Method and device for obtaining rigidity of air spring

An air spring and stiffness technology, applied in the field of obtaining air spring stiffness, can solve the problem of no simple, fast, time-saving and labor-saving air spring parameter information, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

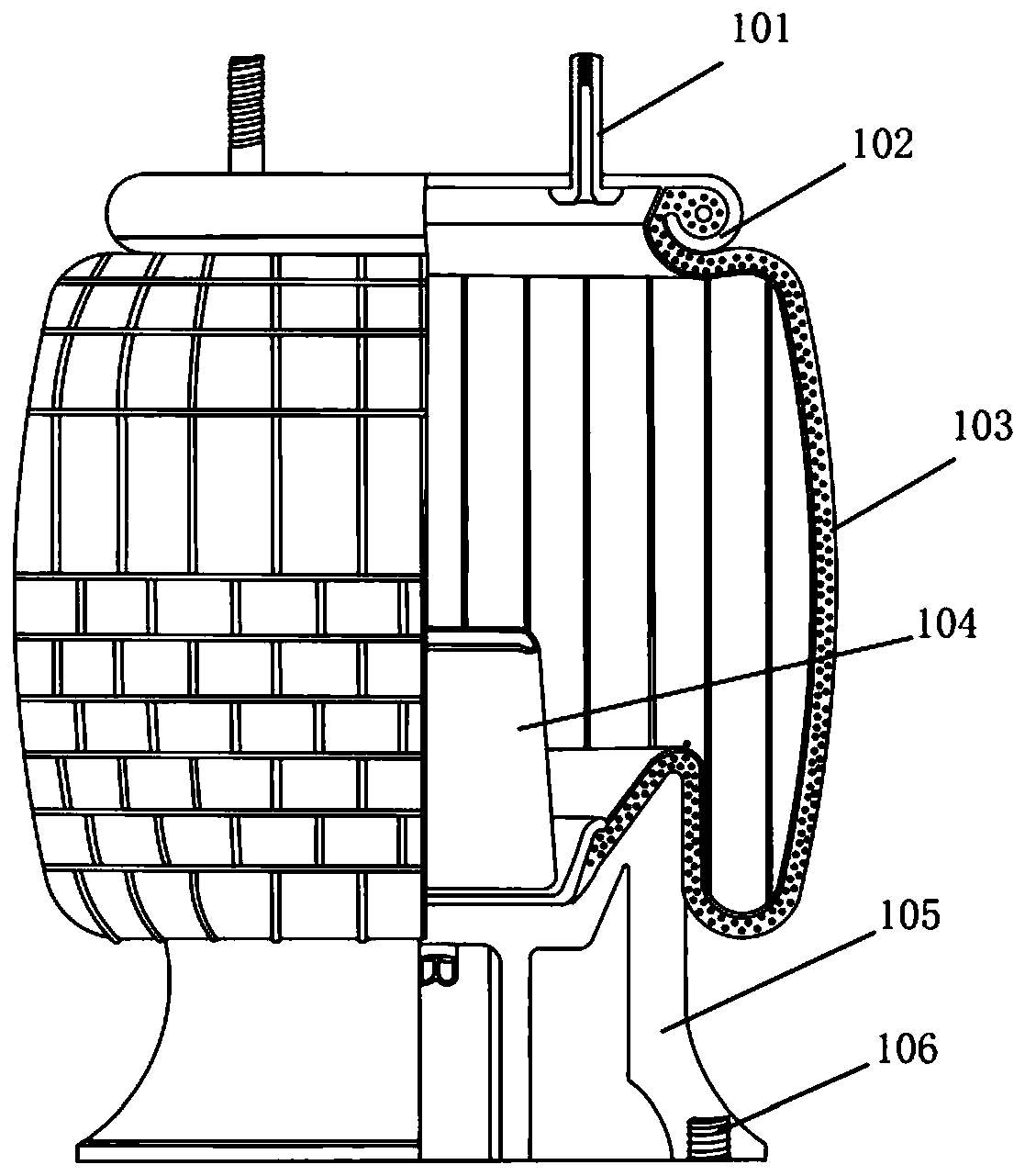

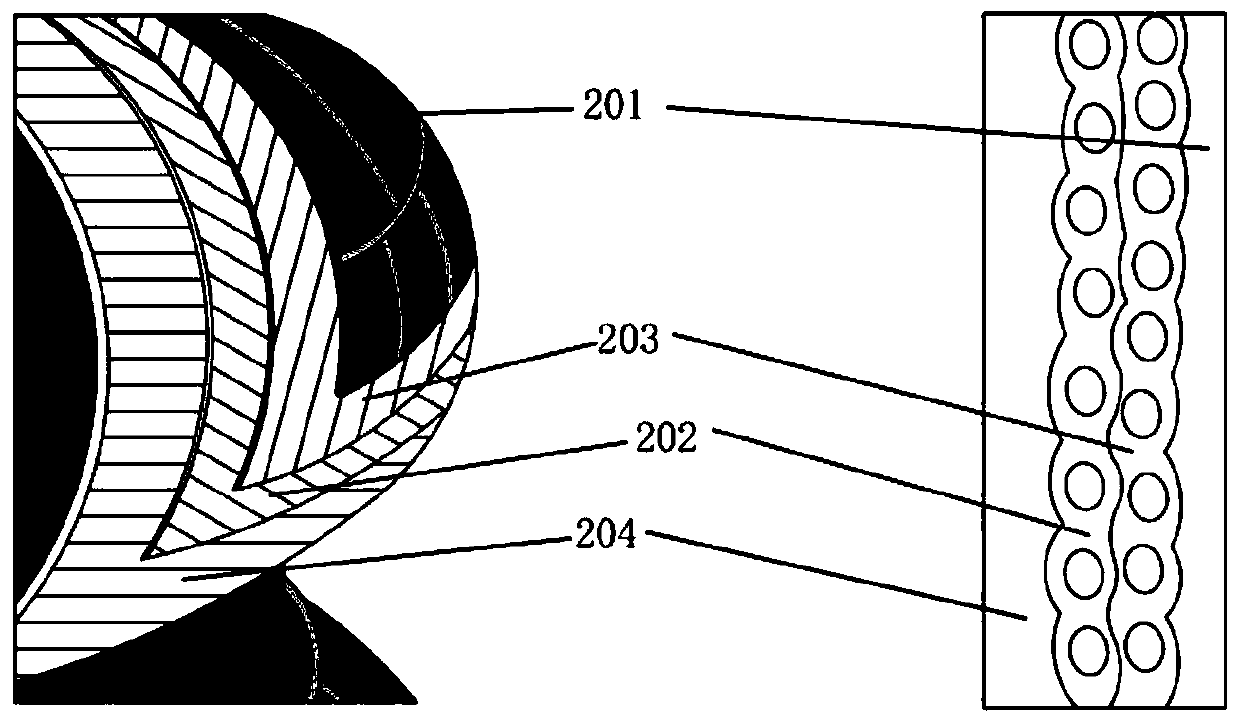

[0089] Such as figure 1 and figure 2 as shown, figure 1 It is a structural schematic diagram of an air spring in this embodiment, figure 2 It is a schematic diagram of the structure and composition of the rubber airbag of the air spring in this embodiment. The air spring is a fluid-solid coupling system composed of fluid (compressed air inside) and solid (rubber airbag, upper cover, piston, etc.). The air spring includes: a stud 101 , an upper cover plate 102 , a rubber air bag 103 , a buffer block 104 , a piston 105 and a screw hole 106 . The rubber airbag mostly adopts a 2-layer ply structure, and its structure is as follows: figure 2 As shown, it mainly consists of outer cover rubber 201, first ply layer 202, second ply layer 203 and inner lining rubber 204. The non-linear characteristics of the rubber airbag structure and constituent materials make the airbag have strong nonlinear characteristics. .

