Patents

Literature

99results about How to "Lower mixing temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

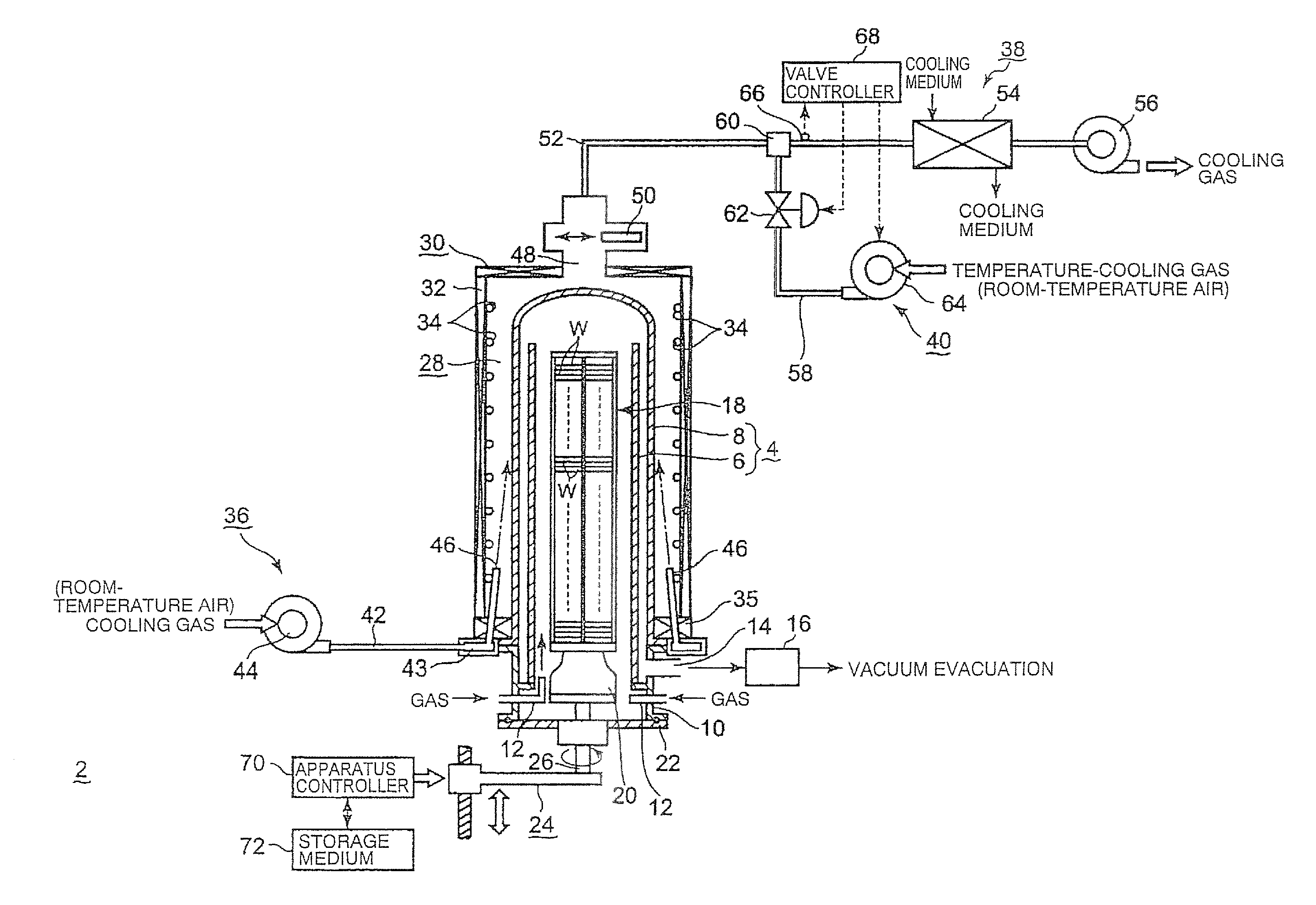

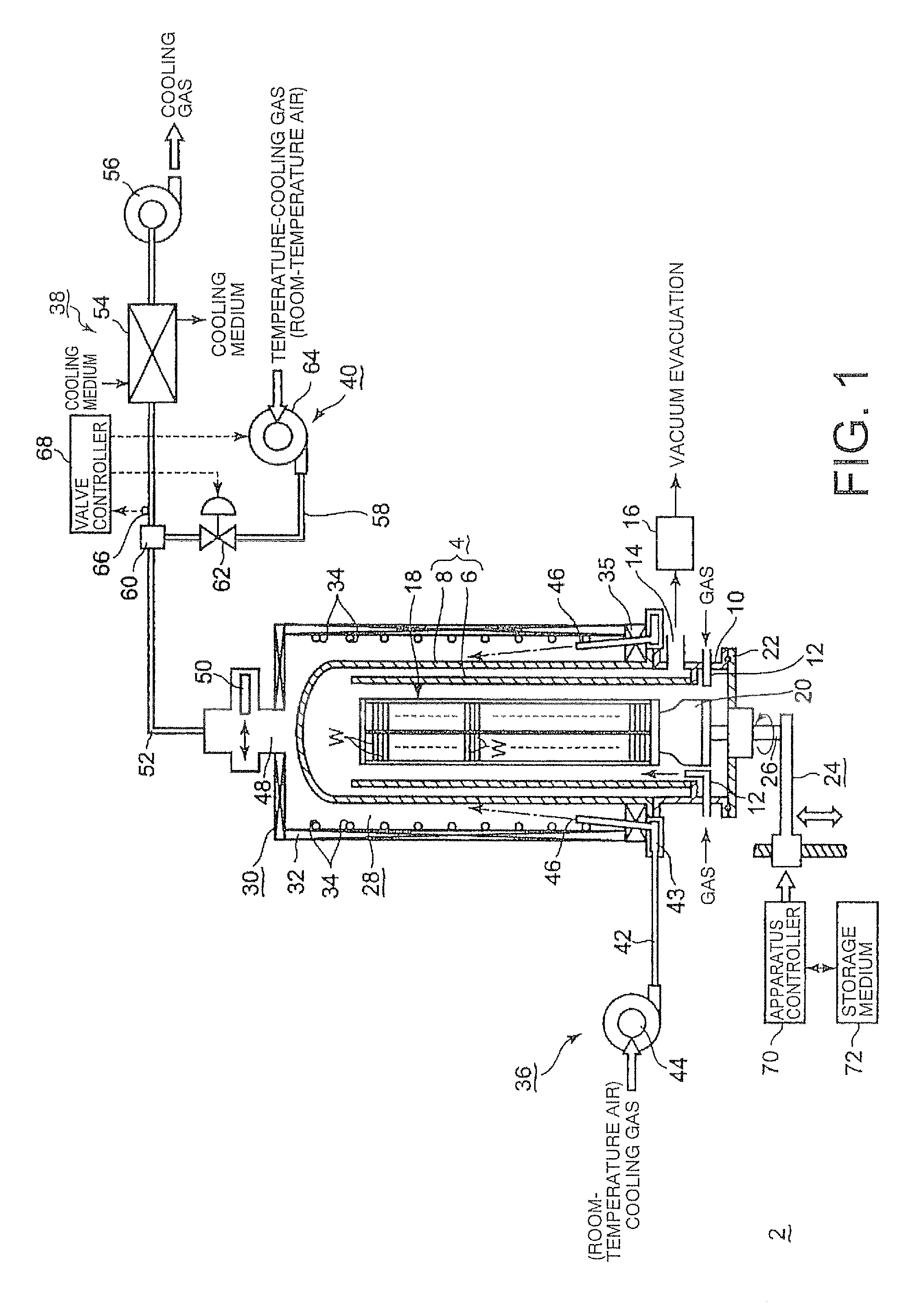

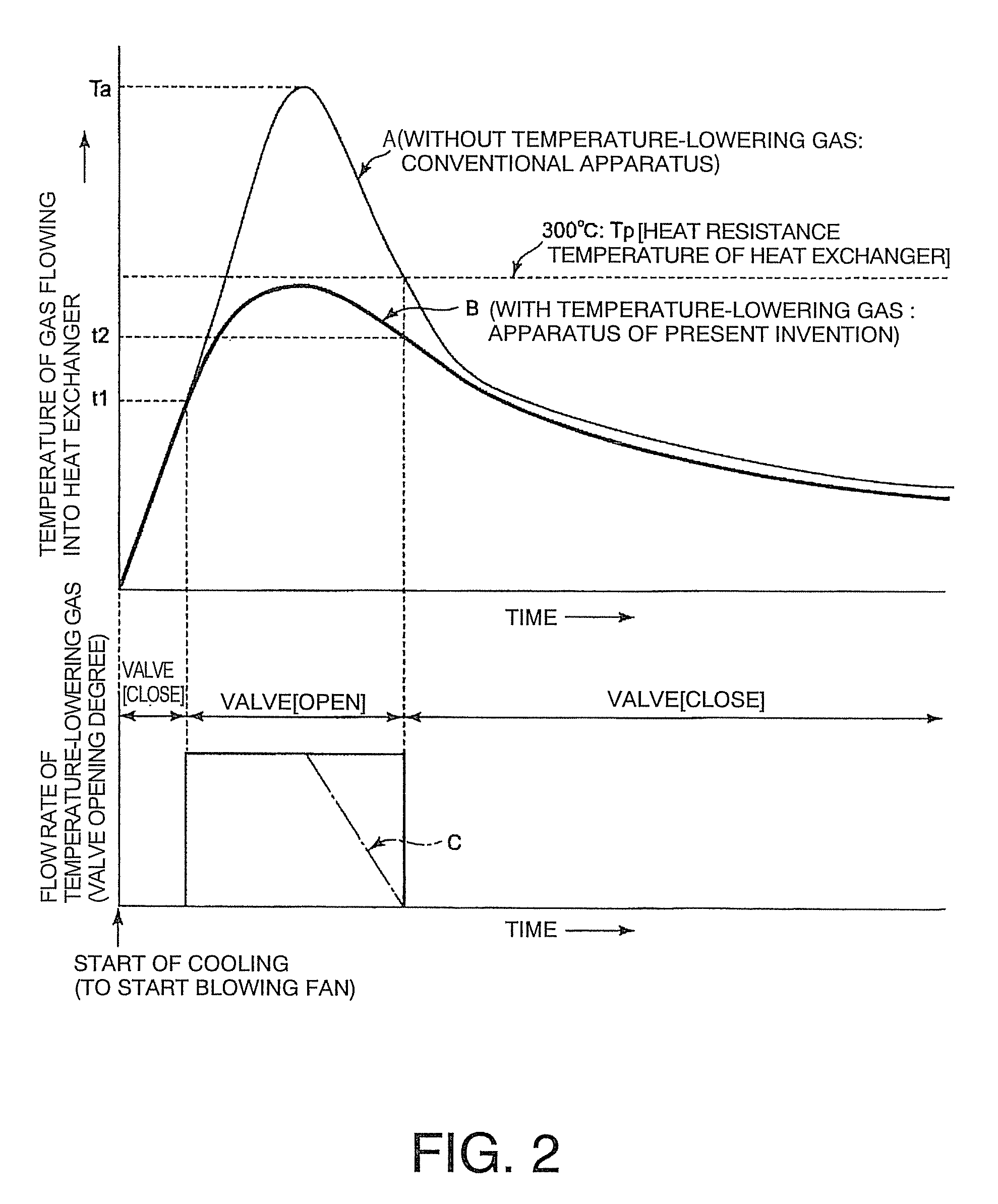

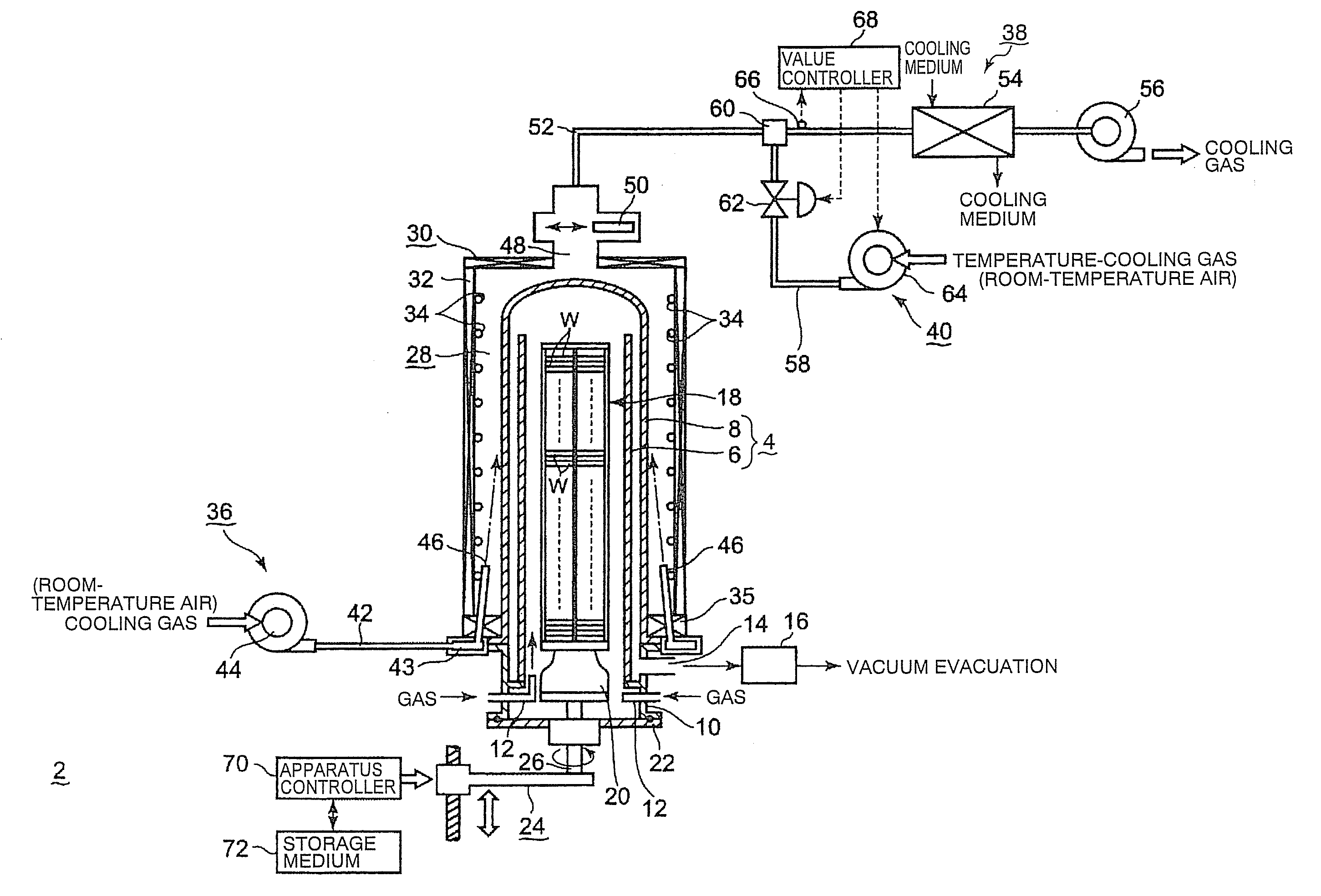

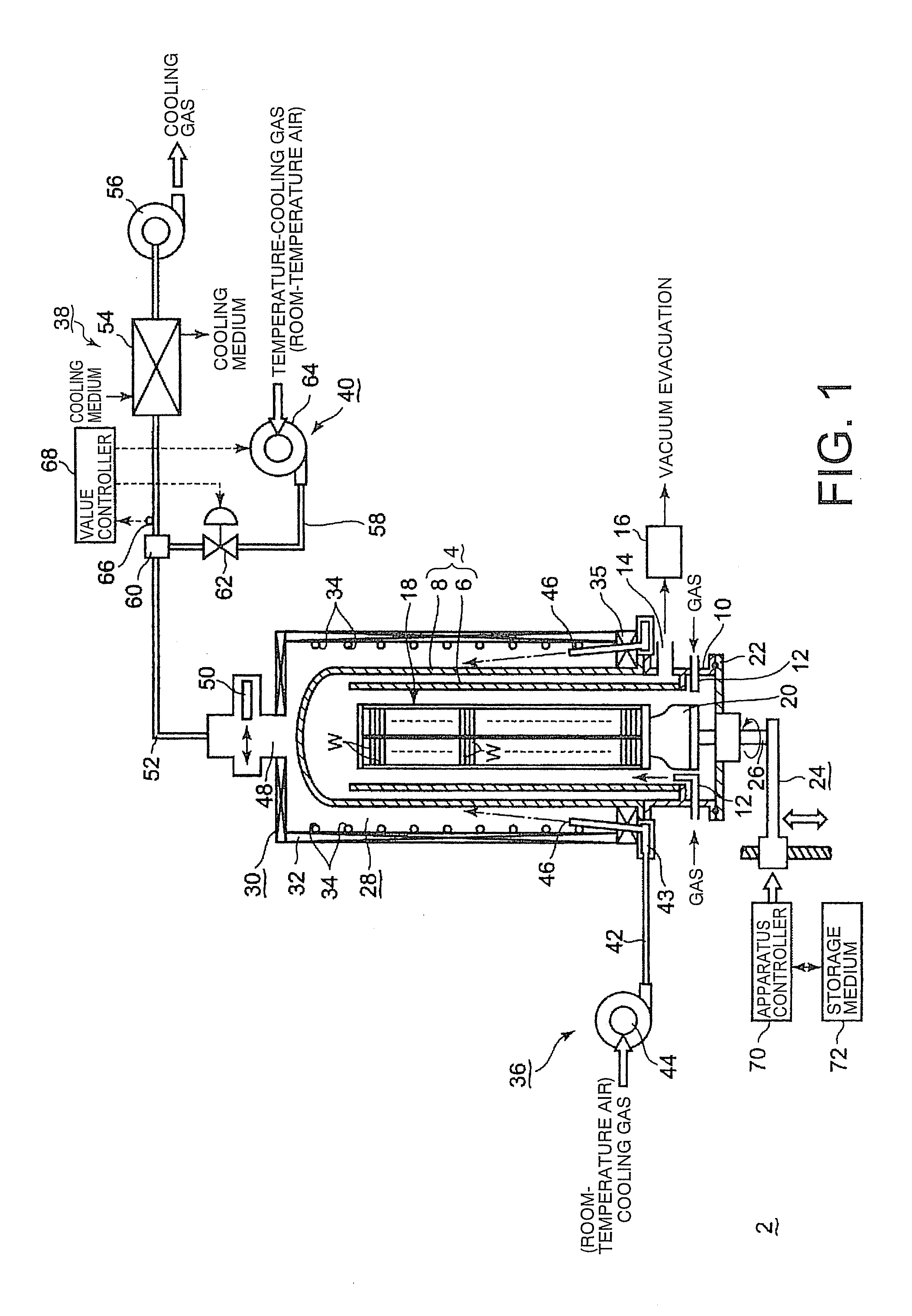

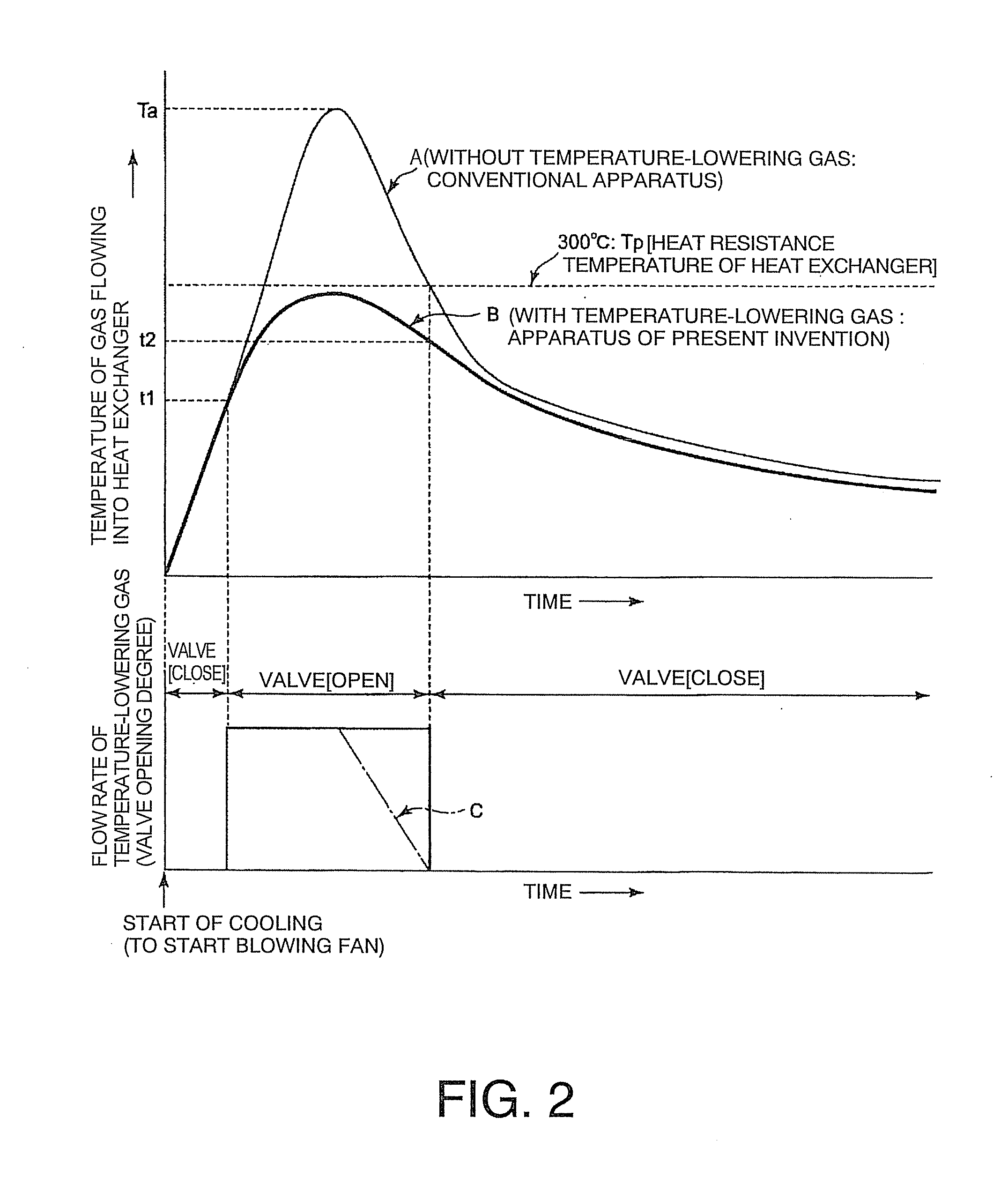

Thermal processing apparatus and cooling method

InactiveUS9099505B2Efficient solutionLow heat resistanceAfter-treatment apparatusSemiconductor/solid-state device manufacturingProcess engineeringHeating furnace

A thermal processing apparatus including: a cylindrical processing vessel; a support unit to be loaded into and unloaded from the vessel; and a heating furnace surrounding an outer periphery of the vessel, with a cooling space therebetween. The furnace is connected to a cooling-gas introduction unit, including a gas introduction passage to which a blowing fan is connected, for introducing a cooling gas into the cooling space during a temperature lowering operation after a thermal process. The furnace is connected to a cooling-gas discharge unit, including a heat exchanger, a suction fan, and a gas discharge passage, for discharging the cooling gas of a raised temperature from the cooling space. Connected to the gas discharge passage at a position upstream of the heat exchanger is a temperature-lowering gas introduction unit for introducing a temperature-lowering gas to the cooling gas of a raised temperature so as to lower its temperature.

