Film for graphene/porous nickel oxide composite super capacitor and preparation method thereof

A supercapacitor, graphene technology, applied in the direction of capacitor electrodes, capacitor parts, etc., can solve the problems of unsatisfactory practical application, unsatisfactory cycle stability, etc., and achieve excellent high-rate performance, increase contact area, and charge and discharge capacity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

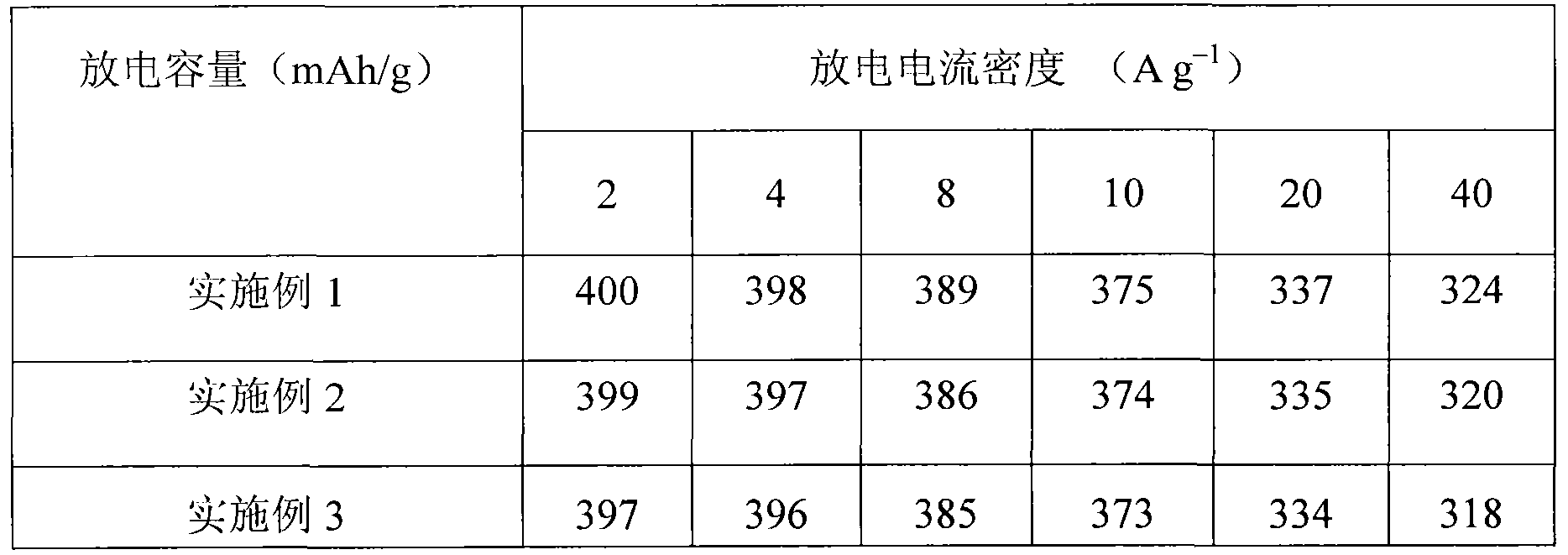

Embodiment 1

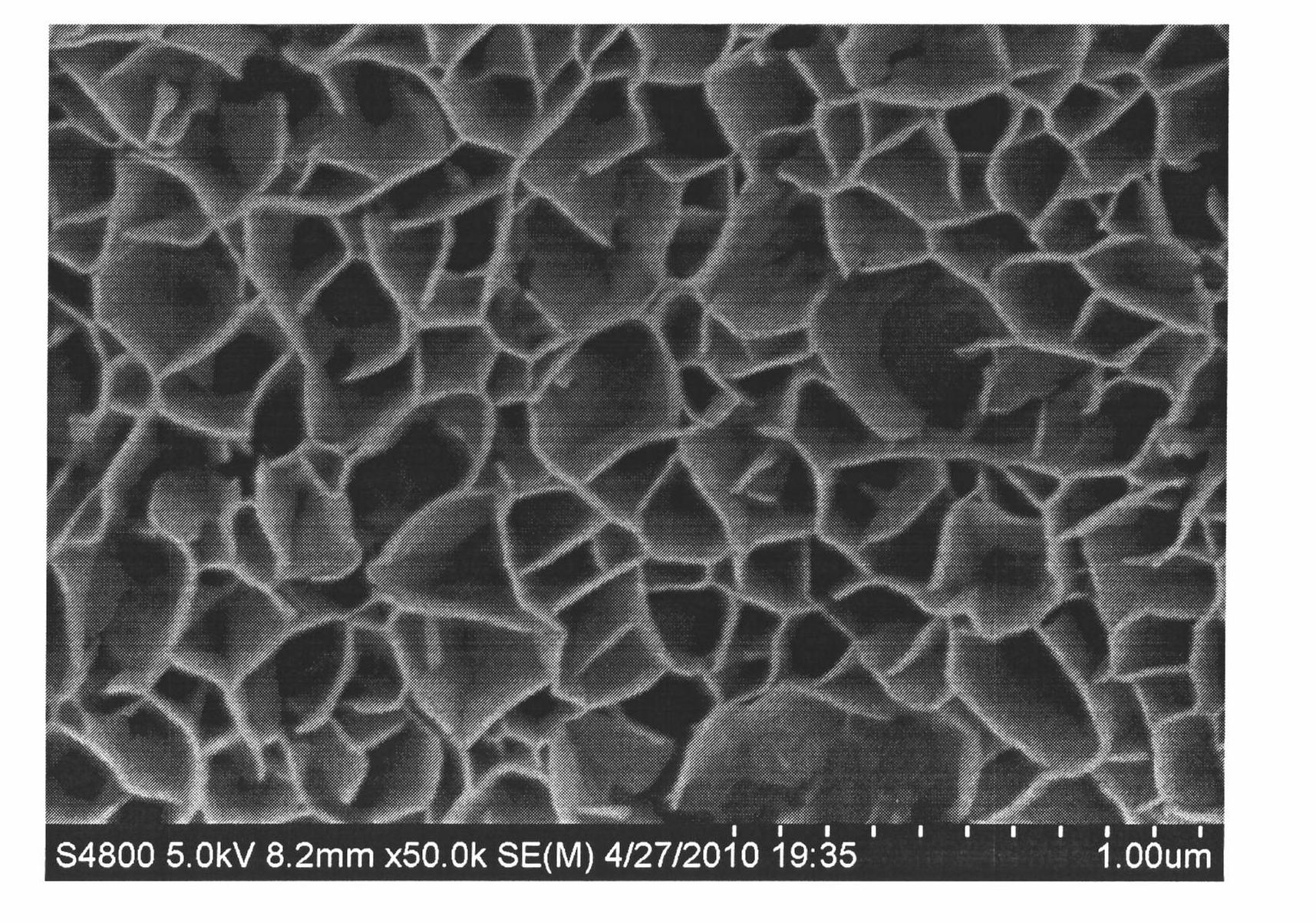

[0018] Weigh 5 g of graphite oxide flakes and add them to 1000 mL of isopropanol solution, then add 0.05 g of magnesium nitrate, and ultrasonicate for 30 minutes to form a stable pale yellow graphite oxide flake sol as the electrolyte. Then the electrolyte was transferred to an electrochemical double-electrode system, in which nickel foam was used as the working electrode, and the optical platinum sheet was used as the auxiliary electrode. The applied voltage is 100V, and the reaction is 30s to obtain graphite oxide film. Then place the graphite oxide film in saturated hydrazine hydrate vapor at 60°C for 12 hours to form a graphene film with a film thickness of 10 nm.

[0019] Weigh 120g of nickel sulfate and 20g of potassium persulfate into a beaker, then add 1000mL of deionized water and stir until completely dissolved. Afterwards, the graphene film supported by nickel foam was vertically pasted on the wall of the beaker, with the conductive surface facing the solution, and...

Embodiment 2

