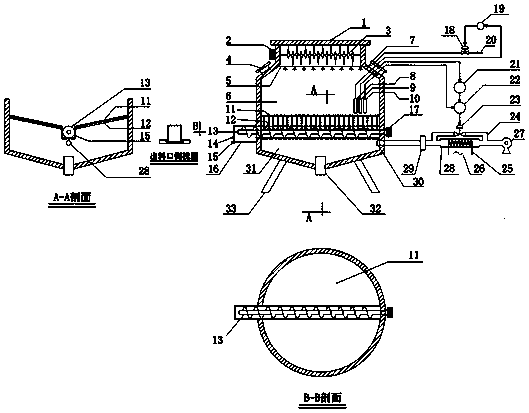

Straw type agricultural waste crushing and composting integral control device and method

A technology for agricultural waste and control devices, which is applied in fertilization devices, agriculture, and the preparation of organic fertilizers. It can solve problems such as low temperature control is difficult to meet requirements, labor time is long, and conditions are not easy to control, so as to shorten the fermentation cycle and save manpower. The effect of physical strength and uniform crushing of particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0045] Embodiment 2: Fixed value continuous control embodiment

[0046] 1) Open the feed port, turn on the straw crushing device, put in the straw, the straw is crushed to particles with a particle size of 3-5cm, and the charging amount should account for 2 / 3-3 / 4 of the total volume of the material composting room;

[0047] 2) The given humidity setting value is 50-65%, the temperature setting value is 40-60°C, and the oxygen amount setting value is 10-20%;

[0048] 3) Every 10 minutes of feeding, add high-efficiency straw-degrading compound bacterial agent through the spare port, and the addition amount is 300:1;

[0049] 4) The whole process is automatically controlled, and the parameters can be adjusted appropriately by observing the parameters every day. After the heap is mature, the material is discharged from the discharge port.

Embodiment 3

[0050] Embodiment 3: program control embodiment

[0051] 1) Open the feed port, turn on the straw crushing device, put in the straw, the straw is crushed to particles with a particle size of 3-5cm, and the charging amount should account for 2 / 3-3 / 4 of the total volume of the material composting room;

[0052] 2) The given humidity setting value is 50%, the temperature setting value is 40°C, and the oxygen volume setting value is 10%;

[0053] 3) Every 10 minutes of feeding, add high-efficiency straw-degrading compound bacterial agent through the spare port, and the addition amount is 300:1;

[0054] 4) Observe the fertilizer maturity every day. When it is observed that the fertilizer enters the high temperature stage, adjust the given humidity setting value to 60%, the temperature setting value to 55°C, and the oxygen amount setting value to 20%;

[0055] 5) Continue to observe the fertilizer maturity every day. When it is observed that the fertilizer enters the cooling perio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com