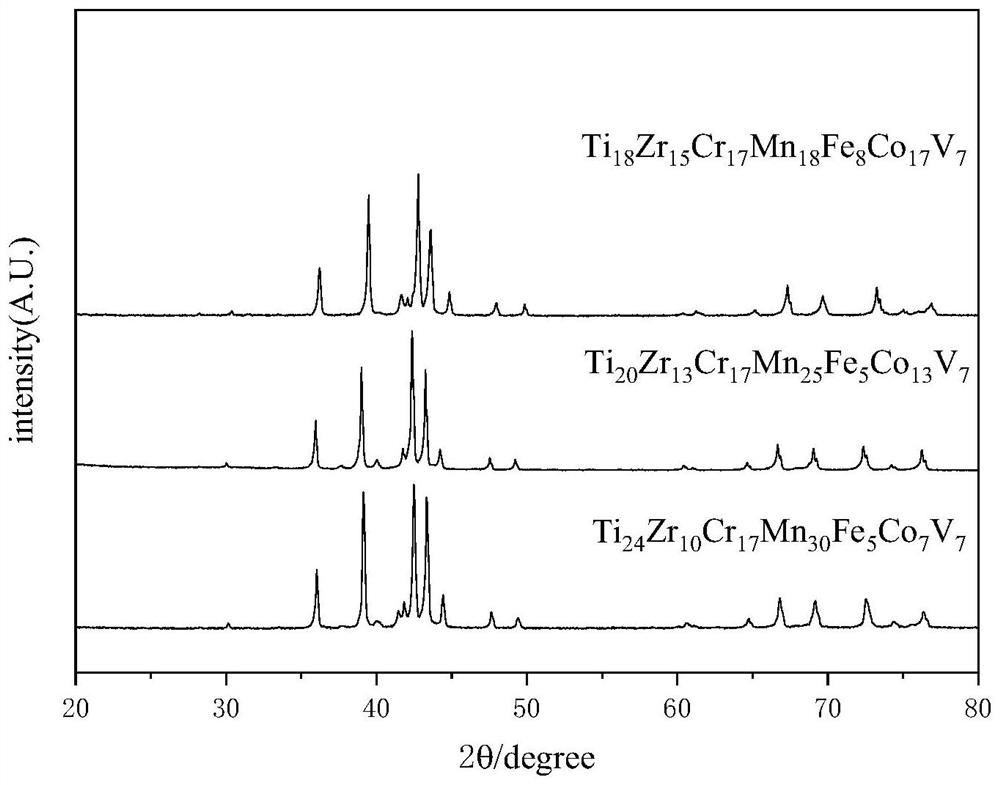

[0043] Ti 18 Zr 15 Cr 17 Mn 18 Fe 8 Co 17 V 7 The specific preparation steps of the high-entropy alloy are as follows:

[0044] (1) each element of high purity is used as material, each component raw material is weighed according to the atomic ratio of the subscript of chemical formula, and the total trace amount of raw material taken is (50 ± 0.01) g;

[0045] (2) Put the weighed raw materials of each component into the water-cooled crucible in the high-vacuum arc melting furnace according to the degree of volatility of the components (Mn is volatile at the bottom), turn on the cooling water, close the furnace door, first Open the roughing valve. After one or two minutes, close the roughing valve, fill in a little argon, and discharge the air that may remain in the pipeline. Then open the roughing valve and molecular pump, and wait until the vacuum in the furnace reaches 2*10 -3 After Pa, fill with argon as protective gas;

[0046] (3) First, smelt the pure titanium a...

