Magnesium based hydrogen storing alloy composite material and production thereof

A technology of magnesium-based hydrogen storage alloy and composite material, which is applied in the field of ball milling preparation of magnesium-based alloy composite material and its powder, which can solve the problems of poor oxidation resistance, corrosion resistance, slow hydrogen absorption and desorption speed, and high hydrogen absorption and desorption temperature. problems, to achieve the effects of superior corrosion resistance, fast hydrogen absorption and desorption, and high electrochemical capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

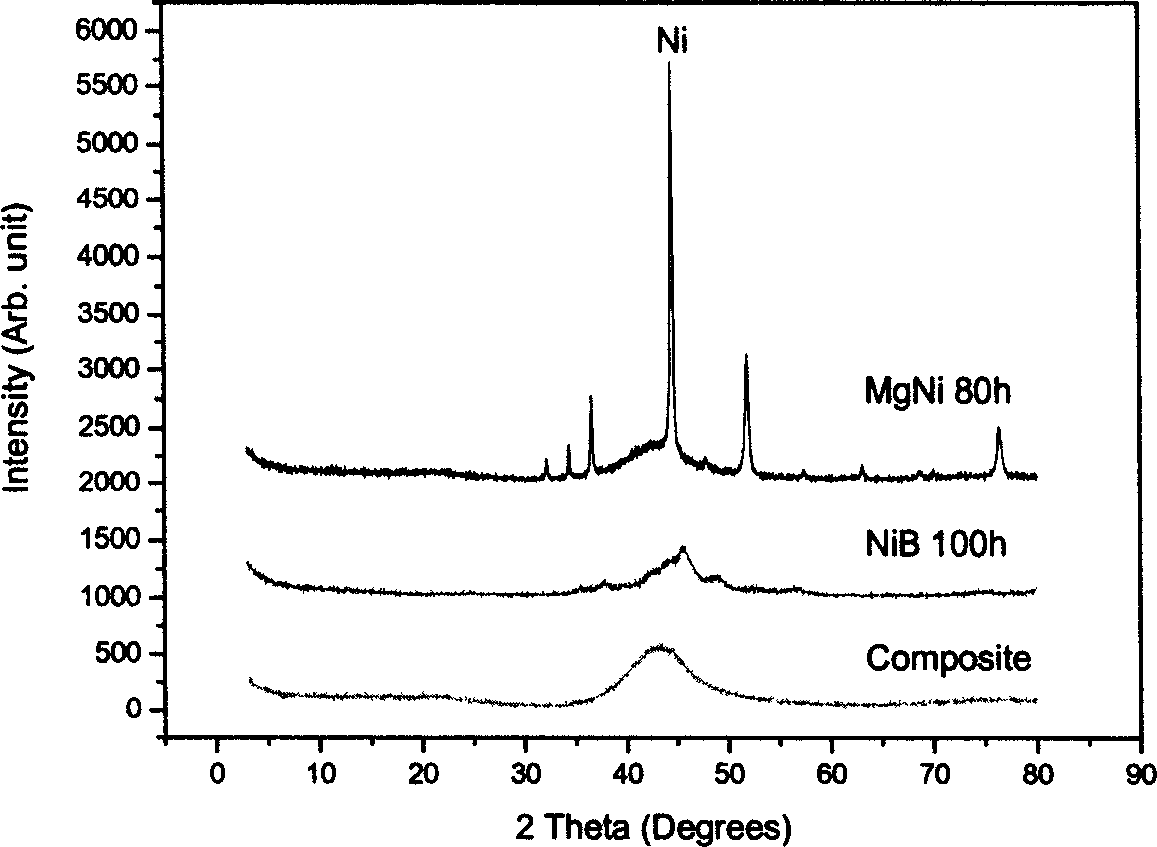

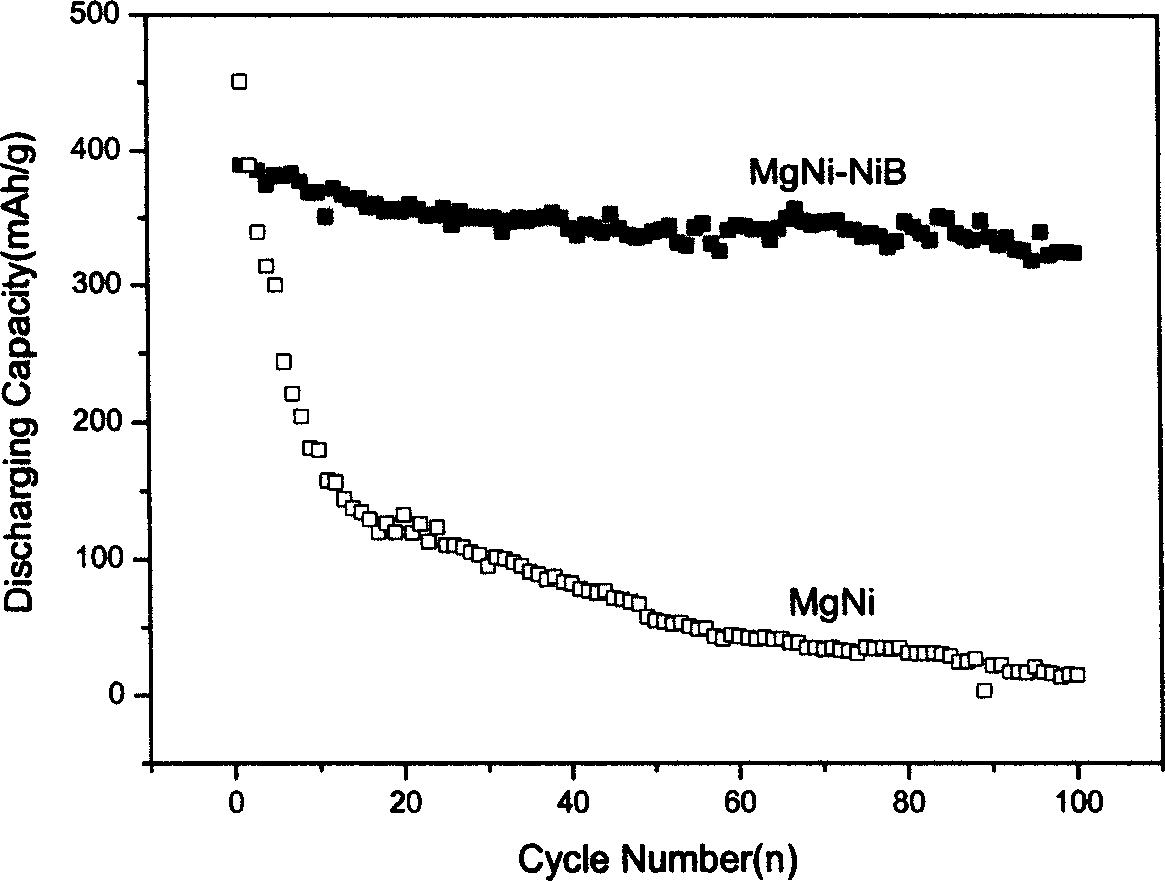

[0019] Mix Mg, Ni and other metal powders evenly according to the ratio of MgNi, place them in a sealed stainless steel grinding tank, put stainless steel balls in a weight ratio of 1:20, and fill with 1MPa hydrogen. The rotational speed of the ball mill was 450 rpm. The ball milling time was 80 hours. Use the same method to weigh Ni and B powders according to the NiB stoichiometric ratio, mix them evenly, and the rotating speed of the ball mill is 500 rpm. After ball milling for 100 hours, take it out, mix MgNi90wt% and NiB10wt% evenly according to the weight percentage, add it into a stainless steel grinding jar, fill it with argon, and the ball milling speed is 400 rpm, and ball milling for 10 hours. The product is subjected to X-ray diffraction phase analysis, scanning electron microscope and determination of alloy capacity. X-ray diffraction pattern ( figure 1 ) pointed out that the diffraction peak of the alloy before compounding was obviously broadened, and the diffr...

Embodiment 2

