Patents

Literature

50results about How to "Reduce the amount of experiments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

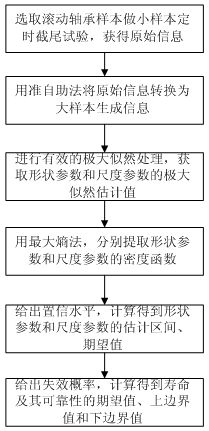

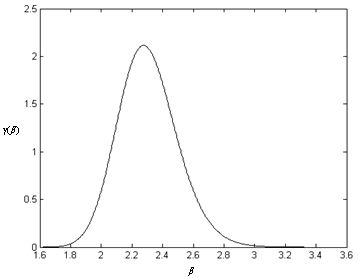

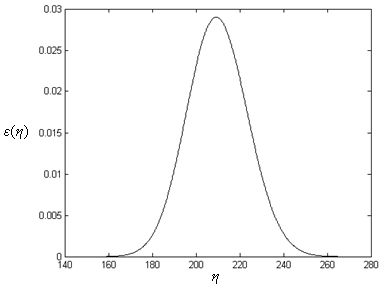

Poor information theory fusion-based product life characteristic information extraction method

InactiveCN102081767AAccurate acquisitionRestore original propertiesInstrumentsPattern recognitionSmall sample

The invention relates to a poor information theory fusion-based product life characteristic information extraction method, which comprises the following steps of: acquiring original information of a small sample; transforming the original information into large-sample generating information by using a right self-service method and performing effective maximum likelihood processing, and acquiring maximum likelihood estimated values of large-sample content of two parameters, namely a Weibull distribution shape parameter and a scale parameter; extracting density functions of the two parameters by using a maximum entropy method; giving a confidence level, and calculating estimation intervals and expected values of the two parameters through the density functions of the shape parameter and the scale parameter respectively; and giving a failure probability, and acquiring the product life characteristic information through Weibull distribution life of the two parameters and reliability calculation thereof. The method has no requirement on completeness of the original information of the small sample, does not need priori information of the shape parameter and the scale parameter, can effectively recover total original characteristics of the product life, disclose nature of the product life information, more accurately acquire the product life characteristic information and reduce the experimental quantity of the product.

Owner:HENAN UNIV OF SCI & TECH

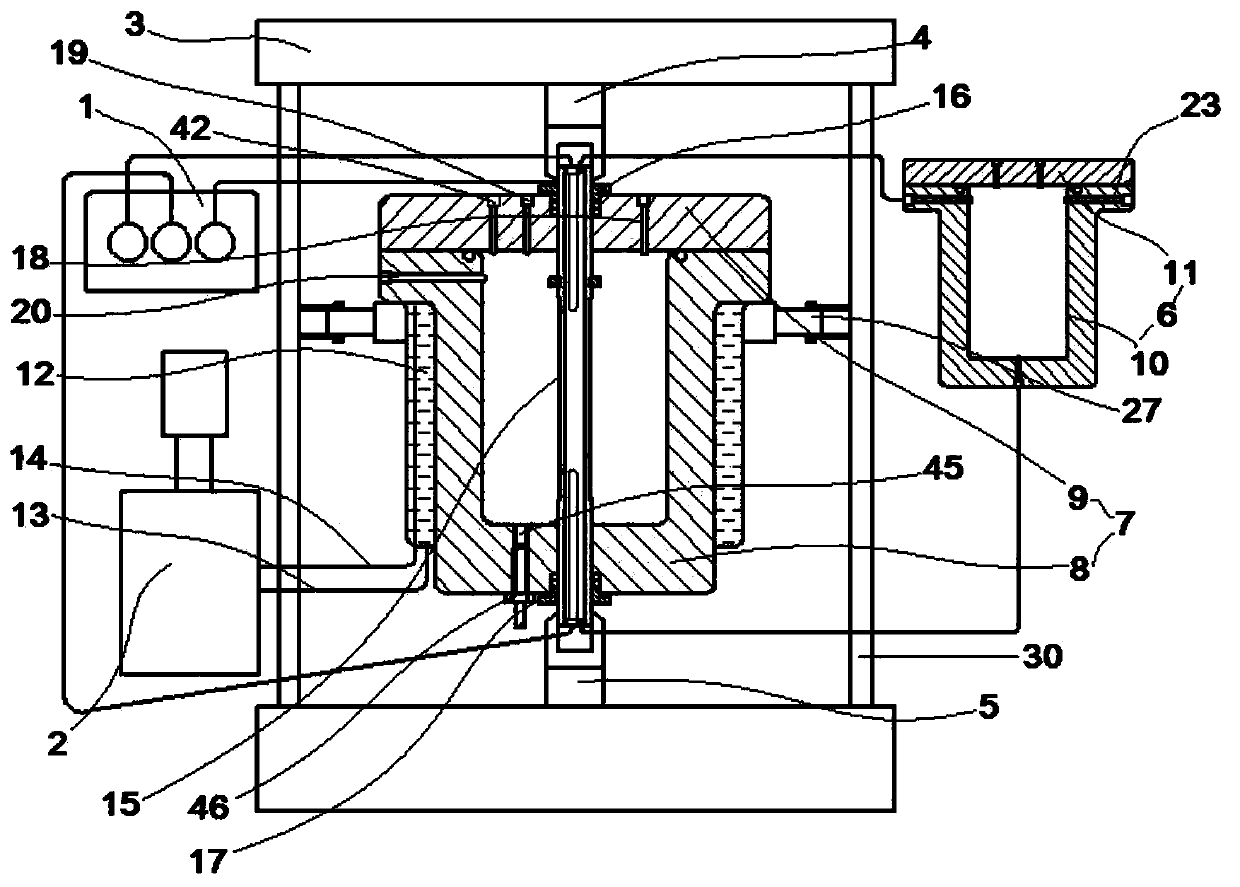

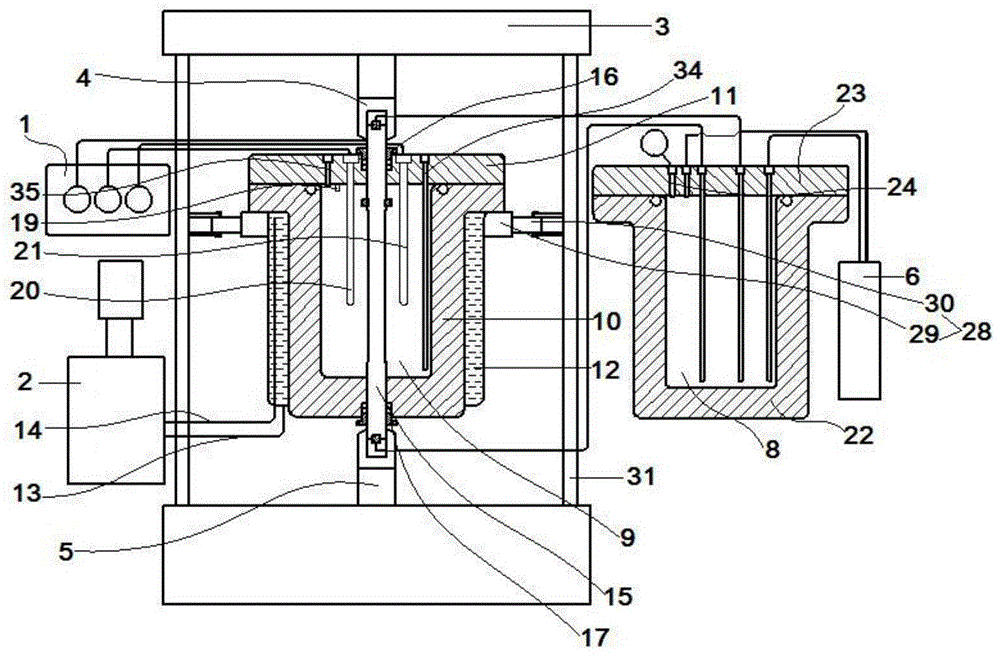

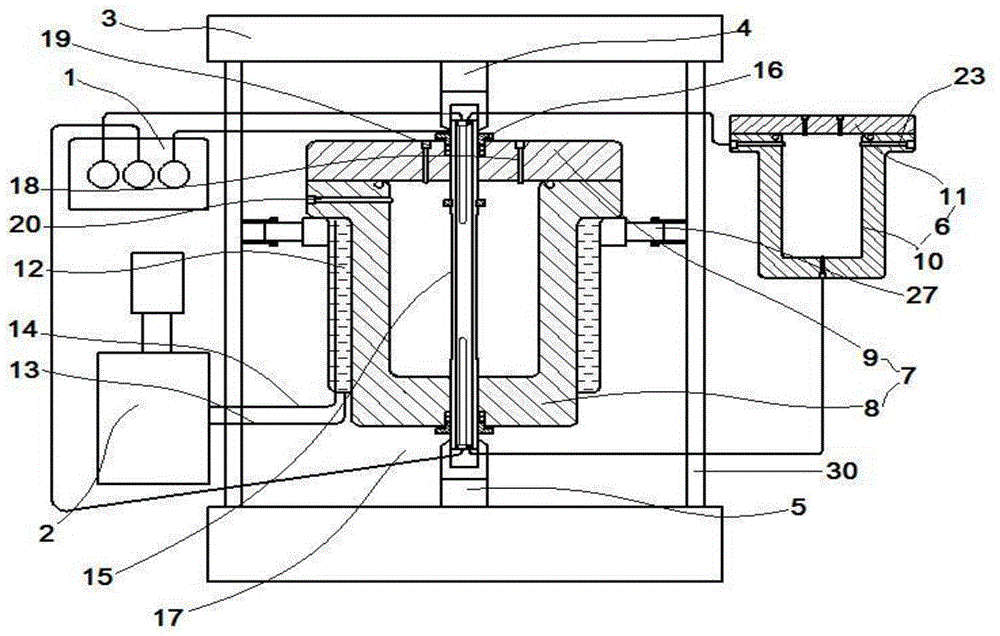

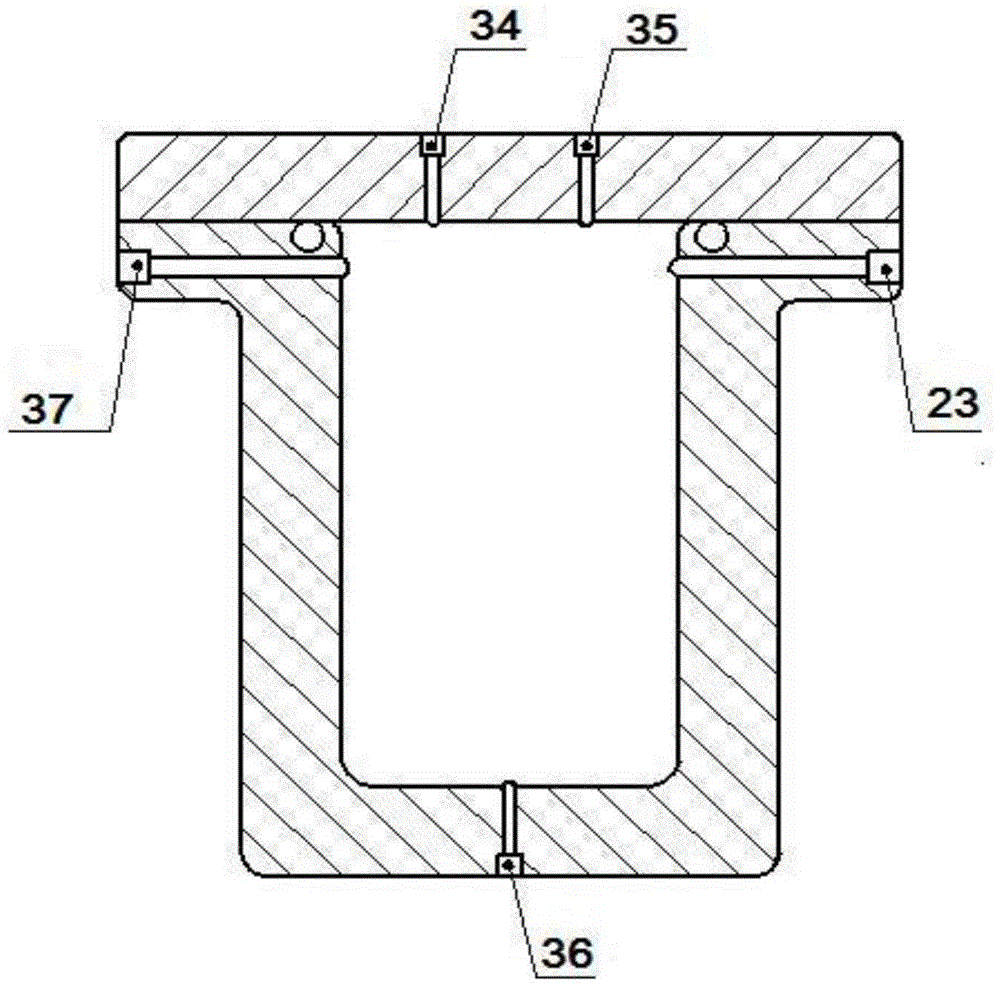

High temperature and high pressure corrosion hydrogen permeation testing device and method

ActiveCN104568727AReduce the amount of experimentsAvoid influenceWeather/light/corrosion resistanceFatigue loadingCarbon dioxide corrosion

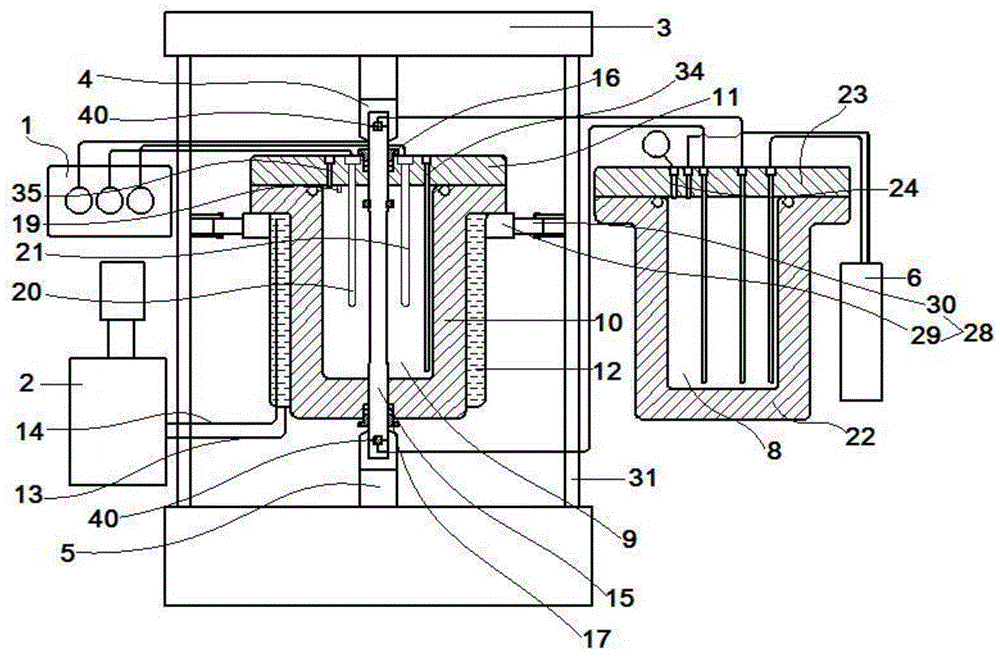

The invention discloses a high temperature and high pressure corrosion hydrogen permeation testing device and method. When fatigue limit is measured, after hydrogen permeation current is stabilized under the given corrosion condition, step type fatigue loads are applied to a test sample material from a smaller one to a larger one, and when the hydrogen permeation current is increased along with increase of the load, dislocation movement inside the test sample material is caused by the load, and the load is considered as the fatigue limit of the test sample material in the environment. The device and the method disclosed by the invention have the characteristics that a quantitative relation between the fatigue load state and the hydrogen permeation amount can be measured in situ on line in a high-pressure carbon dioxide corrosion state, the internal relation between the stress and segregation diffusion of hydrogen can be intuitively reflected, and a mutual relation among multiple data is established.

Owner:ZHEJIANG UNIV OF TECH

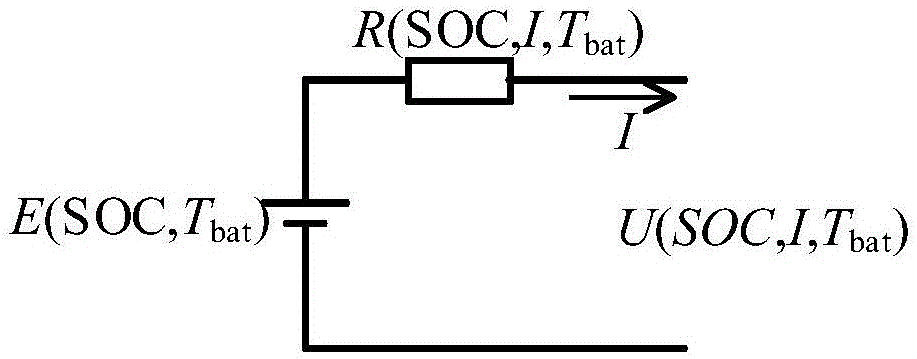

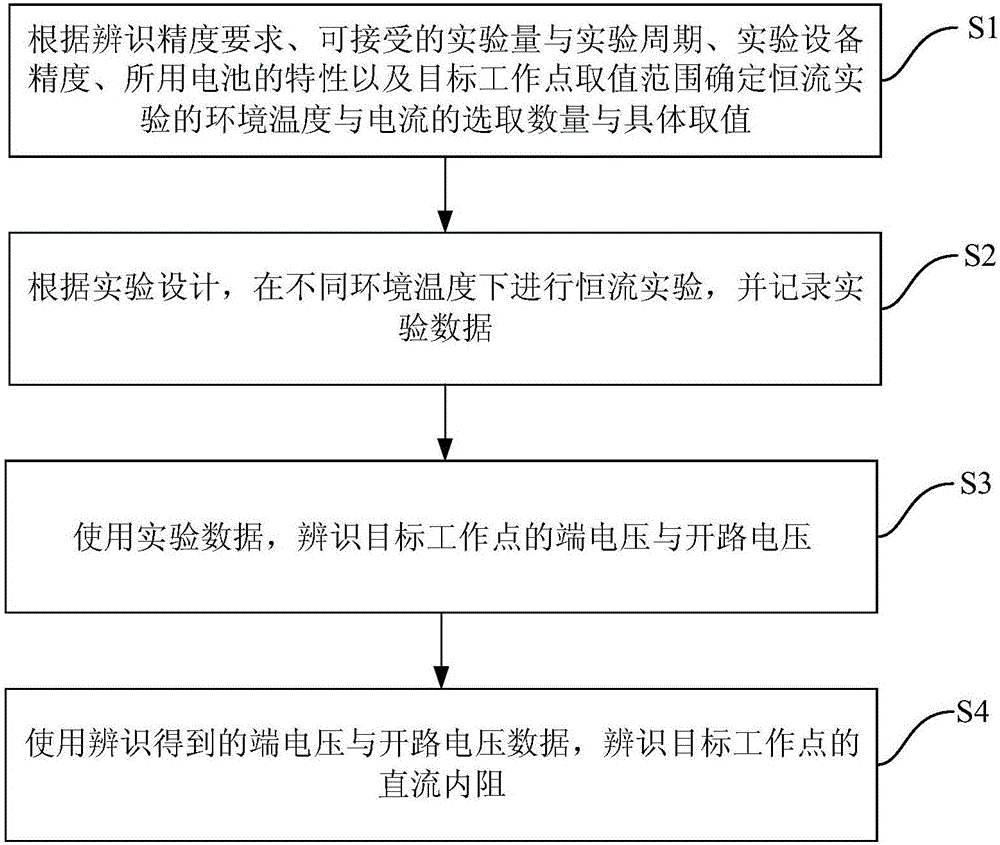

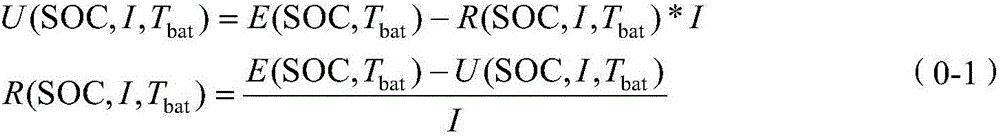

Method of identifying open-circuit voltage and direct-current internal resistance of battery based on constant current experiment

ActiveCN106772098AReduce the amount of experimentsImprove recognition accuracyElectrical testingElectrical batteryTerminal voltage

The invention provides a method of identifying open-circuit voltage and direct-current internal resistance of a battery based on constant current experiment, and belongs to the technical field of batteries. The method comprises: performing constant current experiment at different ambient temperatures, performing fitting or interpolation on same working current with SOC (state of charge) and terminal voltage data under different battery temperatures to obtain identification value of the working current relative to the SOC and terminal voltage data under the specified battery temperature by making use of the characteristic that parameters of a direct-current internal resistance model are of continuous monotonous relationship with working current and battery temperature; performing fitting or interpolation on the same SOC with battery temperatures and terminal voltage data of different working currents so as to obtain a terminal voltage and working current relational expression, using the relational expression to identify terminal voltage of a part where the working current is 0, and adding a constant to correct the terminal voltage to obtain open-circuit voltage; using the obtained terminal voltage and the open-circuit data to solve direct-current internal resistance. Compared with traditional methods, the method of the invention has suitable experimental quantity and high identification precision and is more suitable for engineering application.