Owner:TOKYO ELECTRON LTD

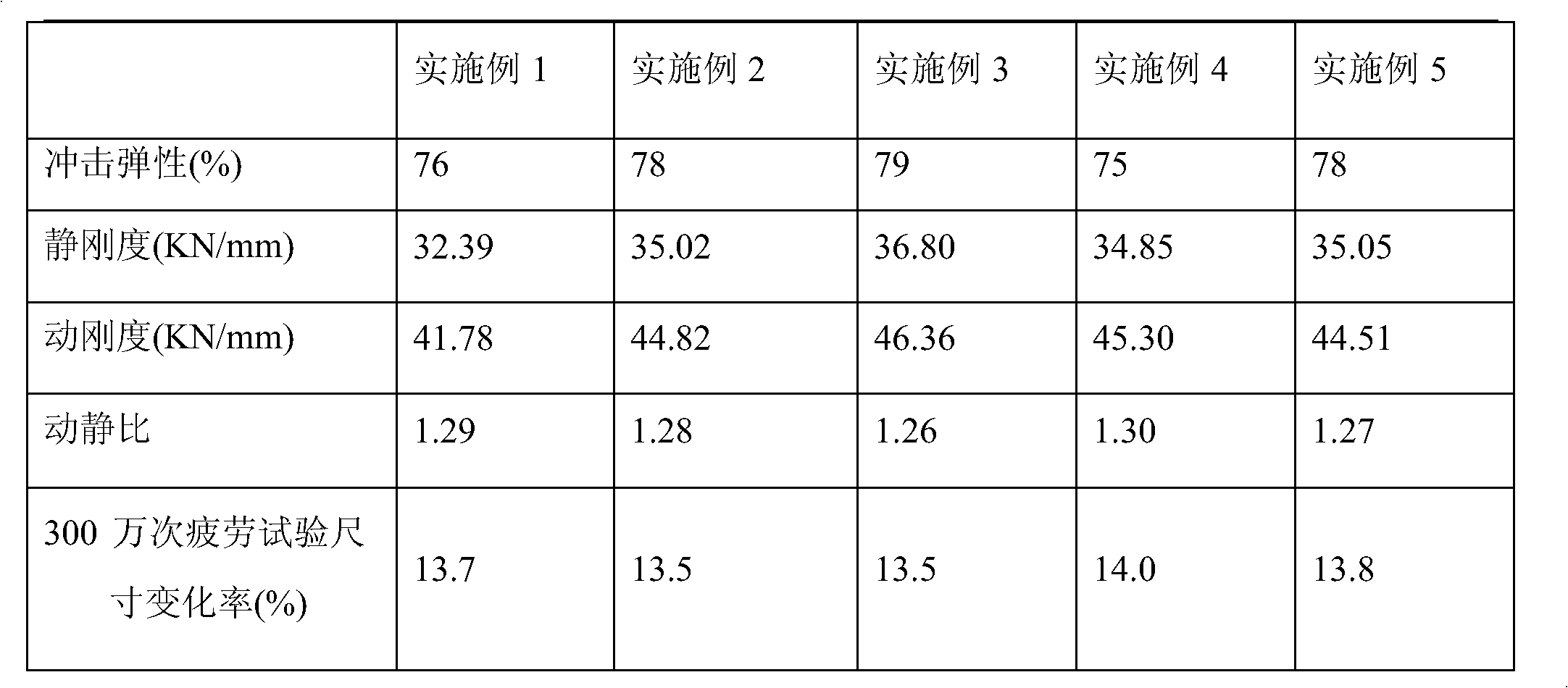

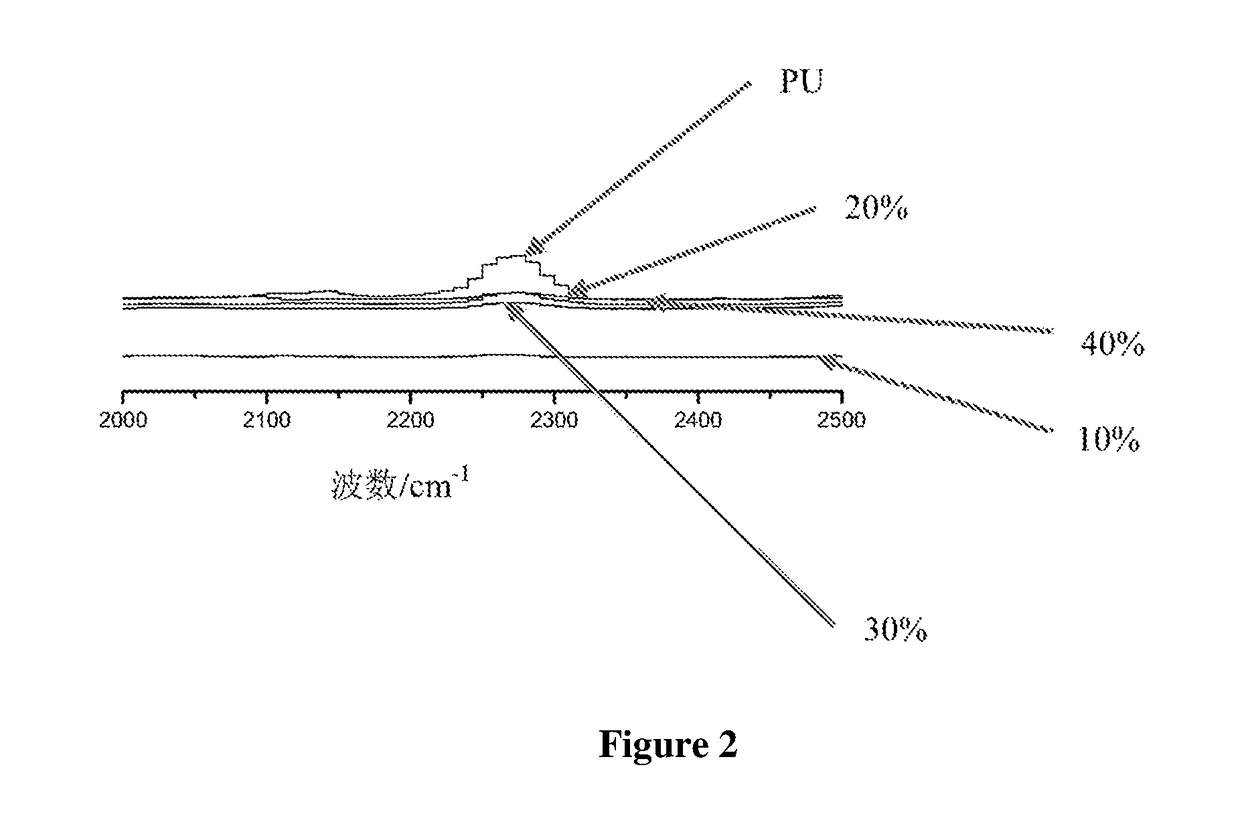

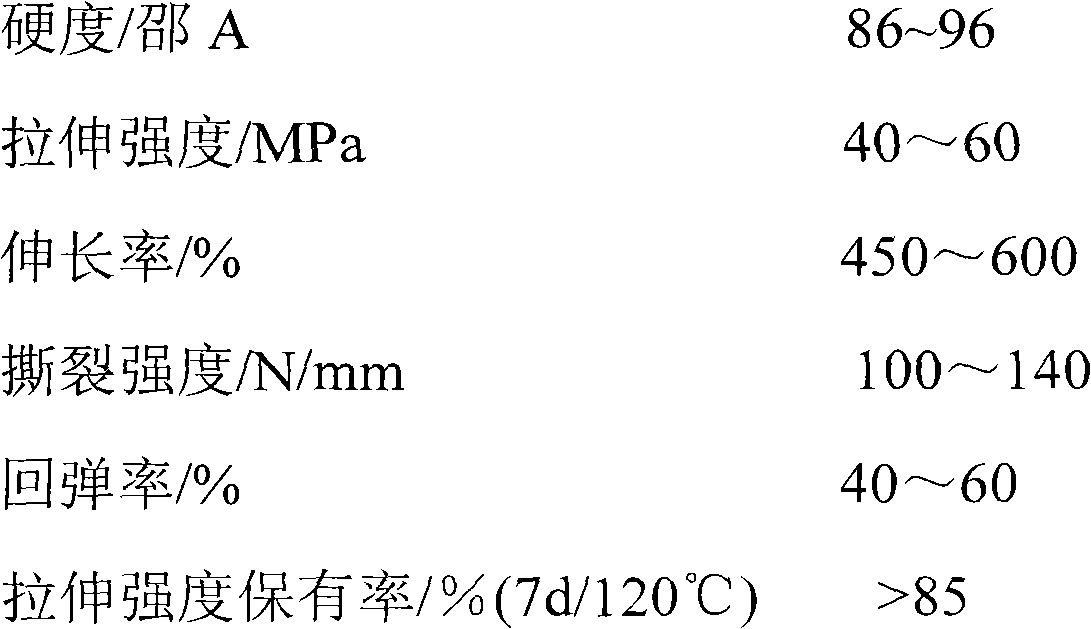

Microporous polyurethane elastomer compound with excellent dynamic performance and preparation method thereof

The invention belongs to the field of polyurethane elastomer synthesis, and particularly relates to a preparation method of a microporous polyurethane elastomer compound with excellent dynamic performance. The compound is characterized in that the compound consists of a polyol mixture component and a modified isocyanate component. The preparation method has the advantages as follows: (1) a quasi-prepolymer method is adopted to process microporous polyurethane elastomer material, the two components has similar viscosity and similar mass mixing ratios, the material mixing temperature is low, the materials are easy to mix evenly, the process control condition is simple, and the operation is easy; and (2) the microporous polyurethane elastomer material prepared by using the compound disclosed by the invention has the advantages that a ratio of dynamic stiffness to static stiffness is smaller than or equal to 1.35, the impact elasticity is larger than or equal to 75 percent, the appearance is not damaged after 3,000,000 times of fatigue tests and the dimensional change rate is smaller than or equal to 20 percent, so that the compound can be used for preparing high-performance products such as damping cushion blocks of high-speed railways and damping elements of automobiles.

Owner:SHANDONG INOV POLYURETHANE

A kind of warm mix asphalt additive and preparation method thereof

InactiveCN102268189ALower mixing temperatureClimate change adaptationBuilding insulationsMelamine formaldehydeReaction temperature

A warm-mix asphalt additive machine preparation method, the additive is formed by reacting the following components in parts by weight: 4-15 parts of alkoxysilane, 1-8 parts of polyether, 0-1 part of melamine formaldehyde resin, and 0 parts of acid catalyst -1 part, 0-1 part of alkali catalyst, 2-10 parts of deionized water, 30-100 parts of solvent; the preparation method comprises the following steps: (1) adding a quantitative amount of solvent and Alkoxysilane, heated to 80°C; (2) Add a mixture of acid catalyst, base catalyst, and deionized water, and react at a constant temperature of 80°C for 90 minutes; (3) Heat up to 100°C, condense and reflux for 120 minutes, and collect about 55ml of distillate; ( 4) Add an acid catalyst and a certain amount of polyether into the flask, heat up the esterification reaction for 180 minutes; (5) evacuate, condense and reflux for 30 minutes, cool down to room temperature, add a certain amount of melamine formaldehyde resin and stir evenly, add an appropriate amount of alkali catalyst to adjust the pH = 8 or so, the finished product is obtained.

Owner:杭州市城市建设科学研究院

Aerated food products and methods for producing them

InactiveUS20080213453A1Low efficacyEffectivenessMilk preparationFrozen sweetsSURFACTANT BLENDHydrophobin