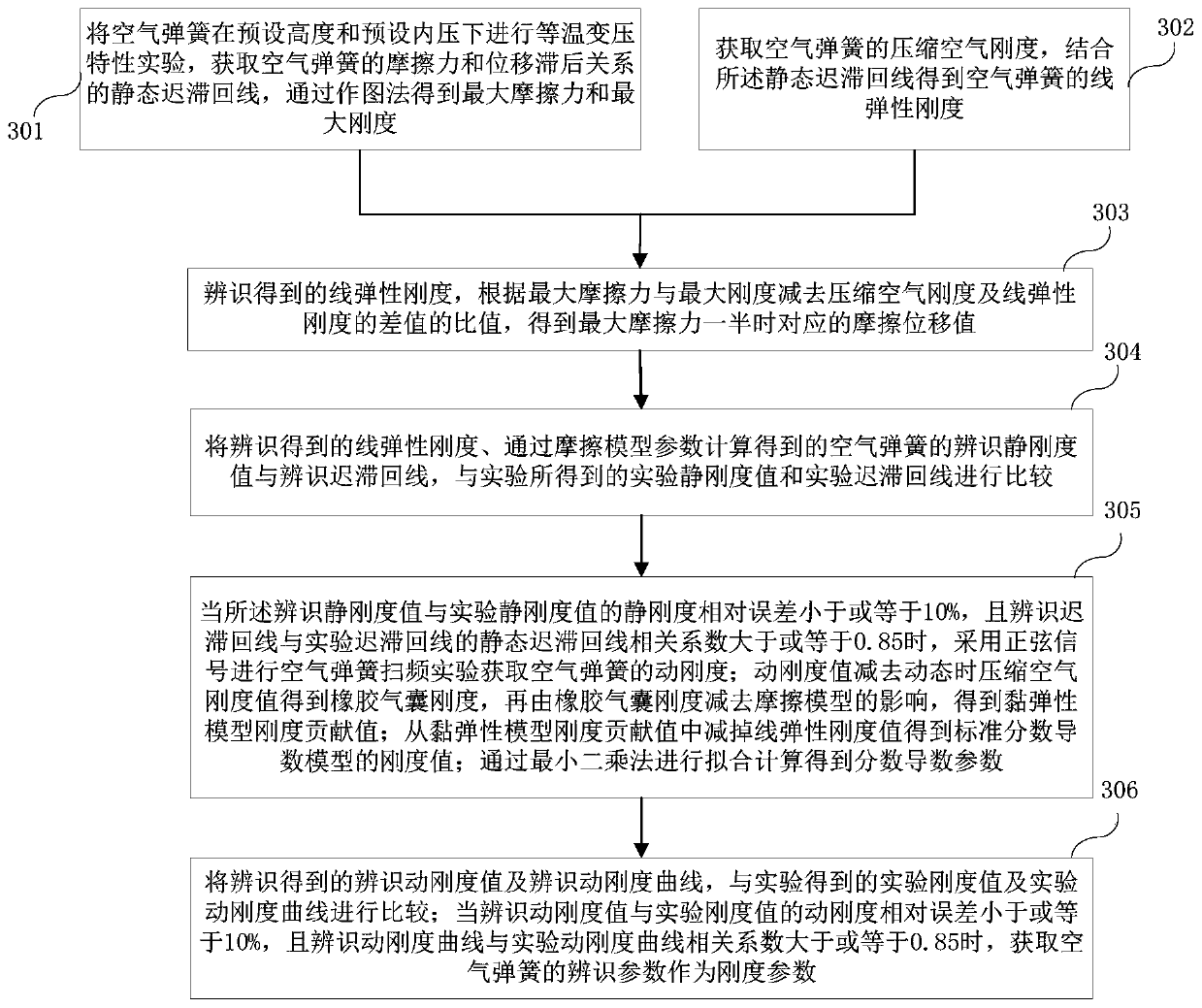

[0090] Such as image 3 As shown, it is a schematic flow chart...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com