Owner:TSINGHUA UNIV

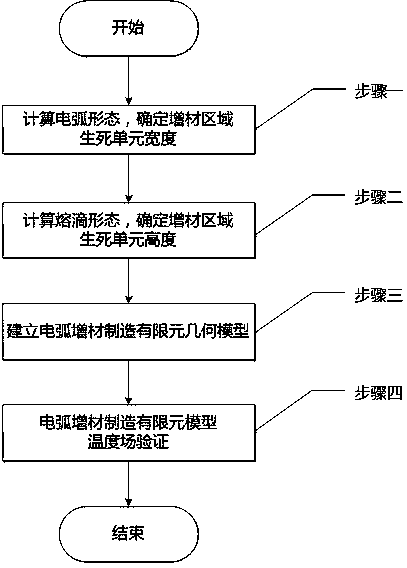

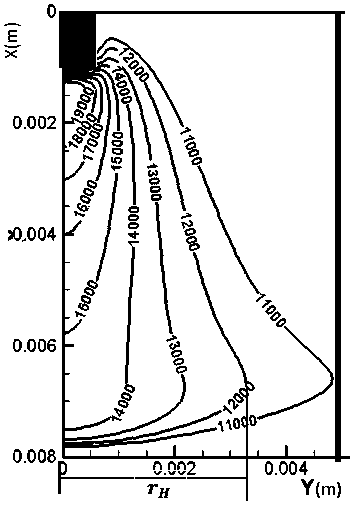

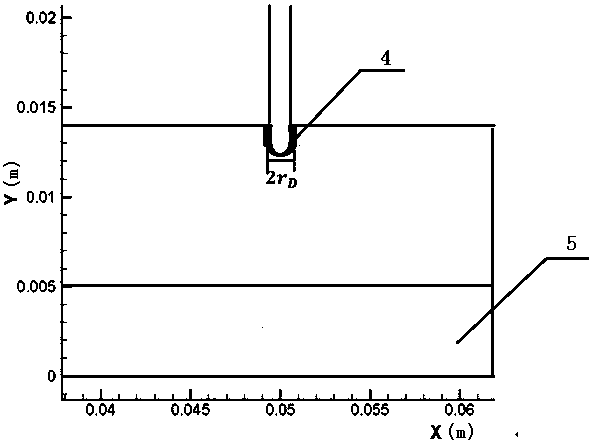

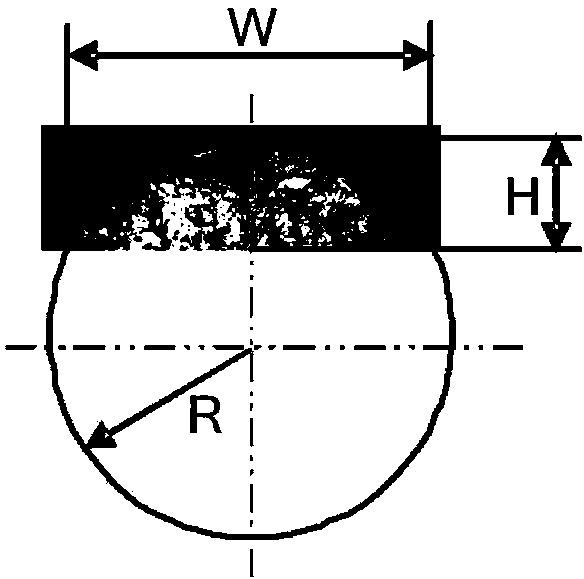

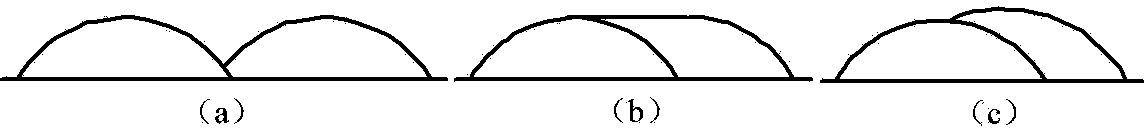

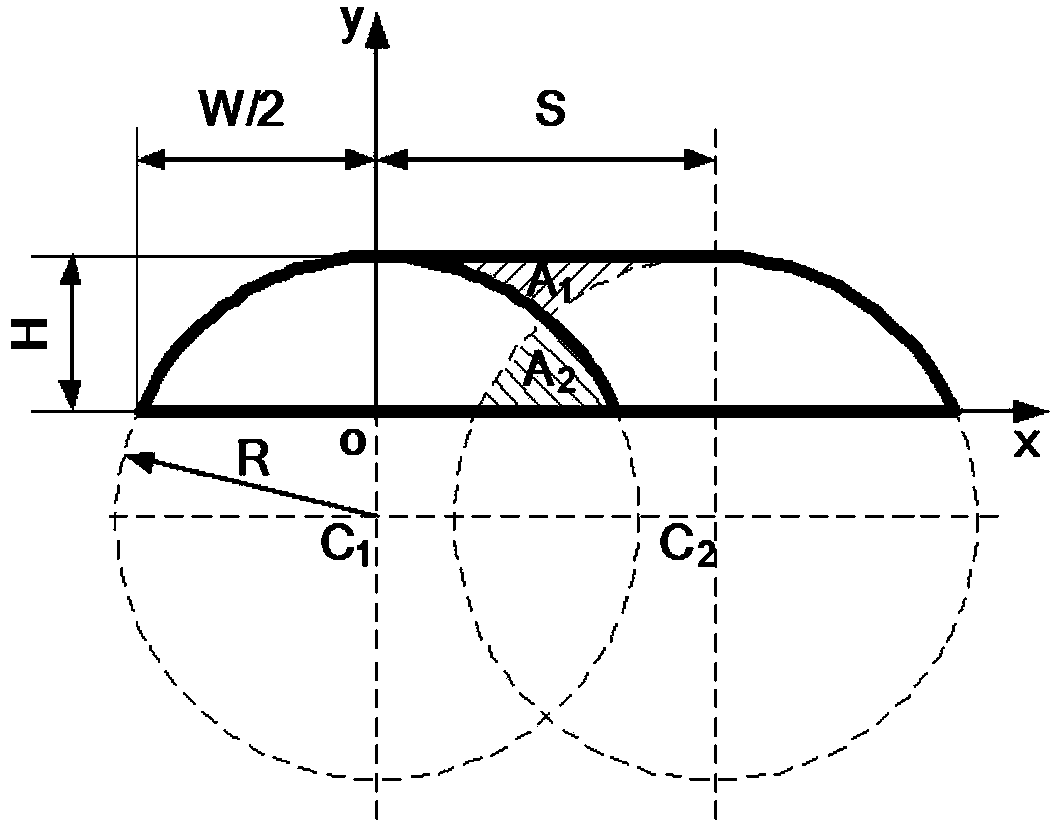

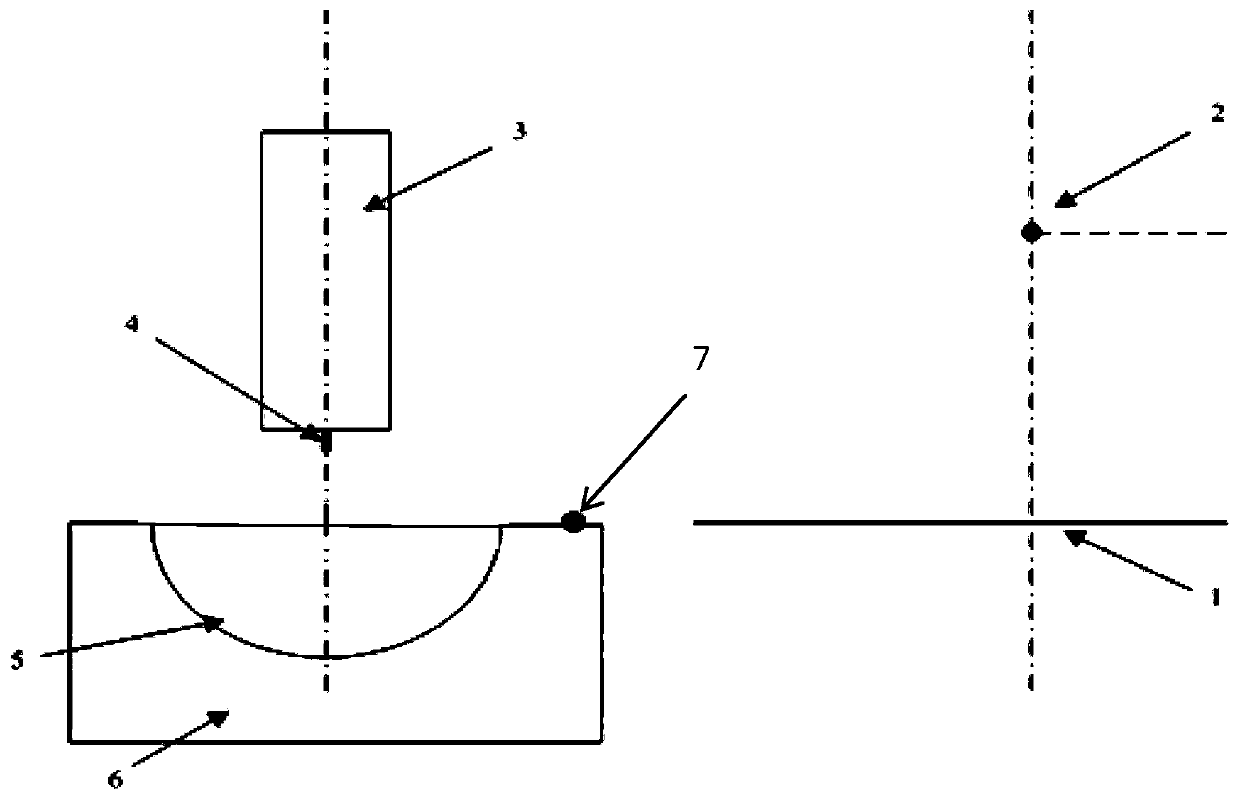

Arc additive manufacturing finite element modeling method

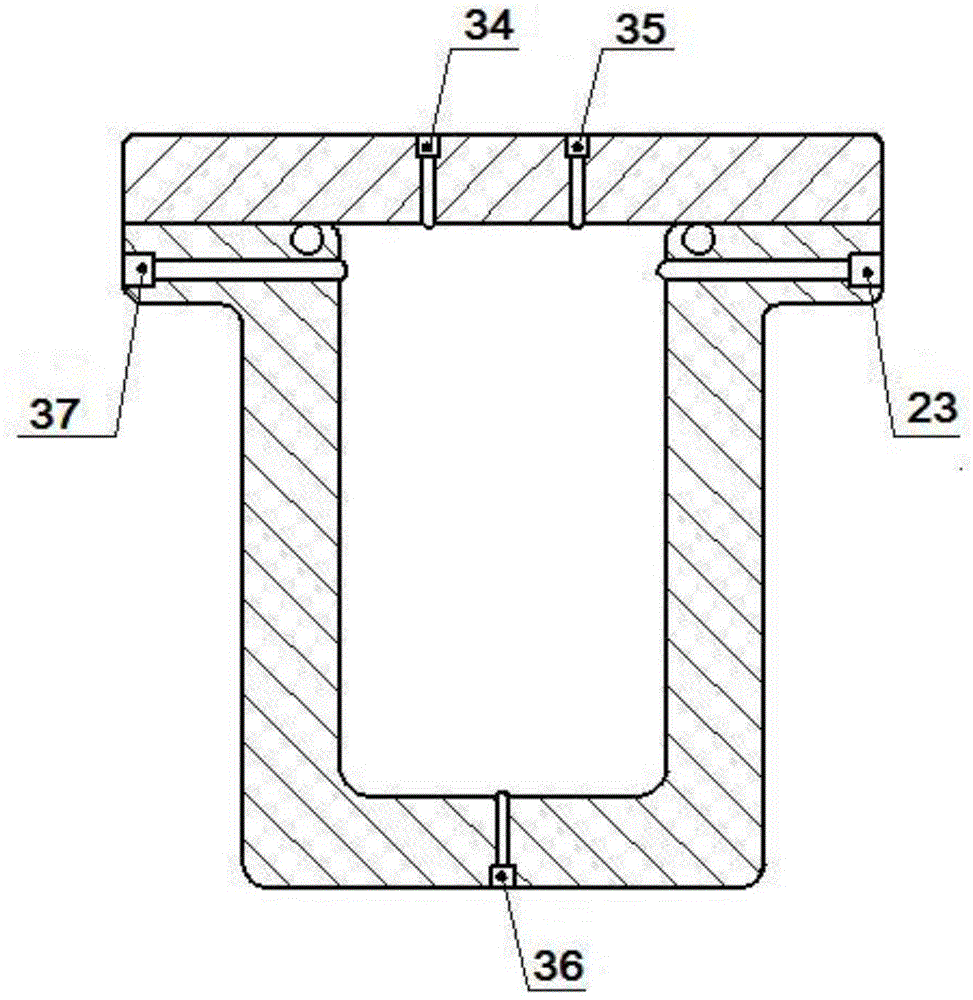

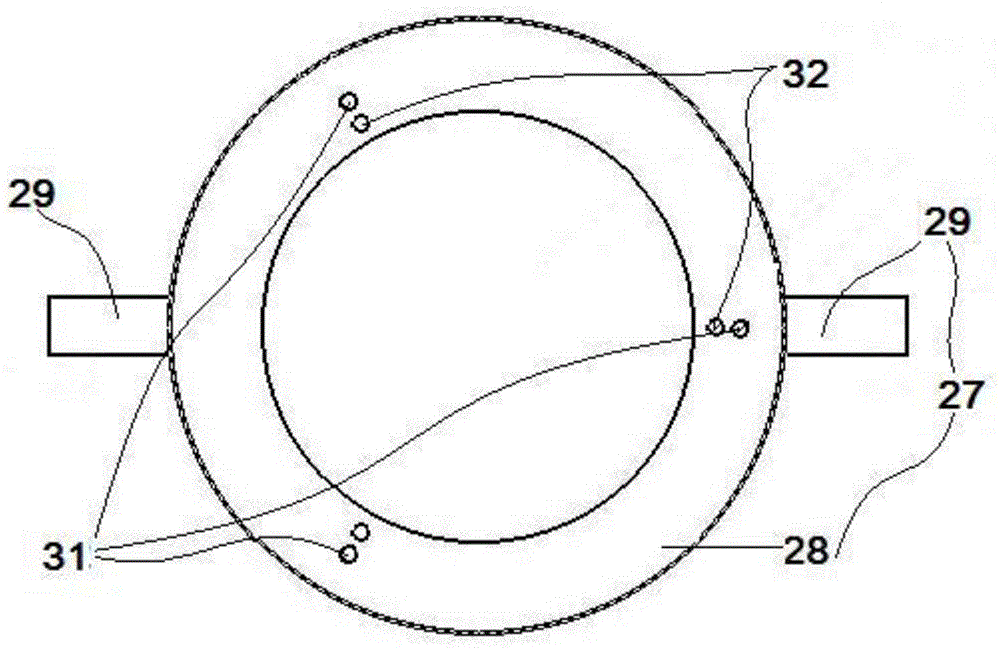

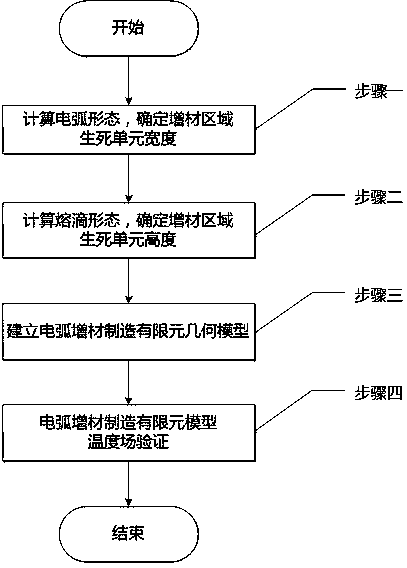

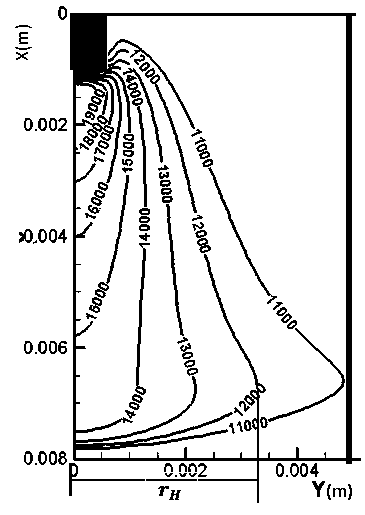

ActiveCN107066700AReduce the amount of experimentsImprove calculation accuracyDesign optimisation/simulationSpecial data processing applicationsGeometric modelingElement modeling

The invention discloses an arc additive manufacturing finite element modeling method. The method comprises the following steps of: calculating an arc shape and determining the width of an additive area birth-death element; calculating a molten drop shape and determining the height of the additive area birth-death element; establishing an arc additive manufacturing finite element geometric model according to the width of the additive area birth-death element and the height of the additive area birth-death element; correcting the arc shape and the molten drop shape through verifying the temperature distribution of the arc additive manufacturing finite element geometric model, so as to correct the arc additive manufacturing finite element geometric model. According to the method disclosed by the invention, the geometric size of the additive area birth-death element can be determined before the arc additive manufacturing finite modeling by adopting an arc additive manufacturing simulation process, combining an arc shape simulation technology, a molten drop shape simulation technology and a finite element simulation technology and carrying out experimental verification, so as to realize the correct calculation of arc additive manufacturing finite element simulation.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for improving surface evenness of laser rapid forming metal part

InactiveCN103433487AImprove flatnessHigh shape accuracyIncreasing energy efficiencyTime-ConsumingMaterials science

The invention relates to a method for improving the surface evenness of a laser rapid forming metal part. According to the method, a formula related to cladding line width and cladding line height can be deduced according to a critical ideal overlapping model of adjacent cladding tracks, the ideal overlapping rate (the optimal scanning interval) of the adjacent cladding tracks can be figured out through the formula, so that the plane scanning process for overlapping the cladding lines into a plane can be carried out with the ideal overlapping rate as the technological parameter. Through the model, the optimal scanning interval can be determined scientifically and efficiently, the forming evenness of an overlapping plane is accordingly improved, repeated, tedious, time-consuming and labor-consuming experiment exploring processes are avoided, meanwhile, the manufacturing cost such as raw material loss and equipment loss are saved, and the method is suitable for popularization and application.

Owner:SHENYANG POLYTECHNIC UNIV

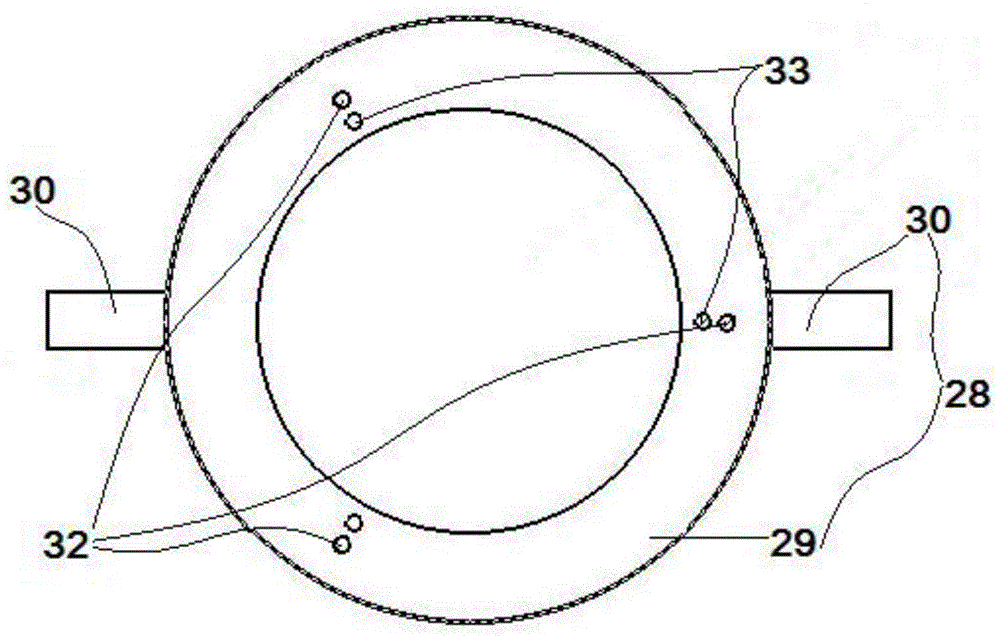

Dynamic testing apparatus and testing method for high-pressure hydrogen permeation

ActiveCN104897490AReduce the amount of experimentsShorten test timeMaterial strength using repeated/pulsating forcesDiffusionFatigue loading

The invention discloses a dynamic testing apparatus and testing method for high-pressure hydrogen permeation. According to the invention, hydrogen permeation quantity is measured in the process of stretching of a sample; and the quantitative relation between the state of fatigue load and hydrogen permeation quantity is measured on line in situ in different high-pressure hydrogen environments, the internal link between stress and segregation and diffusion of hydrogen can be visually presented, and that the hydrogen diffusion coefficient, acceleration amount and hydrogen acceleration amount of a material are directly related to dislocation movement under different conditions is indirectly found out through analysis, so a reliable data basis is provided for determination of dislocation density. The dynamic testing apparatus and testing method provided by the invention have the characteristics of reduction in test dose and reduction in testing time of a single experiment.

Owner:ZHEJIANG UNIV OF TECH

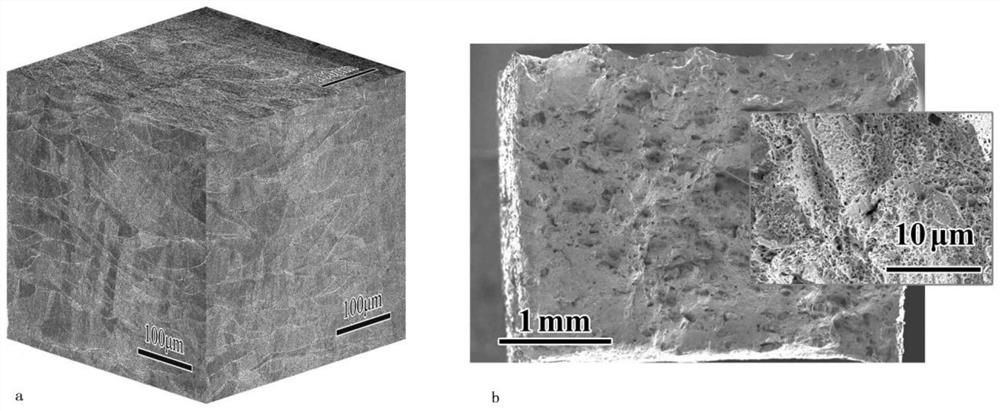

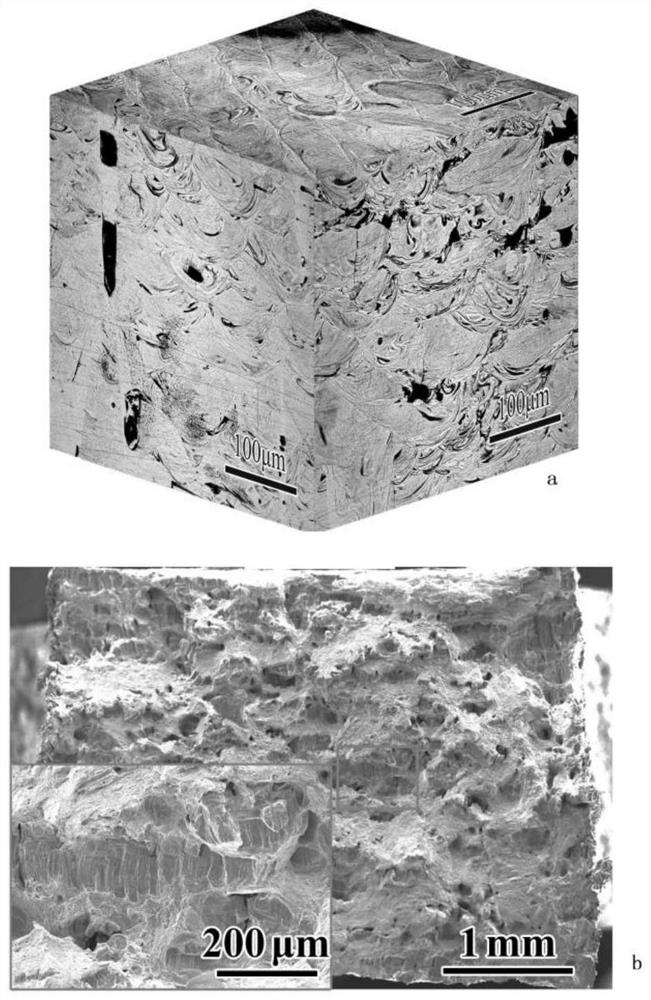

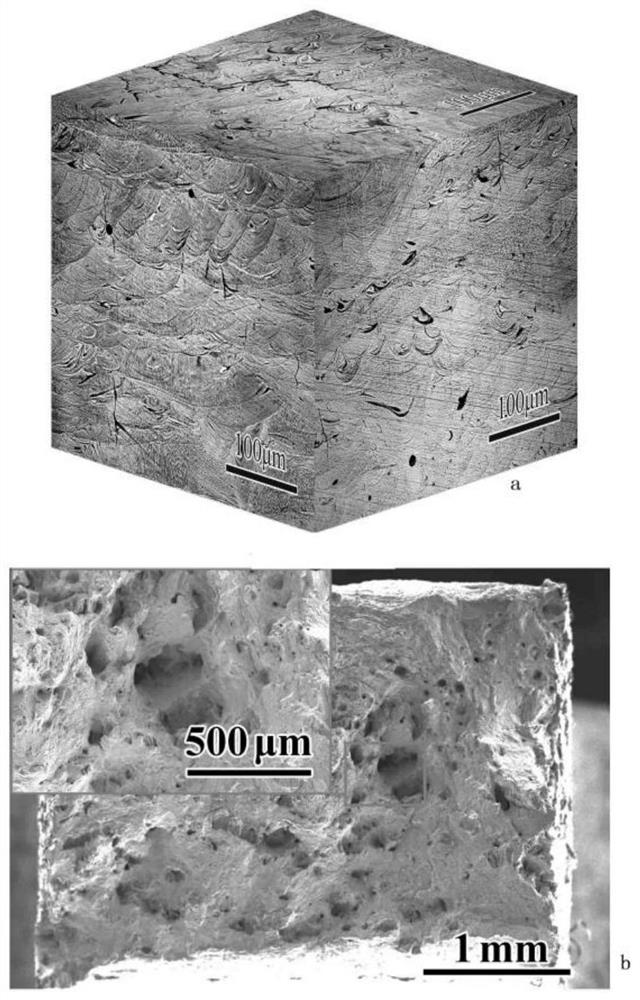

High-entropy alloy selective laser melting process parameter optimization method

ActiveCN113102754AThe print result is accurateDoes not significantly increase workloadAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingDot pitch

The invention discloses a high-entropy alloy selective laser melting process parameter optimization method. The method comprises the following steps: 1, printing a high-entropy alloy sample by adopting a selective laser melting method which is a cross-over experiment of randomly selecting or specifying three process parameters of power, exposure time and line-dot pitch; 2, detecting the relative density of the high-entropy alloy sample obtained in the step 1; 3, performing polynomial fitting on the relative density obtained in the step 2 and the corresponding three process parameters of the power, the exposure time and the line-dot pitch in the step 1, wherein a polynomial is composed of a cubic term, a quadratic term, a first term and an interactive term about the three parameters respectively; and 4, performing extreme value solving of the relative density on the fitted polynomial, wherein the power, the exposure time and the line-dot pitch corresponding to the extreme value of the relative density are the optimal process parameters. By using the method, an optimization result which is more accurate than that of a traditional optimization process can be obtained.

