A kind of ab for tritium storage 5 Type rare earth hydrogen storage alloy and preparation method thereof

A hydrogen storage alloy and rare earth technology, which is applied in the field of AB5 metal hydrogen storage materials, AB5 type rare earth hydrogen storage alloy and its preparation, can solve the problems of raw material cost increase, and achieve the effects of reduced manufacturing cost, small hysteresis and low slope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

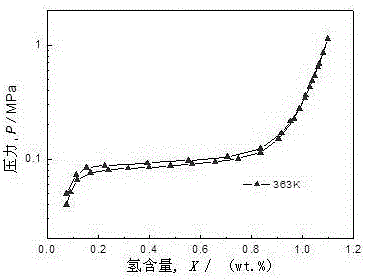

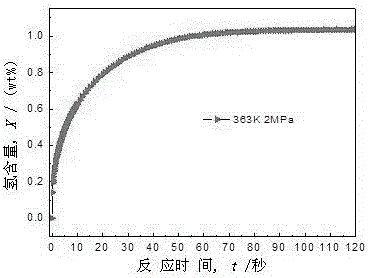

Embodiment 1

[0029] carry out La 0.9 Mg 0.1 Ni 4.25 al 0.75 For the smelting of hydrogen storage alloys, raw material metals with a purity of 99.9% are selected, and the burning loss of La and Al is compensated by 2%, and the burning loss of Mg is compensated by 15%. Other materials do not need to be compensated due to small burning losses. The Ni raw material is composed of a foil material and a bulk material, and other metal raw materials are all bulk materials. The amount of foil material is enough to completely wrap the Mg block, and the remaining Ni metal is made of block material. Put the prepared La, Ni (lump) and Al into the water-cooled copper crucible in the vacuum magnetic levitation induction melting furnace, among which La is placed at the bottom of the water-cooled copper crucible, then Al is placed, and Ni (lump) is placed on the top ). In addition, after wrapping the Mg block with Ni foil, put it into the holding bottle in the vacuum magnetic levitation induction melti...

Embodiment 2

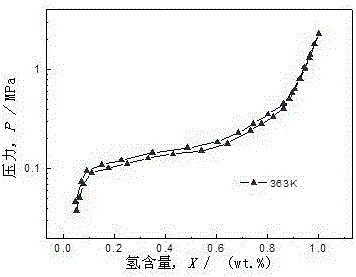

[0033] carry out La 0.8 Mg 0.2 Ni 4.25 al 0.75 For the smelting of hydrogen storage alloys, the raw material metals with a purity of 99.5% are selected, and the burning loss of La and Al is compensated by 2%, and the burning loss of Mg is compensated by 14%. The Ni raw materials are composed of foil and block materials respectively. Other metal raw materials are blocks. The amount of foil material is enough to completely wrap the Mg block, and the remaining Ni metal is all made of block material. Put the prepared La, Ni (block), and Al into the water-cooled copper crucible, among which La is placed at the bottom of the water-cooled copper crucible, then Al is placed, and Ni (block) is placed on the top. In addition, after wrapping the Mg block with Ni foil, put it into the holding bottle in the vacuum magnetic levitation induction melting furnace. Mechanical pump and molecular pump are used to evacuate the furnace cavity of the vacuum magnetic levitation induction melting...

Embodiment 3

[0037] carry out La 0.9 Mg 0.1 Ni 4.25 mn 0.75 For the smelting of hydrogen storage alloys, the raw material metal with a purity of 99.95% is selected, and the burning loss of La is compensated by 2%, the burning loss of Mn is compensated by 5%, and the burning loss of Mg is compensated by 12%. It is composed of foil and block, and the rest of the metal materials are made of block. The amount of Ni foil is enough to completely wrap the Mg block, and the remaining Ni metal is all made of block material. Put the prepared La, Ni (block), and Mn into the water-cooled copper crucible, among which Mn is placed at the bottom of the water-cooled copper crucible, then La is placed, and Ni (block) is placed on the top. In addition, after wrapping the Mg block with Ni foil, put it into the holding bottle in the vacuum magnetic levitation induction melting furnace. Mechanical pump and molecular pump are used to evacuate the furnace cavity of the vacuum magnetic levitation induction m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com