Embodiment 2

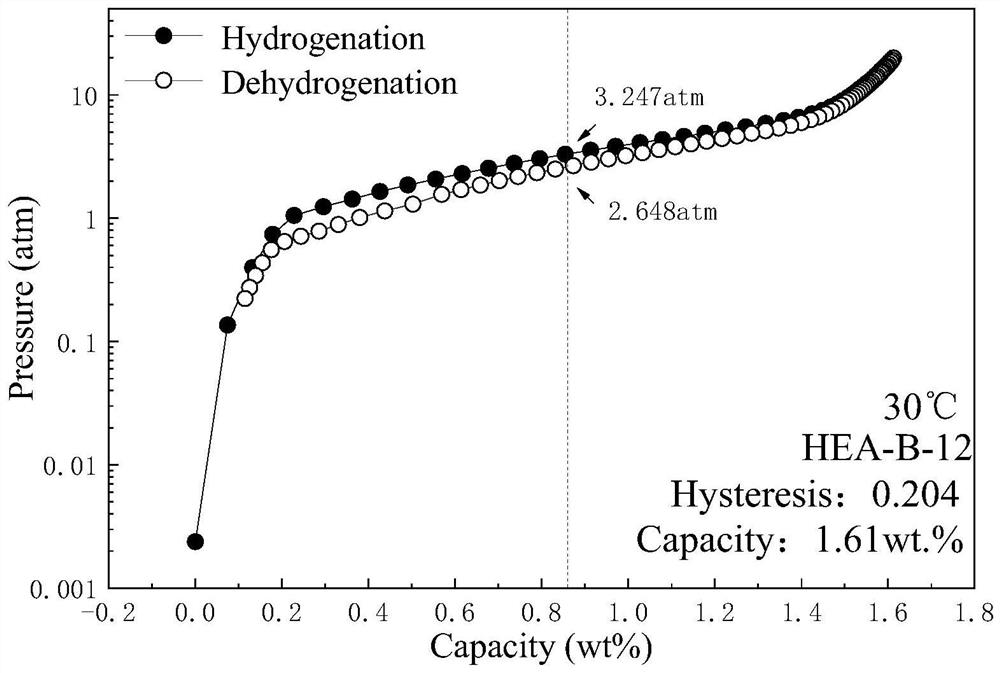

[0049] Ti 20 Zr 13 Cr 17 Mn 25 Fe 5 Co 13 V 7 The specific preparation steps of the high-entropy alloy are as follows:

[0050] (1) each element of high purity is used as material, each component raw material is weighed according to the atomic ratio of the subscript of chemical formula, and the total trace amount of raw material taken is (50 ± 0.01) g;

[0051] (2) Put the weighed raw materials of each component into the water-cooled crucible in the high-vacuum arc melting furnace according to the degree of volatility of the components (Mn is volatile at the bottom), turn on the cooling water, close the furnace door, first Open the roughing valve. After one or two minutes, close the roughing valve, fill in a little argon, and discharge the air that may remain in the pipeline. Then open the roughing valve and molecular pump, and wait until the vacuum in the furnace reaches 2*10 -3 After Pa, fill with argon as protective gas;

[0052] (3) First, smelt the pure titanium a...

Embodiment 3

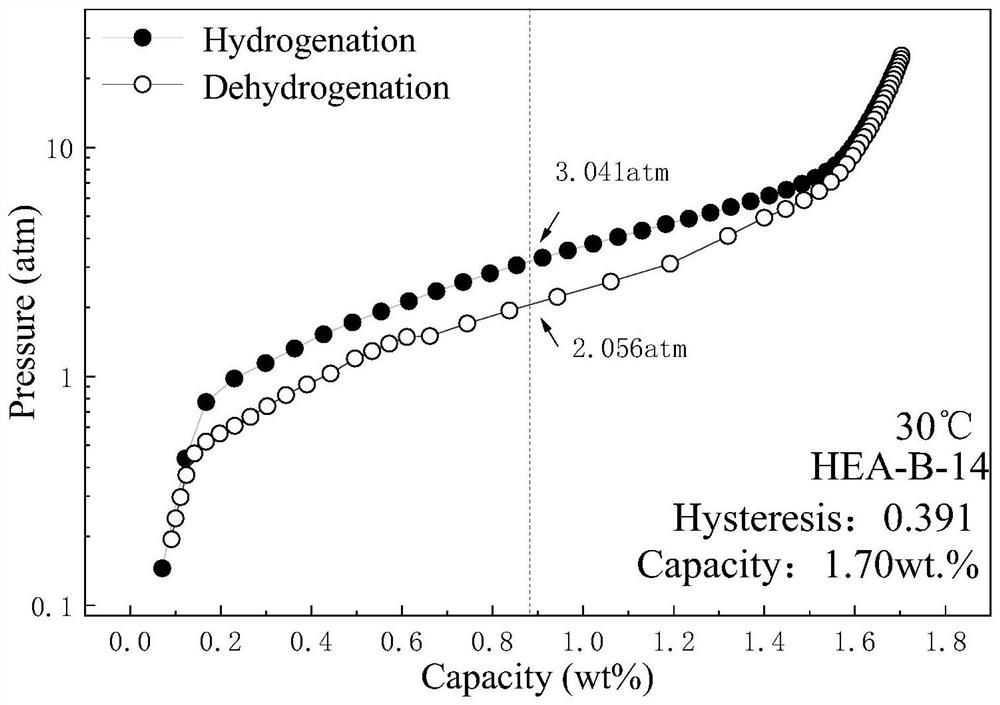

[0055] Ti 24 Zr 10 Cr 17 Mn 30 Fe 5 Co 7 V 7 The specific preparation steps of the high-entropy alloy are as follows:

[0056] (1) each element of high purity is used as material, each component raw material is weighed according to the atomic ratio of the subscript of chemical formula, and the total trace amount of raw material taken is (50 ± 0.01) g;

[0057] (2) Put the weighed raw materials of each component into the water-cooled crucible in the high-vacuum arc melting furnace according to the degree of volatility of the components (Mn is volatile at the bottom), turn on the cooling water, close the furnace door, first Open the roughing valve. After one or two minutes, close the roughing valve, fill in a little argon, and discharge the air that may remain in the pipeline. Then open the roughing valve and molecular pump, and wait until the vacuum in the furnace reaches 2*10 -3 After Pa, fill with argon as protective gas;

[0058] (3) First, smelt the pure titanium at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com