Method for improving surface evenness of laser rapid forming metal part

A technology of laser rapid prototyping and surface smoothness, which is applied in the direction of improving energy efficiency and process efficiency, and can solve the problems of difficult control of the size and shape accuracy of laser rapid prototyping parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

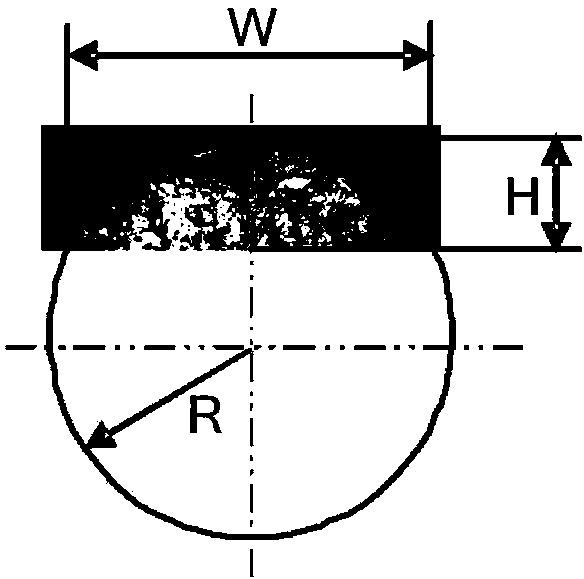

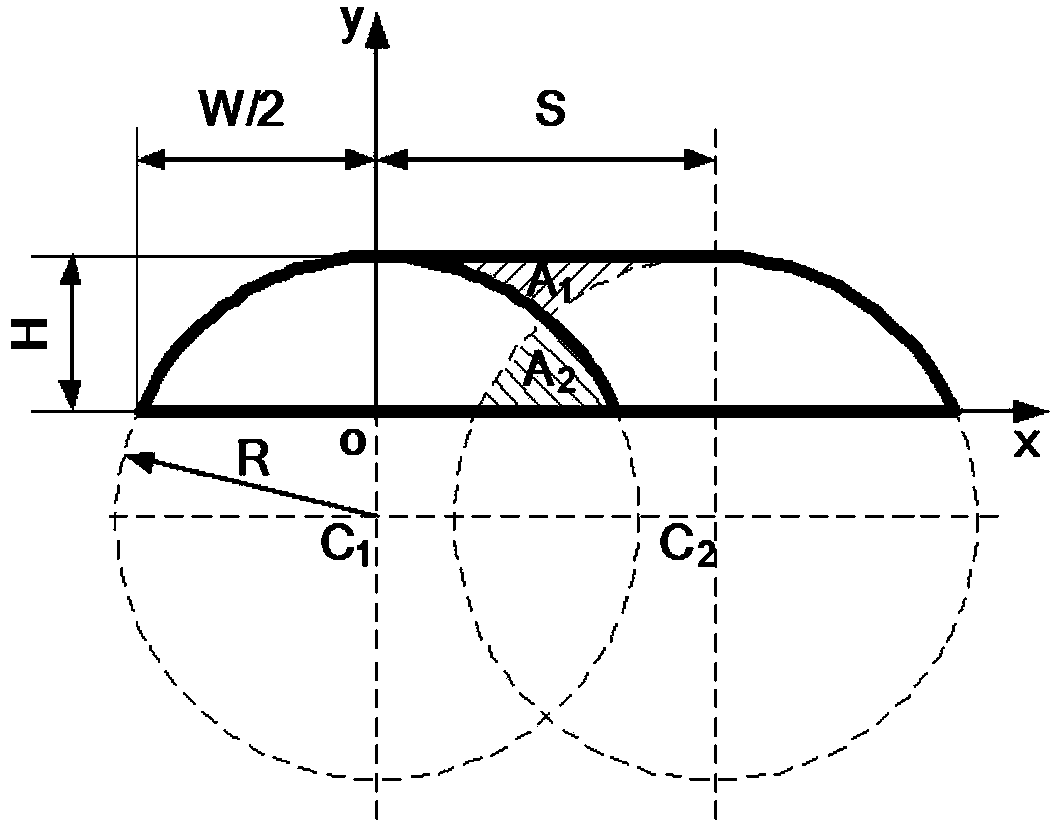

[0051] According to the range of the main process parameters of the rapid prototyping technology in the present invention (see Table 1), different commonly used value combinations are selected for single-pass cladding experiments (that is, the laser power P is selected from 500 / 600 / 700 / 800 / 900W, and the spot diameter D is selected from 2 / 3 / 4mm, the powder feeding rate M is selected as 2 / 4 / 6 / 8 / 10g / min, and the scanning speed V is selected as 2 / 4 / 6 / 8 / 10mm / s), and all experiments under the combination of the above process parameters are comprehensively compared It is found that the line width and line height of the cladding line formed under the parameters of laser power P=700W, spot diameter D=3mm, powder feeding rate M=4g / min, and scanning speed V=6mm / s are the highest. Stable, the most regular geometric shape, the most uniform size, relatively high surface finish, and the best wettability with the substrate; using the combination of the above process parameters, the measured si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com