Synthetic method of Mg-based hydrogen storage alloy

A technology of hydrogen storage alloy and synthesis method, applied in the field of synthesis, can solve problems such as poor reaction kinetics and thermodynamic performance, poor corrosion resistance, hindering application, etc., to enhance reaction kinetics and thermodynamic performance, improve charge and discharge capacity and Corrosion resistance, hydrogen absorption and desorption temperature requirements are not high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

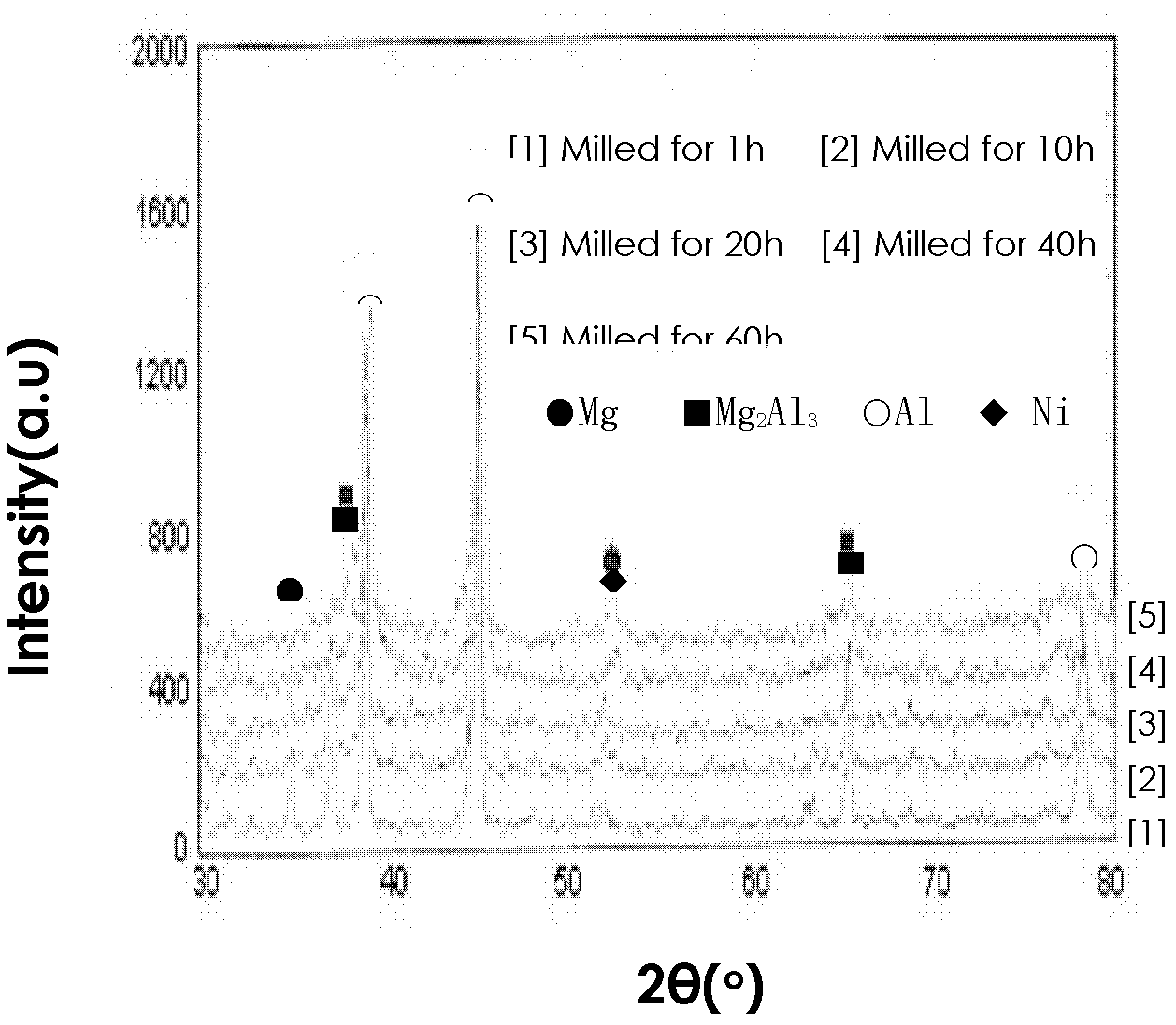