[0021] Mg, Ni metal powder by Mg 1.9 Al 0.1 Ni 0.9 Cu 0.1 The stoichiometric ratio is uniformly mixed, and pressed into small pieces with a diameter of 25 mm and a thickness of 20 to 50 mm under a pressure of 30 MPa. The small pieces of the mixture were sealed in a stainless steel container, filled with 0.5 MPa argon gas, placed in a crucible resistance furnace, heated to 540°C, and kept at a constant temperature for 4 hours to allow it to diffuse evenly and fully. After the product is cooled, it is pulverized, mixed evenly according to the weight percentage of MgNi90wt%, NiB10wt%, put it into a stainless steel grinding tank, fill it with argon, and the speed of the ball mill is 400 rpm, and the ball mill is 60 hours. The product is subjected to X-ray diffraction phase analysis, scanning electron microscope and measurement of alloy capacity, and the alloy particle size reaches 50-300nm. Mix the alloy powder with 300wt% carbonyl nickel powder evenly, make an electrode sampl...

Embodiment 3

[0023] Mg by ball milling 1.8 Al 0.2 The ratio of Ni to prepare magnesium-based alloys. By weight percent Mg 1.8 Al 0.2 Mix Ni 90wt% and NiB 10wt% evenly, add it into a stainless steel mill jar, fill it with argon gas, and mill at a rotational speed of 400 rpm for 100 hours. The product is subjected to X-ray diffraction phase analysis, scanning electron microscope and measurement of alloy capacity, and the alloy particle size is 10nm-150nm. Mix the alloy powder with 300wt% carbonyl nickel powder evenly, make an electrode sample with a diameter of 1.0cm under a pressure of 30MPa, weigh the mass of the small piece and calculate the true content of the active material, and then use two pieces of foam with a diameter of 2.5cm Nickel sandwiches the small pieces in the middle, compacts them with a pressure of 10MPa, and spot welds the tabs. The electrochemical capacity is determined by the test electrode, sintered NiOOH / Ni(OH) 2 It is measured by a three-electrode system consi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com