Bentonite two-way swelling force measuring instrument

A bentonite and measuring instrument technology, which is applied in the direction of measuring force, measuring device, soil material testing, etc., can solve the problems of poor control of the range of pressure sensors, failure to reflect the overall situation, and inability to ensure the tight fit of bentonite samples, etc., to achieve The effect of high degree of automation, large functions and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing:

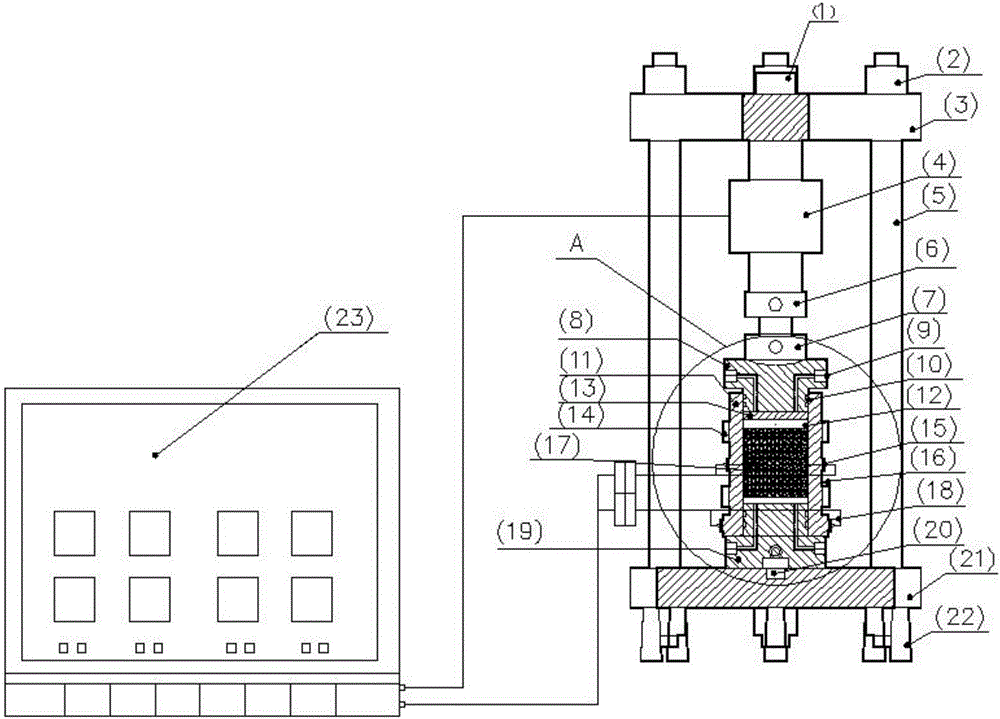

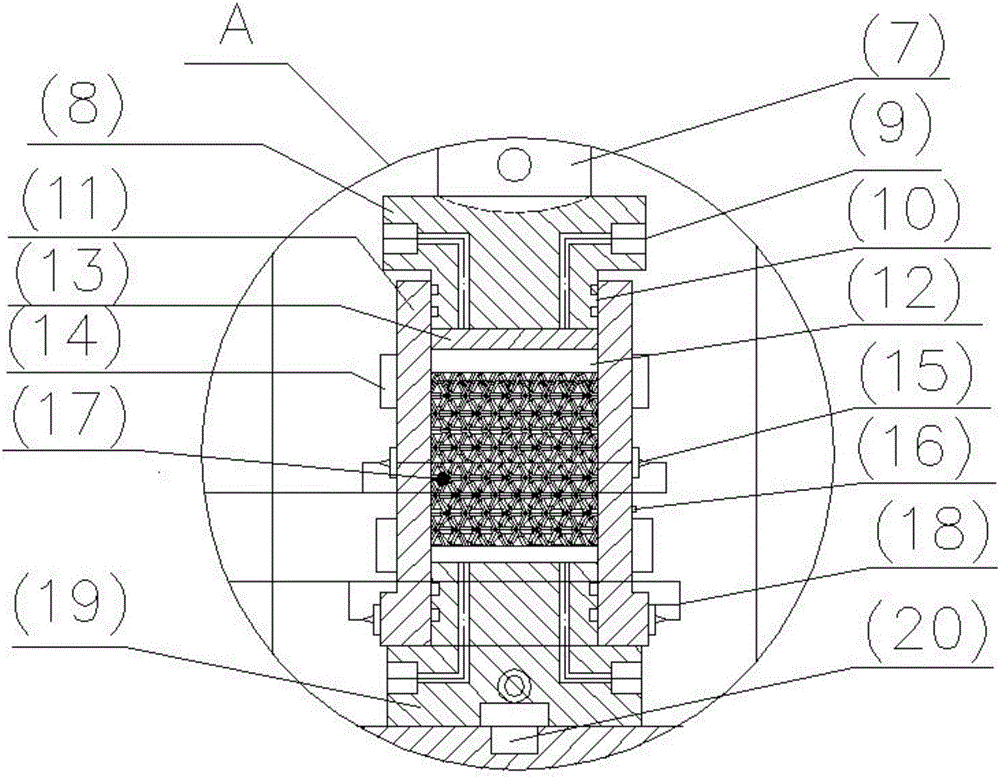

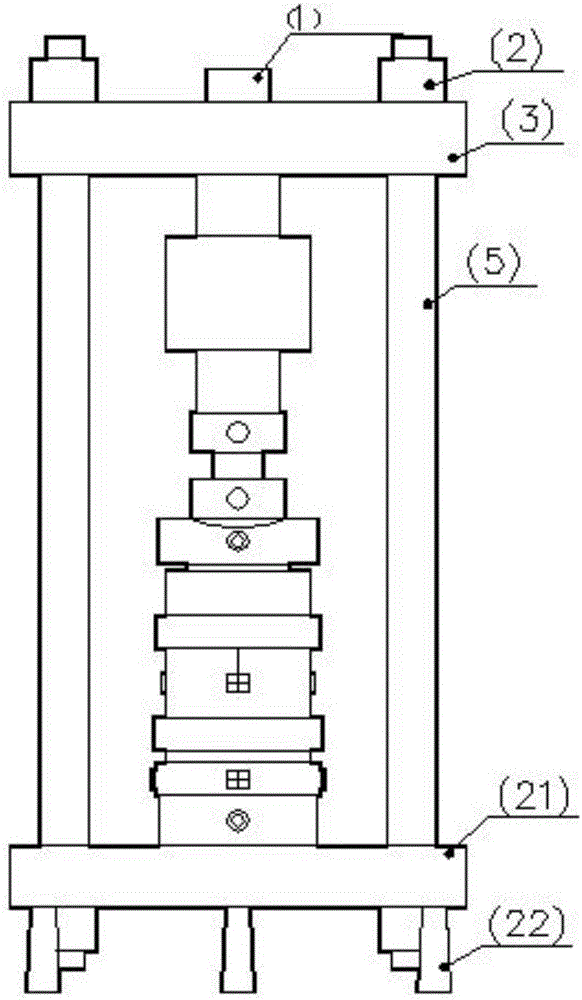

[0029] Such as Figure 1 to Figure 4Shown: including set bolt (1), lock nut (2), top cover (3), load cell (4), column screw (5), throwing cap (6), pressure head (7), upper piston rod (8), pipe joint (9), sealing ring (10), expansion barrel (11), water-permeable pad (12), heat insulation pad (13), heating ring (14), strain gauge (15), temperature sensor ( 16), bentonite sample (17), temperature compensation plate (18), lower piston rod (19), positioning pin (20), base (21), support pin (22), data acquisition system (23), with The lower piston rod (19) of the pipe joint (9) is connected with the positioning pin (20) on the base (21), and the upper piston rod (8) and the lower piston rod (19) ends are placed with a water-permeable pad (12) and Put sealing ring (10), the expansion barrel (11) that described bentonite sample (17) is housed is enclosed within on the piston rod,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com