Method of degrading organic pollutants

A technology of organic pollutants and pollutants, applied in water pollutants, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of weak catalytic peroxide performance and large Cu dissolution, and achieve catalyst structure stability, Excellent performance and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

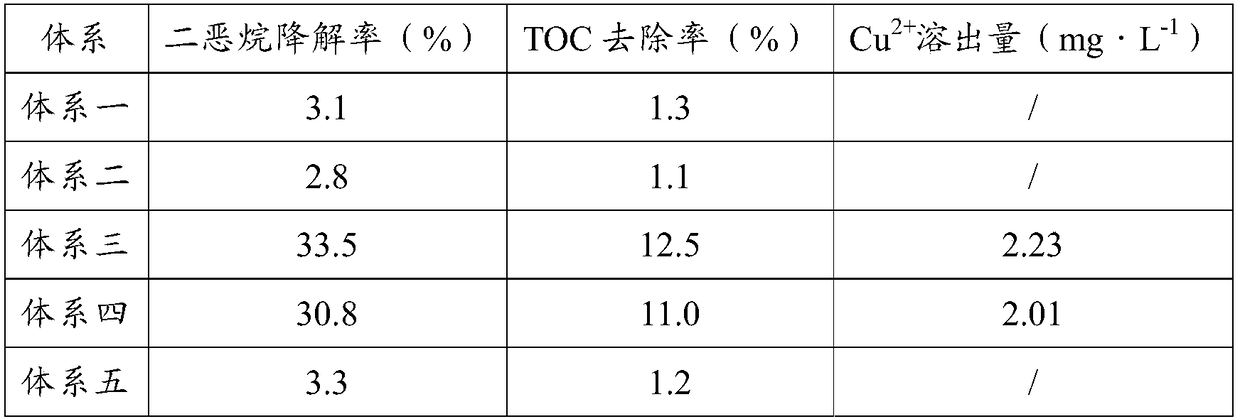

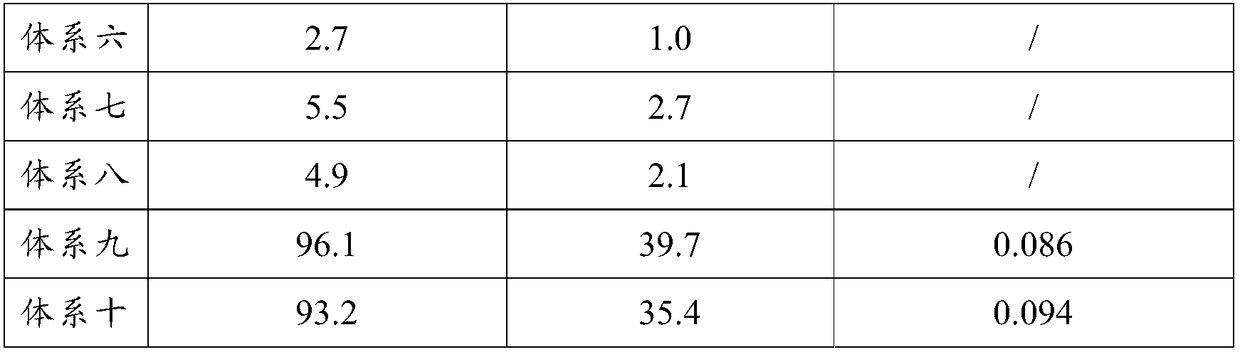

[0022]This embodiment utilizes a kind of Cu-containing layered metal hydroxide of the present invention to catalyze the steps in the degradation of organic pollutants by peroxides, and compare different Cu(II), Mg(II), Fe(III), Al(III) Ratio of Cu(II)-Mg(II)-Fe(III)LDHs, Cu(II)-Fe(II)-Fe(III)LDHs and Cu(II)-Mg(II)-Al(III)LDHs catalyzed Degradation efficiency, total organic carbon (TOC) removal rate and Cu 2+ Dissolution amount:

[0023] A. Cu(II)-Mg(II)-Fe(III)LDHs (Cu(II):Mg(II):Fe(III) molar ratio is 1:1:1) catalytic hydrogen peroxide system

[0024] Step 1, add 0.1mmol·L -1 Ethylbenzene in groundwater and 2.0mmol·L -1 Hydrogen peroxide, pH 7.0;

[0025] Step 2, add 0.1g L under stirring -1 Catalyst Cu(II)-Mg(II)-Fe(III) LDHs of the present invention (Cu(II):Mg(II):Fe(III) molar ratio is 1:1:1) After the reaction bottle is placed in shock In the bed, the rotation speed is 150rpm, the temperature is 25°C, and the reaction time is 6.0h. This is System 1.

[0026] B. Cu(...

Embodiment 2

[0045] This embodiment utilizes a Cu(II)-Mg(II)-Fe(III) LDHs (Cu(II):Mg(II):Fe(III) molar ratio of Cu(II)-Mg(II):Fe(III) layered metal hydroxide of the present invention is 2.5:2.5:1) Catalyzed steps in peroxide degradation of organic pollutants, comparing hydrogen peroxide alone, sodium persulfate and CuO, MgO and Fe respectively 2 o 3 Catalytic hydrogen peroxide, sodium persulfate and catalyst Cu(II)-Mg(II)-Fe(III) LDHs (Cu(II):Mg(II):Fe(III) mol ratio of the present invention are 2.5:2.5: 1) The degradation efficiency, total organic carbon (TOC) removal rate and Cu 2+ Dissolution amount:

[0046] A. Use hydrogen peroxide system alone

[0047] Step 1, add 0.1mmol·L -1 Dioxane in groundwater and 2.0mmol·L -1 Hydrogen peroxide, pH 7.0;

[0048] Step 2: Place the reaction bottle in a vibrating bed with a rotation speed of 150 rpm, a temperature of 25° C., and a reaction time of 6.0 h. This is System 1.

[0049] B. Use sodium persulfate system alone

[0050] Step 1, add ...

Embodiment 3

[0082] A Cu(II)-Fe(II)-Fe(III) LDHs (Cu(II):Fe(II):Fe(III) molar ratio of Cu(II)-Fe(II):Fe(III) molar ratio is 2.5:2.5 : 1) The method of catalyzing peroxide degradation organic pollutants is to compare the degradation rate of nitrobenzene (a kind of semi-volatile organic pollutants), TOC removal rate and Cu 2+ Dissolution amount:

[0083] Step 1. Add 0.1mmol·L -1 Add 1.0, 5.0 and 10.0mmol L to the surface water of nitrobenzene -1 After hydrogen peroxide, adjust the pH to 7.0, and the above systems are marked as system 1, 2 and 3; add 0.1mmol·L -1 Add 1.0, 5.0 and 10.0mmol L to the surface water of nitrobenzene -1 After potassium persulfate, adjust the pH to be 7.0, and the above-mentioned systems are marked as systems four, five and six;

[0084] Step 2. Under stirring conditions, add 0.05, 0.25, 0.5, 0.05, 0.25, 0.5g·L -1 Catalyst Cu(II)-Fe(II)-Fe(III)LDHs of the present invention (Cu(II):Fe(II):Fe(III) molar ratio is 2.5:2.5:1) in system one, two, three , 4, 5 and 6; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com