Owner:TIANJIN UNIV

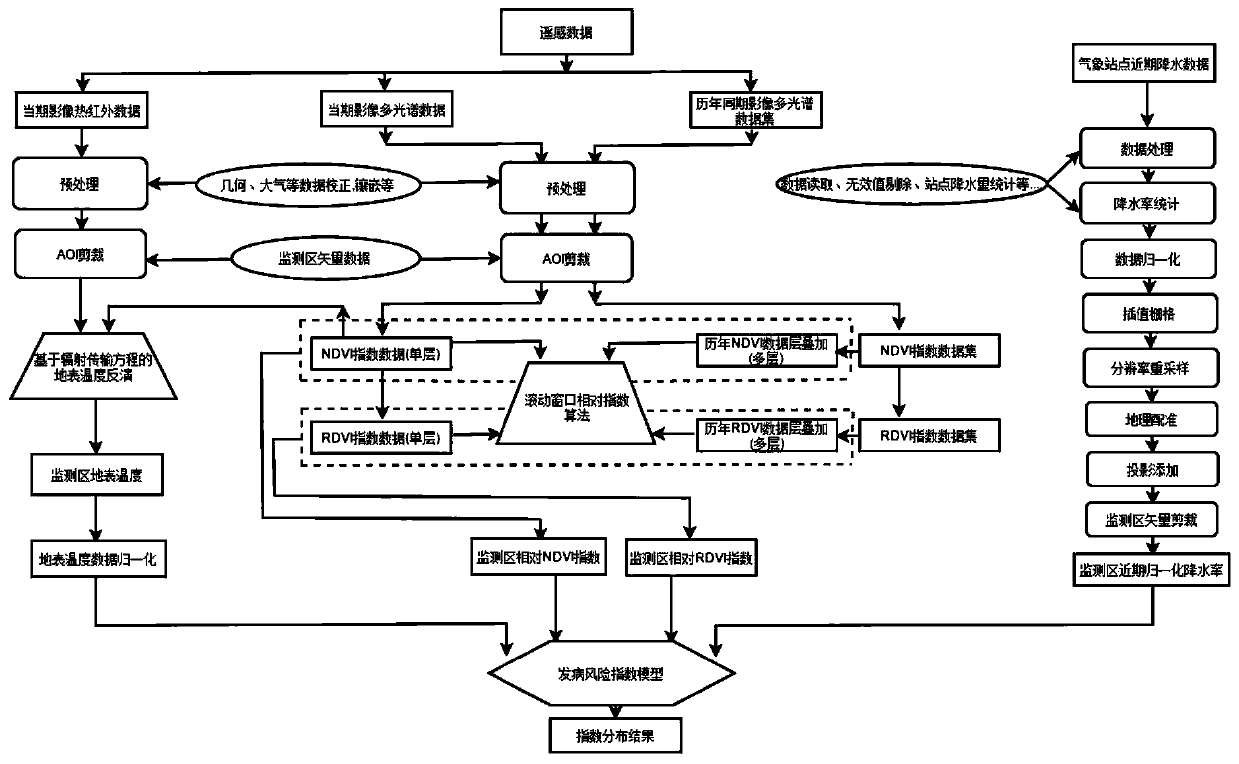

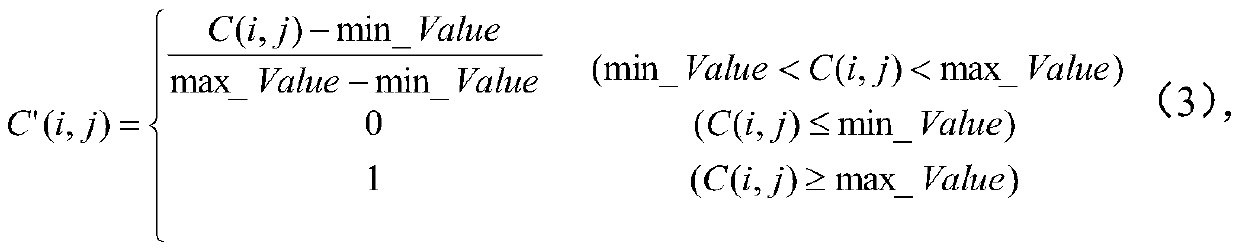

Wheat scab monitoring method based on satellite remote sensing

PendingCN110363675AAvoid interferenceDescribe wellData processing applicationsColor/spectral properties measurementsDisease monitoringSensing data

The invention discloses a wheat scab monitoring method based on satellite remote sensing, and belongs to the technical field of remote sensing monitoring, and the method comprises the steps: firstly obtaining the remote sensing data and meteorological rainfall data of a wheat planting region in a predicted year and N years before the predicted year, wherein the remote sensing data comprise multispectral data and thermal infrared remote sensing data; calculating a relative growth vigor index by utilizing the multispectral data; obtaining a normalized surface temperature index by using the multispectral data and the thermal infrared remote sensing data; obtaining a normalized precipitation index by using the meteorological precipitation data; and finally, calculating the wheat scab incidenceindex of the predicted year by utilizing the relative growth vigor index, the normalized earth surface temperature index and the normalized rainfall index. According to the method, the interference of the difference of wheat growth vigor in different areas in large-scale monitoring on the gibberellic disease monitoring model can be well reduced, and the objectivity and practicability of gibberellic disease remote sensing monitoring are improved.

Owner:中科光启空间信息技术有限公司

High pressure hydrogen penetration test device and method

ActiveCN104880400AReduce the amount of experimentsShorten test timeWeather/light/corrosion resistanceHigh pressure hydrogenTested time

The invention discloses a high pressure hydrogen penetration test device and method. The method comprises measuring a hydrogen permeation amount in sample stretching, and carrying out on-line in-situ measurement on quantitative relationships between a fatigue load state and the hydrogen permeation amount in different high pressure hydrogen environments, wherein the quantitative relationships can visually show an internal relationship between stress and hydrogen segregation diffusion and through the quantitative relationships, a direct relationship of dislocation motion, and a hydrogen diffusion coefficient, an acceleration amount and a hydrogen acceleration amount under different conditions is indirectly analyzed so that a reliable data basis is provided for dislocation density determination. The high pressure hydrogen penetration test device and method reduce a test dose and test time of a single test.

Owner:ZHEJIANG UNIV OF TECH

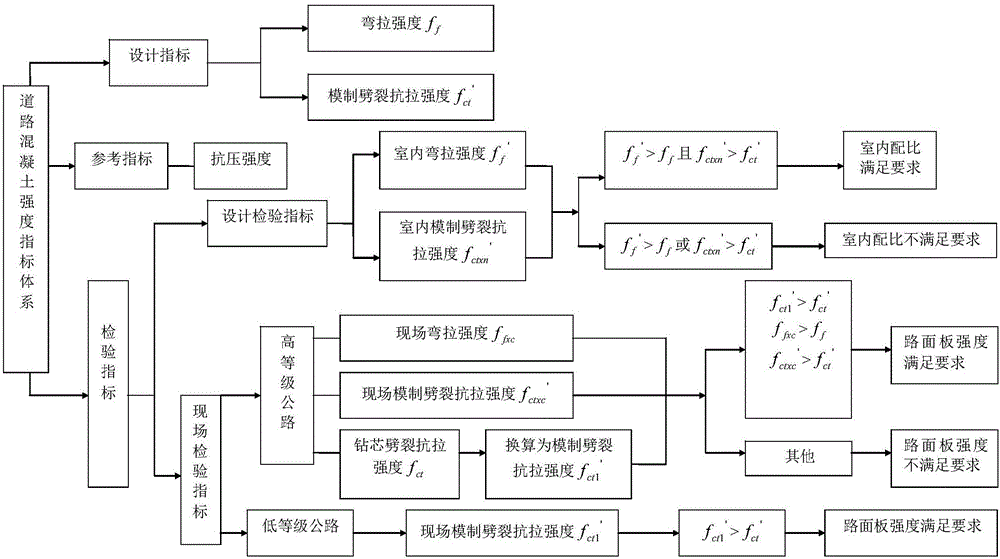

Road cement concrete pavement strength index evaluation method

InactiveCN106769443AImprove accuracyThe influence of non-material factors is smallMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesRating systemTest sample

The invention discloses a road cement concrete pavement strength index evaluation method. During rating of a field pavement slab, test results of the flexural strength of a joist test sample, the splitting tensile strength of a molded cylindrical test sample and the splitting tensile strength of a core sample decide whether the strength of the field pavement slab meet a requirement or not. For a low-grade road, just whether the molding splitting tensile strength meets the standard or not needs to be verified. For a high-grade road, the concepts of the molded cylindrical test sample and the molding splitting tensile strength are introduced, a comparison test for the molding splitting tensile strength, the splitting strength of the core sample and the flexural strength is performed through an indoor test, a mutual relation expression of the flexural strength, the molding splitting tensile strength and the splitting strength of the core sample is established in a regression way, the conventional conversion relation expression of the flexural strength and the splitting strength of the core sample is updated, the molding splitting strength converted from the splitting strength of the core sample is taken as a supplement index during acceptance, and a comprehensive strength index rating system is established to be taken as a rating basis for engineering quality acceptance.

Owner:CHANGAN UNIV

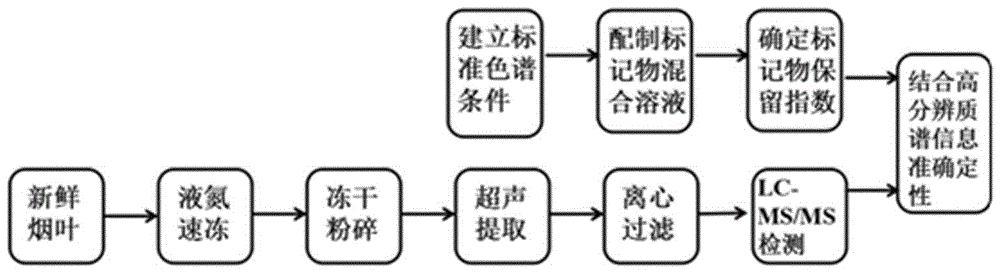

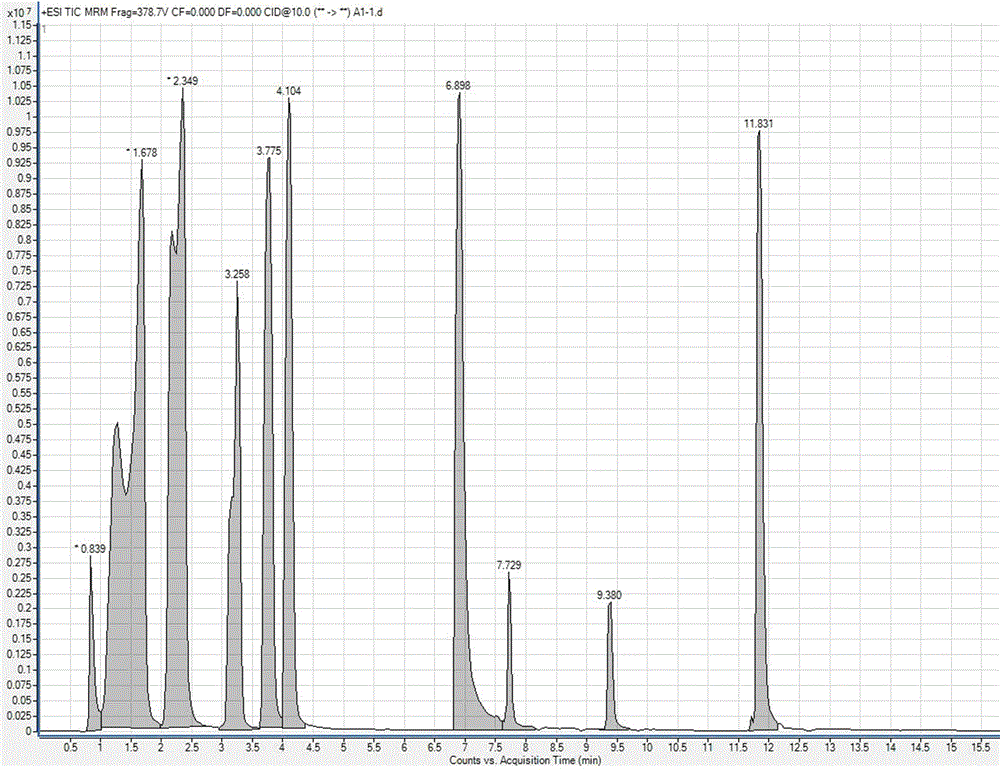

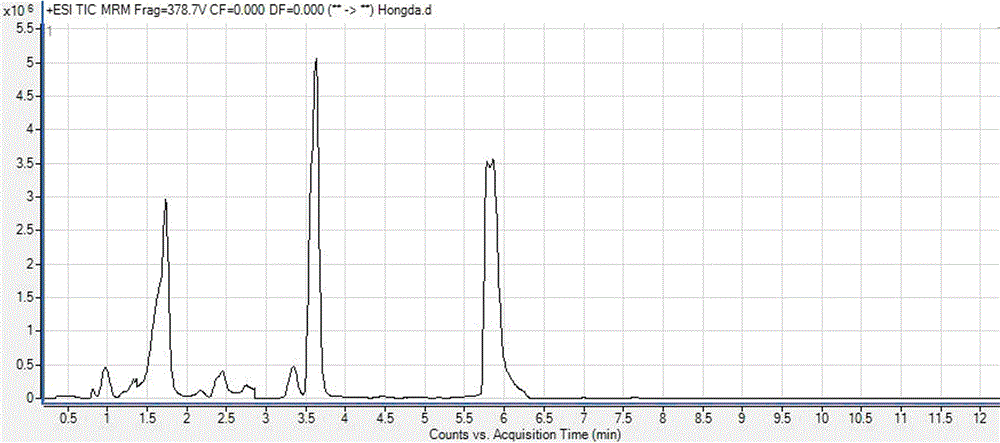

Establishment of liquid chromatographic retention index and application of establishment to compound qualitative aspect

ActiveCN106442787AReduce the amount of experimentsEliminate distractionsComponent separationQuick FreezeFreeze-drying

The invention provides establishment of the liquid chromatographic retention index and application of establishment to a compound qualitative aspect. Establishment specifically includes the following steps that firstly, a mixed solution of a retention index marker is prepared; secondly, under the standard chromatographic condition, LC-MS / MS detects the marker and determines the retention index value of the marker; thirdly, fresh tobacco leaves are quick-frozen with liquid nitrogen, freeze-dried and smashed; fourthly, the smashed sample is added into an extraction solvent and subjected to low-temperature ultrasonic extraction; fifthly, refrigerated centrifugation is conducted, and supernate is obtained and filtered; sixthly, LC-MS / MS detects the supermate and conducts qualitative analysis on a compound contained in the solution. Retention time of compound components in complex sample solutions can be corrected through the retention index marker, and retention time change caused by mobile phases, pressure or use of chromatographic columns different in batch number is avoided. Compared with the prior, multiple times of experiments under the same condition are not needed, the process is simple, cost is low, and qualitative accuracy and uniqueness can be greatly improved.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

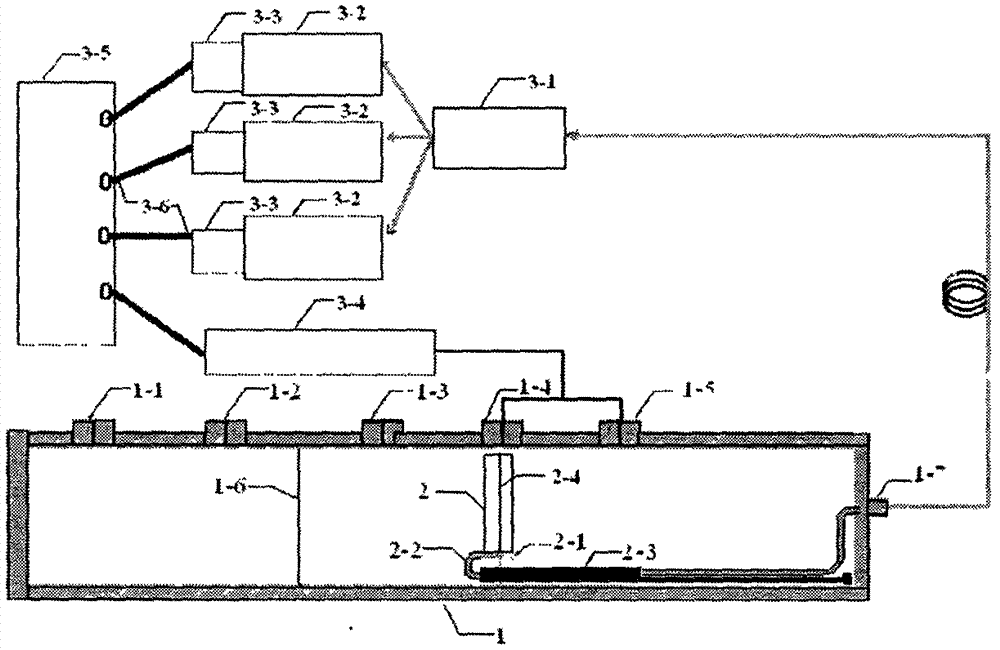

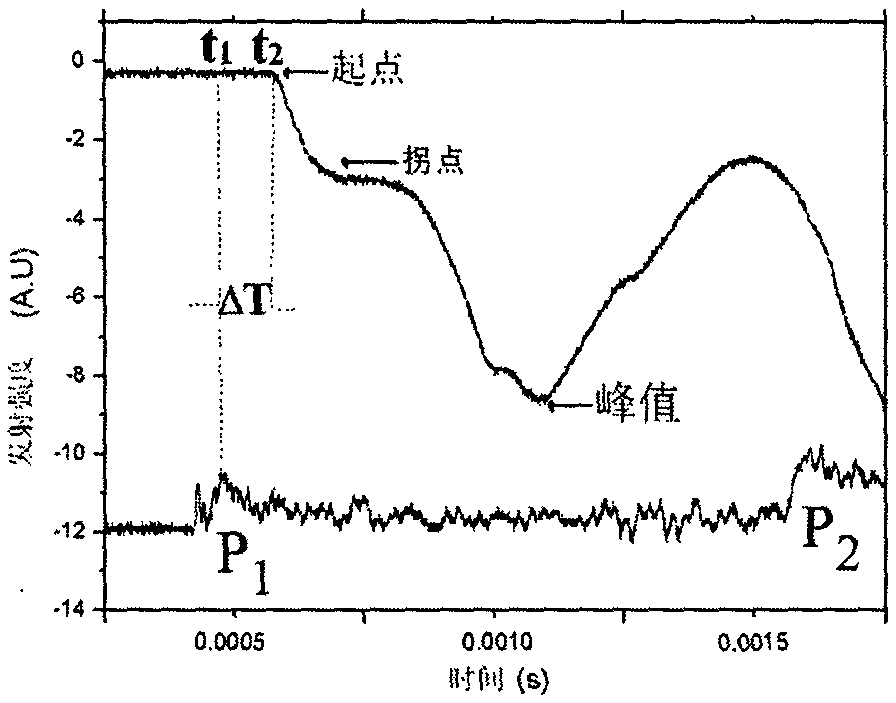

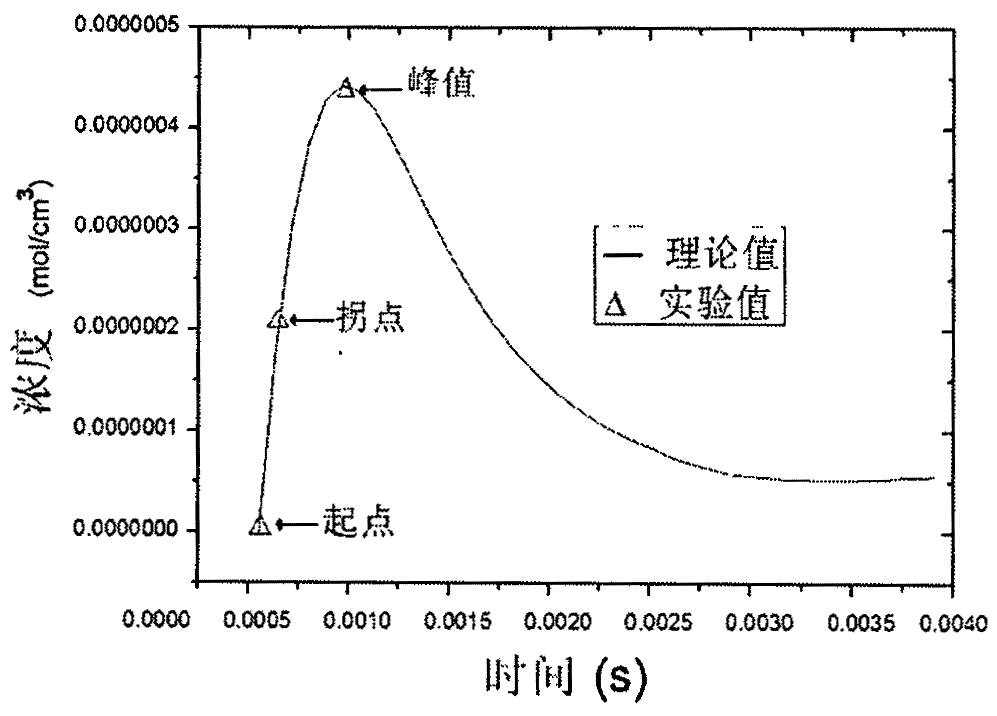

Method and device for researching quick reaction mechanism of energetic material

InactiveCN103776776AHigh sensitivityEasy to operateColor/spectral properties measurementsPhotoelectric conversionEngineering

The invention discloses a method and device for researching the quick reaction mechanism of an energetic material. The method is characterized in that the device for researching the quick reaction mechanism of the energetic material is adopted. The method comprises the following steps: positioning a monochromator in the position of a primary product characteristic spectral line, and recording the intensity time history (namely, time history curve) of the characteristic spectral line through a digital oscilloscope after photoelectric conversion, so as to study the time history of chief constituents of the energetic material decomposed due to impact; simulating the dynamic characteristic curve of the quick reaction of the energetic material with a reaction power calculation program, and correcting the reaction passage of the quick reaction of the energetic material according to the experiment detected occurrence time, inflection point time and maximum peak time of the primary product. A simplified reaction model obtained according to the method focuses on a main path, abandons reaction with poor impact, and can accurately reflect the real processes of the quick reaction of the energetic material under practical experimental conditions.

