Device for preparing high-pressure hydrogen by using metal hydrides

A high-pressure hydrogen and hydride technology, applied in hydrogen production, energy input, etc., can solve problems such as lack of relevant patents, and achieve the effect of ensuring system safety and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

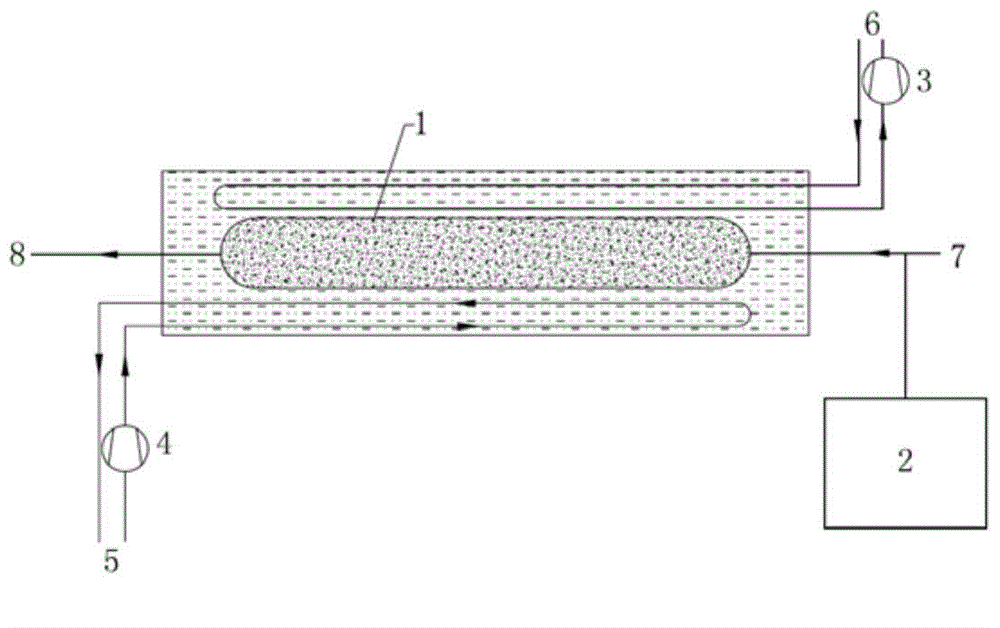

Method used

Image

Examples

Embodiment 1

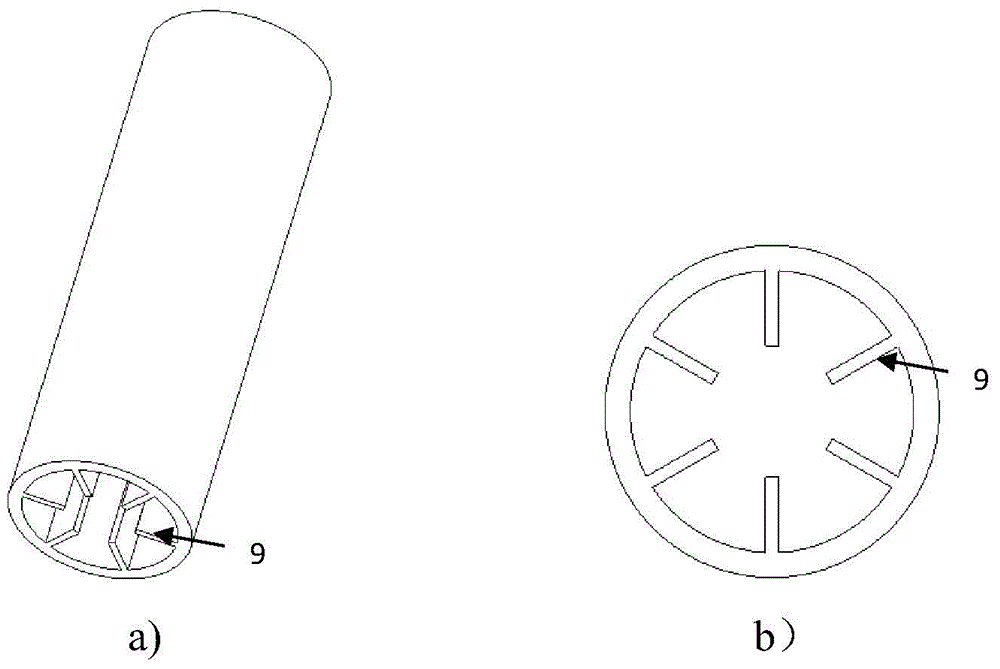

[0033] The reaction bed 1 is designed as a stainless steel tank, and the inner wall of the tank is made into a structure with six heat exchange fins 9. The heat exchange fins 9 are straight and long in the axial direction of the tank, and are evenly distributed at intervals of 60° in the circumferential direction. , the cross-section of the heat exchange fin 9 is rectangular, such as figure 2 (a) and 2(b). This structure can increase the heat exchange area, and conduct the heat to the hydrogen storage alloy inside the tank in time to the maximum extent, which is beneficial to the hydrogen discharge process, and conducts the heat generated by the hydrogen storage alloy inside the tank in time during the hydrogen absorption process. , which is conducive to the hydrogen absorption process.

