Diffusion sample preparation method for measuring metal melt diffusion by screw push type shearing unit method

A shearing unit and sample preparation technology, which is applied in the field of diffusion sample preparation for measuring the diffusion of metal melt by the screw pusher shearing unit method, can solve the problem of inability to prepare and judge whether the sample is completely docked, the accuracy of experimental data is affected, and the sample is easy to produce Holes and other problems to achieve the effect of facilitating research and development, reducing the amount of experiments, and reducing the workload of scientific research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Below the embodiment of the present invention is described in detail, and present embodiment implements under the premise of the method of the present invention, has provided detailed embodiment and concrete operation process, but protection scope of the present invention is not limited to following embodiment .

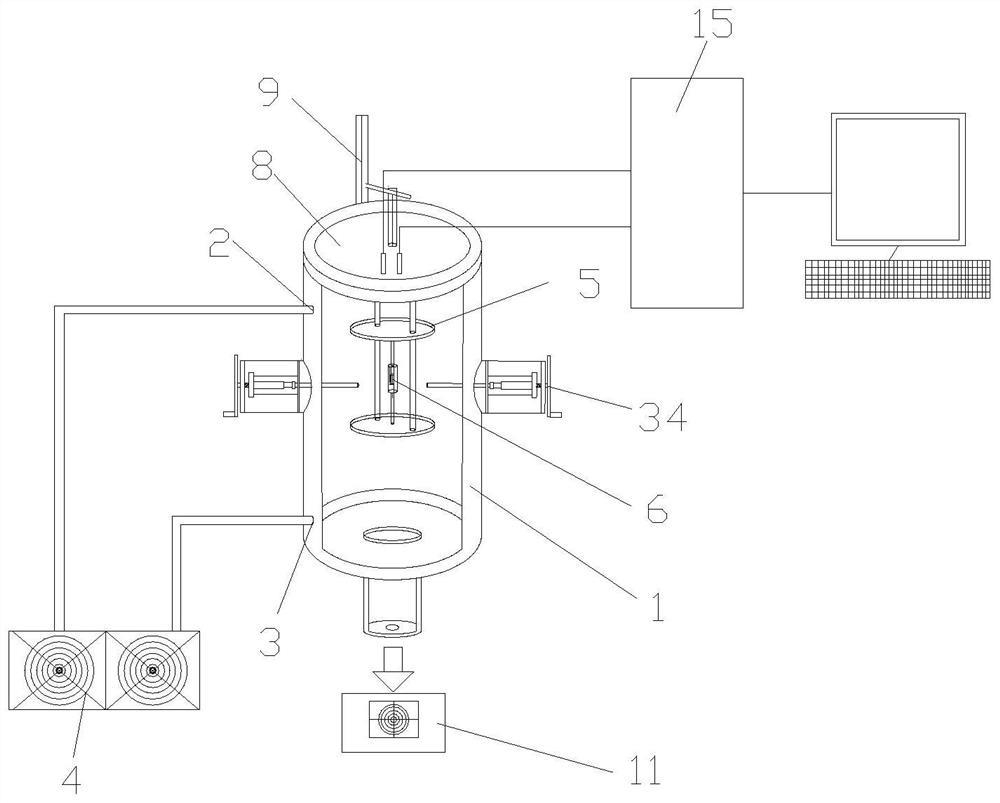

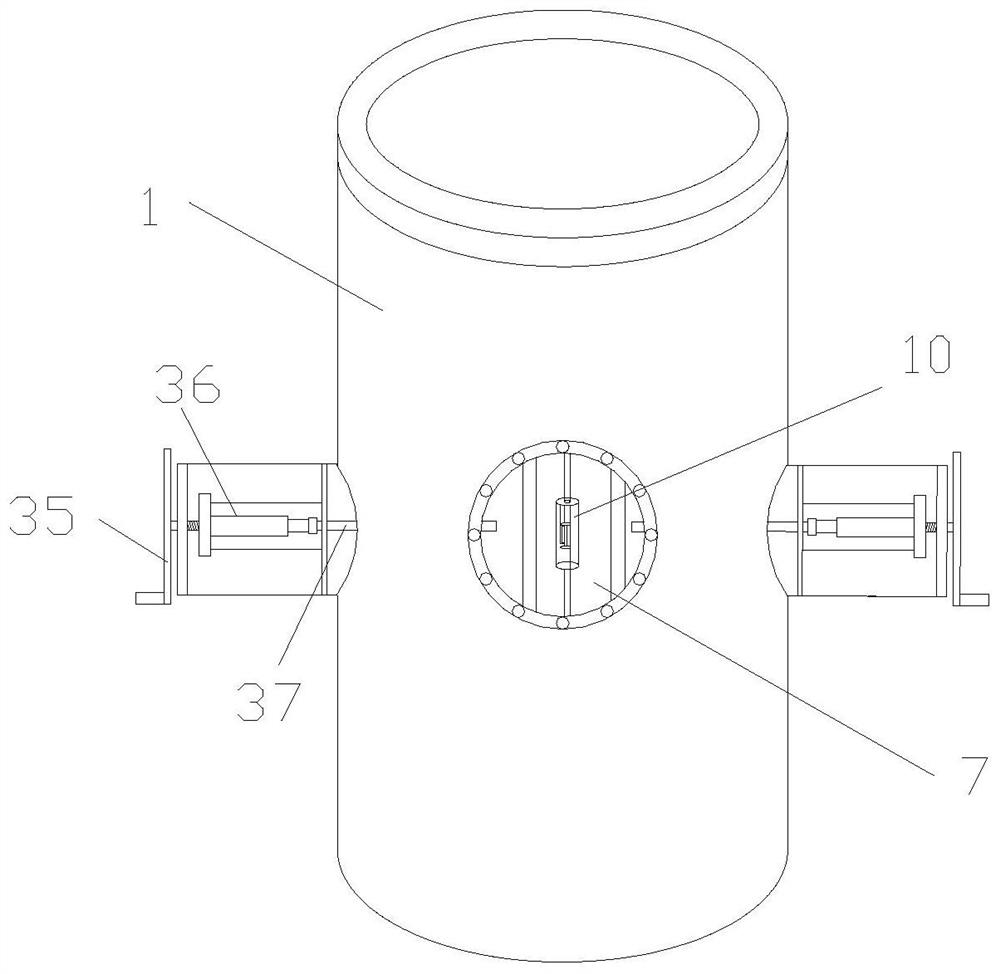

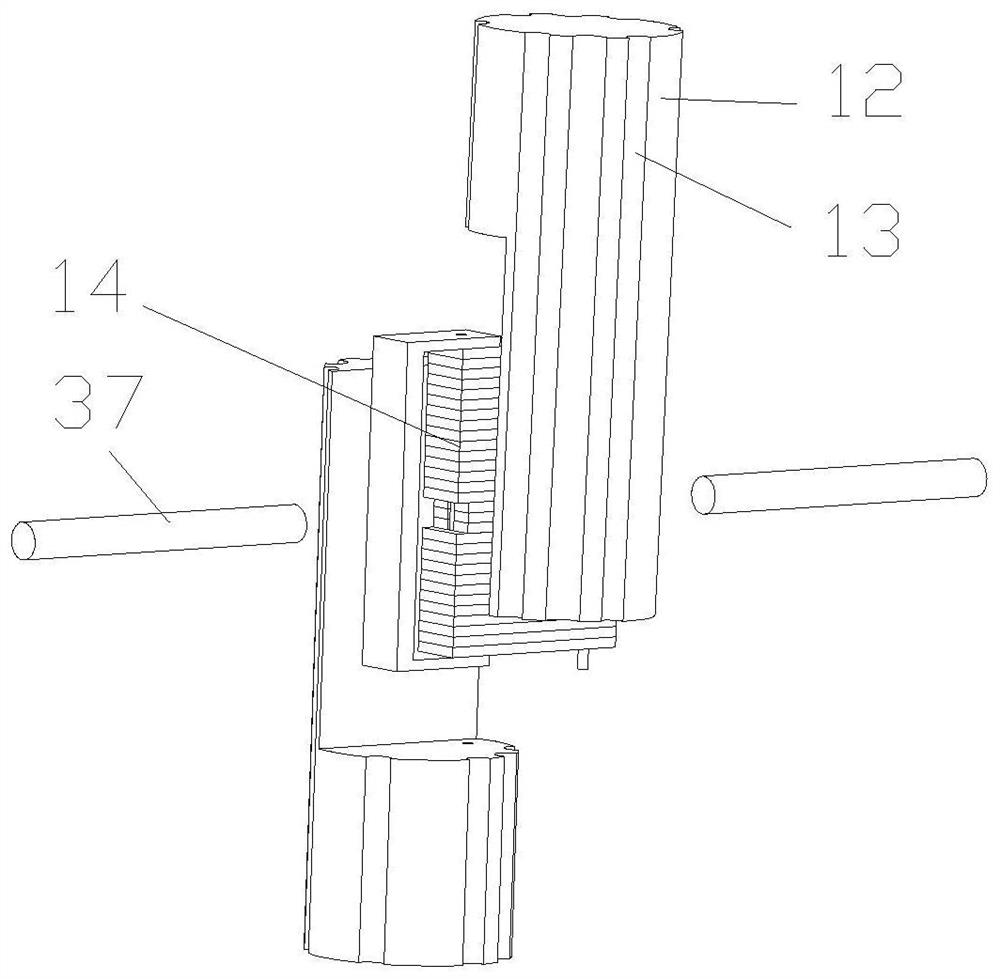

[0057] see Figure 1 to Figure 8 , the present embodiment discloses a kind of equipment used in the method of preparing a diffusion sample for measuring the diffusion of a metal melt by a screw-propelled shearing unit method, comprising a vacuum chamber 1, an interlayer is arranged in the body wall of the vacuum chamber 1, and a vacuum There are water inlet 2 and water outlet 3 arranged up and down on the side wall of the chamber 1. The water inlet 2 and the water outlet 3 are respectively connected to the chiller 4 through water pipes, and the chiller 4 is connected to the interlayer of the vacuum chamber 1 through the water inlet 2. Into the circulating coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com