Method for determining optimal foaming condition of modified asphalt through viscosity

A technology for modifying asphalt and viscosity, which is applied in the field of determining the optimal foaming conditions of foamed asphalt, can solve problems such as the inability to fully reflect the viscosity, and achieve the effects of reducing the amount of experiments, lowering the mixing temperature, and improving the consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] specific implementation plan

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

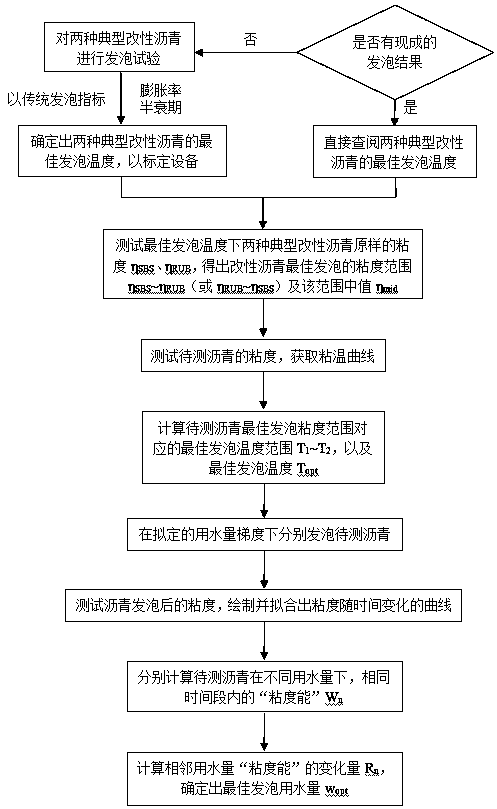

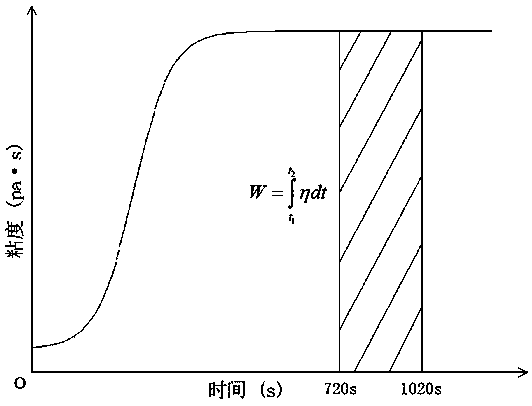

[0029] Such as figure 1 Shown is a schematic flow chart for determining the optimum foaming conditions of modified asphalt by viscosity. The determination of the optimum foaming conditions of modified asphalt is mainly divided into two steps: the determination of the optimum foaming temperature and the optimum water consumption. Firstly, the optimal foaming temperature is directly determined through the viscosity-temperature curve; secondly, the change rate of viscosity energy between different water consumptions is calculated through the foaming test, and then the optimal water consumption is determined.

[0030] This embodiment is a method for determining the best foaming conditions of unknown modified asphalt, including the following steps:

[0031] (1) Query the existing foaming results of the foaming equipment: the optimal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com