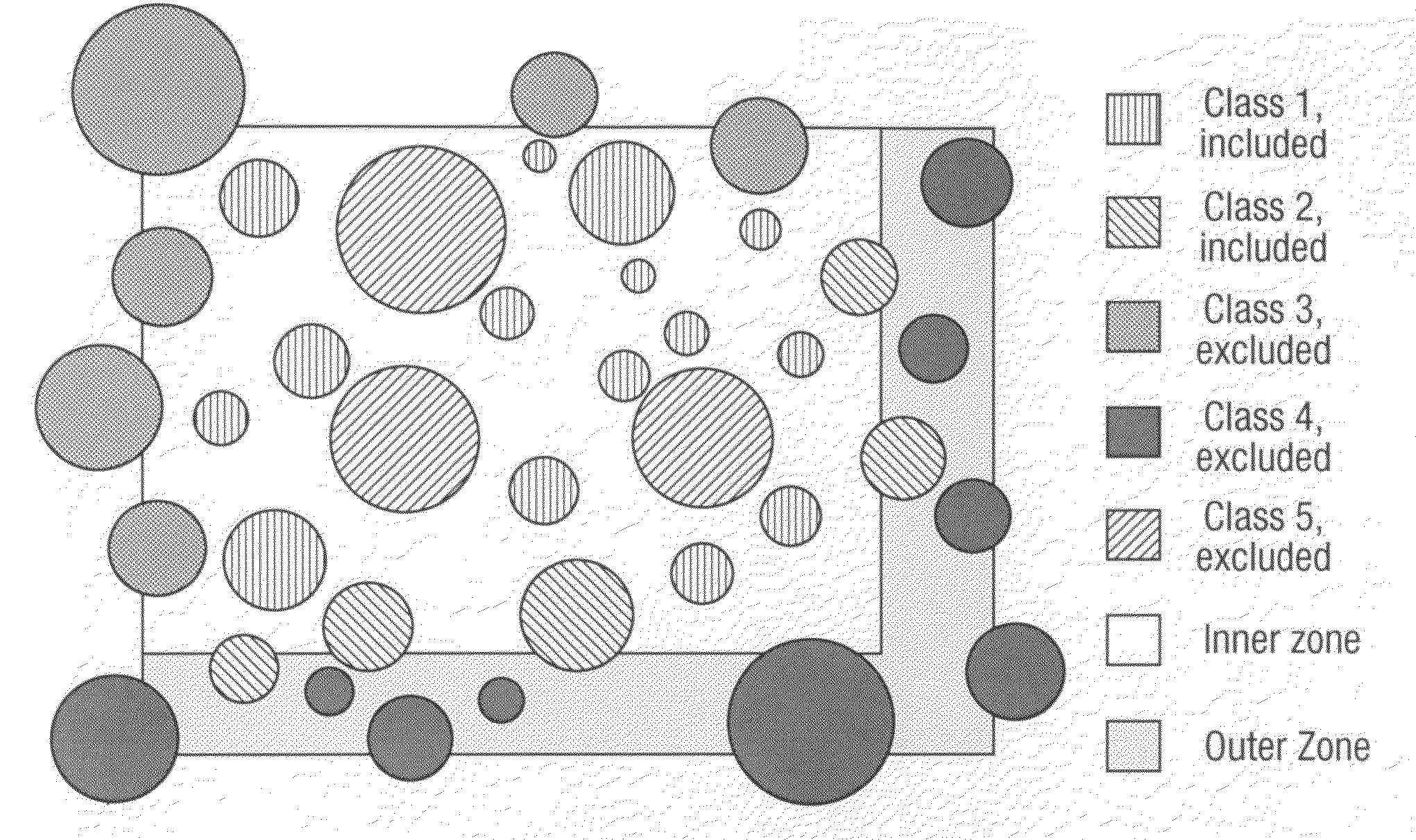

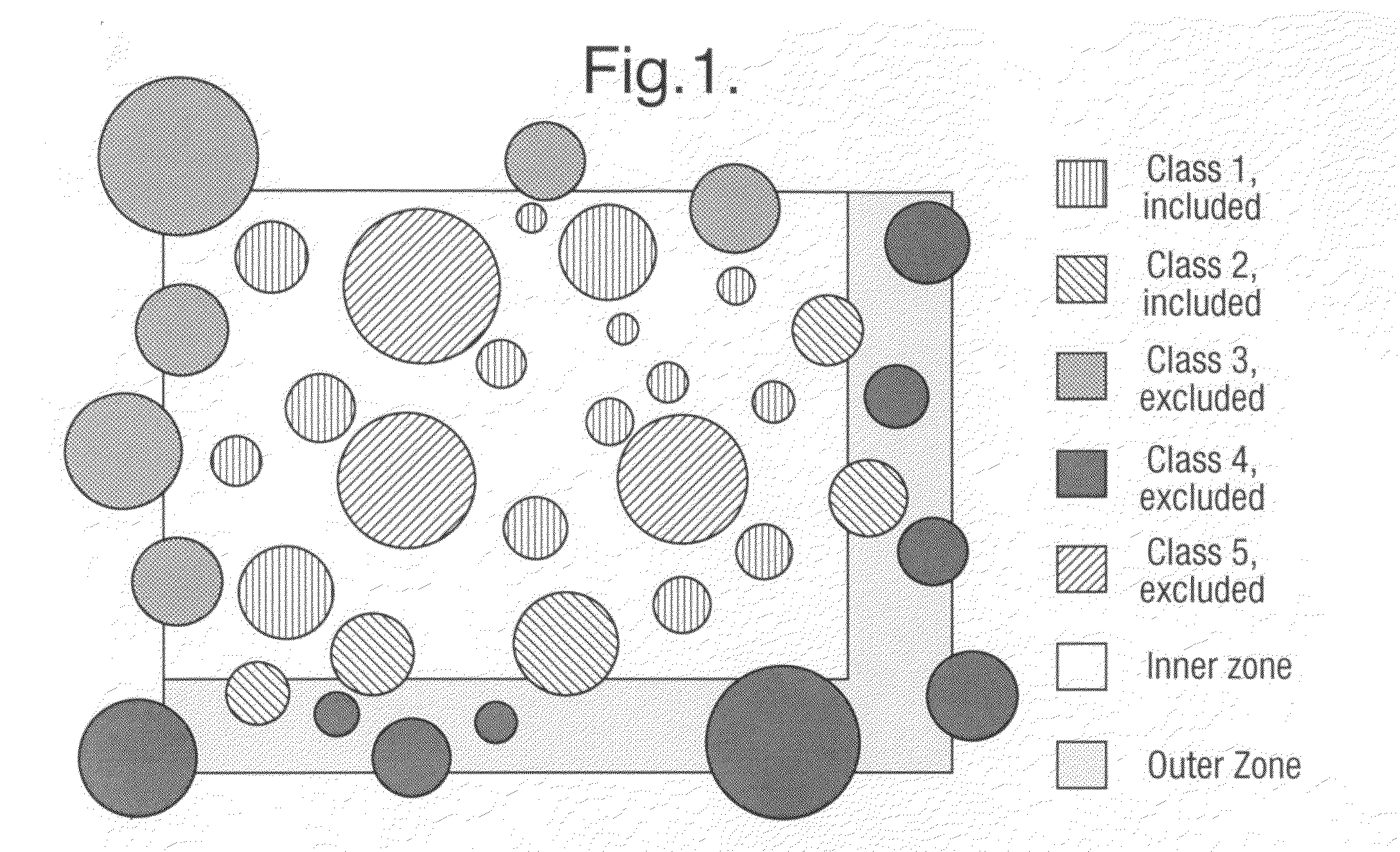

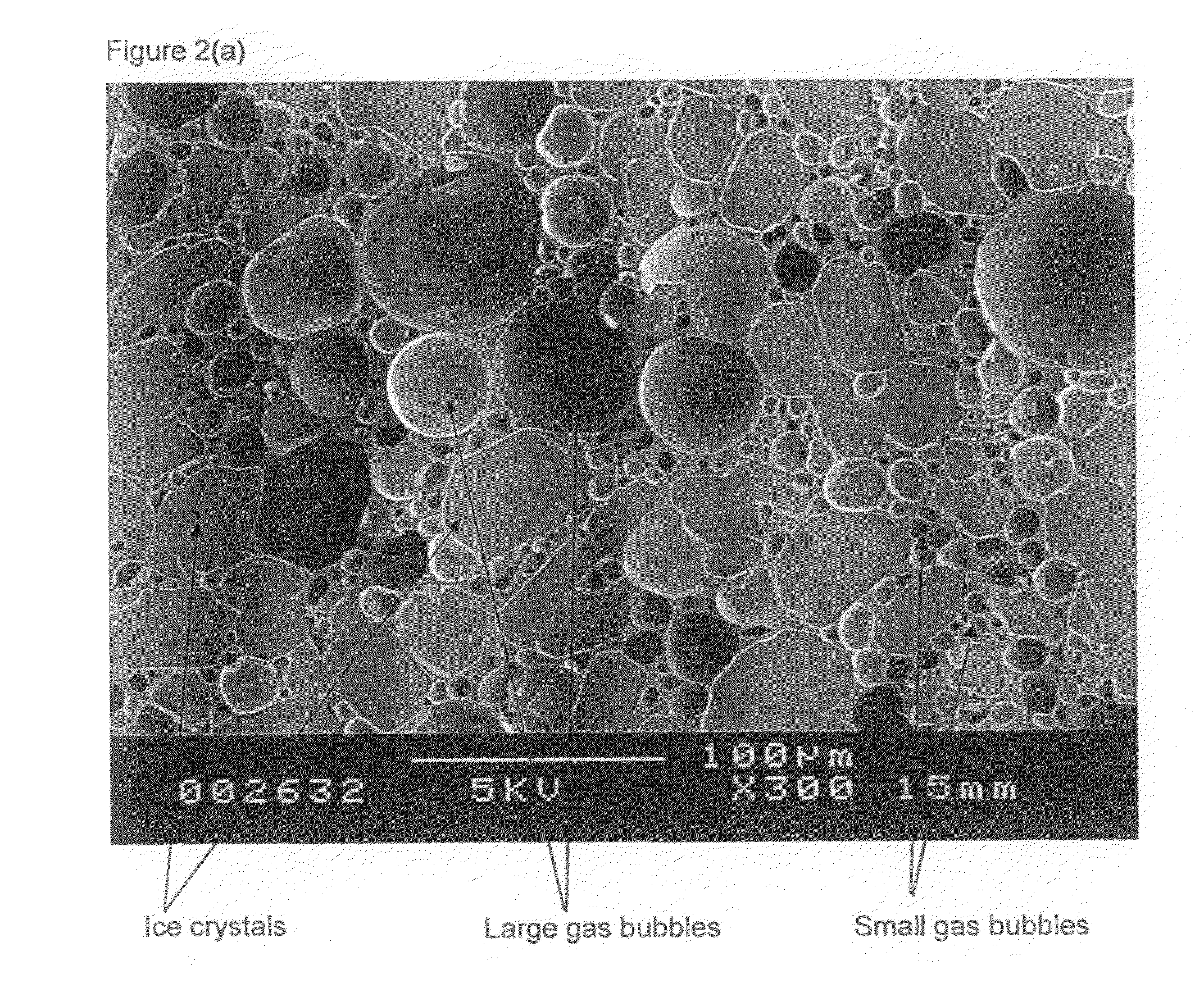

An aerated food product comprising hydrophobin and a surfactant is provided, the aerated food product containing a population of gas bubbles, wherein at least 65% of the gas bubbles have a diameter of less than 20 μm. Processes for producing such an aerated food product are also provided.

