Steam-cured ultra-high-performance concrete for prefabricated bridge deck slab and rapid design and optimization method for mix proportion of steam-cured ultra-high-performance concrete

A technology with ultra-high performance and optimization method, applied in chemical instruments and methods, bridge construction, bridges, etc., can solve the problem of increasing the time cost and economic cost of engineering application, increasing the design difficulty due to the fluctuation of the value, and insufficient adaptability of the construction site, etc. problem, to achieve the effect of universality, easy large-scale production and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

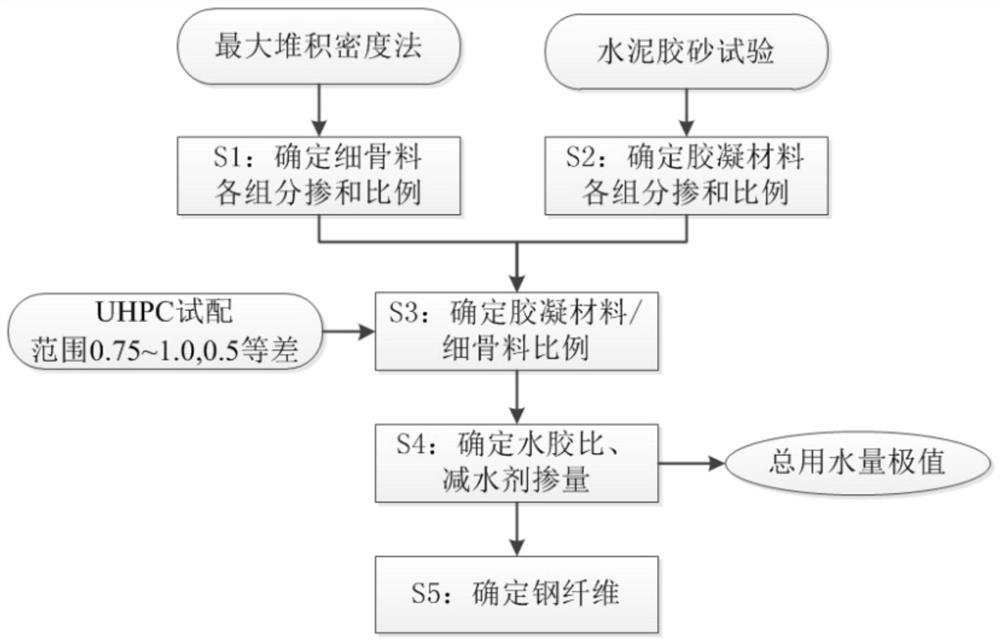

[0033] The "progressive layered filling optimization method" includes the following steps: firstly, the maximum bulk density method is used to determine the blending ratio of fine aggregate, and according to the type of fine aggregate supplied (such as A, B, and C), first, according to A +B to determine the optimal blending ratio of A and B with a ratio difference of 0.05, and then determine the optimal blending ratio of the A / B mixture to C according to the composite stacking of the A / B optimal blend ratio mixture +C at a ratio difference of 0.05, thus Determine the optimal blending ratio of A+B+C; the second step is to prepare the cement mortar test block to determine the blending ratio of each component of the cementitious material, first determine the blending ratio of cement and silica fume, and then according to the basic requirements of workability , on the premise of not reducing the strength, determine the blending ratio of microbeads; the third step is to determine th...

Embodiment 2

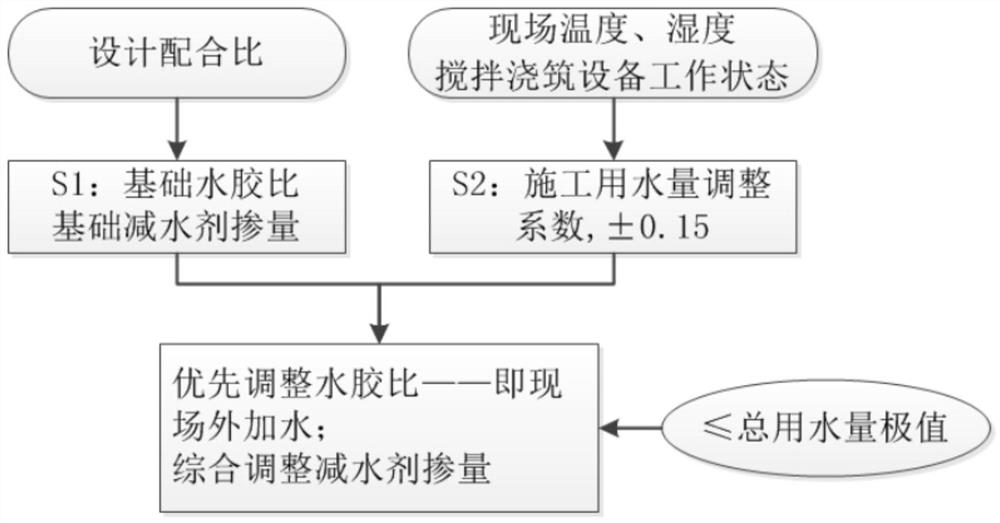

[0035] "On-site optimization method based on total water consumption" includes the following steps: first determine the design mix ratio and the extreme value of total water consumption, the total water consumption includes water added and water in water reducer; secondly determine the site ambient temperature, humidity and According to the working state of the mixing equipment, determine the adjustment coefficient of the total water consumption ±15% according to the state of the mixture. This step ensures that the water consumption is ≤ the extreme value of the total water consumption, and comprehensively adjusts the water-binder ratio and the amount of water reducing agent to obtain the optimal construction. mix ratio.

Embodiment 3

[0037] The optimal mix ratio of steam-cured ultra-high performance concrete for prefabricated slab determined based on the method of Examples 1 and 2 is as follows:

[0038] The steam-cured ultra-high performance concrete for prefabricated panels is composed of cementitious materials, fine aggregate, steel fibers, water reducing agent and water, and the cementitious materials are composed of cement, silica fume and microbeads. In parts by mass, the UHPC includes 100 parts of cementitious material, 100-130 parts of fine aggregate, 17-21 parts of steel fiber, 2.0-3.0 parts of water reducing agent, and 15-19 parts of water; The proportions of the components are 70-78 parts of cement, 15-20 parts of silica fume, and 2-15 parts of glass microbeads. The cement is made of ordinary Portland cement with the label of 52.5; the silica fume is made of BK93 semi-encrypted type, and the particle size is divided into 1-20 μm, of which the particle size is between 5-15 μm, accounting for more...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com