Owner:河南教育学院

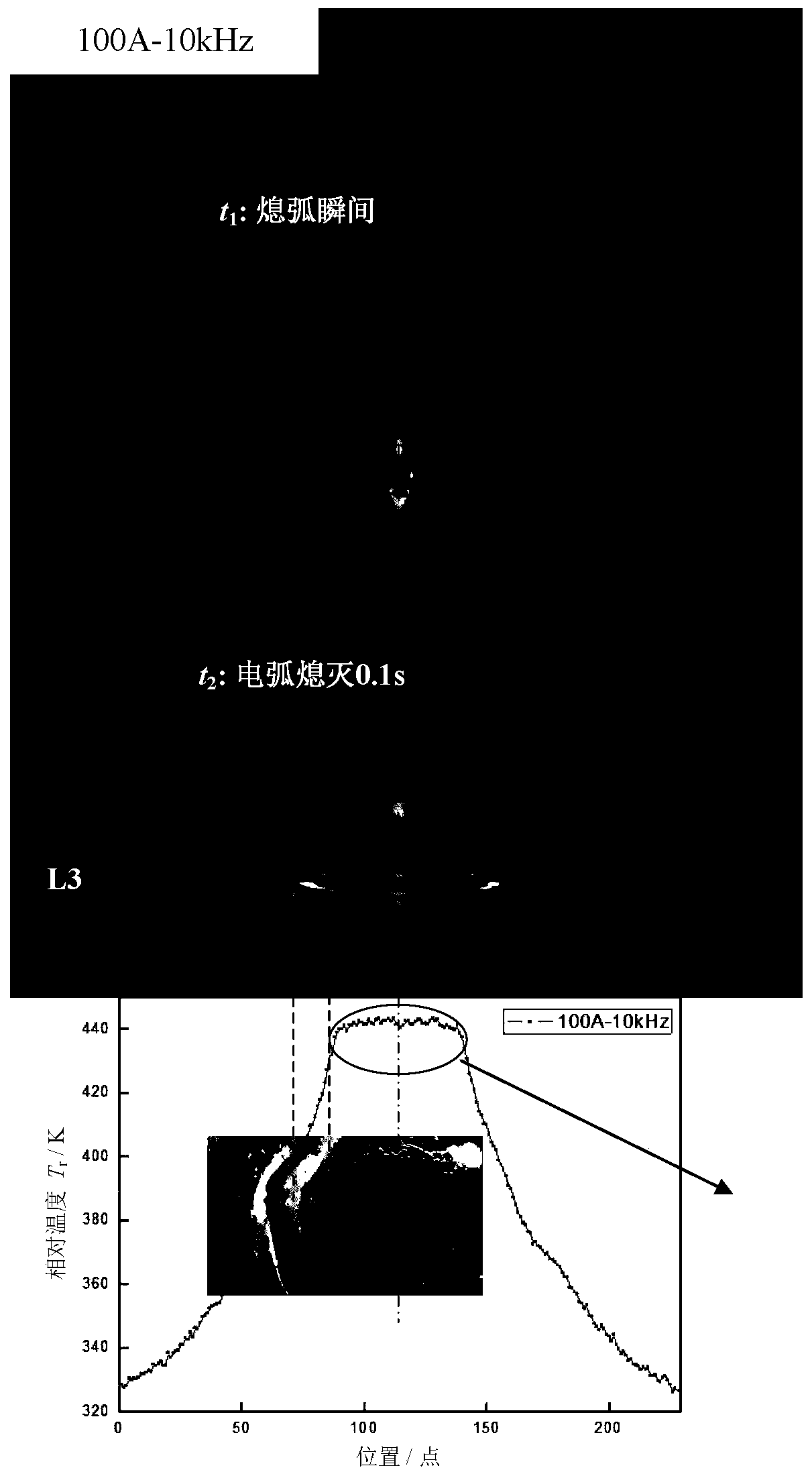

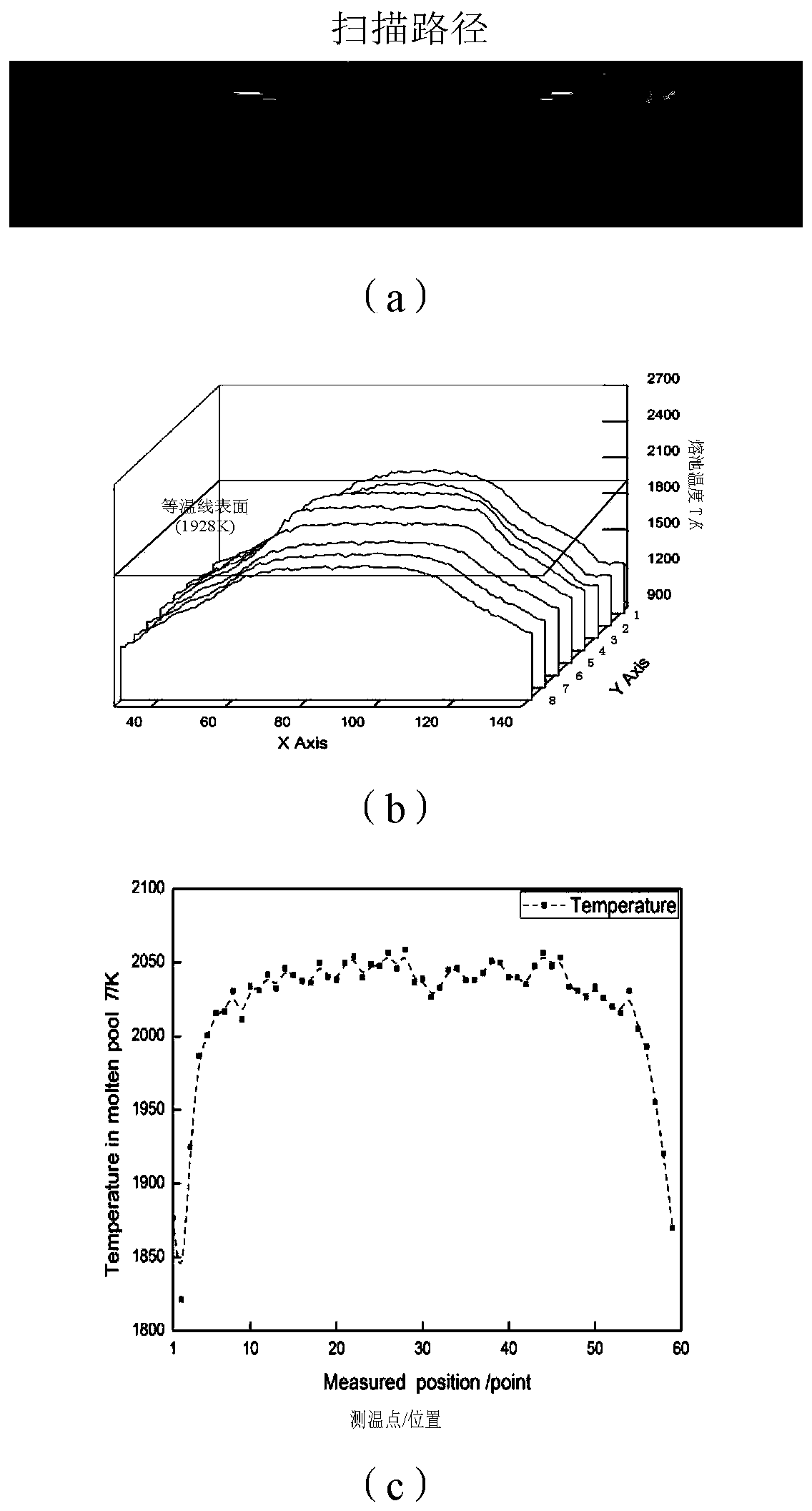

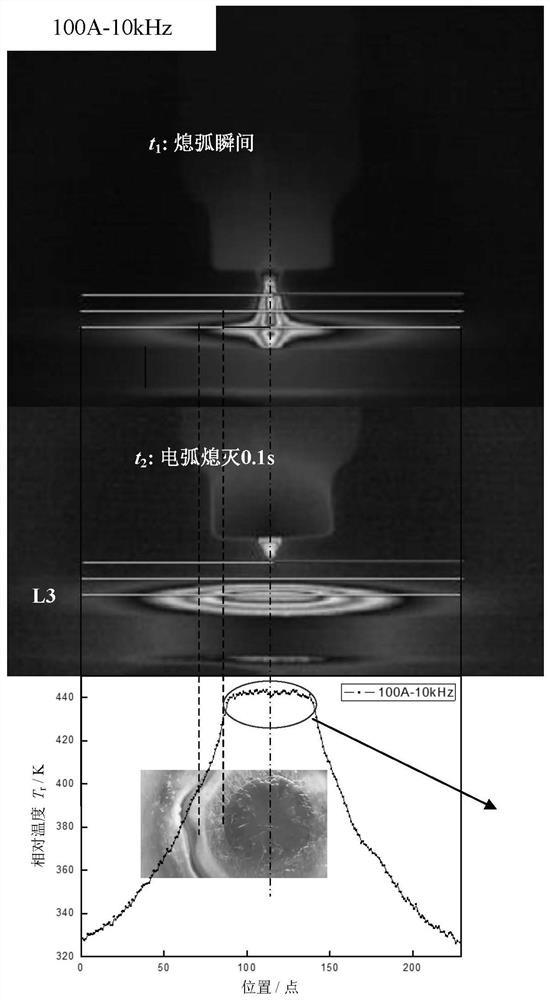

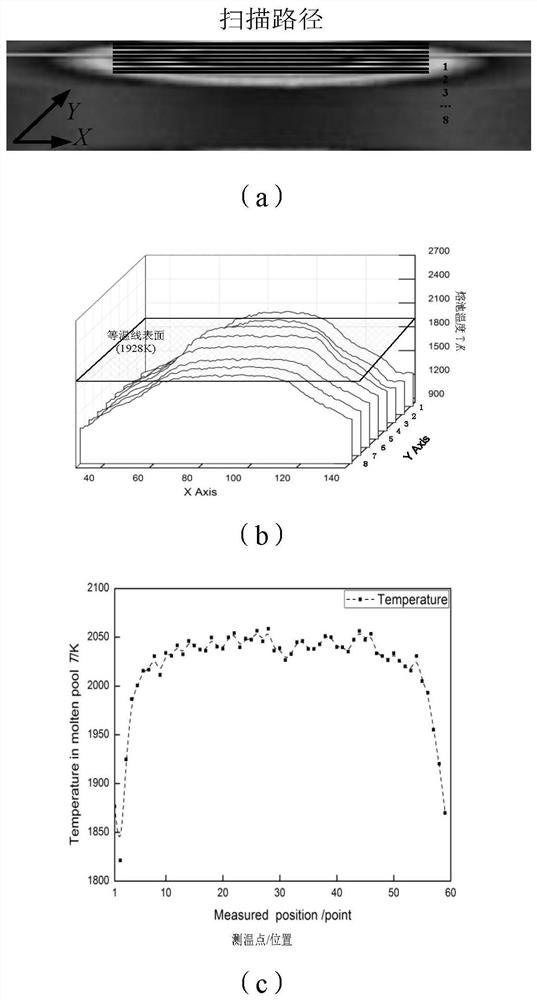

Titanium alloy electric arc welding molten pool surface temperature field measuring device and method

ActiveCN110657892AAccurately obtain emissivity valuesAccurate collectionThermometers using electric/magnetic elementsUsing electrical meansHeat-affected zoneMetallurgy

The invention discloses a titanium alloy electric arc welding molten pool surface temperature field measuring device and method. An industrial detection thermal infrared imager and a thermocouple arecombined and applied to titanium alloy electric arc welding molten pool surface temperature field measurement, and the radiance value of a fixed point on the surface of a heat affected zone of a welding molten pool can be obtained. Secondly, the invention further provides a method for calculating the radiance of the surface of the welding molten pool, the radiance of the area between the fixed point and the center of the welding molten pool is solved by combining the radiance value obtained by the fixed point, then the temperature of each point is obtained, the experimental amount is greatly reduced, and the surface temperature field information of the titanium alloy welding molten pool can be accurately and comprehensively obtained.

Owner:BEIHANG UNIV

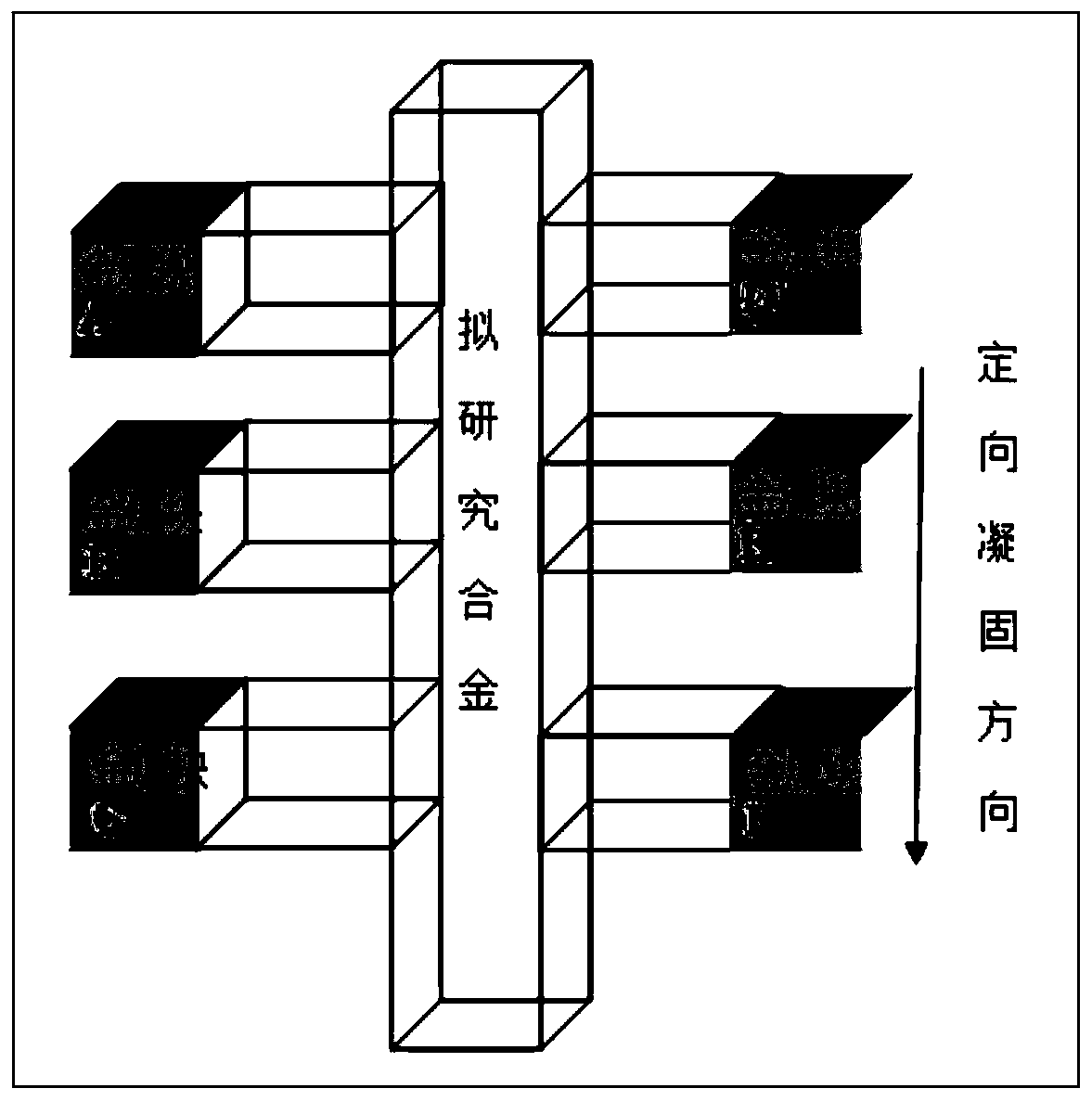

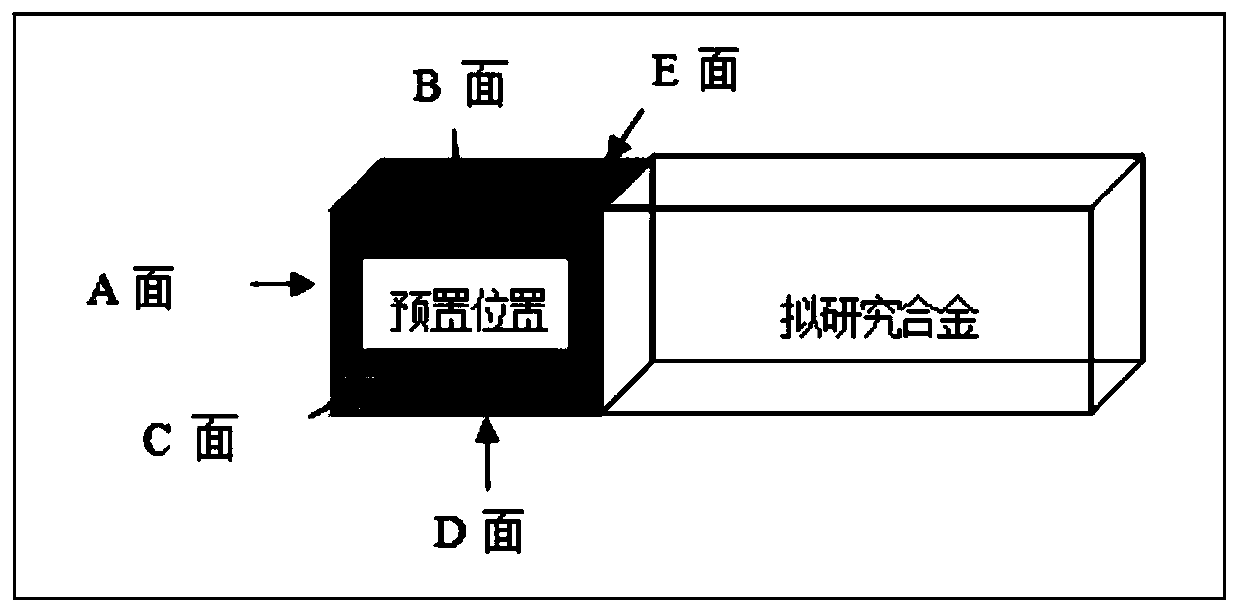

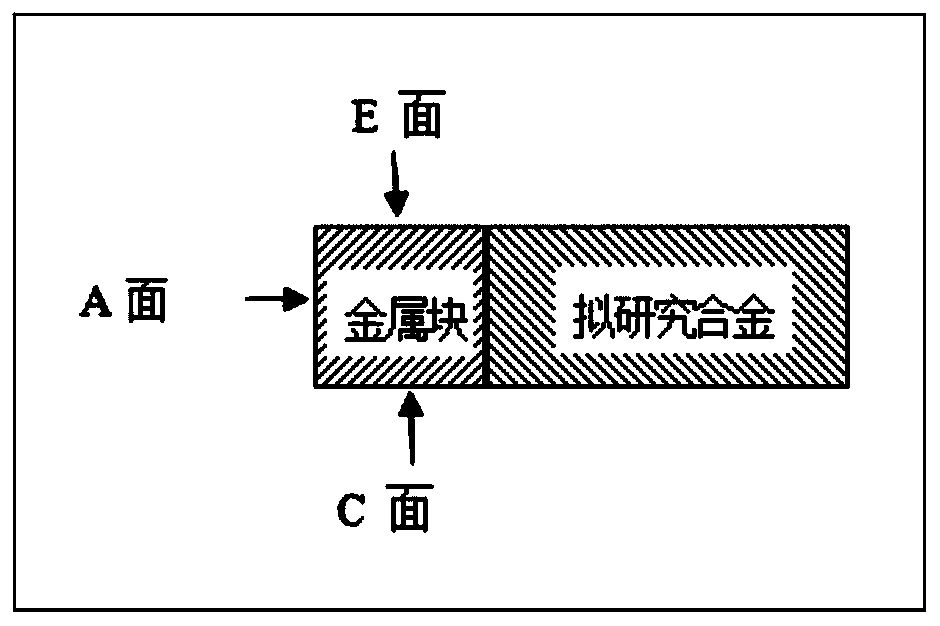

A high-throughput preparation method for superalloy materials

ActiveCN108620538BReasonable process designSimple operation processFoundry mouldsFoundry coresWaxHigh flux

Owner:辽宁红银金属有限公司

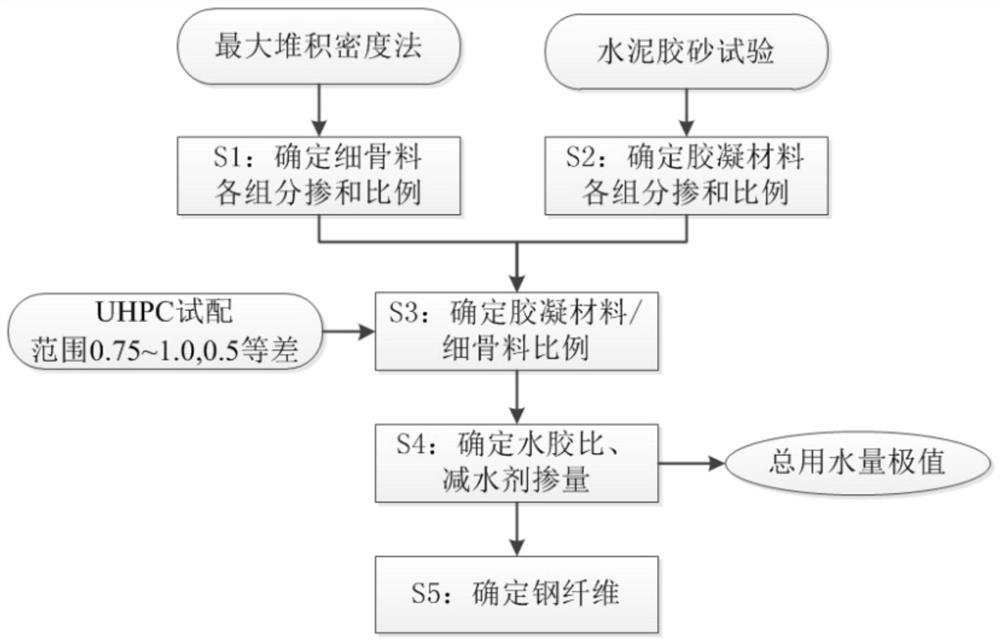

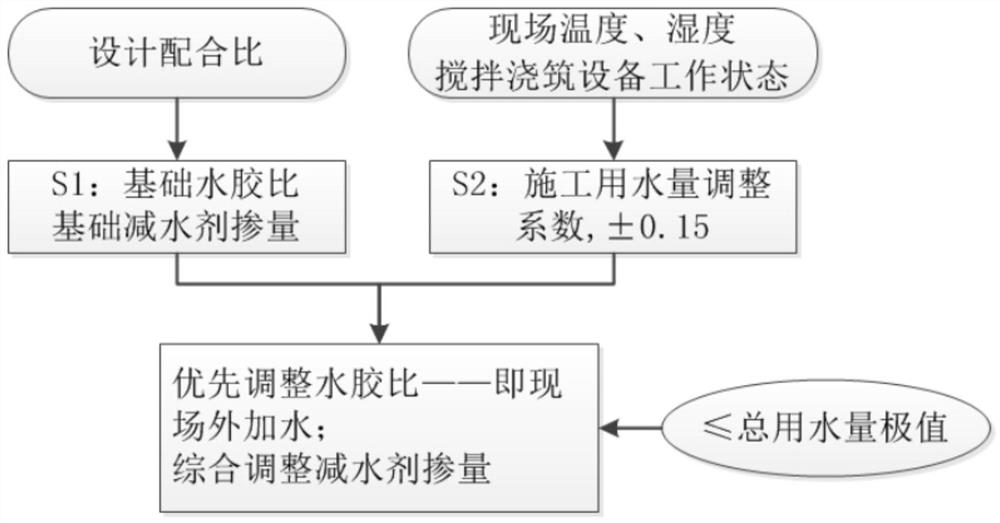

Steam-cured ultra-high-performance concrete for prefabricated bridge deck slab and rapid design and optimization method for mix proportion of steam-cured ultra-high-performance concrete

ActiveCN114315284AGuarantee product qualityIncreased durabilitySolid waste managementMixing operation control apparatusBridge deckStructural engineering

The invention relates to steam-cured ultra-high performance concrete for a prefabricated bridge deck slab and a rapid design optimization method of a mix proportion, namely a progressive layered filling optimization method. The method comprises the following steps: determining the mixing proportion of fine aggregate; preparing a cement mortar test block, and determining the doping proportion of each component of the cementing material; determining the basic proportion of the cementing material to the fine aggregate; determining a water-binder ratio and a water reducing agent mixing amount; the steel fiber mixing amount is determined, and the UHPC mixing proportion is obtained; and preparing the steam-cured ultra-high performance concrete of the prefabricated bridge deck slab. The method quickly completes the design of the mix proportion based on available raw materials, does not need excessive theoretical calculation, and is convenient and efficient. Meanwhile, the invention further provides a field optimization method based on the total water consumption, the field optimization method is suitable for optimization of the field mix proportion, under the control principle of the total water consumption, the mix proportion can be flexibly and flexibly adjusted based on the field condition, multiple test verification is not needed any more, iteration of the laboratory-construction field mix proportion can be reduced for multiple rounds, and the construction efficiency is improved. And the influence on the construction progress is reduced.