Owner:CONOPCO INC D B A UNILEVER

Method for forming cellulose

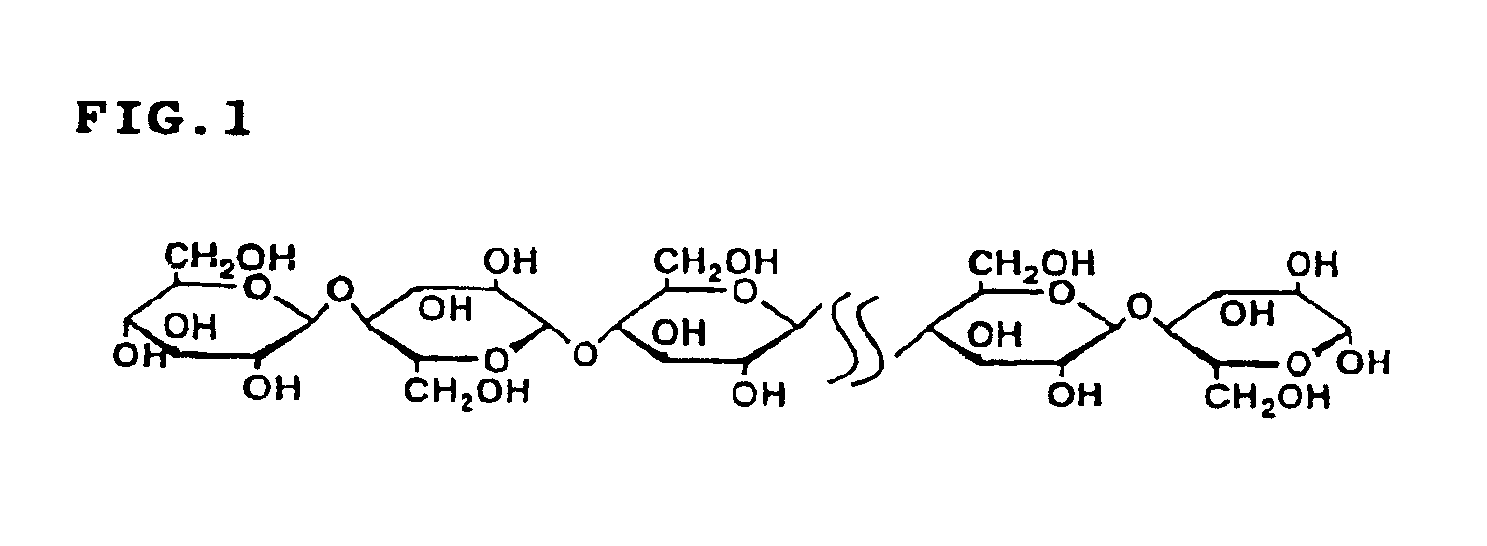

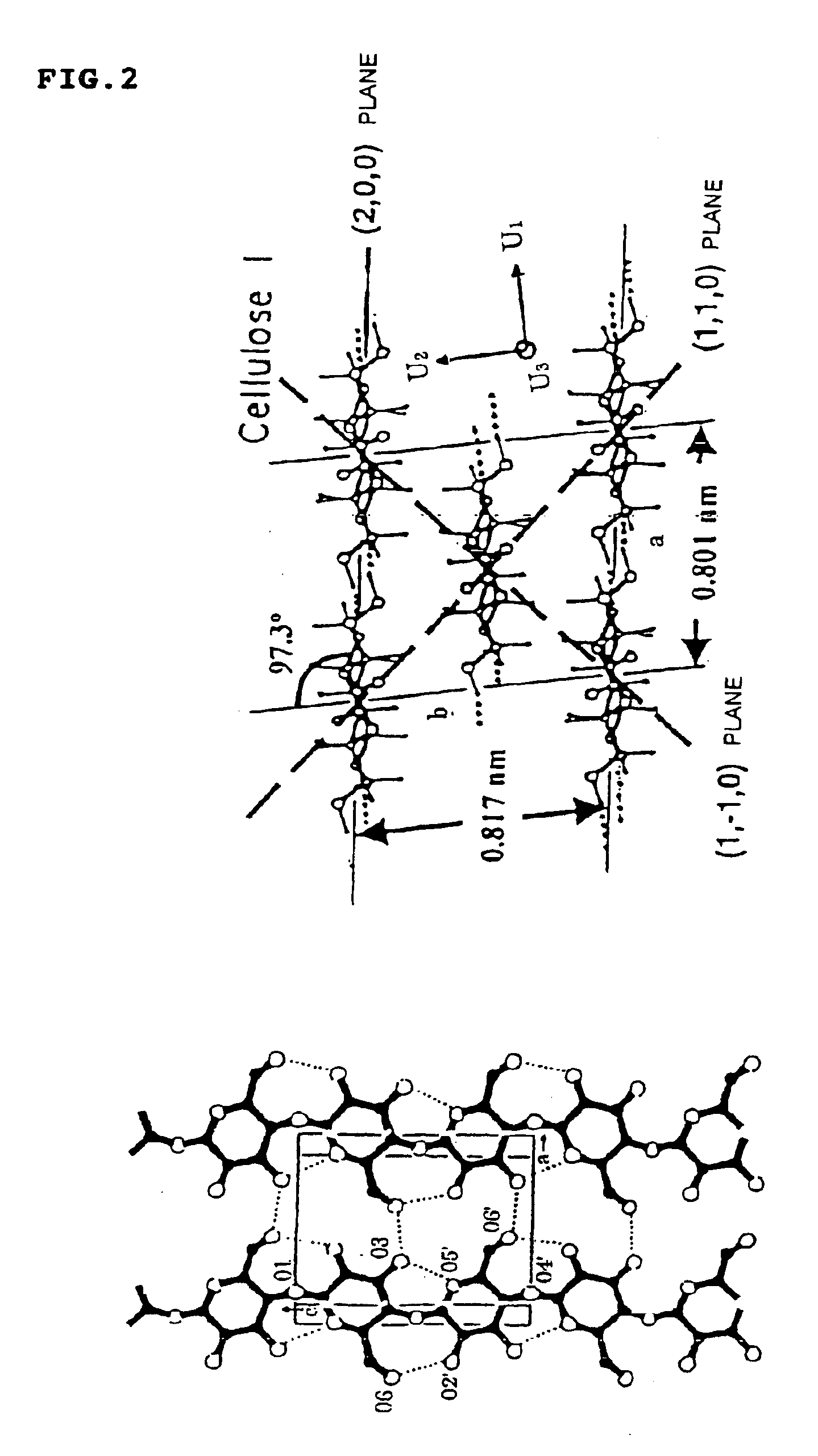

InactiveUS6921820B2Raise temperature of mixtureLow mixture temperaturePretreatment with water/steamSugar derivativesSolventCellulose

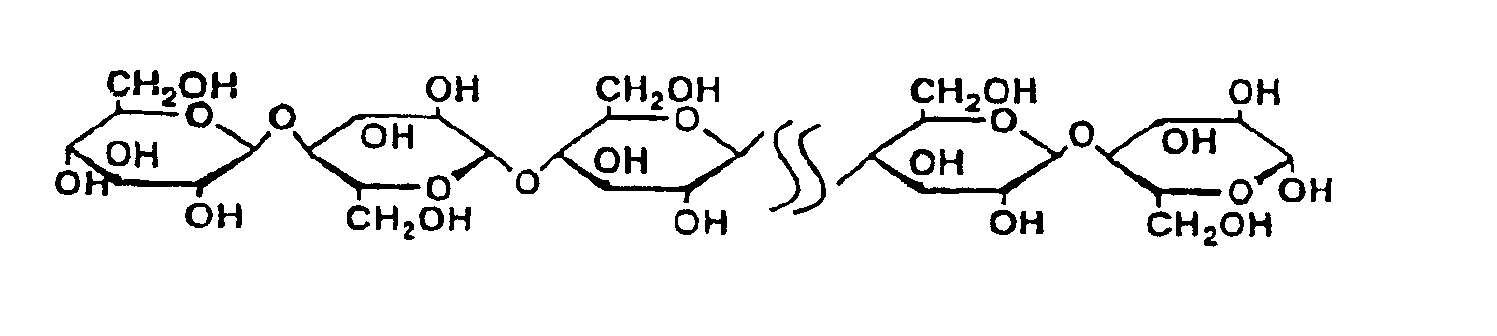

A method for forming II-type cellulose, which comprises introducing together a slurry having water and a I-type cellulose dispersed therein and water in the state of high temperature and high pressure to a tubular reactor (28) contacting the I-type cellulose with a hot water in a supercritical state or subcritical state for a predetermined time in the tubular reactor (28), to thereby cleave a part of the hydrogen bonds in the I-type cellulose and dissolve the I-type cellulose into the water in a supercritical state or subcritical state, cooling a cellulose solution discharged from the tubular reactor (28) in a cooler (30) to room temperature or lower, followed by allowing to stand, to thereby precipitate crystals of II-type cellulose having a molecular weight lower than that of the I-type cellulose, and separating the resultant II-type cellulose from a solvent. The method allows the preparation of pure II-type cellulose by the use of a simple process.

Owner:TOYOTA JIDOSHA KK +1

Polyurethane, modified asphalt and mixture material containing same and pavement structure

InactiveUS20180312437A1High strengthExtended service lifeIn situ pavingsBuilding insulationsHydrogenPolyol

A polyurethane is obtained by continuously reacting a polyurethane prepolymer in an asphalt or asphalt mixture material system under high temperature. The prepolymer is prepared by: adding a polymerization inhibitor, catalyst and isocyanate component in a reaction container, adding a polyol to the reactor while stirring at room temperature under nitrogen, increasing the temperature to 50-80° C., and maintaining the temperature to react for 0.5-6 hours. A polyurethane modified asphalt, a mixture material containing the polyurethane and a polyurethane modified asphalt pavement structure can be prepared. The synthesis condition of the polyurethane is mild, and a secondary reaction with the air and an active hydrogen component in the asphalt can occur during maintenance and formation to further increase the strength of a mixture material. The standard Marshall stability at 60° C. meets the petroleum asphalt requirement, such that a service life of the asphalt pavement can be increased.