[0034] When the hydrogen storage alloy adopts Ti-Mn-based metal hydride, during the heating and pressurizing process, at 80°C, after about 120 minutes, the internal pressure of the compress...

Embodiment 2

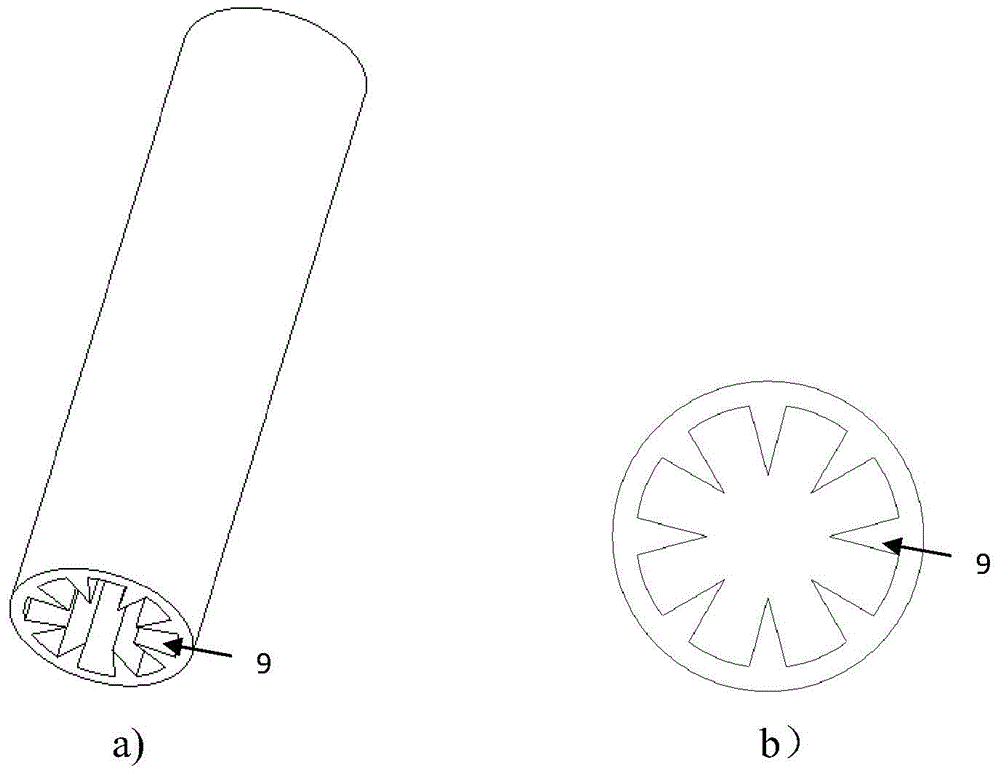

[0036] In this embodiment, the heat exchanging fins 9 are replaced with triangular heat exchanging fins, the hydrogen storage alloy is replaced with a Ti-Cr-based metal hydride, and the other components are the same as in Embodiment 1.

[0037] The reaction bed 1 is designed as a stainless steel tank, and the inner wall of the tank is made into a structure with 8 heat exchange fins 9. The heat exchange fins 9 are straight and long in the axial direction of the tank, and are evenly distributed at intervals of 45° in the circumferential direction. , the cross-section of the heat exchange fin 9 is an equilateral triangle, such as image 3 (a) and 3(b). This structure can increase the heat exchange area, and conduct the heat to the hydrogen storage alloy inside the tank in time to the maximum extent, which is beneficial to the hydrogen discharge process, and conducts the heat generated by the hydrogen storage alloy inside the tank in time during the hydrogen absorption process. ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com