Owner:SHANDONG TRAFFIC PLANNING DESIGN INST +1

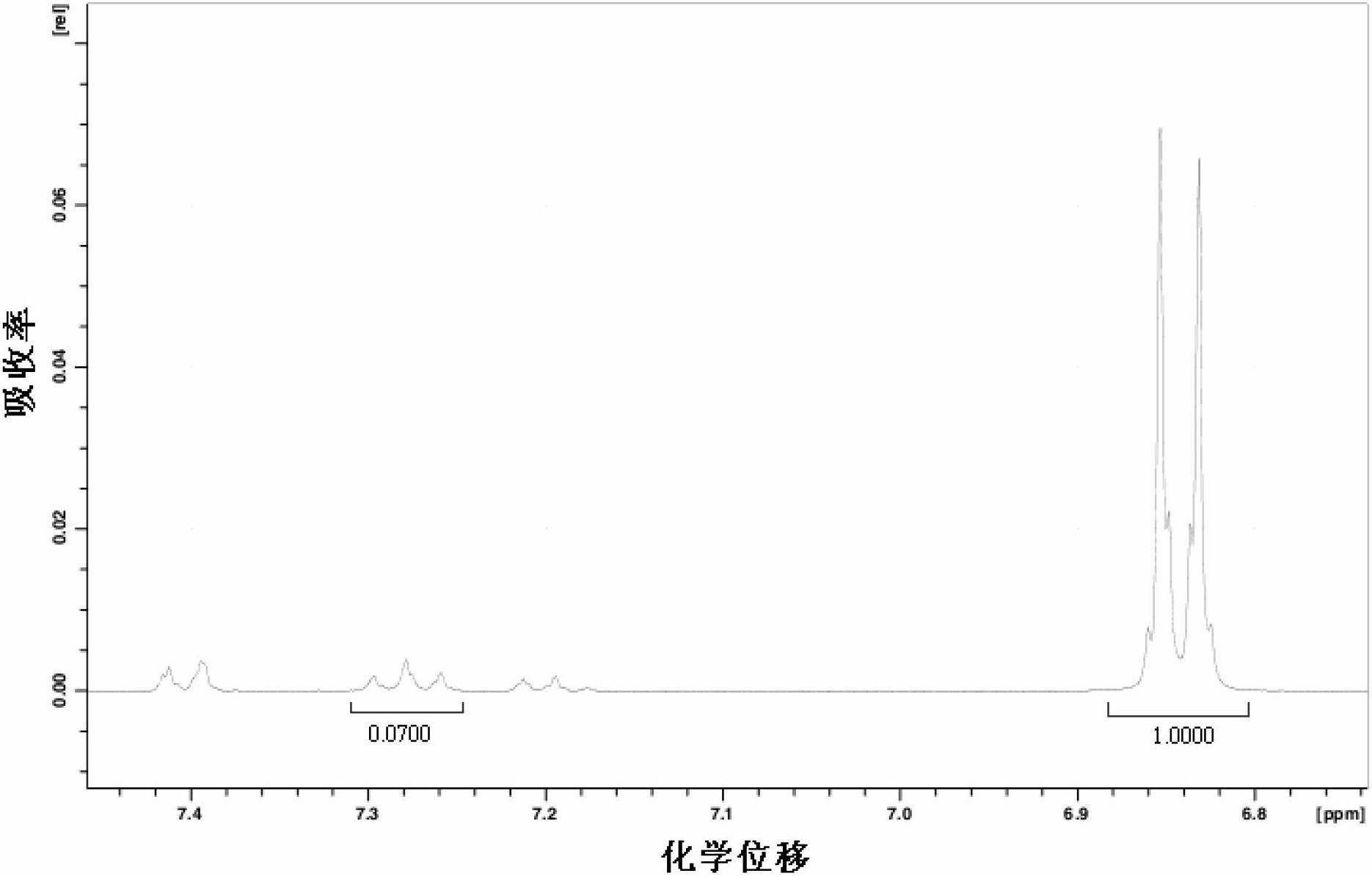

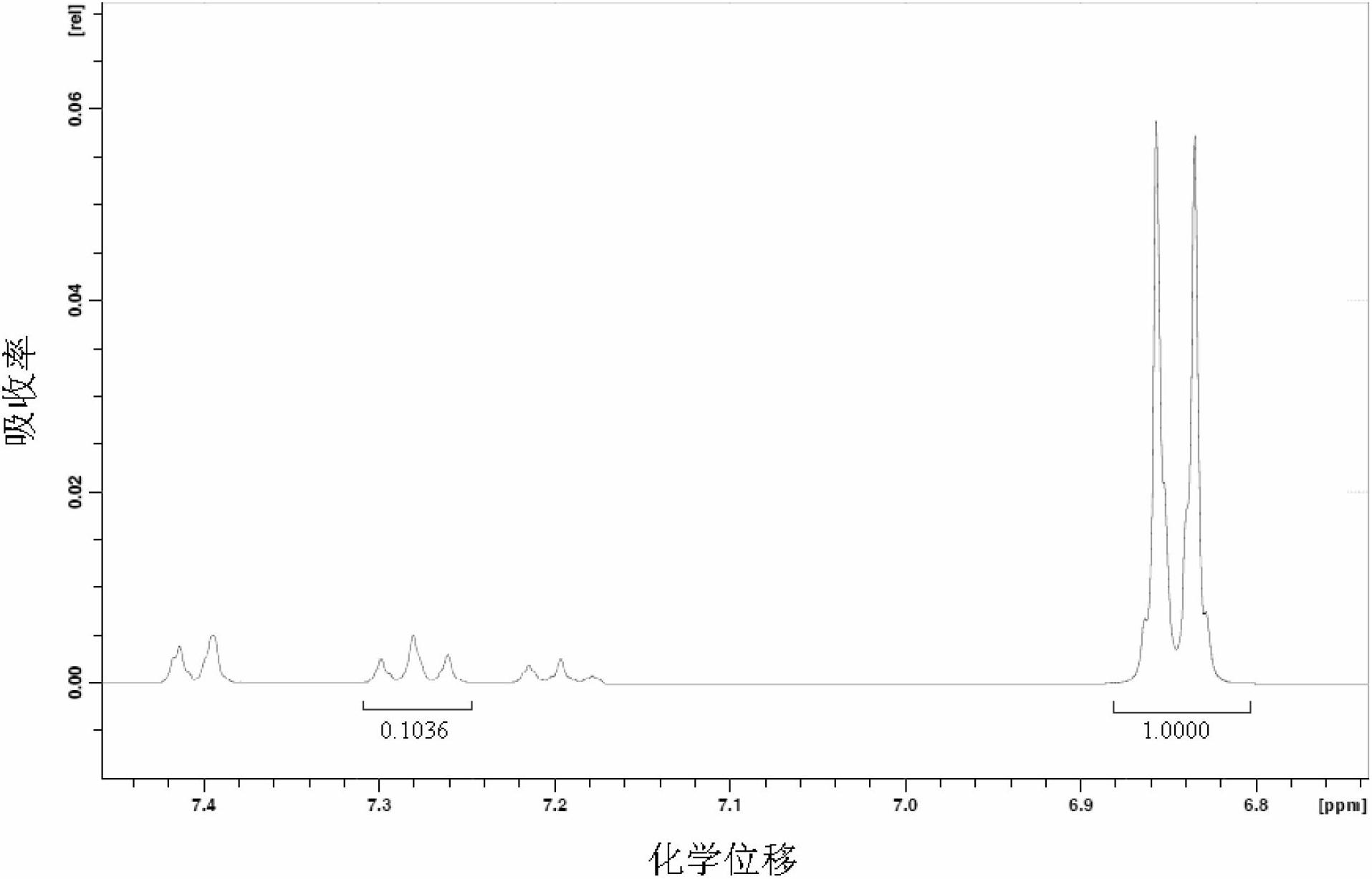

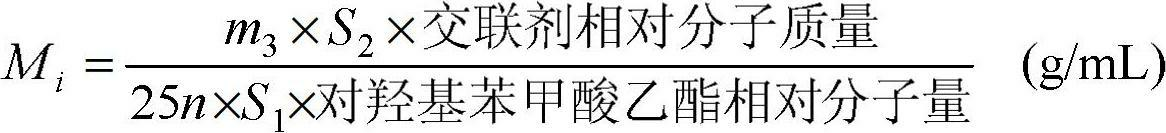

Test method of optimal cross-linking agent diffusion time in production process of high-voltage cable material

InactiveCN102636511AHigh data accuracySave test time and costAnalysis using nuclear magnetic resonanceTested timeMagnetic tube

The invention discloses a test method of optimal cross-linking agent diffusion time in the production process of a high-voltage cable material, relates to a test method of a cross-linking agent diffusion time in the production process of the high-voltage cable material. The method can be used for solving the problem that the optimal cross-linking agent diffusion time in the production process of the cross-linkable high-voltage cable material is hard to determine. The method comprises the following steps: in the production process, sampling 1 g of m from particles at intervals of 0.5 hour, placing the material in absolute ethyl alcohol to stand at a constant temperature, filtering, and then collecting the filtrate; adding a chloroform solution of ethyl p-hydroxybenzoate in a nuclear magnetic tube, volatilizing the chloroform, adding the filtrate in the nuclear magnetic tube, and adding a deuterated chloroform, uniformly mixing, testing a H spectrum of the to-be-tested solution in the test tube in the step sixth, computing the concentration difference of the cross-linking agent at the particle centre at two adjacent sampling times, and determining the optimal cross-linking agent diffusion time. The method provided by the invention has the advantages of high tested data precision, small experimental amount, shortened test time and low cost. The method is used for testing the optimal cross-linking agent diffusion time in the production process of the high-voltage cable material.

Owner:HARBIN UNIV OF SCI & TECH

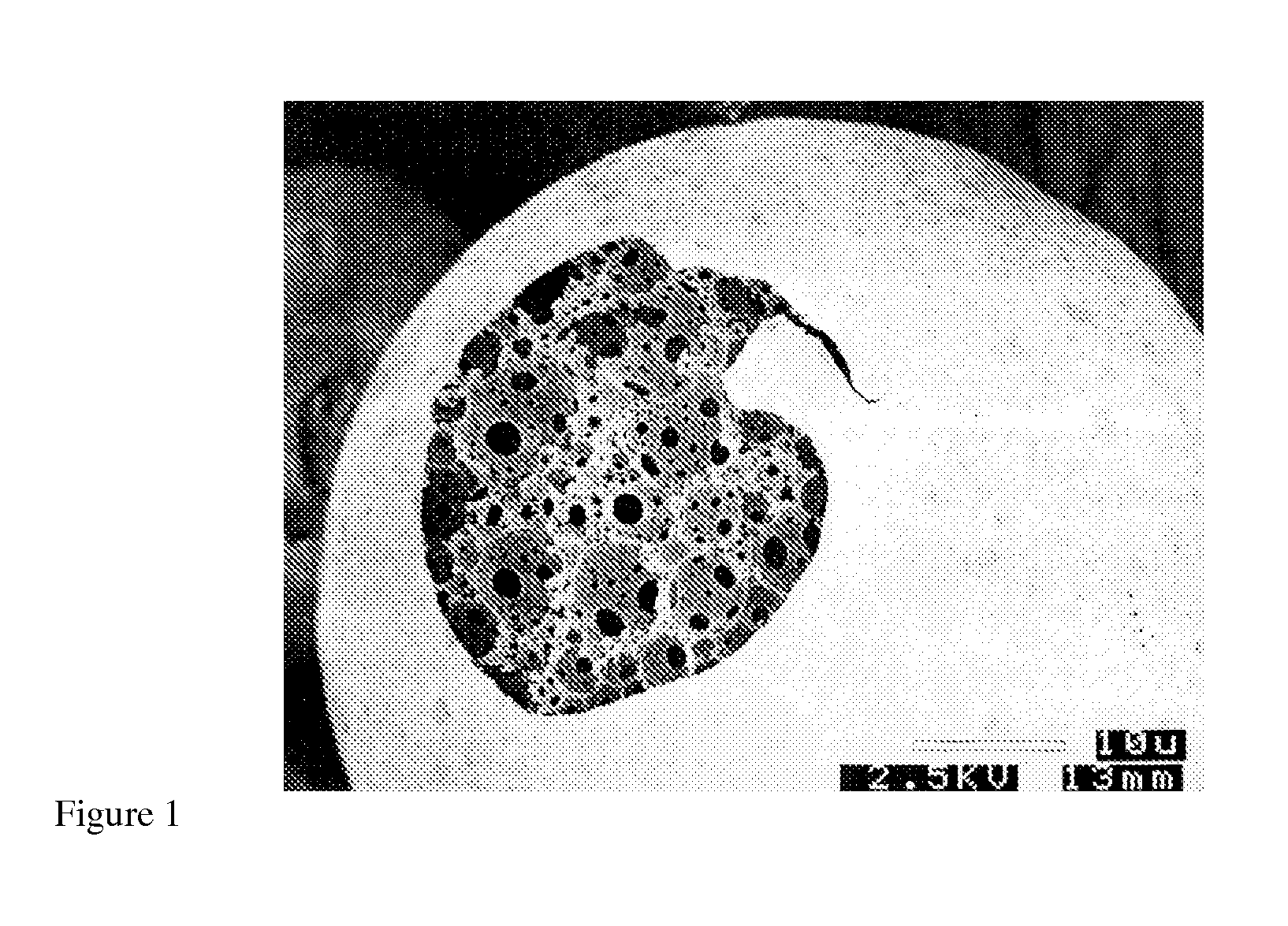

Process for Reducing Residual Surface Material from Porous Polymers

InactiveUS20120309851A1Lower requirementEasy to useCosmetic preparationsToilet preparationsPorosityMaterials science

The present invention relates to methods for removing residual surface material from porous polymerized particle surfaces. The particles thus produced have an increase in surface porosity and uniformity in a variety of applications. Desirably, substantially the entire surface communicates with the interior of the particles. Also provided are the particles produced by such methods, further modifications of such particles, and methods for using the particles in a variety of applications. All described methods, compositions, and articles of manufacture are within the scope of the invention.

Owner:LI NAI HONG +3

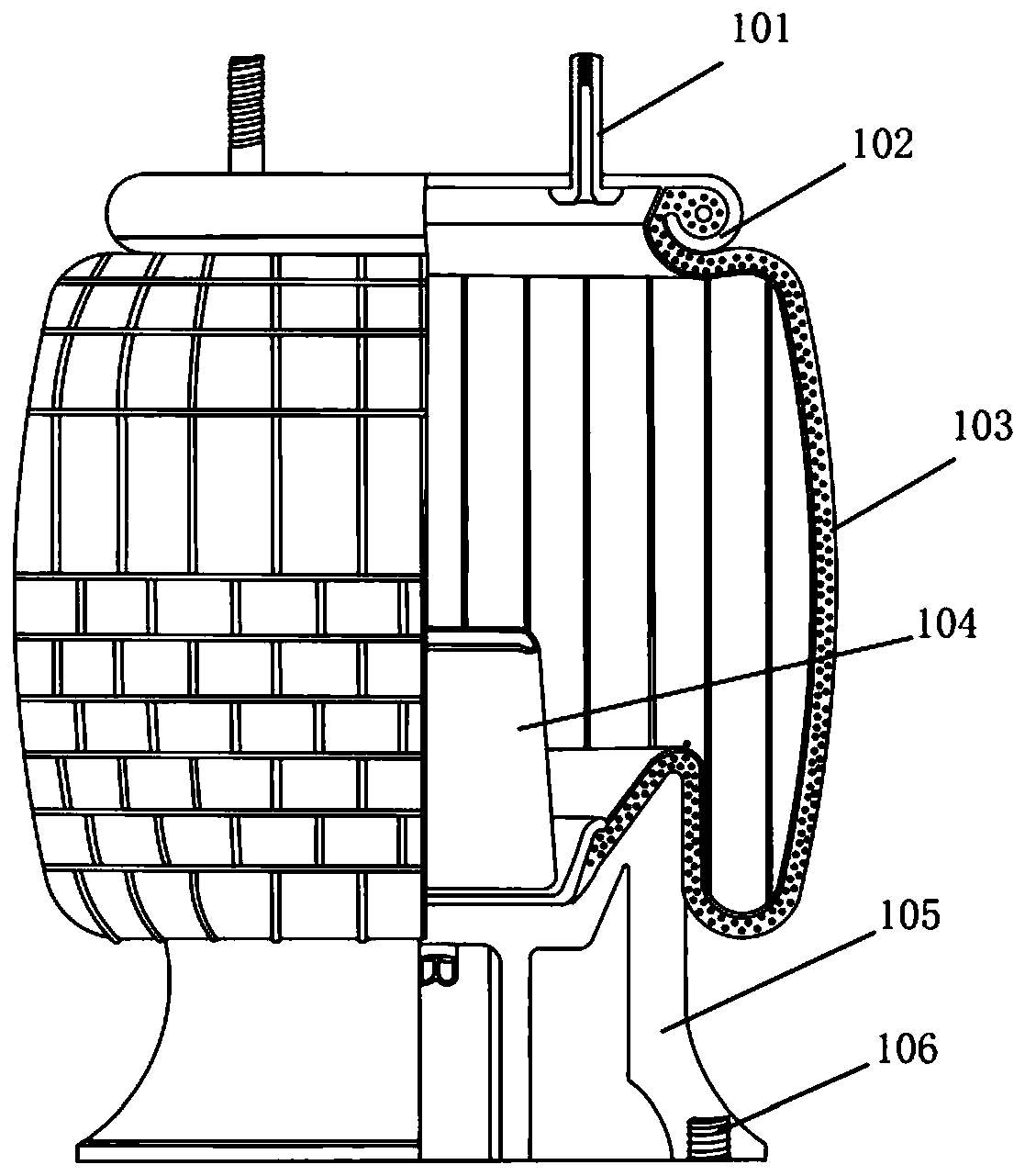

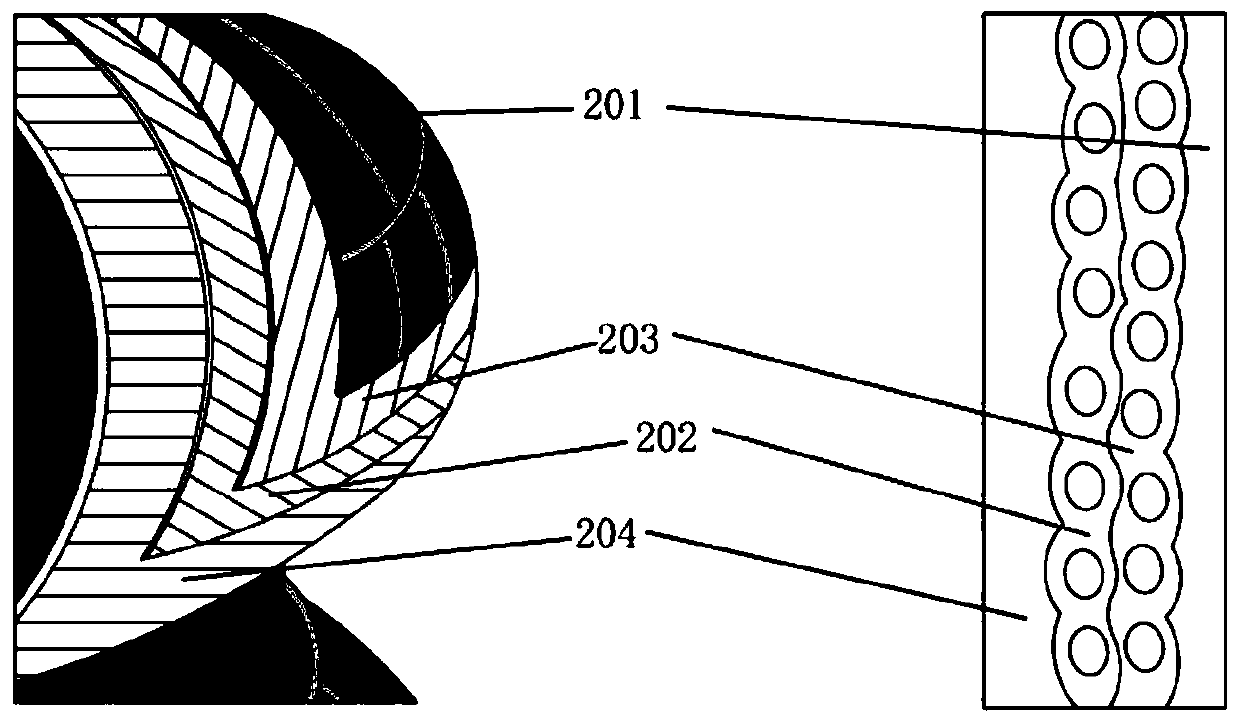

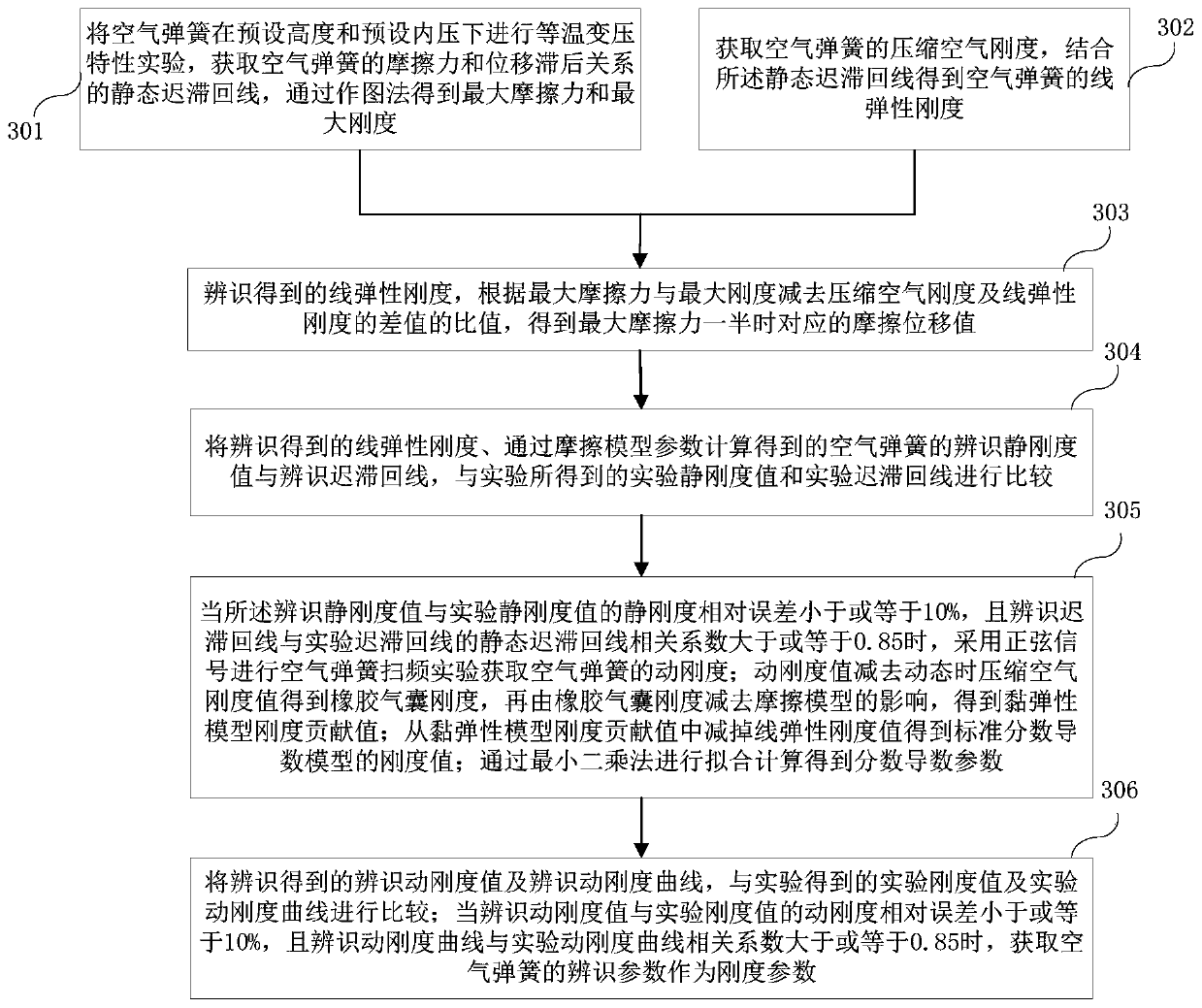

Method and device for obtaining rigidity of air spring

PendingCN110516324AEfficient identificationImprove the level of research and developmentSpecial data processing applicationsHysteresisDynamic stiffness

The invention provides a method and device for obtaining rigidity of an air spring. The method comprises the steps: obtaining a static hysteresis loop of the air spring through an experiment, and drawing a graph to determine the maximum friction force and maximum rigidity of a coulomb friction model; calculating compressed air rigidity and linear elastic rigidity; determining a displacement valuecorresponding to half of the maximum friction force; comparing the calculated static stiffness with the actually measured static stiffness and hysteresis loop and meeting the precision requirement; obtaining the dynamic stiffness of the air spring through an experiment, and subtracting the compressed air stiffness value and the coulomb friction model stiffness value from the dynamic stiffness experiment value to obtain a viscoelastic model stiffness value; subtracting the linear elastic stiffness value to obtain a stiffness contribution value of the fractional derivative model, and fitting bya least square method to obtain a fractional derivative parameter; and comparing the calculated dynamic stiffness value with the actually measured dynamic stiffness value and meeting the precision requirement. The method can effectively identify the parameters of the rubber air bag model, can establish a parameter database, can calculate the rigidity of the air spring and carry out accurate mechanical property matching, facilitates the design and optimization of an air bag process, and improves the research and development level of an enterprise.

