Method for applying waste lithium ion battery cathode material to nickel-cobalt battery anode material

A lithium-ion battery and cathode material technology, applied in the field of nickel-cobalt battery anode material preparation, can solve the problems of high cost, high energy consumption, waste, etc., and achieve the effects of low environmental pollution, good cycle life and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

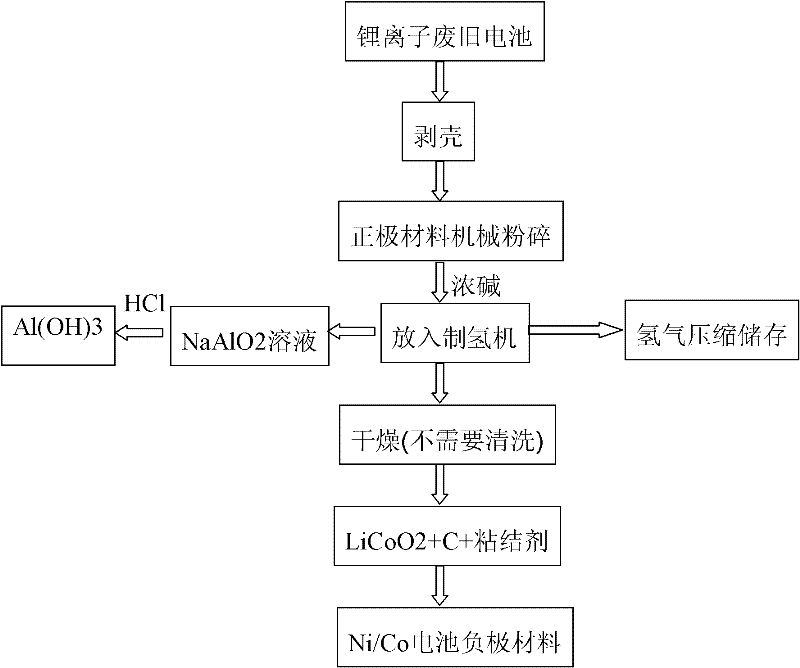

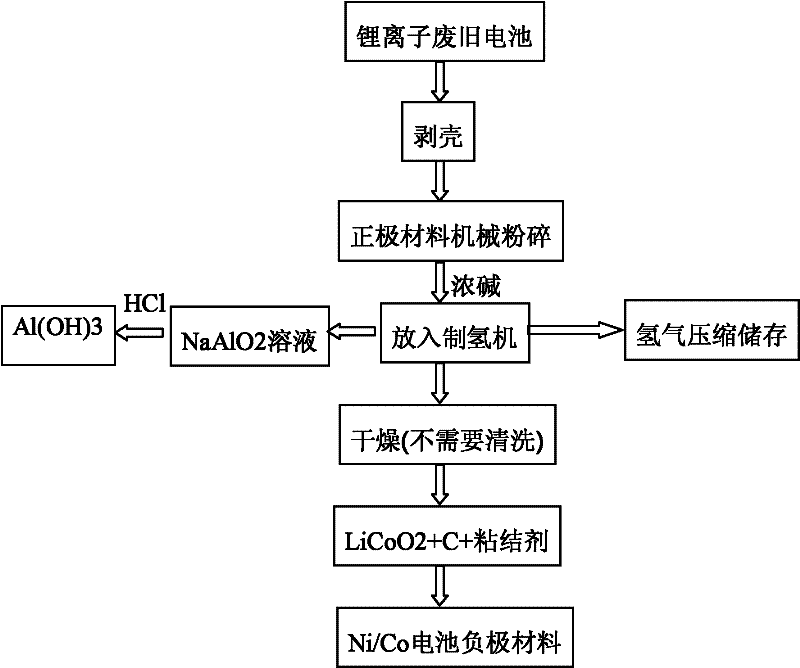

[0015] as attached figure 1 According to the process, take 10kg lithium-ion battery, cut the battery in water, separate the positive electrode material from other components, put the positive electrode material into a mechanical pulverizer, and put the pulverized material into the hydrogen generator at room temperature. Add 1000ml of NaOH solution with a mass concentration of 30% to the hydrogen generator, and react until no bubbles are generated. The hydrogen generator compresses and stores the generated hydrogen in cylinders after drying, and at the same time prevents the possibility of explosion after the released hydrogen mixes with air. The filtrate is collected, adding mass concentration is 10% hydrochloric acid, adjusts the pH value to be 8-10, obtains white Al(OH) 3 Precipitate, wash and dry the precipitate and save it for other use. The resulting filter residue contains LiCoO 2 , acetylene black and a small amount of conductive agent, dry at 80 degrees. Weigh the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com