Owner:ZHONGLU HI TECH (BEIJING) HIGHWAY TECHNOLOGY CO LTD +1

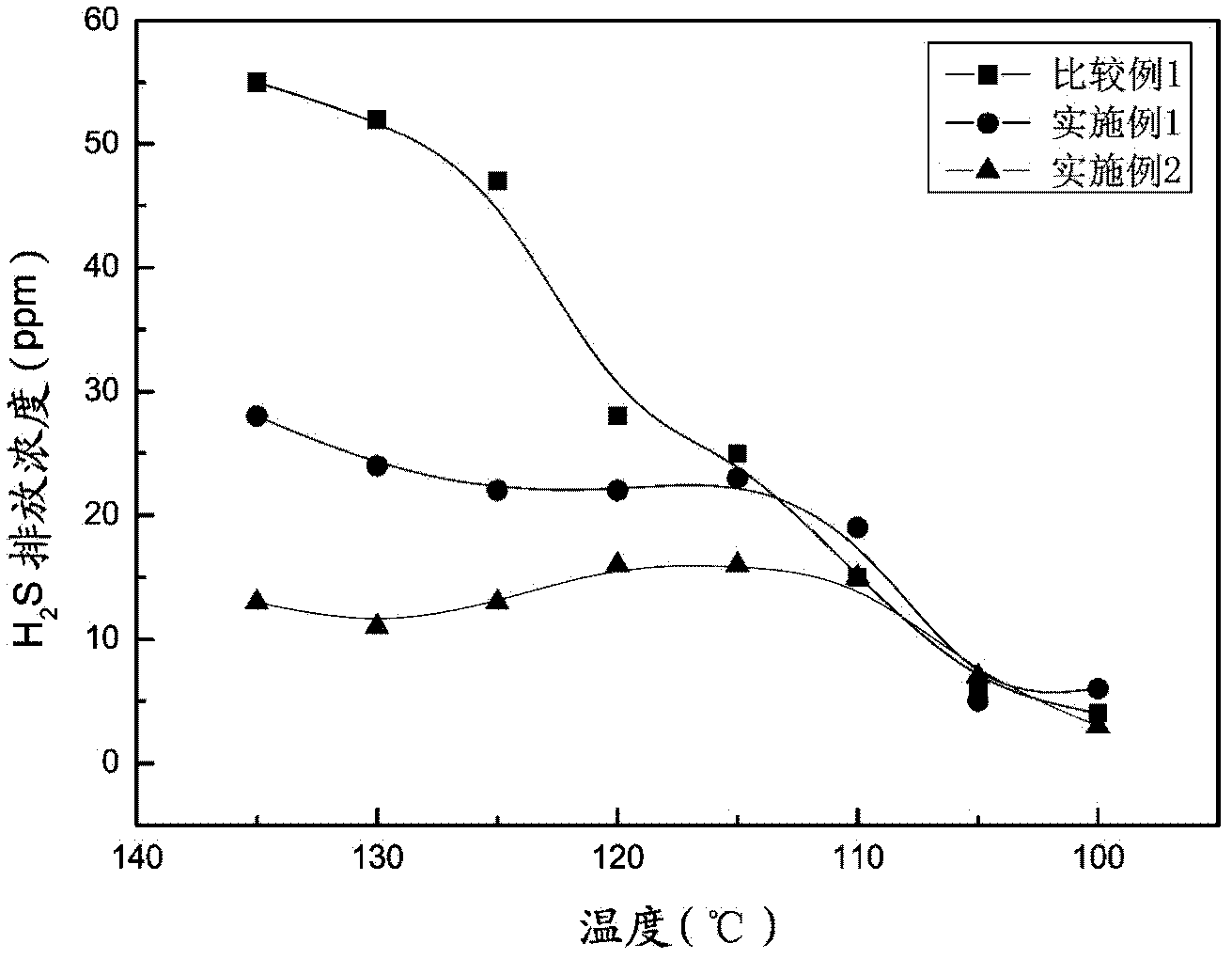

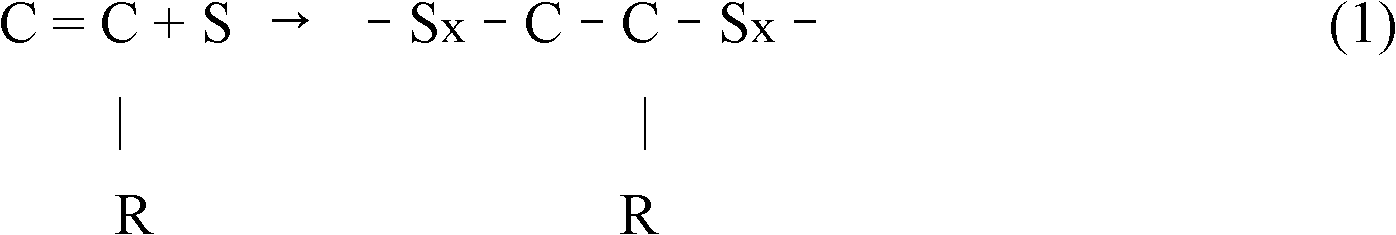

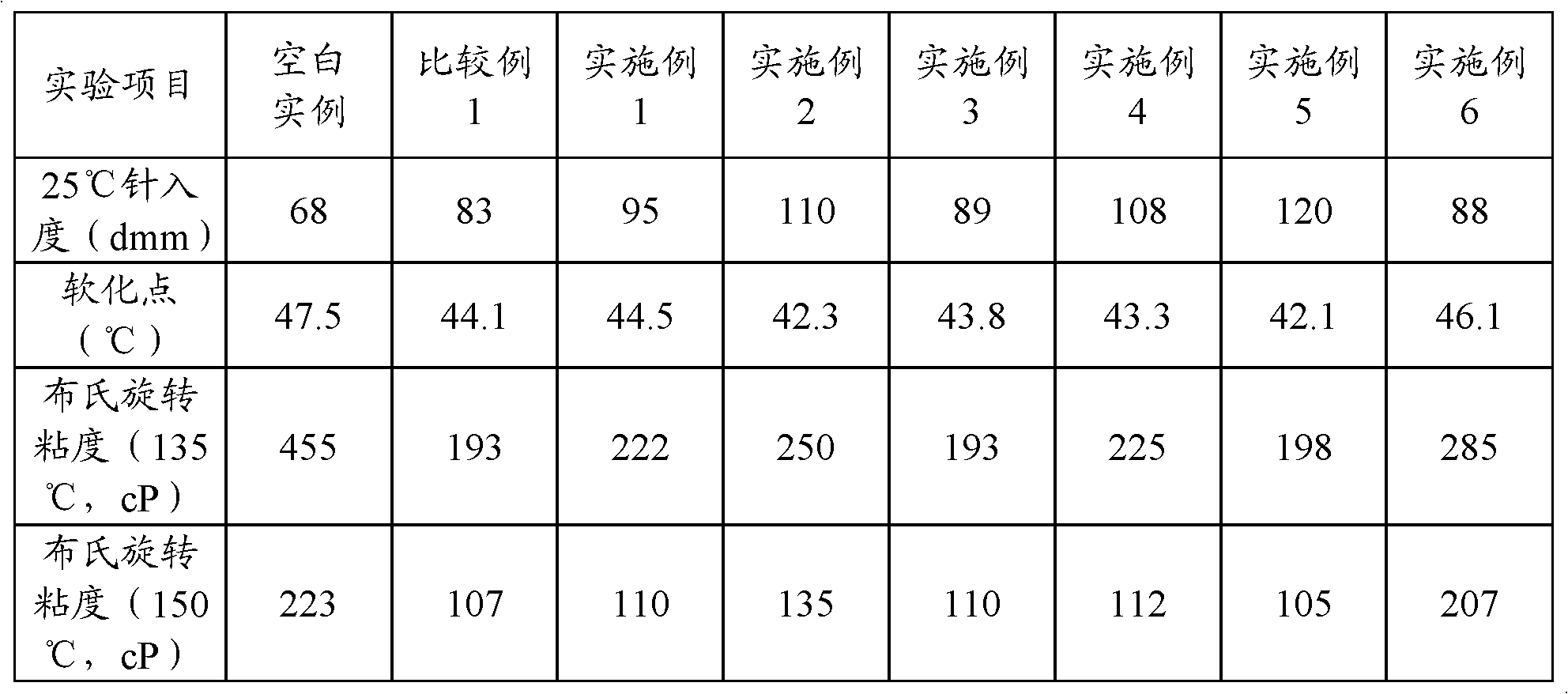

Warm mixed asphalt and preparation method thereof

ActiveCN102321373APerformance advantageAdvantage Odor ControlClimate change adaptationBuilding insulationsSulfurAsphalt

The invention provides warm mixed asphalt and a preparation method thereof. The warm mixed asphalt provided by the invention is composed of matrix asphalt, plasticized sulfur, an odor removing agent, and a fragrance enhancing agent. The warm mixed asphalt is prepared from components of, by weight: 100 parts of matrix asphalt, 10 to 35 parts of plasticized sulfur, 0.05 to 1 part of the odor removing agent, and 0.02 to 0.5 parts of the fragrance enhancing agent. The plasticized sulfur comprises components of, by weight: 100 parts of elementary sulfur and 5 to 25 parts of a plasticizing agent. With the warm mixed asphalt provided by the invention, influences on human bodies and environmental pollution caused by harmful gases discharged during a sulfur asphalt construction process can be effectively reduced. The asphalt can be warm-mixed with aggregate under a temperature below 135 DEG C, such that energy consumption is reduced.

Owner:浙江宝盈爱思开新材料科技有限公司

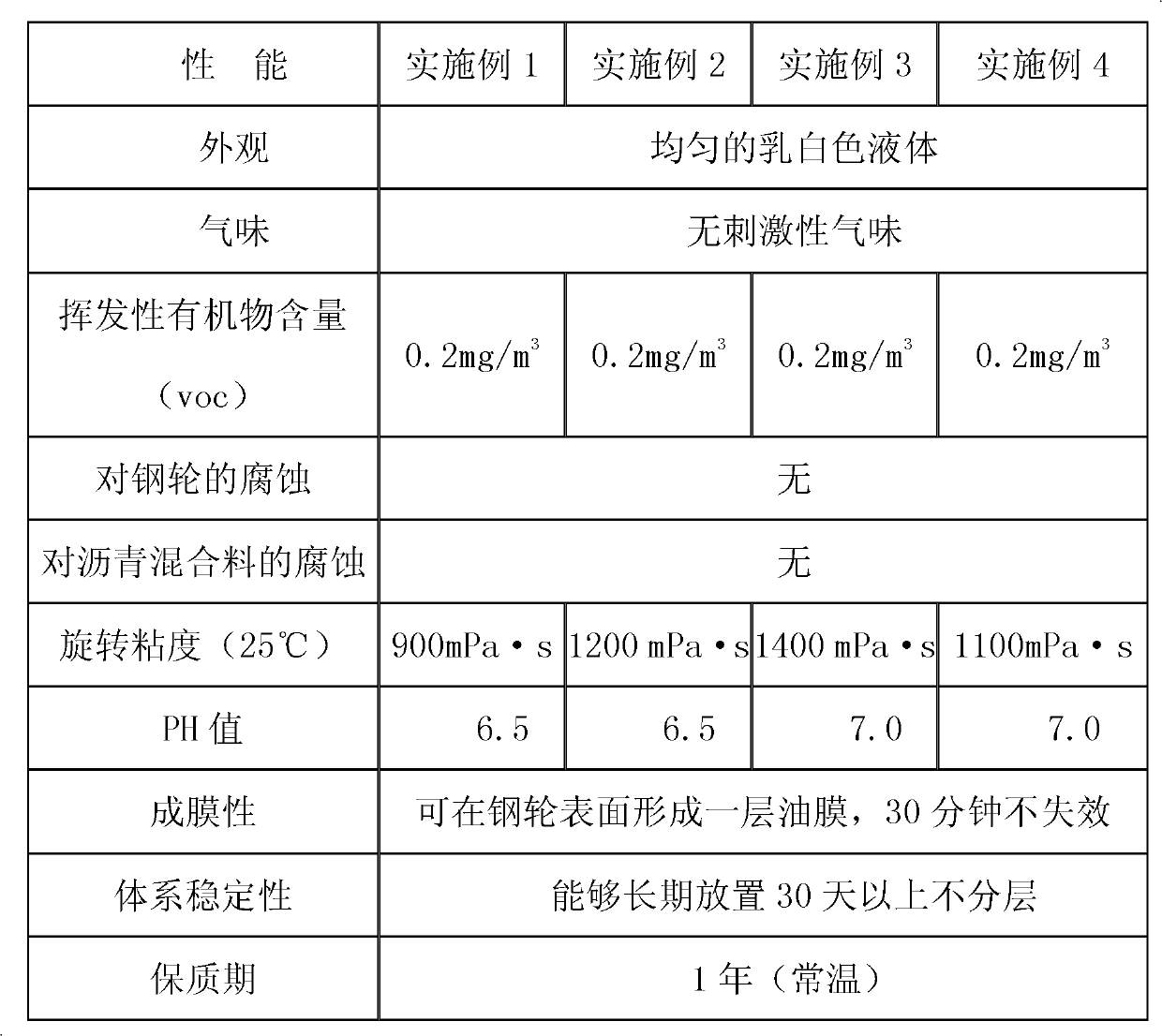

Insulator for low-temperature construction of asphalt pavement road roller and method for preparing same

ActiveCN102167939ANo pollution in the processNo chemical reactionClimate change adaptationCoatingsGreenhouseEngineering

The invention belongs to the technical field of preparation of insulators for the construction of asphalt pavement road rollers and relates to an insulator for the low-temperature construction of road rollers and a method for preparing the same. The insulator is mainly prepared by mixing silicone oil, compound emulsifier, glycerin, pH regulator, preserving agent and water. The insulator has the advantages of high chemical stability, high high-low temperature resistance, no corrosion to steel wheels, small amount of coating, lasting insulating effect, environment friendliness and the like. By using the insulator, the asphalt mixture pavement is guaranteed to be constructed at the ultralow temperature (15 DEG C below zero), so that the working season is greatly prolonged; and during normal-temperature construction, by using the insulator, the mixing temperature of the asphalt mixture is reduced to 15 to 20 DEG C under the condition of unchanging the compaction degree and the emitted greenhouse gases are reduced in the mixing process and the environment-friendly and energy saving requirements are met.