Owner:JIANGXI UNIV OF SCI & TECH

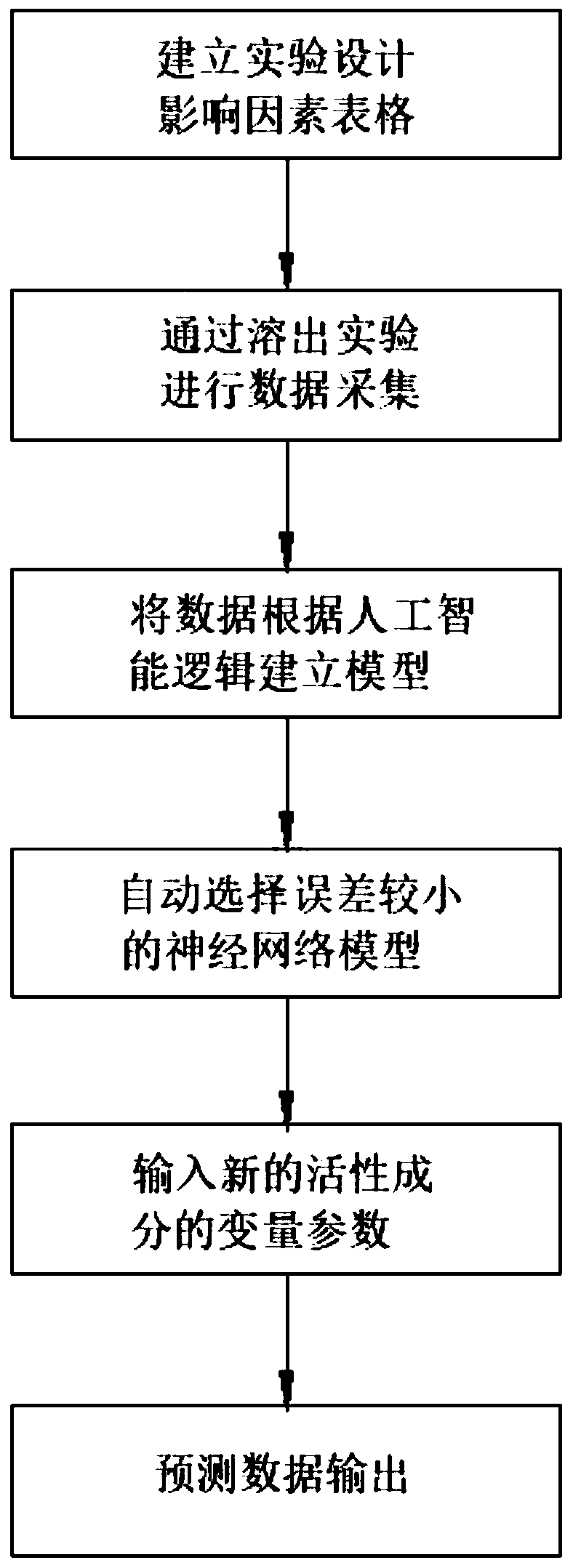

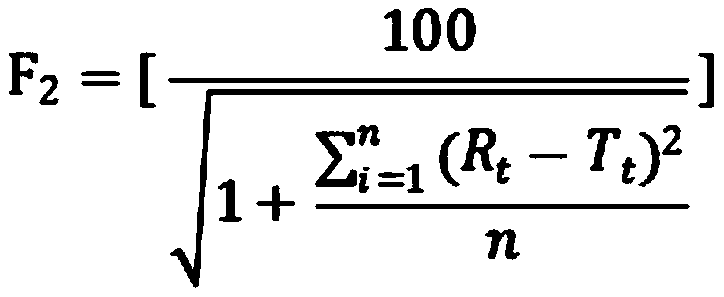

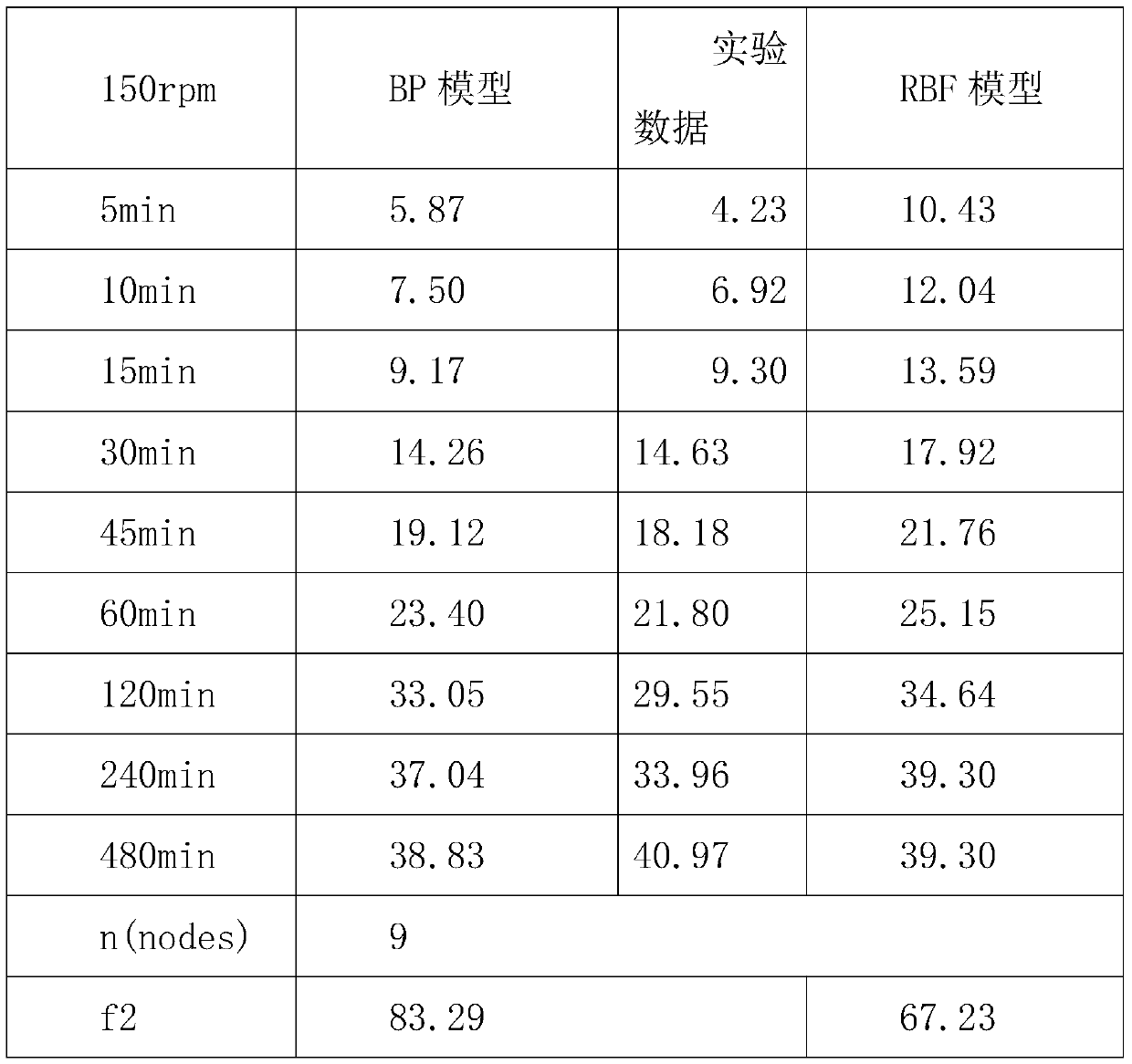

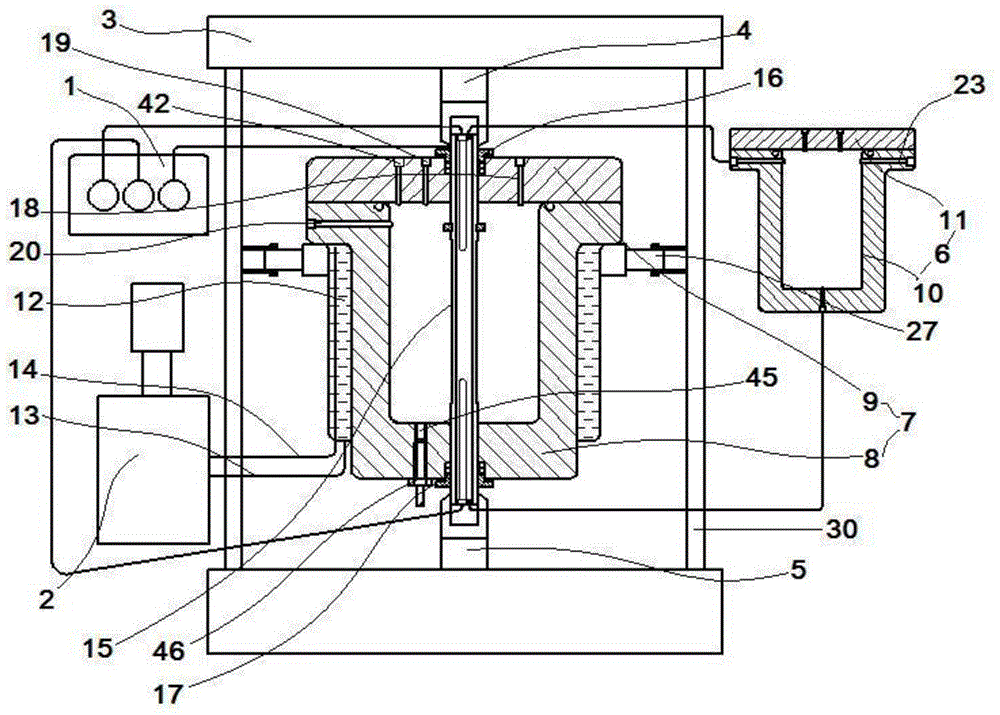

Method, device and system for predicting dynamic solubility of active ingredients through artificial intelligence

PendingCN110766156AReduce the amount of experimentsImprove forecast accuracySurface/boundary effectForecastingMachine learningNetwork model

The invention discloses a method, device and a system for predicting dynamic solubility of active ingredients by artificial intelligence. The method comprises the following steps: S1, randomly selecting data in a factor influencing the solubility of an active component compound as variable data, obtaining solubility data through multiple groups of experiments under the condition that other influence factors are not changed, and establishing a neural network model by taking the variable data and the corresponding solubility data as parallel sample experiment data; and S2, inputting new variabledata of the active component into the neural network model established in the step S1 as an input variable, calculating prediction data through the neural network model established in the step S1, and performing correction by utilizing an export formula to predict the solubility of the active component compound. Artificial intelligence is adopted to predict a single-factor investigation experiment result to reduce the experiment amount required by an experiment, so that the research and development time and cost are reduced, abnormal data with relatively large experiment errors are eliminatedaccording to the standard deviation of parallel experiments, and the solubility prediction accuracy is improved.

Owner:王昊昱 +2

High temperature and high pressure corrosion hydrogen permeation test device and test method

ActiveCN104568727BReduce the amount of experimentsShorten test timeWeather/light/corrosion resistanceCarbon dioxide corrosionHigh pressure

The invention discloses a high temperature and high pressure corrosion hydrogen permeation testing device and method. When fatigue limit is measured, after hydrogen permeation current is stabilized under the given corrosion condition, step type fatigue loads are applied to a test sample material from a smaller one to a larger one, and when the hydrogen permeation current is increased along with increase of the load, dislocation movement inside the test sample material is caused by the load, and the load is considered as the fatigue limit of the test sample material in the environment. The device and the method disclosed by the invention have the characteristics that a quantitative relation between the fatigue load state and the hydrogen permeation amount can be measured in situ on line in a high-pressure carbon dioxide corrosion state, the internal relation between the stress and segregation diffusion of hydrogen can be intuitively reflected, and a mutual relation among multiple data is established.

Owner:ZHEJIANG UNIV OF TECH

A Finite Element Modeling Method for Arc Additive Manufacturing

ActiveCN107066700BReduce the amount of experimentsImprove calculation accuracyDesign optimisation/simulationSpecial data processing applicationsModelSimGeometric modeling

The invention discloses an arc additive manufacturing finite element modeling method. The method comprises the following steps of: calculating an arc shape and determining the width of an additive area birth-death element; calculating a molten drop shape and determining the height of the additive area birth-death element; establishing an arc additive manufacturing finite element geometric model according to the width of the additive area birth-death element and the height of the additive area birth-death element; correcting the arc shape and the molten drop shape through verifying the temperature distribution of the arc additive manufacturing finite element geometric model, so as to correct the arc additive manufacturing finite element geometric model. According to the method disclosed by the invention, the geometric size of the additive area birth-death element can be determined before the arc additive manufacturing finite modeling by adopting an arc additive manufacturing simulation process, combining an arc shape simulation technology, a molten drop shape simulation technology and a finite element simulation technology and carrying out experimental verification, so as to realize the correct calculation of arc additive manufacturing finite element simulation.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

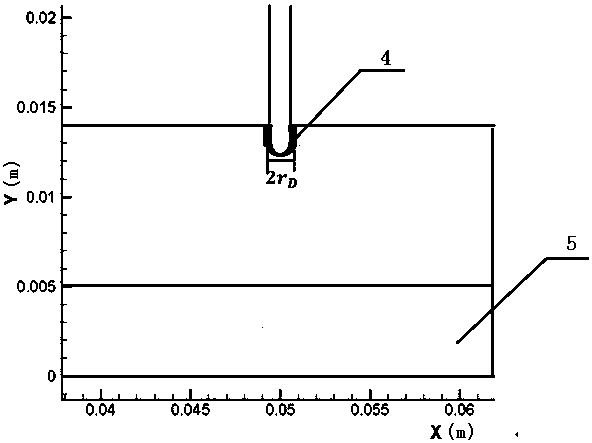

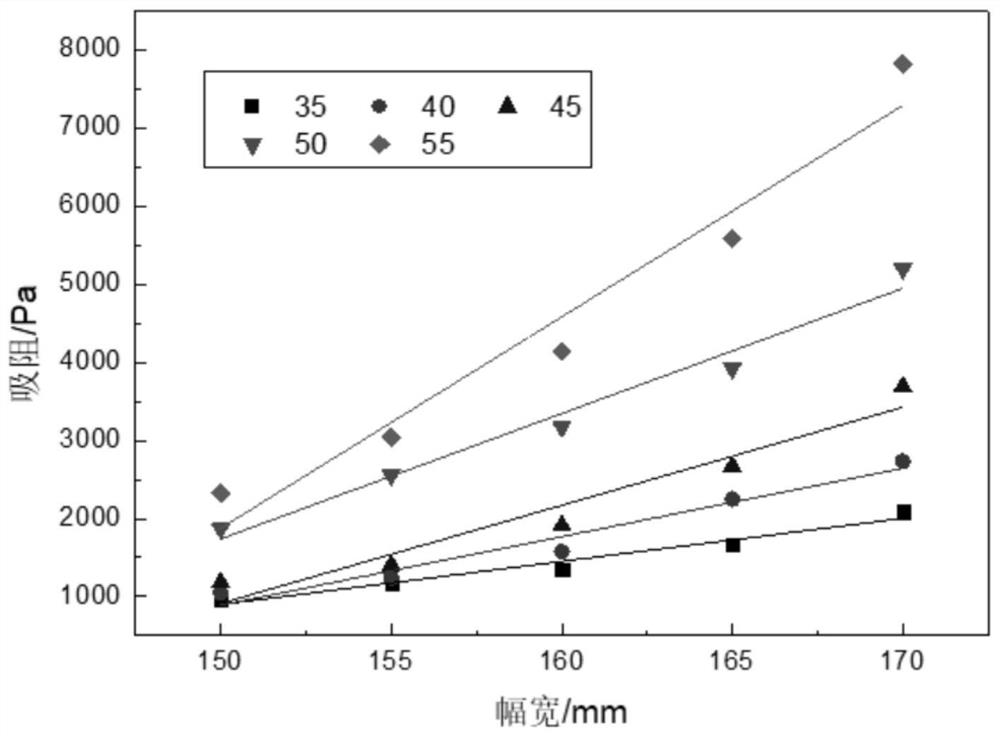

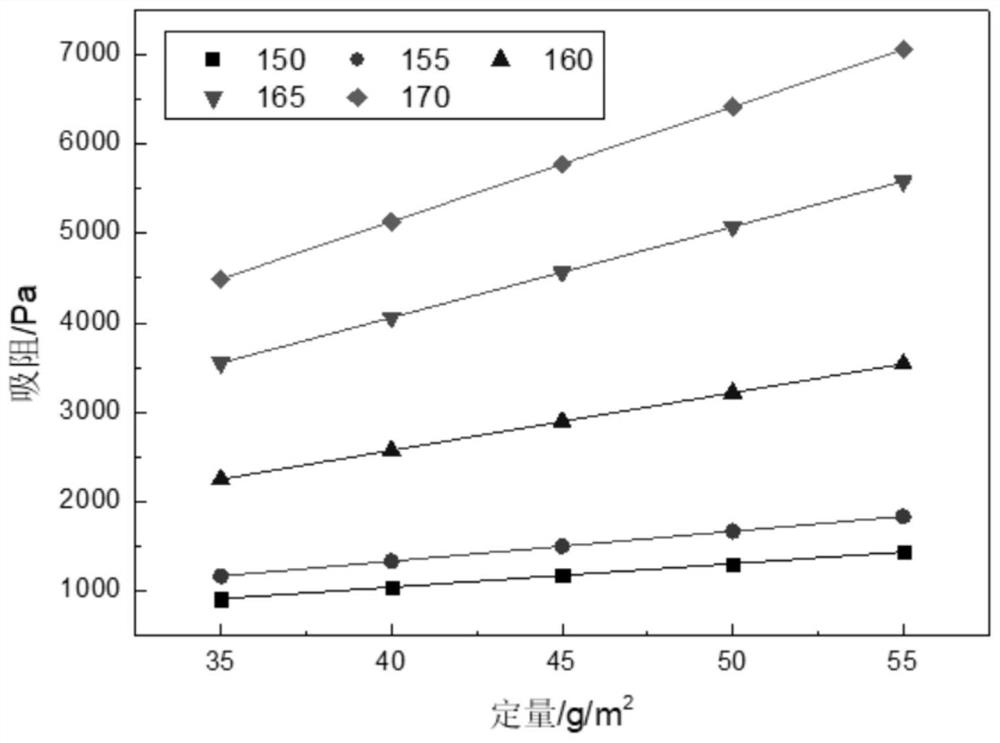

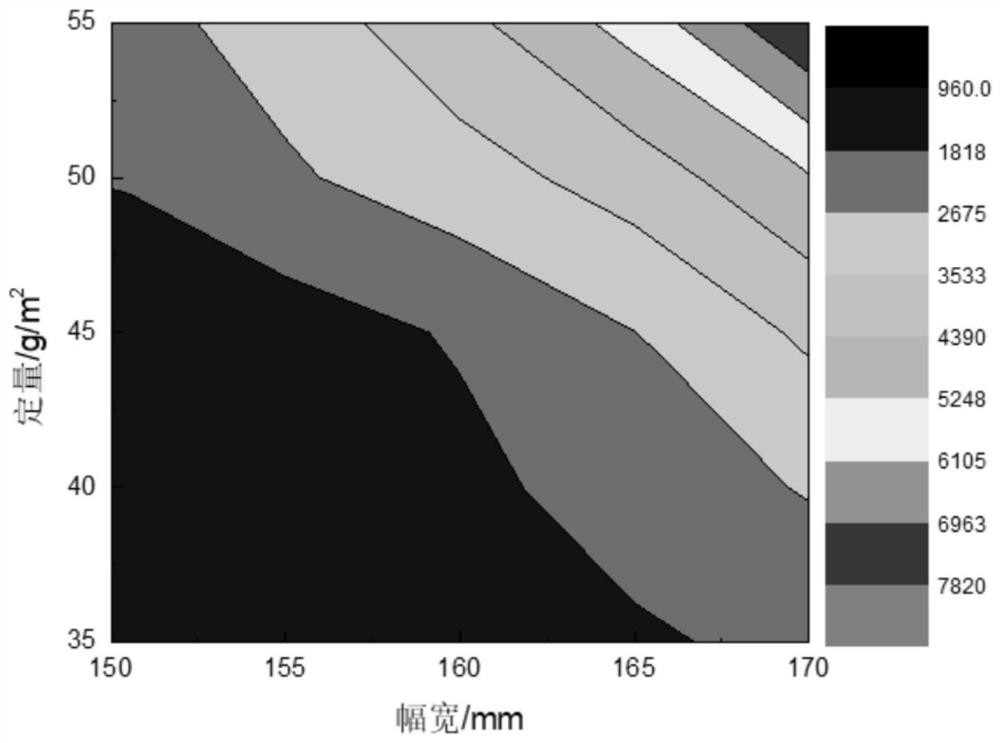

Method for establishing model for predicting suction resistance of paper filter stick

ActiveCN112528494AReduce the amount of experimentsReduce waste of resourcesTobacco smoke filtersDesign optimisation/simulationSimulationPaper filter

The invention relates to a method for establishing a model for predicting suction resistance of a paper filter stick. The method comprises the following steps: preparing different quantitative paper filter stick sheet bases, preparing paper filter stick sheet bases with different widths, forming the paper filter stick, detecting physical indexes of the paper filter stick, establishing a filter stick suction resistance model, and applying and performing inspecting by using the filter stick suction resistance model. The visual and quantifiable model and method are provided for regulation, control and prediction of the suction resistance of the paper filter stick, the method is easy to operate, efficient and easy to implement, a large number of repeated test verification can be avoided, the suction resistance of the filter stick is predicted before an experiment, and a reference basis is provided for formal filter stick forming.

Owner:CHINA TOBACCO YUNNAN REMFG TOBACCO CO LTD

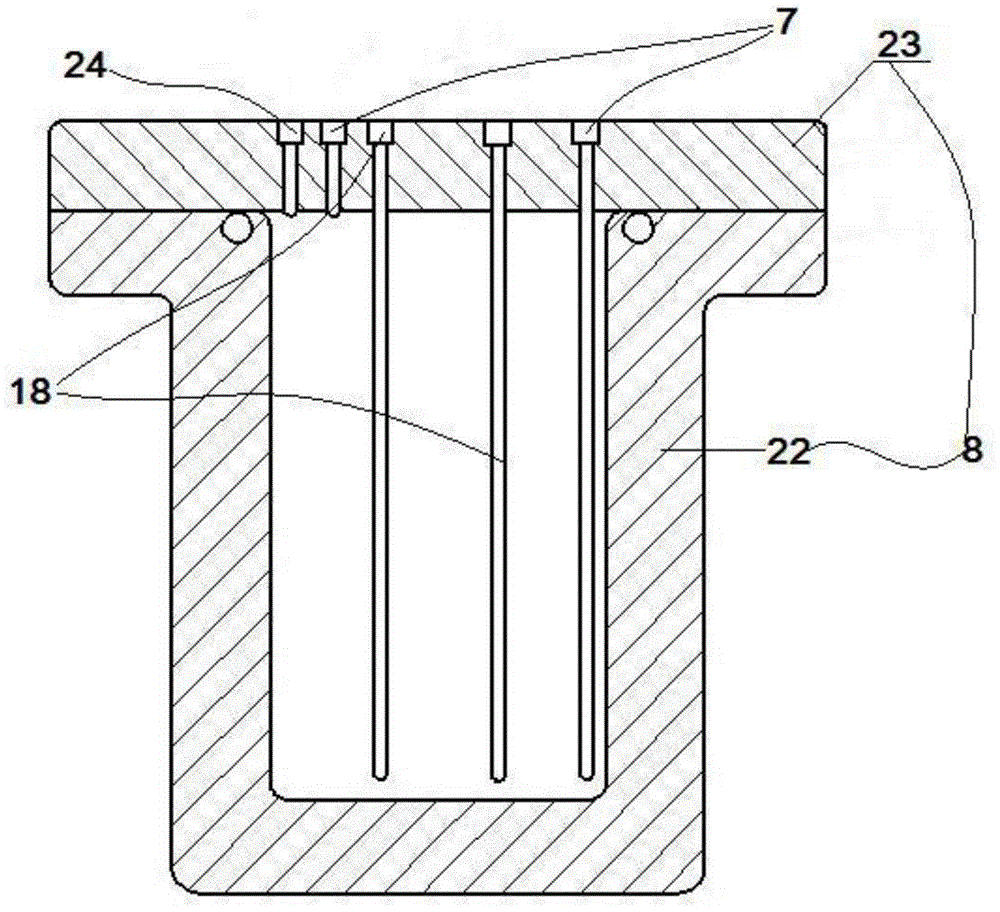

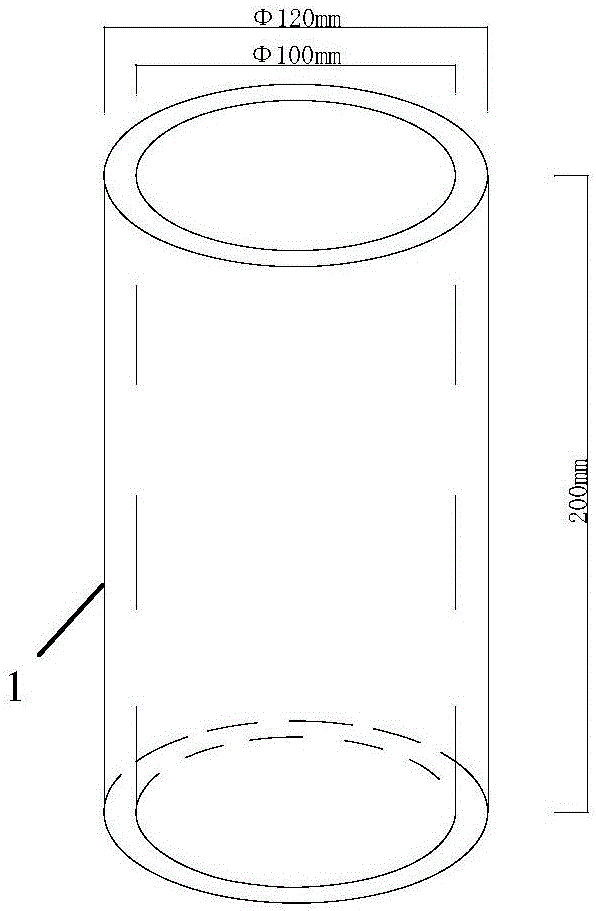

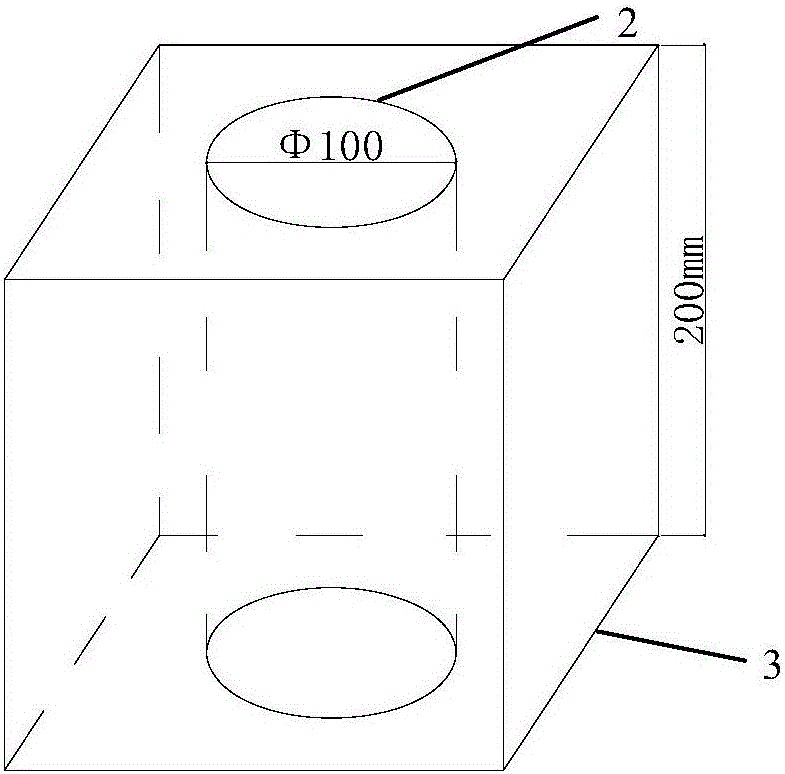

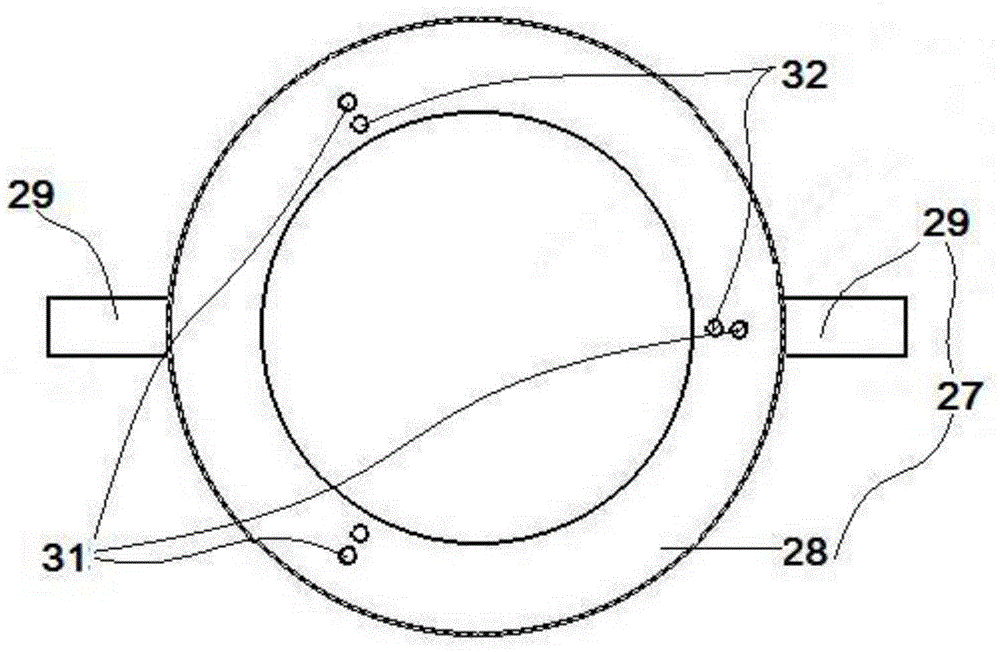

Diffusion sample preparation method for measuring metal melt diffusion by screw push type shearing unit method

