Test method of optimal cross-linking agent diffusion time in production process of high-voltage cable material

A high-voltage cable and production process technology, which is applied in the field of cross-linking agent diffusion time testing, can solve the problem that the optimal cross-linking agent diffusion time is not easy to determine, and achieve the effects of shortening test time and cost, and high data accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

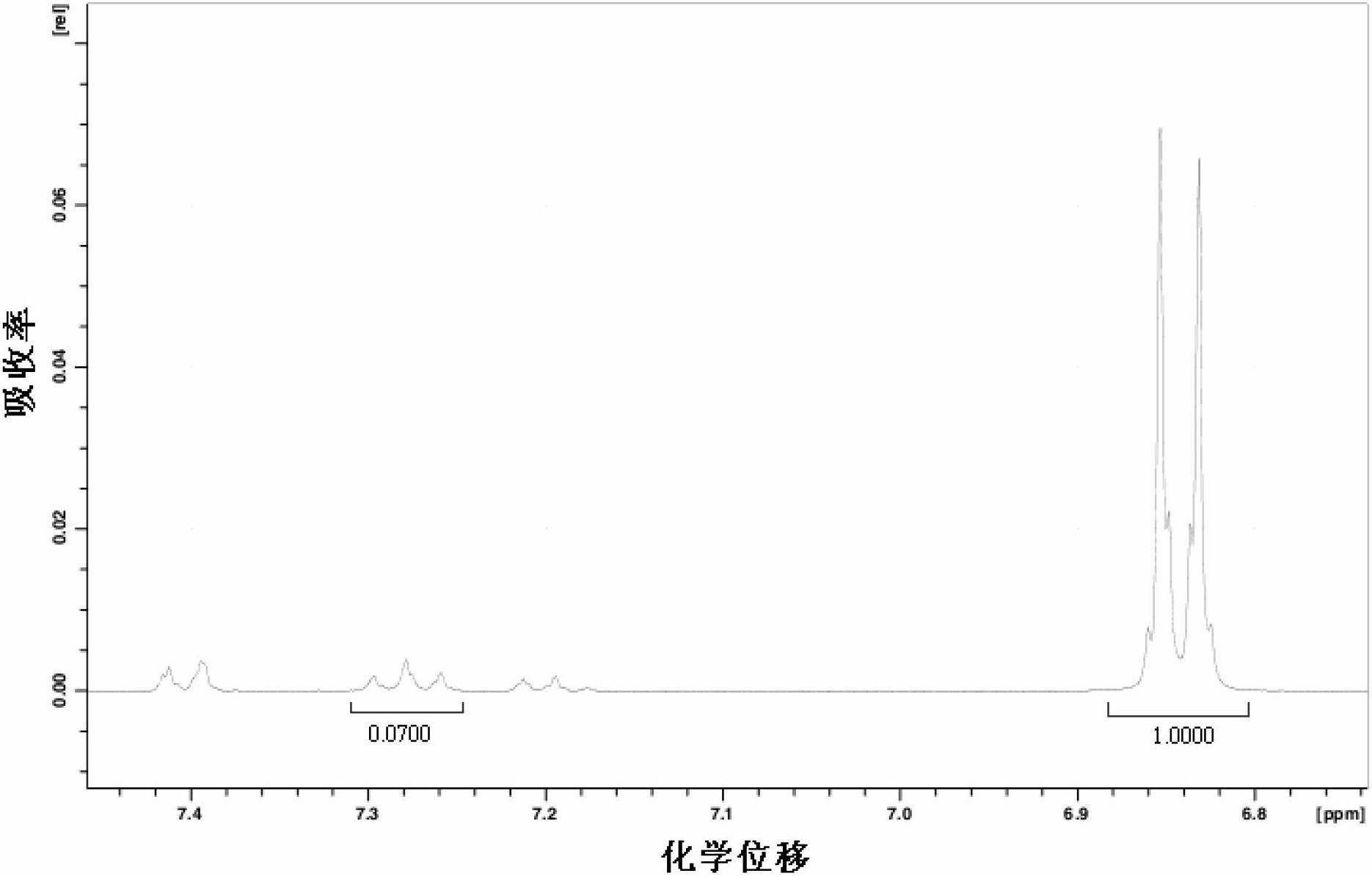

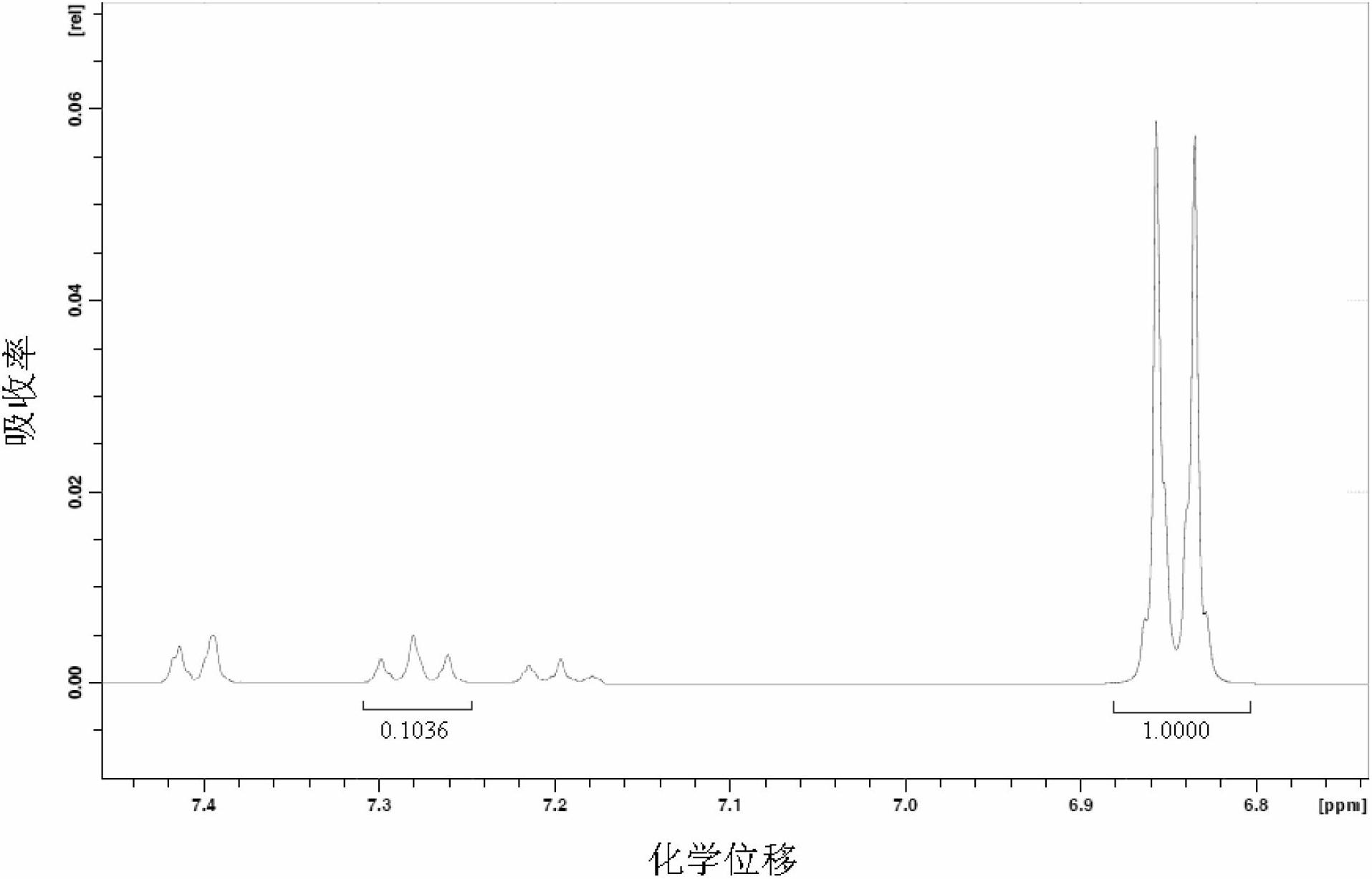

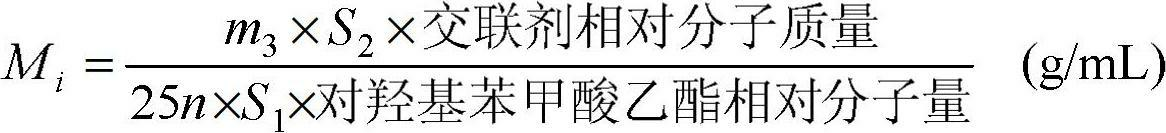

[0035] Specific implementation mode 1: The test method for the optimal crosslinking agent diffusion time in the production process of high-voltage cable materials in this embodiment is carried out according to the following steps:

[0036] 1. In the process of producing high-voltage cable materials by the post-absorption method, the granular purification material obtained by melting and blending raw materials, filtering, granulating, and drying and the granular material composed of liquid crosslinking agent are physically mixed and stored at a constant temperature. , after storage, take out 30-50 grams of granular material every 0.5 hours as a sample, and record the sampling time as i;

[0037] 2. Cut out a cube with a side length of 0.4 to 0.6 mm at the center of the granular material sample obtained by each sampling, and record the mass of the cube as m 1 grams, m 1 =0.2~1.0g;

[0038] 3. Cut m from step 2 1 grams of material and m 2 Put 1 gram of absolute ethanol into a...

specific Embodiment approach 2

[0057] Embodiment 2: This embodiment differs from Embodiment 1 in that in Step 2, a cube with a side length of 0.5 mm is cut from the center of the granular material obtained in each sampling. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0058] Specific implementation mode three: the difference between this implementation mode and specific implementation mode one or two is that in step three, the m obtained in step two is 1 grams of material and m 2 Put one gram of absolute ethanol into the test tube and seal it, then put the test tube into a constant temperature water tank at 65°C, and let it stand for 6-7 hours. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Proportion | aaaaa | aaaaa |

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com