[0021] Weigh 20g graphite oxide flakes and add them to 2000mL isopropanol solution, then add 0.2g magnesium nitrate, and ultrasonicate for 30min to form a stable pale yellow graphite oxide flake sol as electrolyte. Then the electrolyte was transferred to an electrochemical double-electrode system, in which nickel foam was used as the working electrode, and the optical platinum sheet was used as the auxiliary electrode. The applied voltage was 50V, and the reaction was performed for 5 minutes to obtain a graphite oxide flake film. Then place the graphite oxide film in saturated hydrazine hydrate vapor at 75°C for 12 hours to form a graphene film with a film thickness of 50 nm.

[0022] Weigh 240g of nickel sulfate and 40g of potassium persulfate respectively and place them in a beaker, then add 2500mL of deionized water and stir until completely dissolved. Afterwards, the graphene film supported by nickel foam was vertically pasted on the wall of the beaker, with the conductiv...

Embodiment 3

[0024] Weigh 40g of graphite oxide flakes and add them to 2500mL of isopropanol solution, then add 0.4g of magnesium nitrate, and ultrasonicate for 30min to form a stable pale yellow graphite oxide flake sol as the electrolyte. Then the electrolyte was transferred to an electrochemical double-electrode system, in which nickel foam was used as the working electrode, and the optical platinum sheet was used as the auxiliary electrode. The applied voltage was 150V, and the reaction was performed for 5 minutes to obtain a graphite oxide flake film. Then place the graphite oxide film in saturated hydrazine hydrate vapor at 90 °C for 12 h to form a graphene film with a thickness of 100 nm.

[0025] Weigh 480g of nickel sulfate and 80g of potassium persulfate respectively and place them in a beaker, then add 4000mL of deionized water and stir until completely dissolved. Afterwards, the graphene film supported by nickel foam was vertically pasted on the wall of the beaker, with the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com