Owner:山西省交通科技研发有限公司

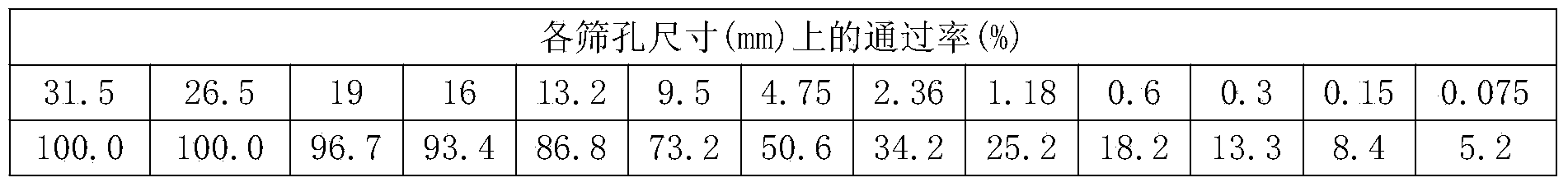

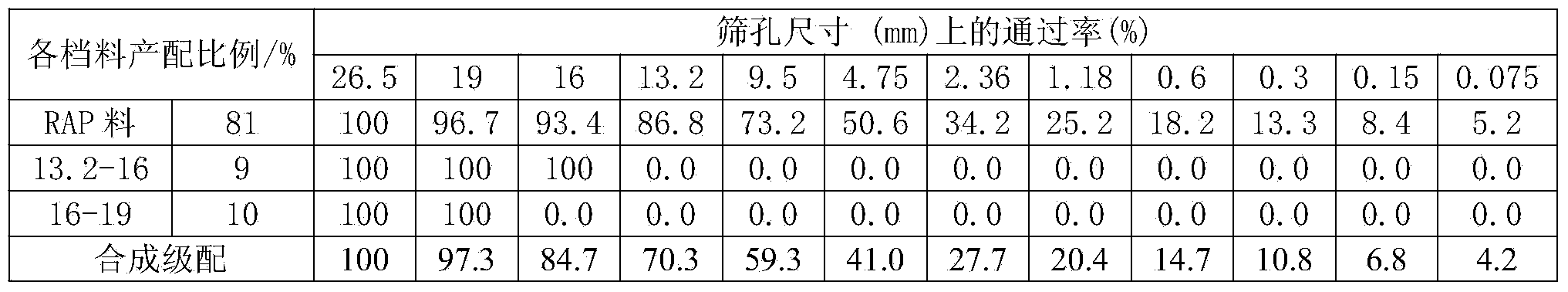

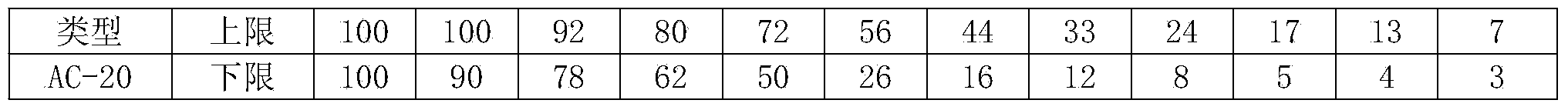

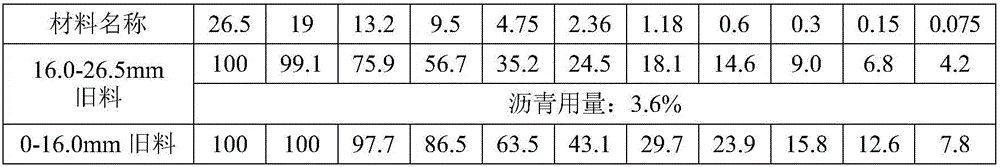

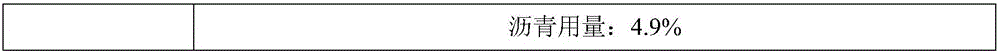

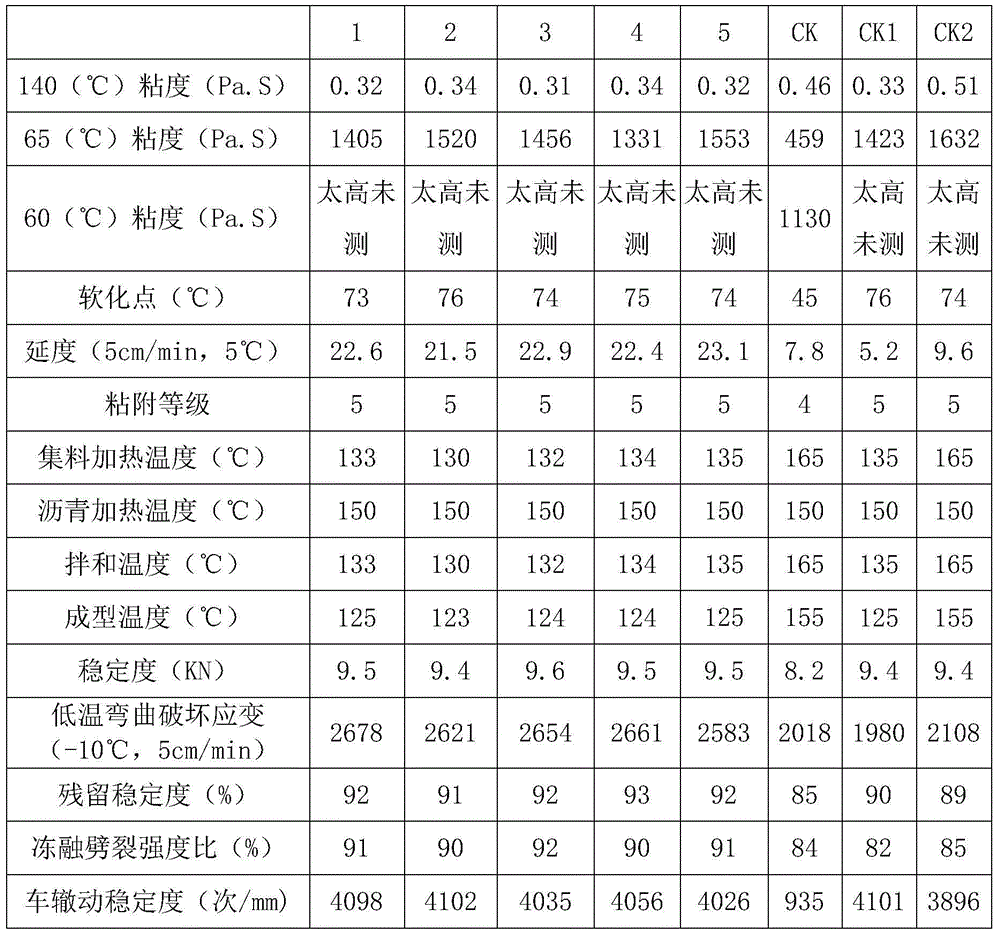

Preparation method of high-performance warm-mix regenerated asphalt mixture

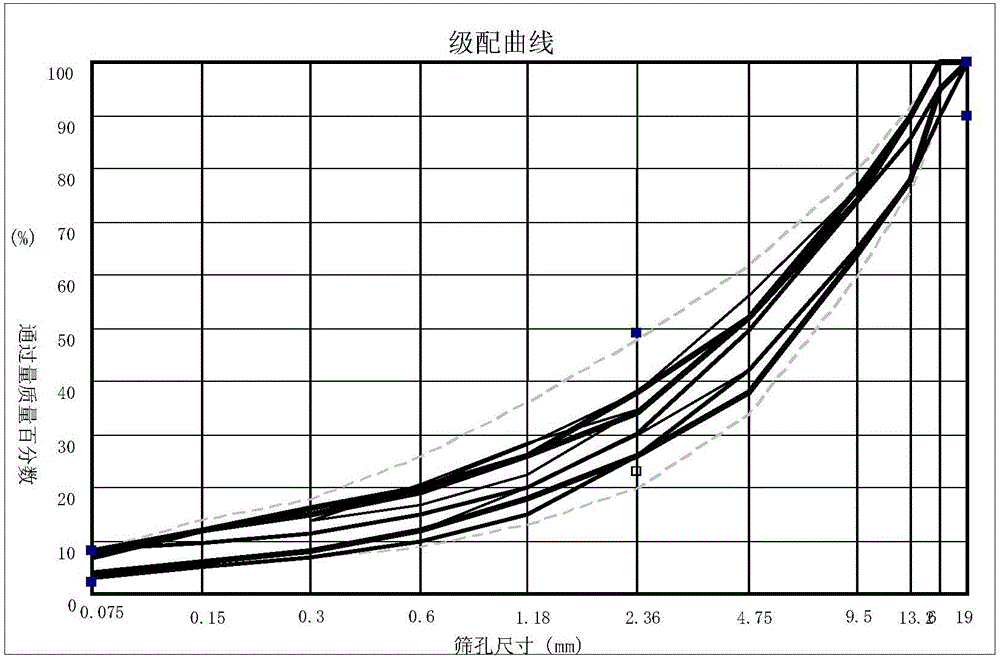

InactiveCN103556560AImprove road performanceLower mixing temperatureClimate change adaptationRoads maintainenceIndex testTest specification

The invention discloses a preparation method of a high-performance warm-mix regenerated asphalt mixture, which comprises the following steps: extracting and screening an old asphalt mixture, determining the size distribution and asphalt content of the mixture, carrying out three-main-index testing on the asphalt, and evaluating old asphalt performance indexes in RAP; determining the doping proportion of the RAP according to the performance indexes of the asphalt in the RAP, wherein the doping proportion is generally 50-100%, and the doping proportion can be higher as the performance indexes of the asphalt in the RAP are higher; determining the optimal doped new asphalt consumption (OACn) of the asphalt mixture by a conventional asphalt mixture Marshall five-point process; and after calculating the doped new asphalt consumption, detecting according to according to the performance indexes specified in Asphalt Pavement Construction Technique Specifications (JTGF40-2004) by a testing method specified in Highway Engineering Asphalt and Asphalt Mixture Test Specifications (JTGE20-2011).

Owner:云南省公路科学技术研究院

Warm-mixing high-elastoplasticity bridge expansion joint sealing material and preparation method thereof

ActiveCN103305015AGood anti-rutting ability at high temperatureLow viscosityClimate change adaptationBuilding insulationsButadiene-styrene rubberBituminous materials

The invention discloses a warm-mixing high-elastoplasticity bridge expansion joint sealing material and a preparation method thereof. The warm-mixing high-elastoplasticity bridge expansion joint sealing material comprises the following components: petroleum asphalt: SBS (Styrene-Butadiene Block Polymer):SBR (Styrene Butadiene Rubber):resin: stabilizing agents: warm-mixing agents=100:(3-10):(1-5):(0-10):(2-6):(1-5), wherein the resin is petroleum resin or abietic resin; and the stabilizing agents are mixtures of sulphur and TOR (trans-polyoctenamer rubber) stabilizing agents, and the proportion of the sulphur to TOR is 4: (1-2). The joint sealing material obtained through a formula has the characteristics of being a warm-mixing type modified asphalt material which has stability at high temperature, cracking resistance at low temperature, good bonding capacity and very good elastic recovery capacity.

Owner:TONGJI UNIV

Asphalt pavement regeneration method

ActiveCN103774537AImprove adsorption capacityImprove bindingIn situ pavingsRoads maintainenceRoad surfaceMaterials science

The invention discloses an asphalt pavement regeneration method. The asphalt pavement regeneration method comprises the following steps: (1) milling and crushing an old asphalt pavement, recycling materials of the old pavement to an asphalt tank, heating, and stirring uniformly; (2) adding inorganic binder and organic additive to mixture of step (1), and stirring uniformly; (3) uniformly stirring asphalt regenerant and hot melting asphalt added to the mixture of step (2) so as to obtain recycled asphalt mixture; (4) paving the recycled asphalt mixture, and compressing so as to complete regeneration of the asphalt pavement. The method is simple in process, good in regeneration effect, low in cost and suitable for industrial application. The method disclosed by the invention has wide prospect in the field of asphalt pavement regeneration.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing 3,3'-dimethyl-4,4'-biphenyl diisocyanate (TODI)-based thermoplastic polyurethane elastomer

The invention discloses a method for preparing a 3,3'-dimethyl-4,4'-biphenyl diisocyanate (TODI)-based thermoplastic polyurethane elastomer. The method comprises the following steps of: (1) adding dehydrated macromolecular diol into TODI, and reacting for 1 hour at the temperature of between 95 and 120 DEG C to generate a prepolymer component A containing 8.0 to 14.0 percent of isocyanate group (NCO); (2) mixing macromolecular diol, chain extender and other auxiliary agents uniformly, keeping the temperature at 40 to 60 DEG C, and mixing the mixture and the component A at the temperature of between 60 and 90 DEG C, wherein the molar ratio of the NCO to the OH group is 0.95:1-1.10:1; and (3) pouring the bubble removed mixture into a die of 160 to 180 DEG C, stirring in 15 to 20 minutes, and curing the stripped semi-finished product for 20 to 24 hours at the temperature of between 100 and 120 DEG C to obtain a finished product. The viscosity difference of the component A and the component B is low in the method, the component A and the component B are easily combined, and the performance of the product can be regulated by regulating the proportion of the macromolecular diol and the small molecular chain extender in the component B.

Owner:LIMING RES INST OF CHEM IND

High-addition-amount plant-mixed warm regenerated asphalt mixture and preparation method thereof

InactiveCN105837090AImprove road performanceEasy to useSolid waste managementRoad surfaceHot Temperature

The invention discloses a high-addition-amount plant-mixed warm regenerated asphalt mixture and a preparation method thereof. The high-addition-amount plant-mixed warm regenerated asphalt mixture includes the following components, by mass, 40-80% of waste asphalt mixture, 16-47% of aggregate, 0-1% of mineral powder, 1-3.5% of asphalt, a regenerating agent accounting for 2-8% of the quantity of the waste asphalt mixture and a warm-mixing agent accounting for 2-6% of the total quantity of the asphalt. The mixing temperature of the waste asphalt mixture and the aggregate can be reduced by 20-30 DEG C. The asphalt mixture can delay aging degree of waste asphalt in the waste asphalt mixture and can be fully compacted in a certain temperature range, which is beneficial to use quantity of an asphalt pavement in later period and also reduces energy consumption and harmful gas emission during the mixing and construction process. The various pavement performance of the high-addition-amount plant-mixed warm regenerated asphalt mixture is similar as that of a common asphalt mixture. The asphalt mixture is improved in high-temperature stability by 20-40%, is improved in fatigue performance by 10-15% than the regenerated asphalt mixture without addition of the warm-mixing agent, and ensures the pavement performance.