PendingCN111964992AAvoid influenceHigh measurement accuracyPreparing sample for investigationDiffusion analysisFusion weldingMetal

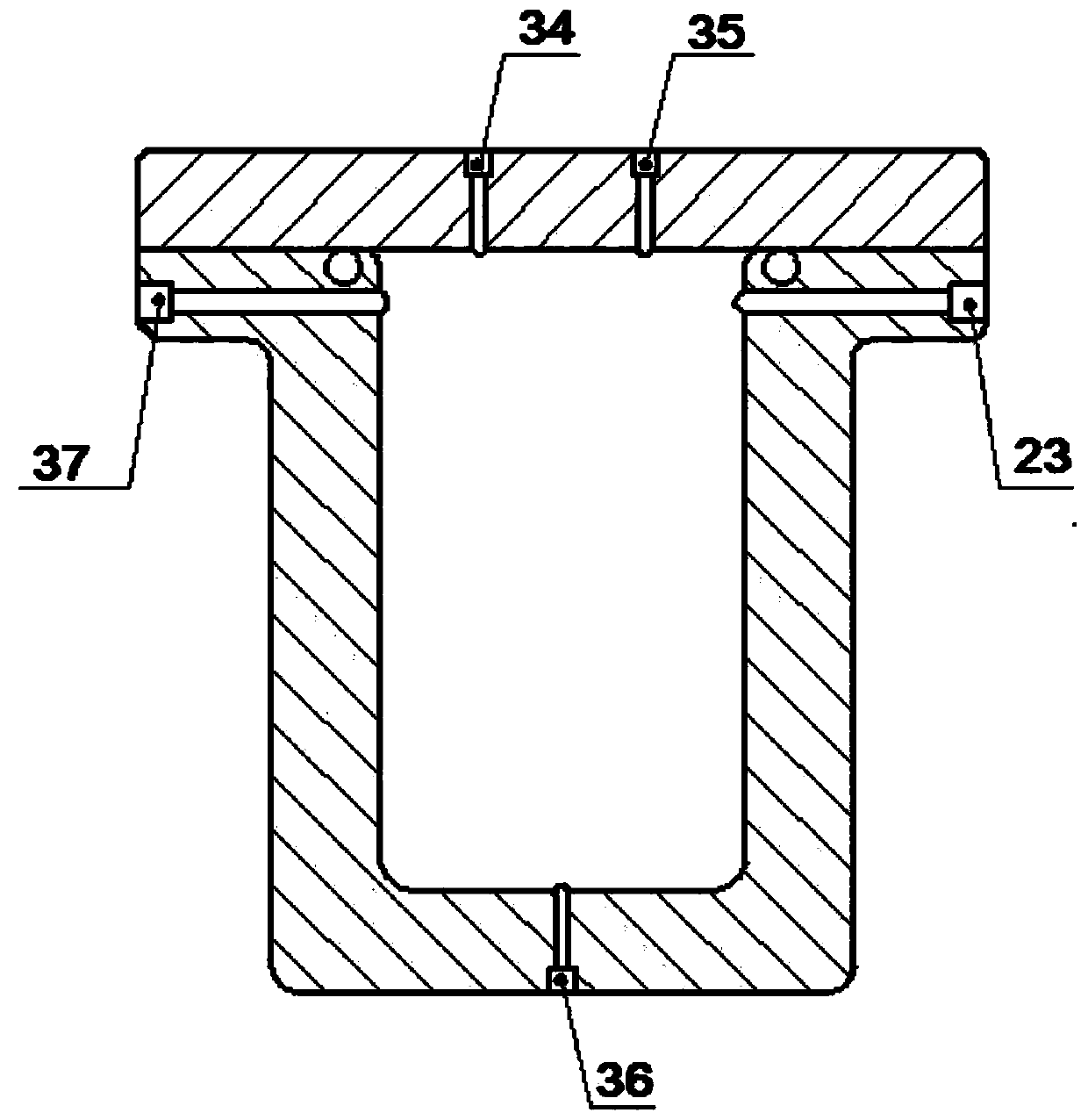

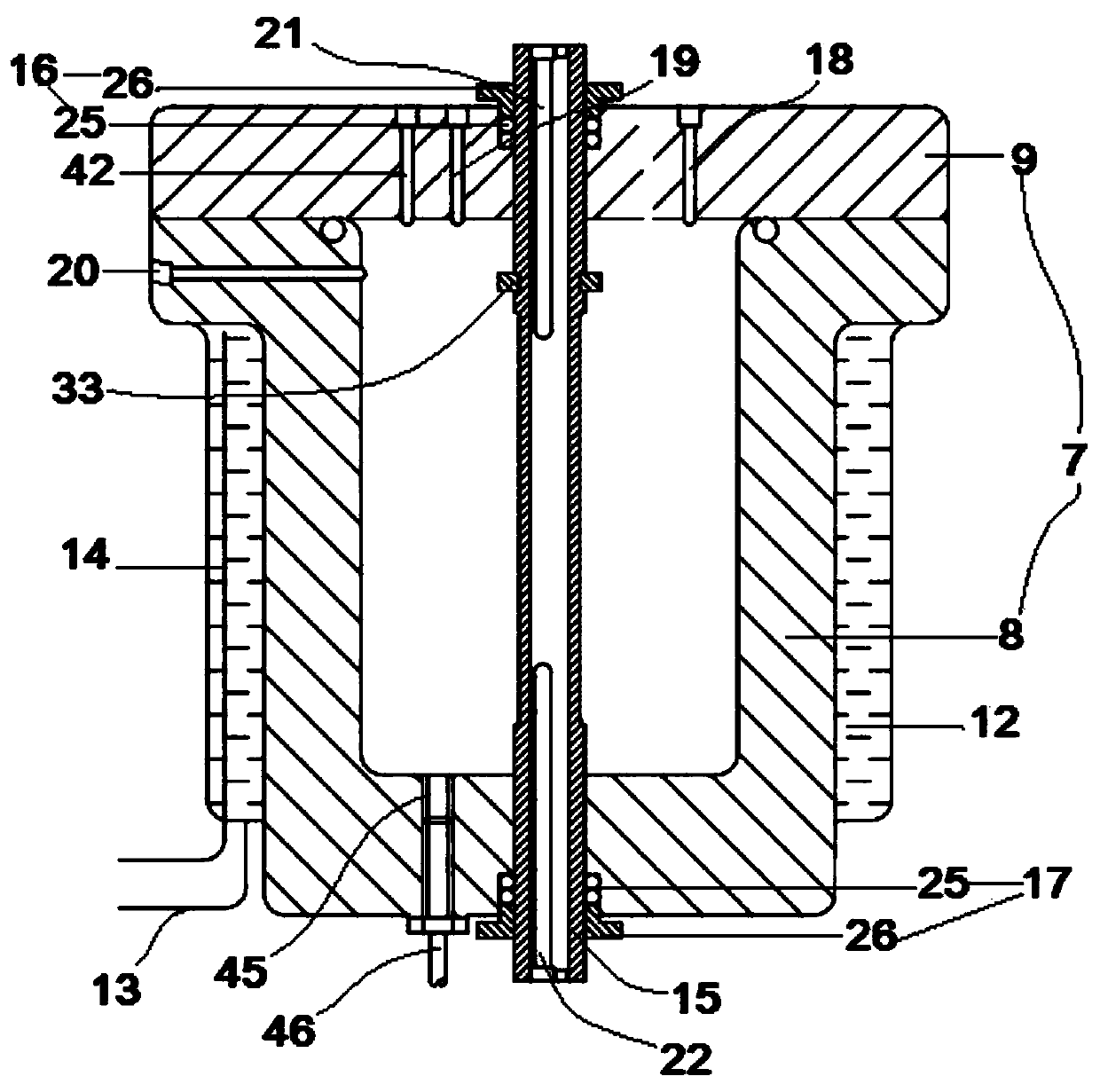

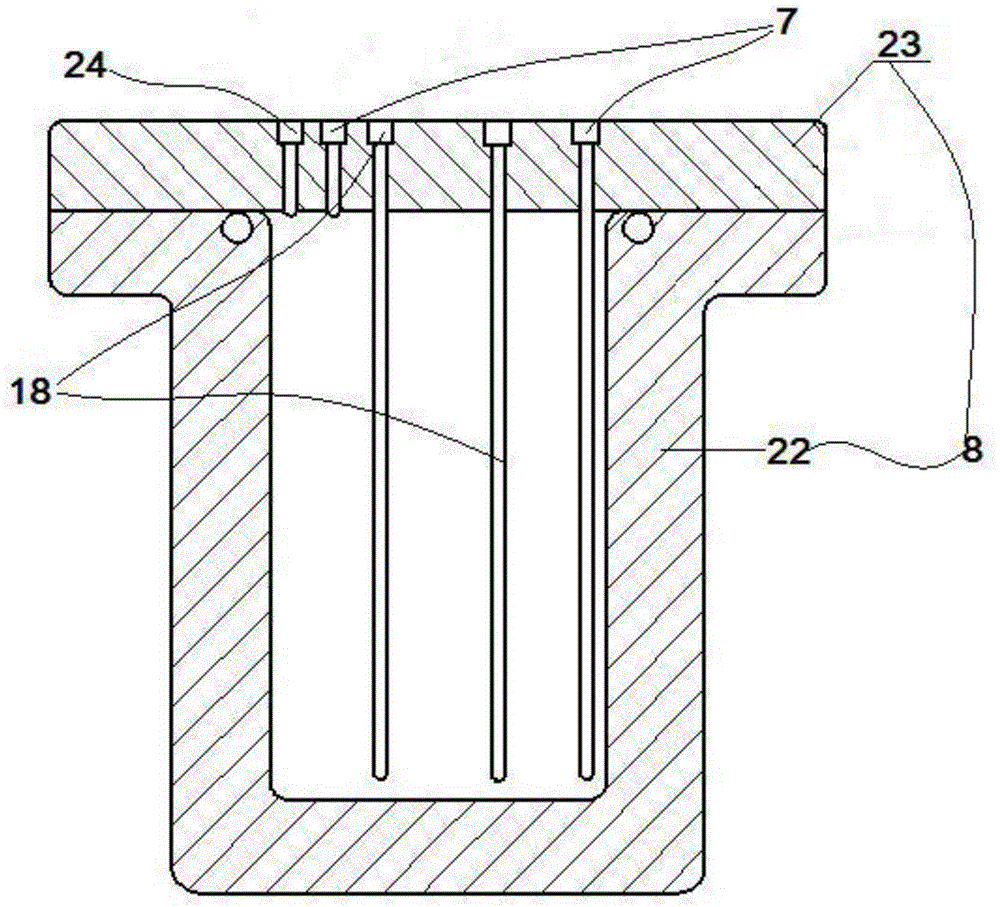

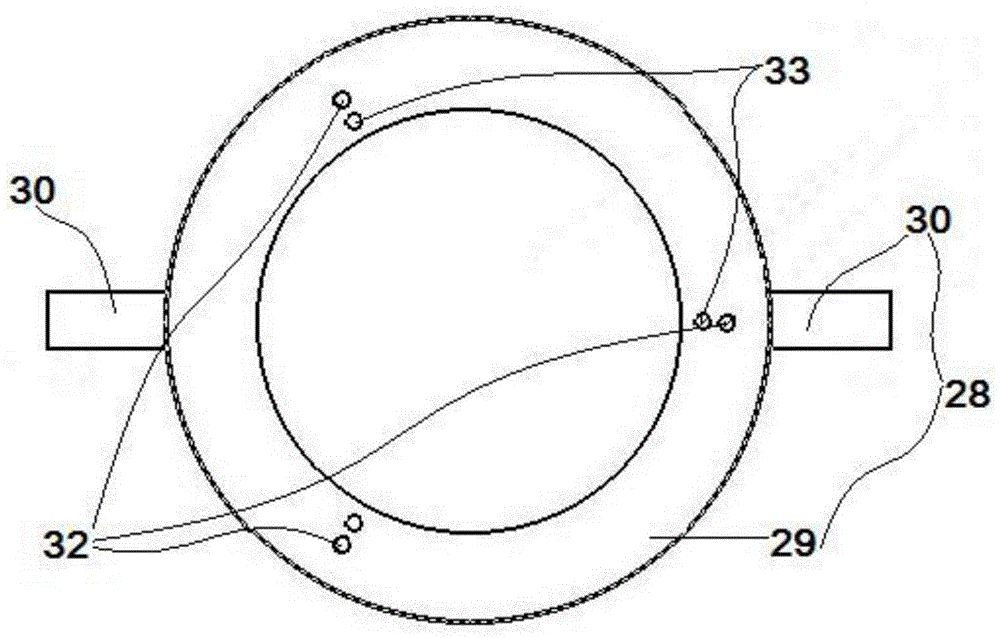

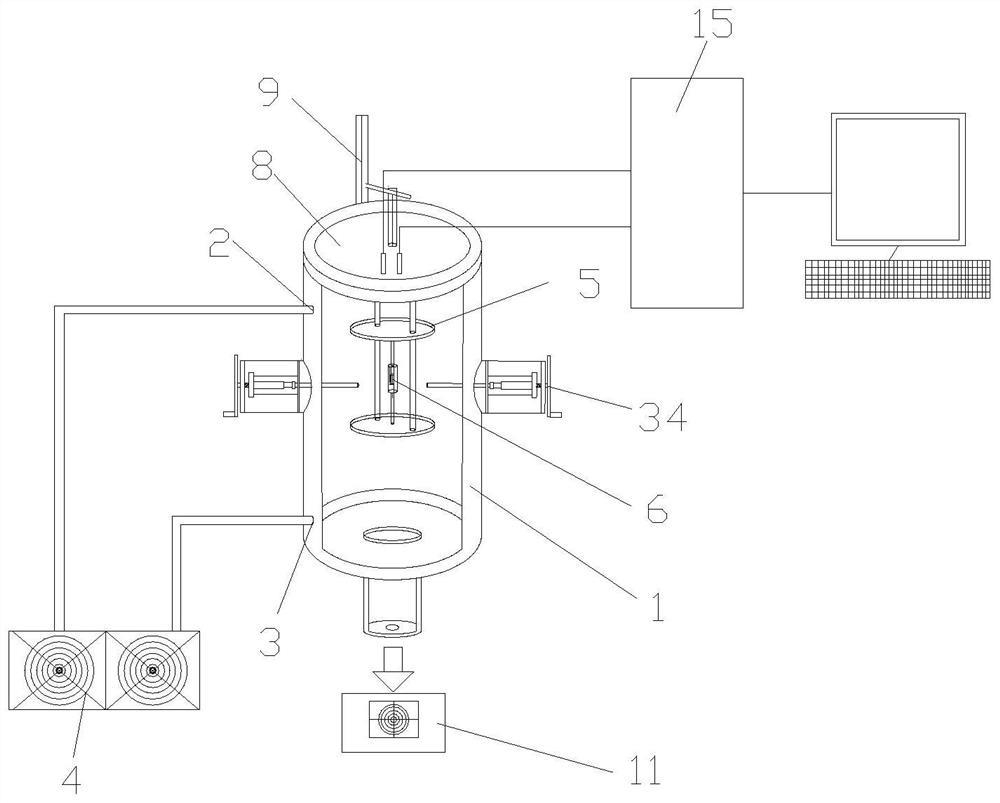

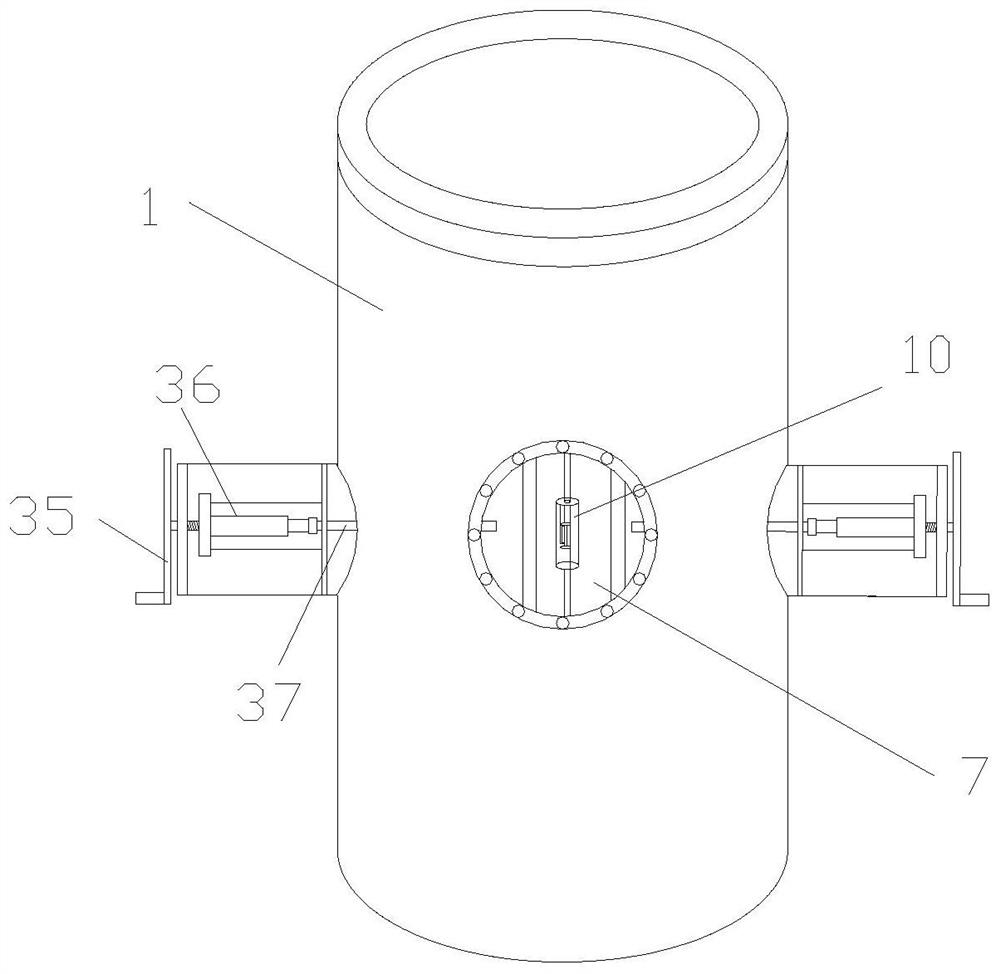

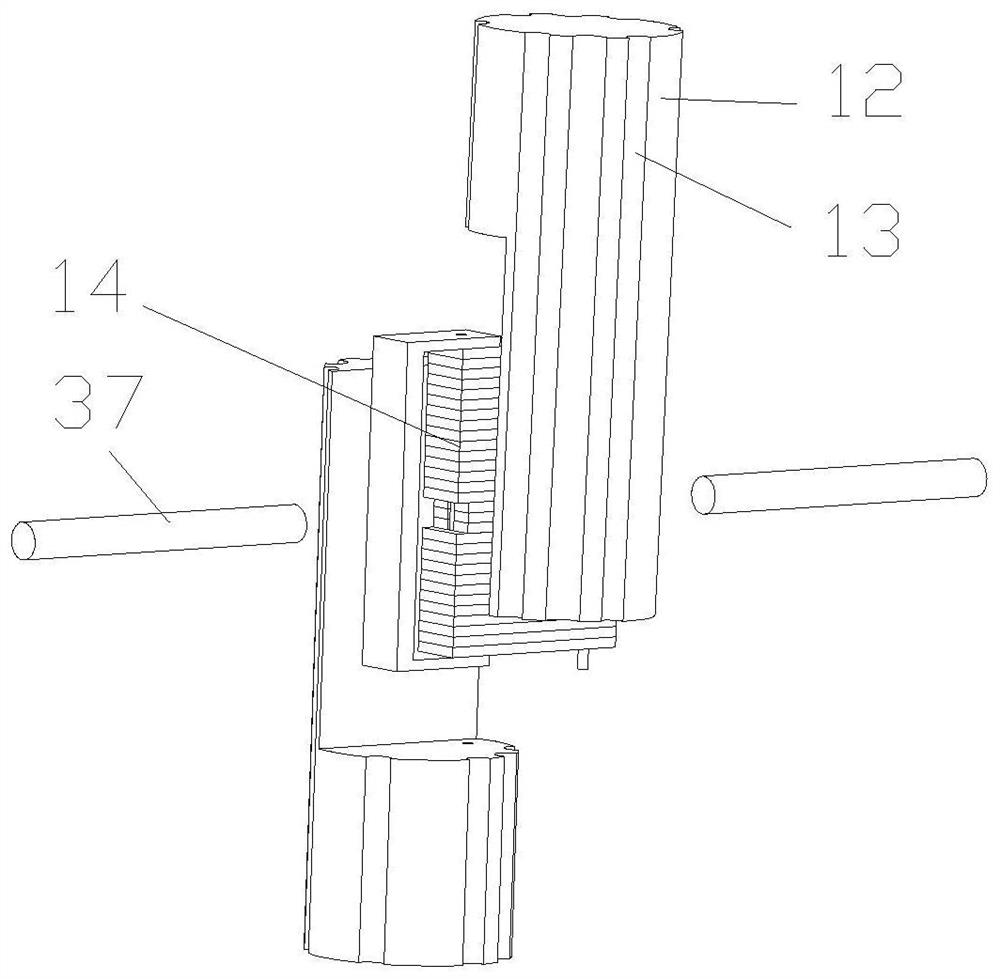

The invention discloses a diffusion sample preparation method for measuring metal melt diffusion by a screw push type shearing unit method. The device comprises a vacuum cavity, wherein a diffusion table is arranged in the vacuum cavity, the diffusion table comprises a base and a diffusion assembly arranged in a cavity of the base, the diffusion assembly is formed by laminating a plurality of ceramic sheets layer by layer, and the diffusion assembly comprises a group of fixed ceramic sheets which are fixedly arranged, a group of movable ceramic sheets which can move rightwards and a group of welding ceramic sheets which can move leftwards and rightwards; the welding ceramic sheet group is located in the middle of the diffusion assembly and located above and below the welding ceramic sheetgroup, and the fixed ceramic sheets and the movable ceramic sheets are arranged at intervals one by one; by pushing each movable ceramic sheet and each fusion welding ceramic sheet to move left and right, butt joint diffusion and slitting of samples are realized. Compared with the prior art, the method has the advantages that the diffusion quality is guaranteed, and the precision of a diffusion test is improved.