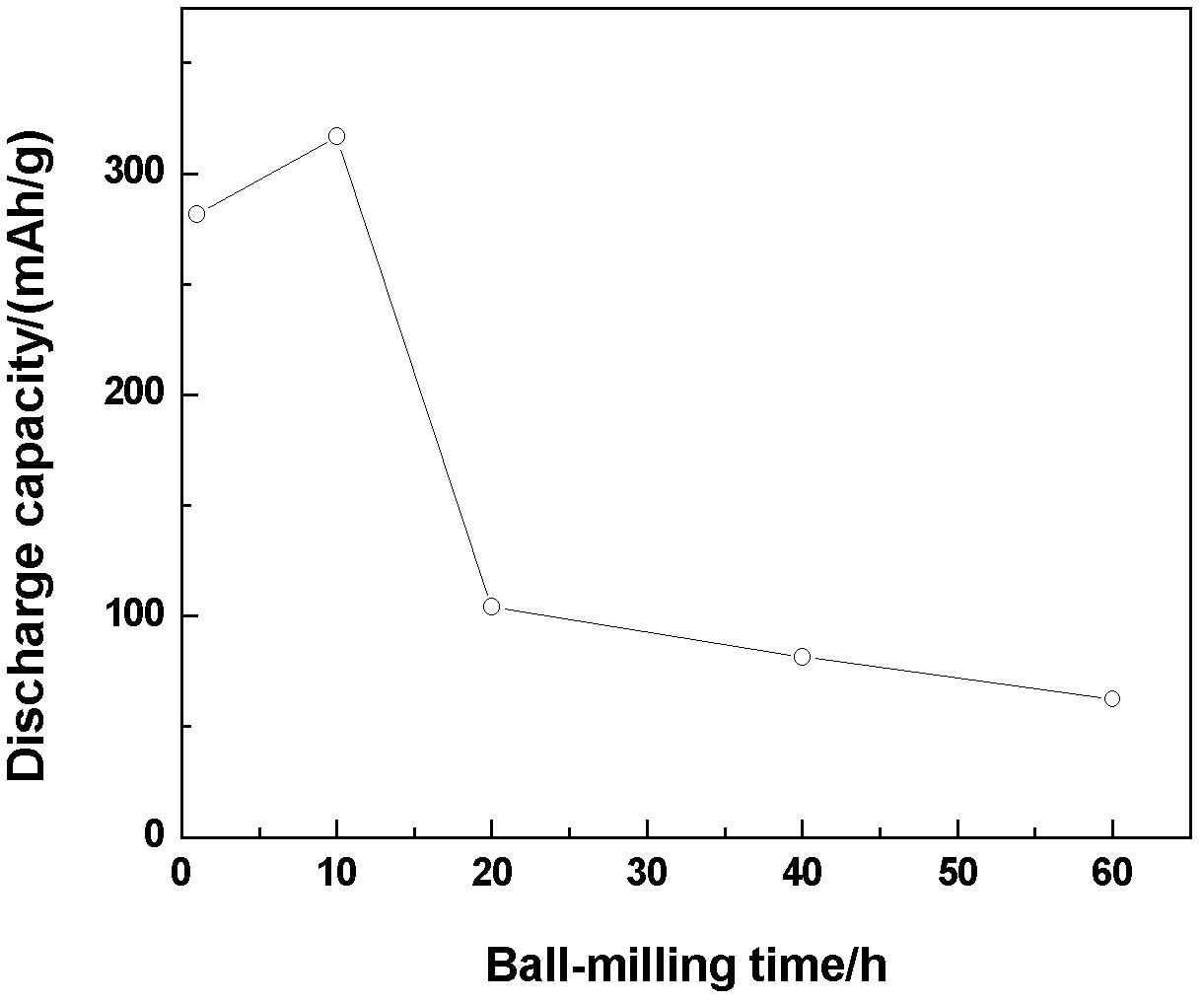

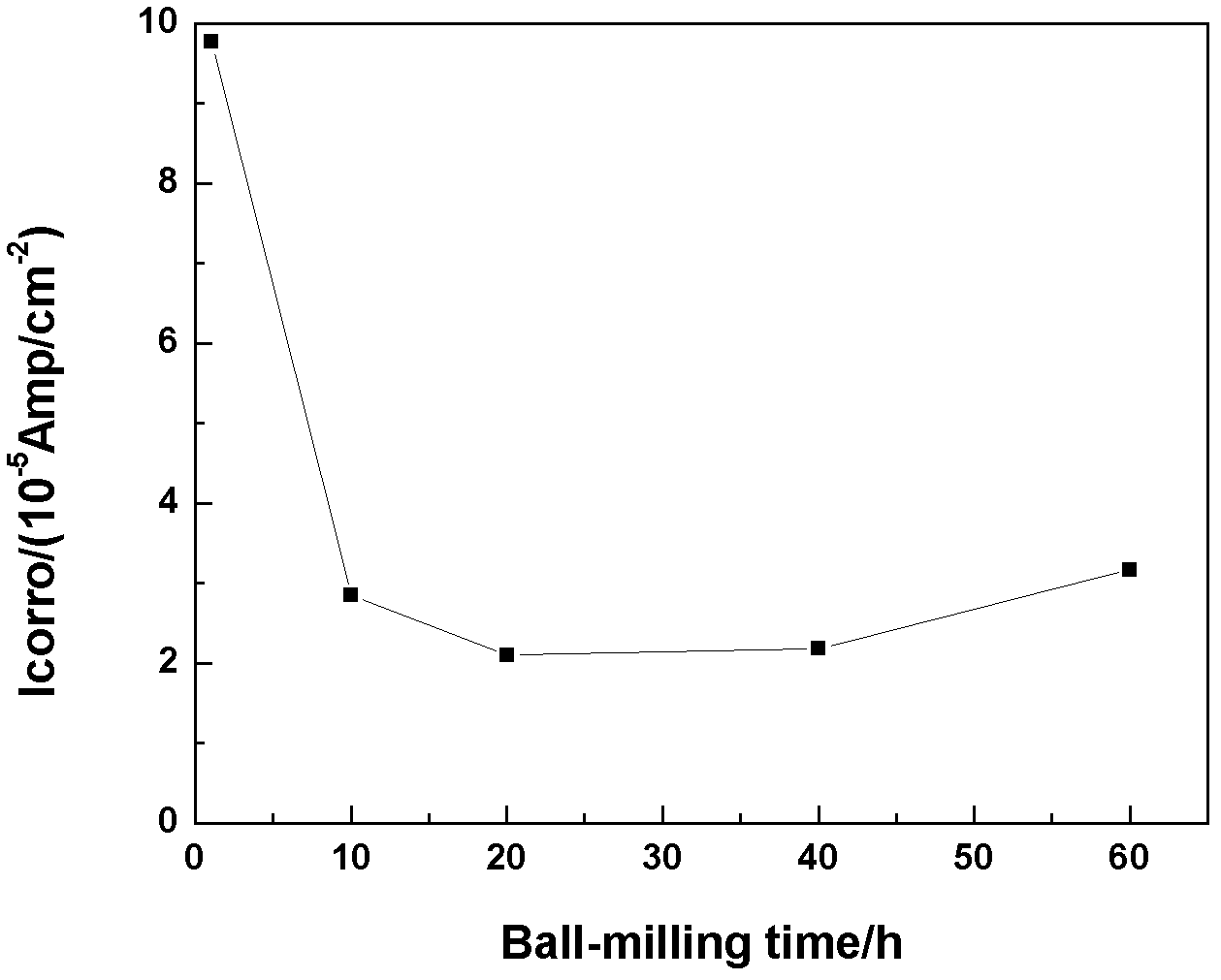

[0006] A synthesis method of Mg-based hydrogen storage alloy, which adopts mechanical alloying to prepare high-performance (M 40 al 60 ) 90 Ni 10 Hydrogen storage alloy, the realization steps of the method: mix pure Mg, pure Al and pure Ni (≥99.99%, mass fraction) with particles larger than 100 μm in a ratio of 36:54:10 into a ball mill jar and ball mill on a high-energy ball mill , The spherical tank and the grinding ball are made of 1Cr18Ni9Ti stainless steel, and the mass ratio of the ball to the material is 10:1. In order to prevent the sample from being oxidized during the ball milling process, the ball tank was evacuated and then filled with argon for protection. Every ball mill 1h, shut down 30min to avoid overheating, ball mill 10h altogether, obtain novel (M 40 al 60 ) 90 Ni 10 Hydrogen storage alloys in which Ml is formed 2 al 3 The new phase, the discharge capacity measured in 6mol / L KOH solution is 316.7mAh / g, and the corrosion current density is 2.84×10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com