Method for operating an internal combustion engine

A technology for internal combustion engines and compressors, applied in the field of operating internal combustion engines, which can solve the problems of high friction turbine impeller and compressor impeller, reduce engine torque generation, unavoidable perception, etc., and achieve the effect of reliable actual value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

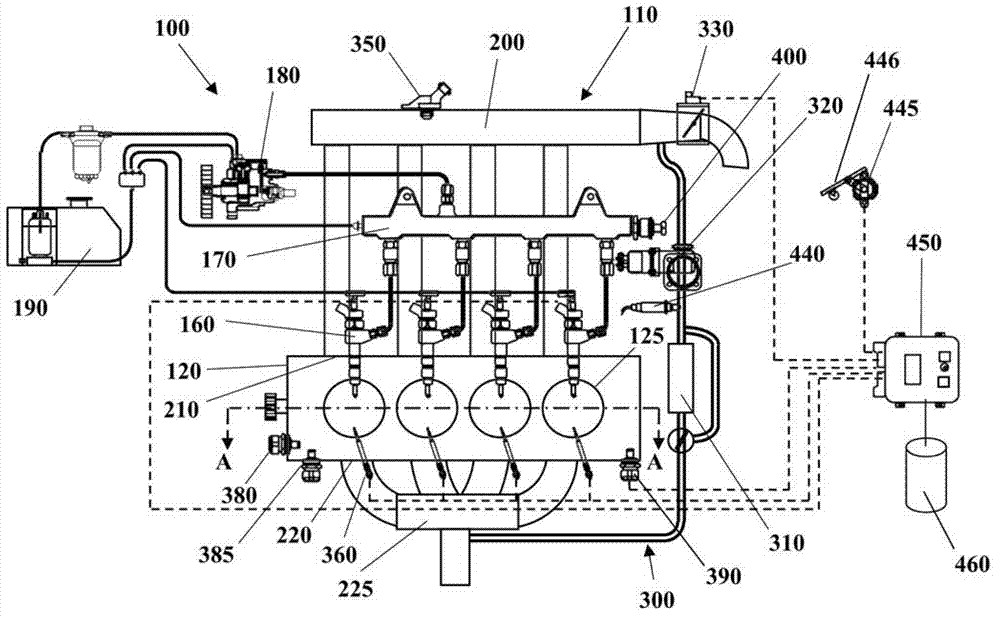

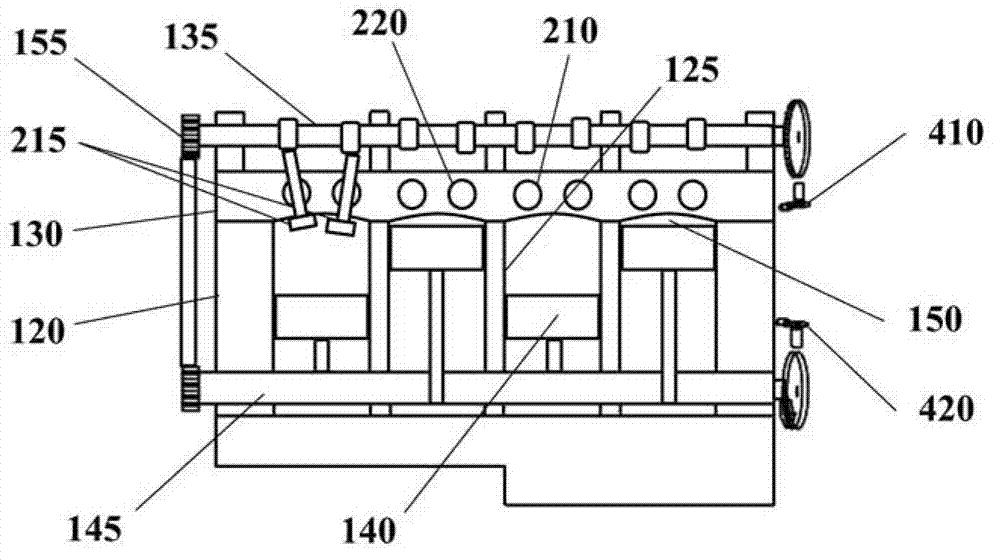

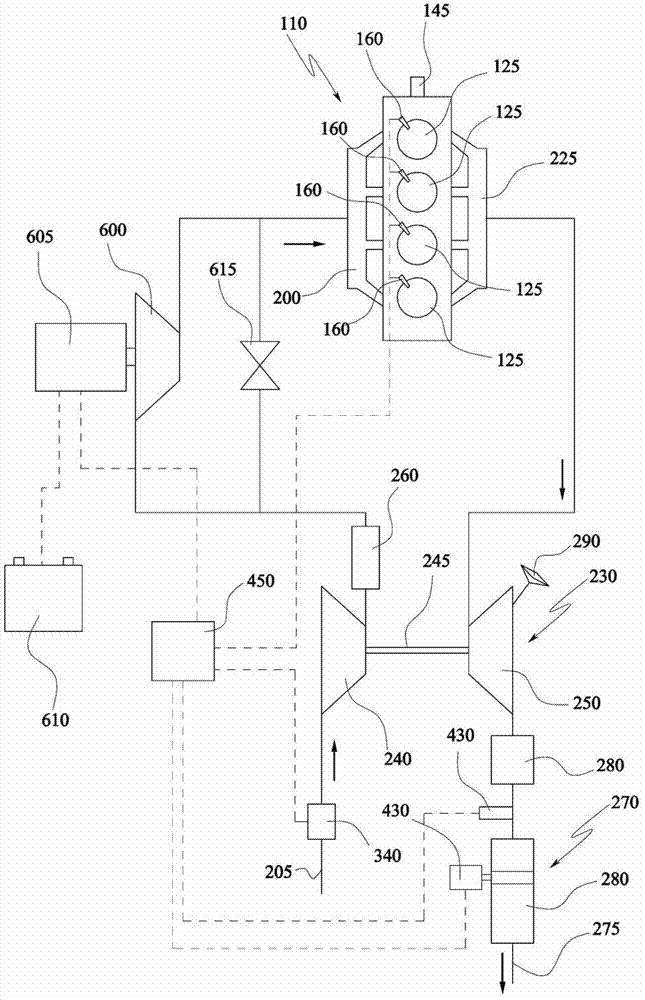

[0127] Some embodiments may include automotive systems 100 such as figure 1 and 2 As shown in , the automotive system 100 includes an internal combustion engine (ICE) 110 , in this example a diesel engine, having an engine block 120 defining at least one cylinder 125 having a piston 140 , the piston 140 is coupled to rotate a crankshaft 145 . Cylinder head 130 cooperates with piston 140 to define combustion chamber 150 . A fuel and air mixture (not shown) ignites after having been disposed in combustion chamber 150 , resulting in thermal expansion of exhaust gases causing reciprocation of piston 140 . Fuel is provided by at least one fuel injector 160 and air is provided through at least one intake port 210 . Fuel is provided to fuel injector 160 at high pressure from fuel rail 170 in fluid communication with high pressure fuel pump 180 which increases the pressure of fuel received from fuel source 190 . Each cylinder 125 has at least two valves 215 actuated by a camshaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com