Owner:HEFEI UNIV OF TECH

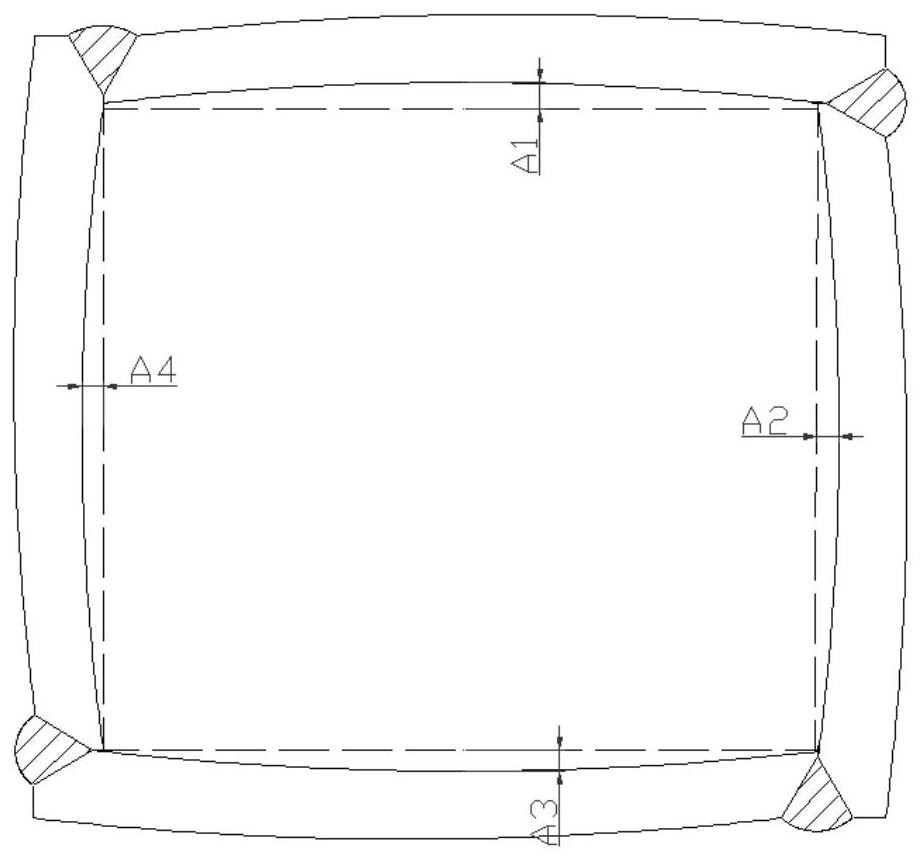

A Method for Controlling and Correcting Fillet Weld Deformation of Large Box Structural Parts

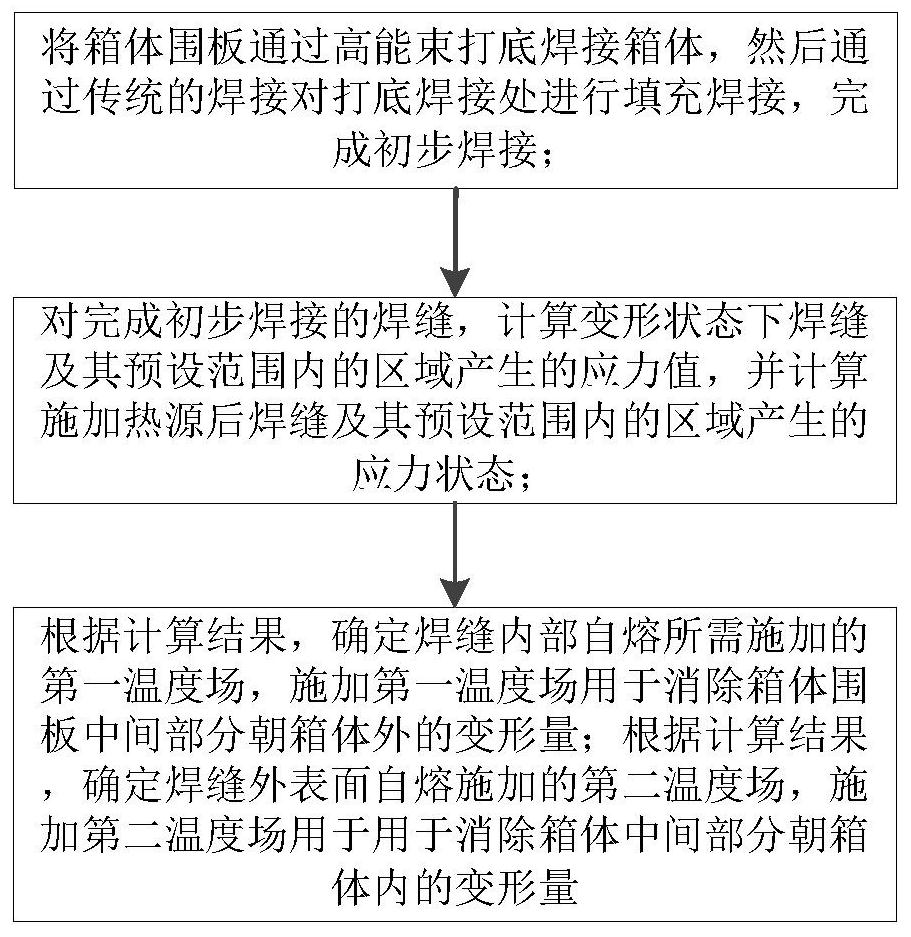

ActiveCN110102924BControl R&D costsReduce the amount of experimentsMetal working apparatusWelding apparatusFillet weldEngineering

The invention discloses a method for controlling and correcting the deformation of the fillet weld of a large-scale box body structure, which includes: welding the box body coaming plate through high-energy beam priming, and then filling the bottom welding place through traditional welding Welding; calculate the stress value produced by the weld seam and the area within the preset range in the deformed state, and calculate the stress state produced by the weld seam and the area within the preset range after applying the heat source; determine the required application for self-melting inside the weld seam The first temperature field is applied, and the first temperature field is applied to eliminate the deformation of the middle part of the box enclosure towards the outside of the box; the second temperature field applied to the outer surface of the weld is determined by self-melting, and the second temperature field is applied to use In order to eliminate the deformation of the middle part of the box body towards the box body, this method can effectively ensure the dimensional stability of the box body structural parts, and obviously correct the welding deformation; use finite element calculation methods to study the deformation mechanism of the fillet welds of large box body structural parts, and realize R&D costs are lower and efficiency is higher.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

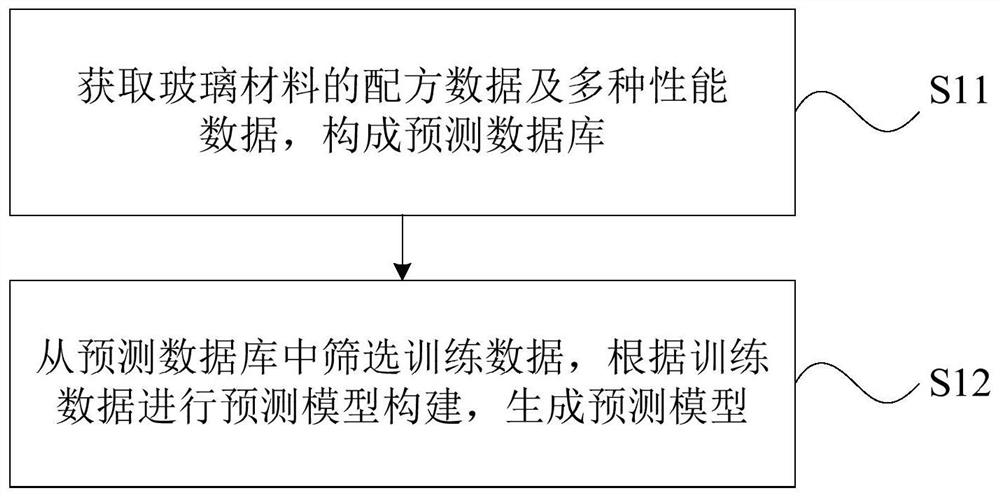

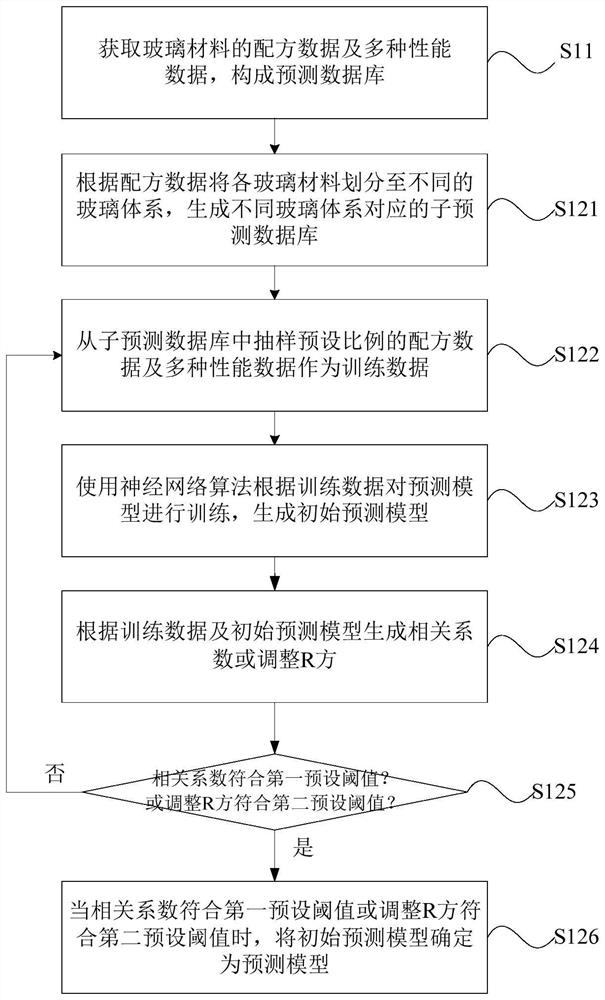

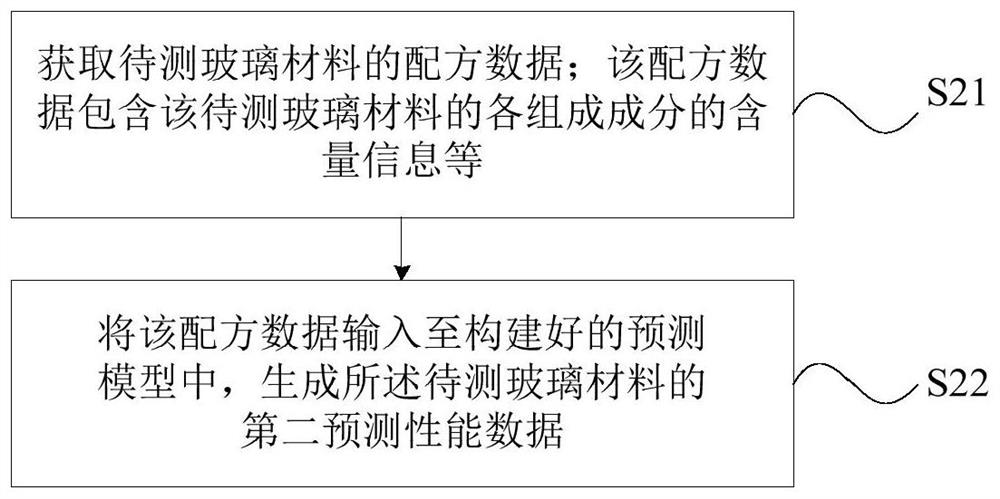

Establishment of predictive model for glass material properties and its predictive method and device

ActiveCN108960493BIncrease R&D SpeedPrediction is accurateDigital data information retrievalForecastingPredictive methodsData mining

The invention discloses a prediction model establishment, prediction method and device for the performance of glass materials. The method for establishing the prediction model includes: obtaining formula data and various performance data of glass materials to form a prediction database; screening training data from the prediction database, according to The training data is used to construct the prediction model and generate the prediction model. By implementing the invention, starting from prediction, a large number of experiments are predicted, which can effectively reduce the amount of experiments, reduce time costs, and increase the rate of research and development of new formulas. At the same time, through the establishment of the model, the ready-made production can be monitored in real time according to the model, and the accurate prediction model can be used to adjust the glass formula or the corresponding production process in real time according to the prediction curve, which is not only conducive to improving product production efficiency, but also conducive to precise control and improvement. Product pass rate.

Owner:SINOMA SCI & TECH

Method for representing density of metal powder sintered body based on molecular dynamics

ActiveCN112927759ALow costReduce the amount of experimentsMolecular entity identificationIncreasing energy efficiencyMolecular dynamicsMaterials science

The invention discloses a method for representing density of a metal powder sintered body based on molecular dynamics. The method comprises the following steps: (1) establishing a calculation simulation model for simulating laser sintering of metal powder; (2) adopting a molecular dynamics method, setting simulation parameters, and simulating the sintering process; (3) after the sintering simulation in the step (2) is finished, outputting the number Ni and the total volume V of atoms of various crystal structures of the sintered body according to a simulation result; and (4) calculating density according to an expression of the density D of the sintered body, wherein in the expression, i is the ith crystal structure in the sintered body, Ni is the number of all atoms of the ith crystal structure, ni is the unit cell atom number of the ith crystal structure to which the atoms belong, and Mi is the unit cell volume of the ith crystal structure to which the atoms belong. According to the method, the effect of representing the density of the sintered body is achieved on the theoretical level, the experimental quantity is reduced, the actual powder sintering cost is remarkably reduced, and the research and development efficiency is improved.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +1

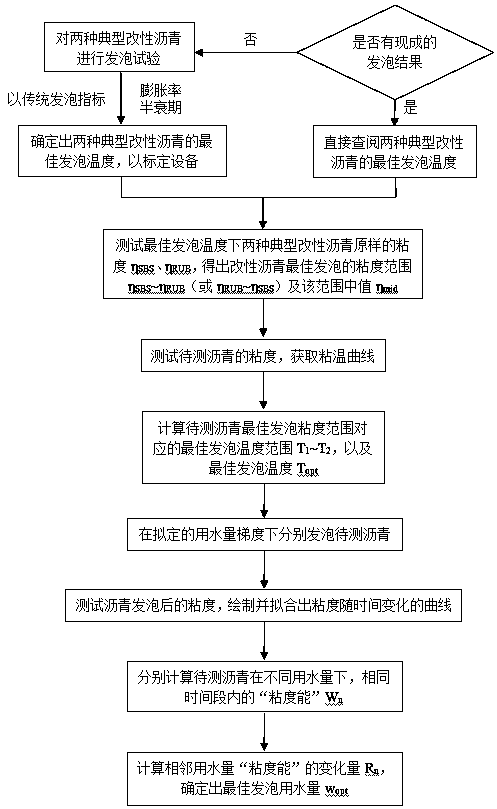

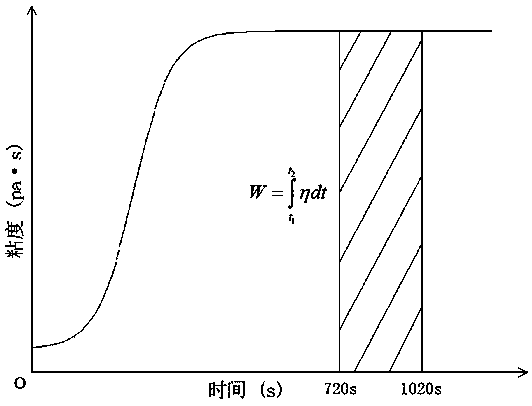

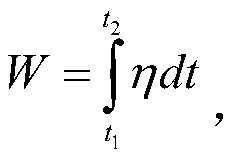

Method for determining optimal foaming condition of modified asphalt through viscosity

ActiveCN111366498ATrial variable reductionReduce the amount of experimentsFlow propertiesMaterial testing goodsProcess engineeringMixing effect

The invention discloses a method for determining the optimal foaming condition of modified asphalt through viscosity. The method comprises the following steps: determining the optimal foaming temperature TSBS and TRUB; calculating an optimal viscosity range; testing the viscosity of the asphalt to be tested, and calculating the temperature T1 to T2 corresponding to the optimal viscosity range andthe temperature Tmid corresponding to the median of the viscosity range; determining the optimal water consumption of asphalt to be measured, performing a foaming test in a planned water consumption range, calculating the viscosity energy of each water consumption in the same time period, and the water consumption when the viscosity energy change is maximum being the optimal foaming water consumption wopt. According to the method, the foaming temperature of the asphalt to be tested can be directly determined through the viscosity of the asphalt to be tested by utilizing the existing foaming data, and two test variables are reduced to one test variable, so that the experimental quantity is greatly reduced. The direct index (viscosity energy) influencing the mixing effect replaces the traditional indirect index to be used as the basis for determining the optimal water consumption, and the obtained result has better consistency with the actual mixing effect, thereby being beneficial to lowering the mixing temperature of the warm-mixed mixture.

Owner:SOUTHEAST UNIV

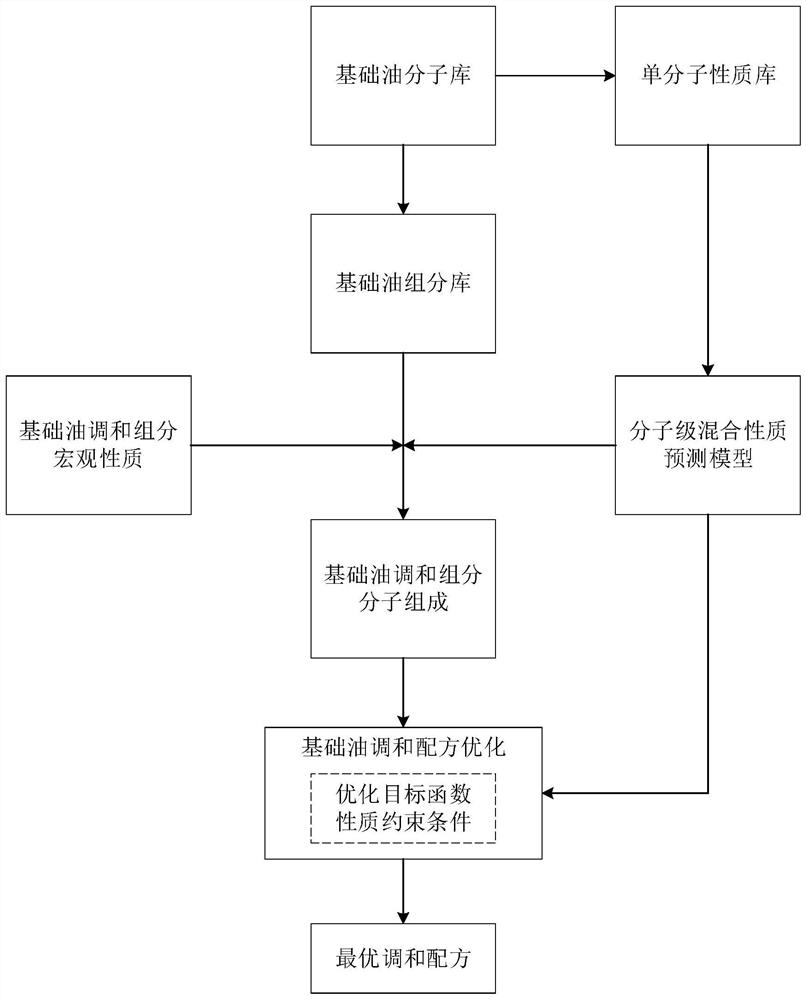

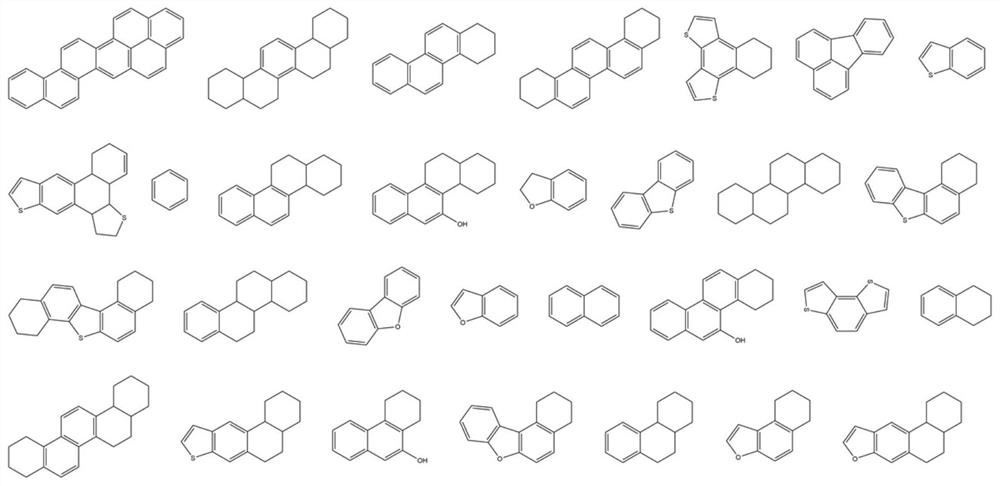

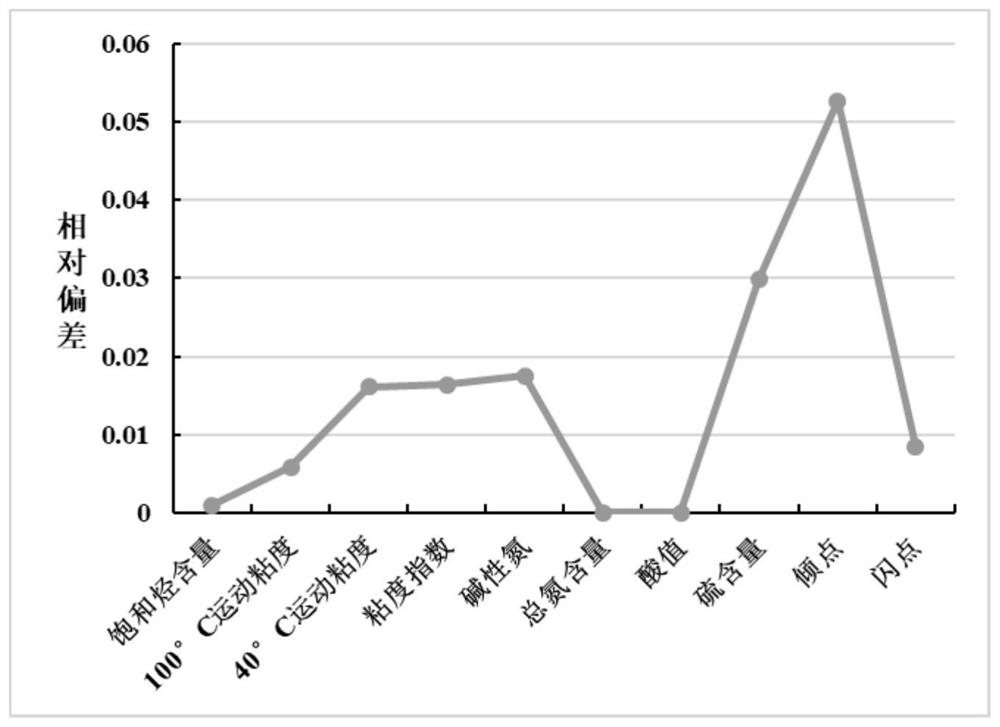

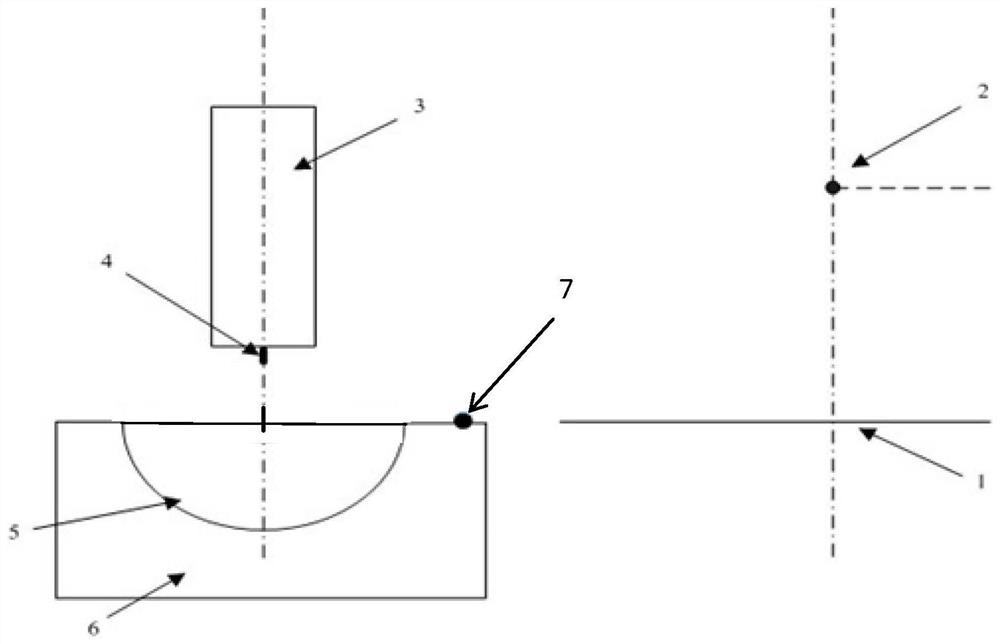

A molecular-level base oil blending optimization method

ActiveCN109949870BImprove accuracyReduce the amount of experimentsFlow propertiesMaterial flash-pointEconomic benefitsProcess engineering

Owner:SYSPETRO TECH CO LTD

Apparatus and method for measuring surface temperature field of molten pool in titanium alloy arc welding

ActiveCN110657892BAccurately obtain emissivity valuesAccurate collectionThermometers using electric/magnetic elementsUsing electrical meansEmissivityMetallurgy

The invention discloses a device and method for measuring the surface temperature field of a titanium alloy arc welding molten pool. The combination of an industrial detection infrared thermal imager and a thermocouple is applied to the measurement of the surface temperature field of a titanium alloy arc welding molten pool, and the heat of the molten pool can be obtained. The emissivity value at a fixed point on the surface of the zone of influence. Secondly, a method for calculating the emissivity of the surface of the molten pool is also proposed, combining the emissivity value obtained from the fixed point to solve the emissivity in the area between the fixed point and the center of the molten pool, and then obtain the temperature of each point, which greatly reduces the amount of experiments , and can accurately and comprehensively obtain the surface temperature field information of the titanium alloy welding pool.

Owner:BEIHANG UNIV

High temperature and high pressure corrosion hydrogen permeation kinetics test device and test method

ActiveCN104568726BReduce the amount of experimentsShorten test timeWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesFatigue loadingHigh pressure hydrogen

The invention discloses a high temperature and high pressure corrosion hydrogen permeation kinetic test device and a test method of the device. When the device is used for carrying out fatigue limit measurement, step type fatigue load is applied to material from small to large under the given corrosion condition after hydrogen permeability current is stable; when the hydrogen permeability current is increased along with the increment of the load, the load is proved to cause dislocation movement in the material, so that the load is the fatigue limit of the material in the environment. After the device and the method are adopted, the quantitative relation between a fatigue load state and hydrogen permeation quantity can be measured in situ in an online way in the high pressure hydrogen sulfide corrosion environment, the internal relation between stress and segregation diffusion of hydrogen can be visually expressed, and the characteristics of the mutual relation of multiple data can be established.

Owner:湖州度信科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com