Owner:JSTI GRP CO LTD

Low-melting-point thermoplastic solid propellant and preparation method thereof

ActiveCN108147934ARealize complementary advantagesImprove mechanical propertiesNon-explosive/non-thermic compositionsPressure gas generationElastomerPlasticizer

The invention relates to a low-melting-point thermoplastic solid propellant and a preparation method thereof, and belongs to the technical field of composite solid propellants. The propellant is prepared from the following components by mass percent: 55%-70% of oxidant, 10%-20% of thermoplastic elastomer binder, 10%-20% of plasticizer, 5%-20% of metal fuels and 3%-8% of auxiliaries. The prepared low-melting-point thermoplastic solid propellant has the advantages that melting mixing and forming of the thermoplastic propellant at a relatively low temperature lower than 95 DEG C can be realized,process safety of thermoplastic propellant preparation is greatly improved, a curing and cross-linking process in comparison with a thermoplastic propellant is cut out, process flow is shortened, production efficiency is improved, production cost is reduced and repeated processing of waste products can be realized.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Counter Tapered Thermoplastic Elastomers

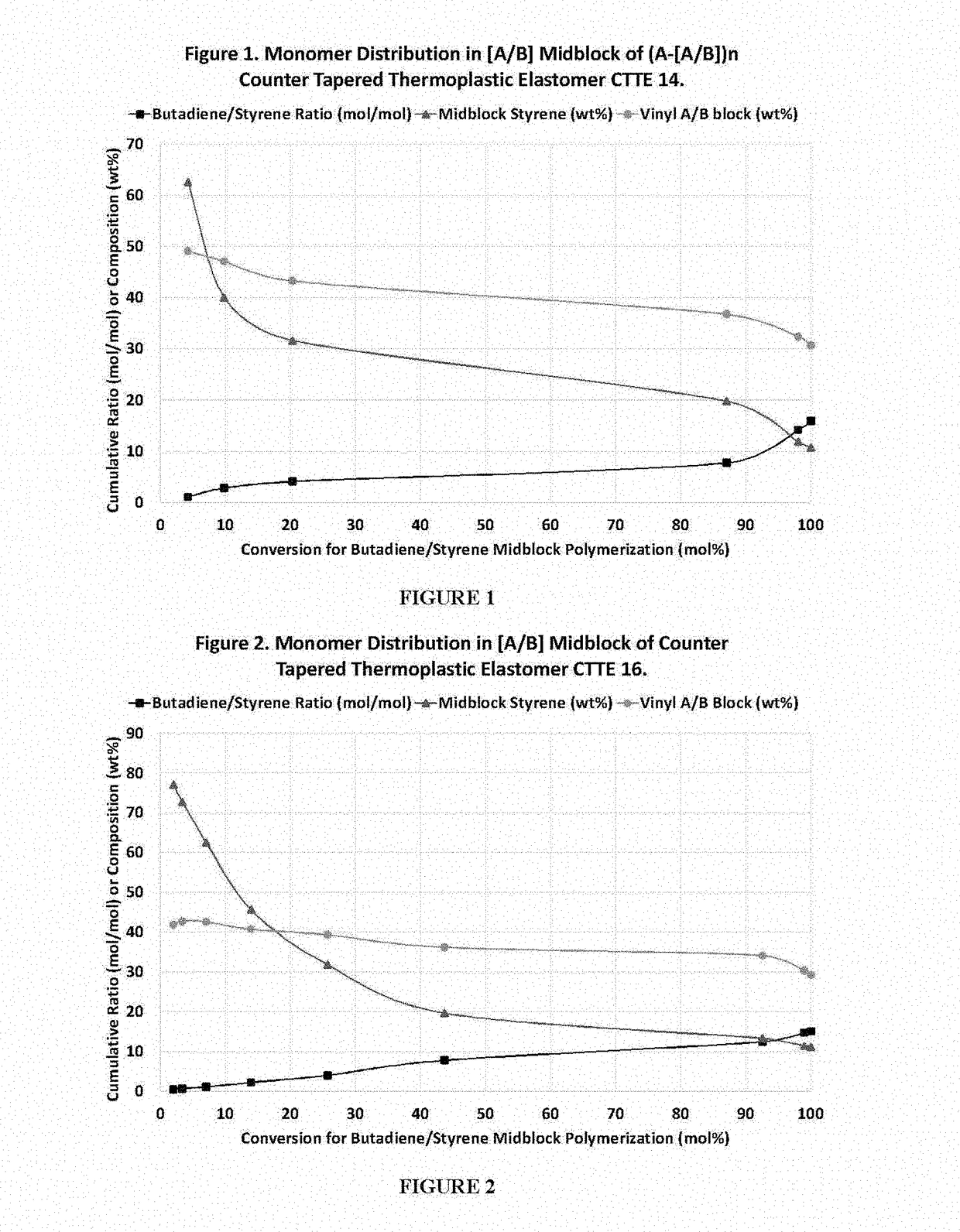

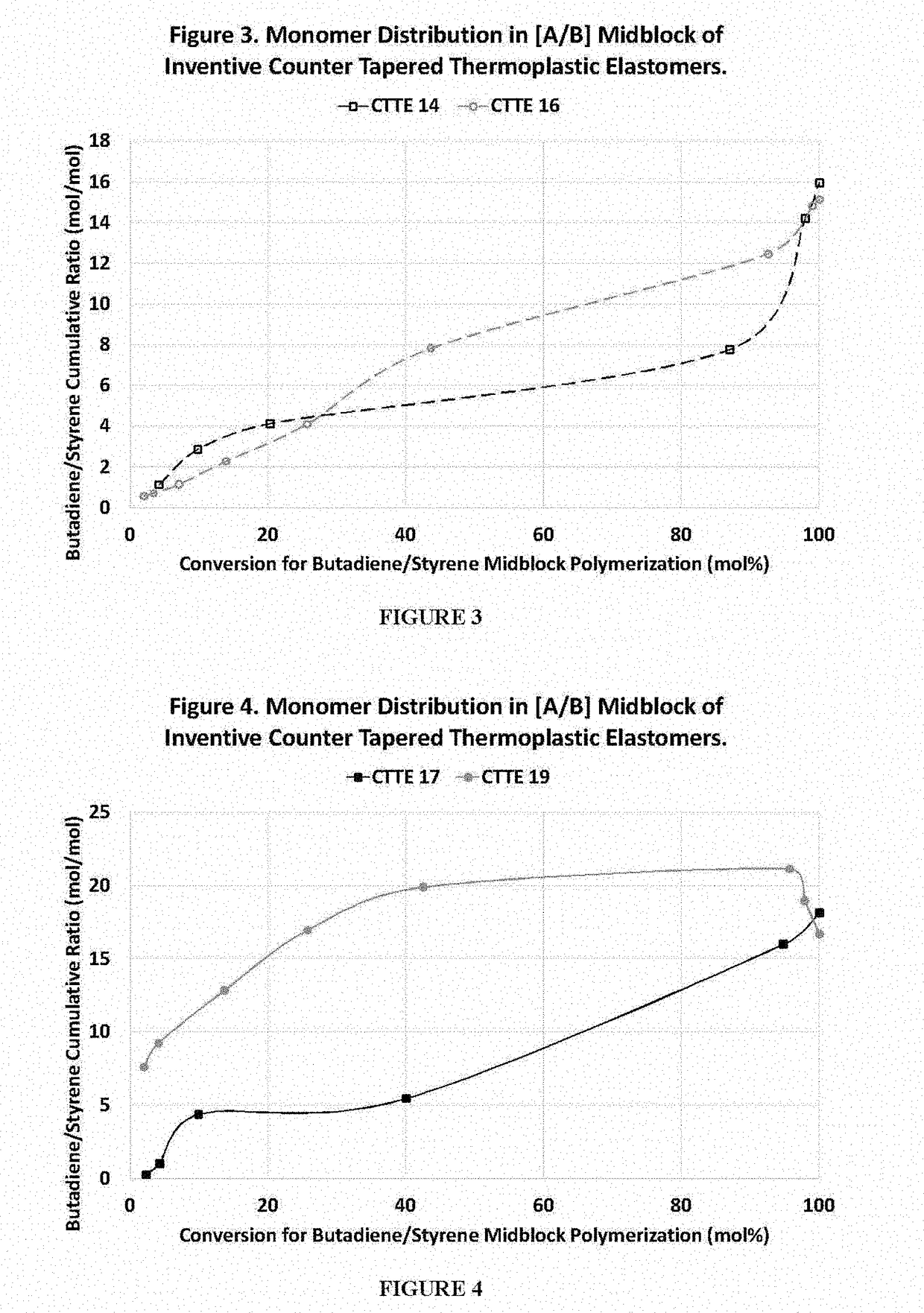

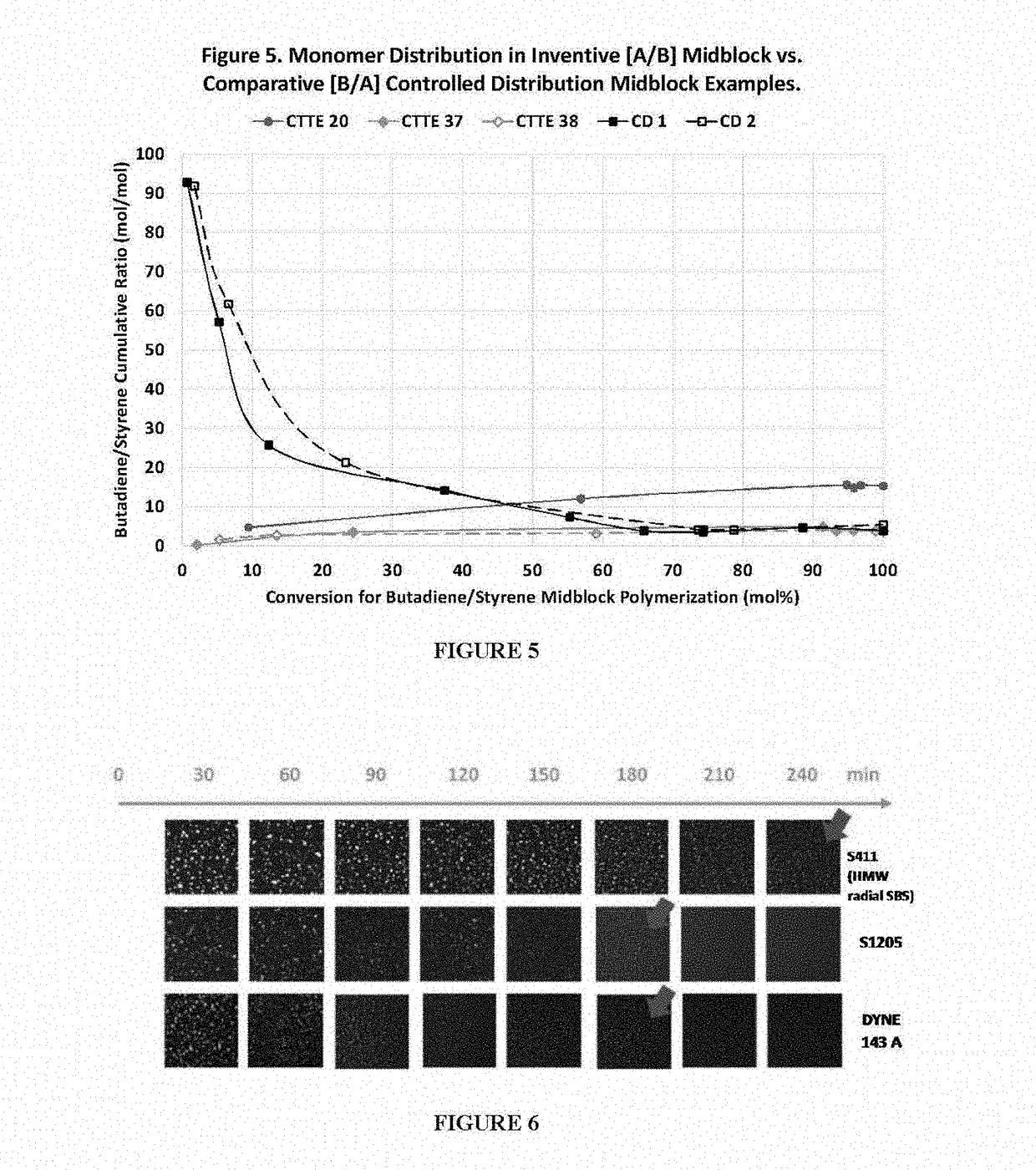

A counter tapered thermoplastic elastomer composition comprising: (a) a counter tapered diblock A-[A / B] copolymer with a peak molecular weight from 20,000 to 250,000, which includes a monovinyl aromatic homopolymer block A with a peak molecular weight of at least 8,000 and a counter tapered copolymer block [A / B] with a vinyl content of at least 15 weight percent based on the amount of conjugated diene units in the diblock copolymer; and (b) a block copolymer selected from the group consisting of linear triblock copolymers having a peak molecular weight that is at least about 1.5 times the peak molecular weight of the counter tapered diblock A-[A / B] copolymer described In (a), multiarm coupled block copolymers having a peak molecular weight that is at least about 2.5 times the peak molecular weight of the counter tapered diblock A-[A / B] copolymer described in (a), and mixtures thereof; and (c) wherein the ratio of (a) to (b) in the counter tapered thermoplastic elastomer composition is from about 1:5 to about 5:1. The counter tapered thermoplastic elastomer compositions provide in the applications: i) easy processing such as short dispersion time, low mixing temperature, low viscosity, excellent storage stability; and ii) better reinforcement such as high elastic response, wide range of performance grade, high adherence, higher filler loading capacity, and better compromise between high and low temperature properties; which make them suitable for a broad range of applications such as road paving, roofing, shingles, waterproofing membranes, adhesive tapes and labels, contact and sprayable adhesives, and sealants.

Owner:DYNASOL ELASTOMEROS S A DE

Composite warm-mixed flame-retarding antiskid asphalt tunnel pavement material and preparation method thereof

ActiveCN105837091AReasonable construction depthImproves rutting resistanceSolid waste managementClimate change adaptationFiberRoad surface

The invention discloses a composite warm-mixed flame-retarding antiskid asphalt tunnel pavement material which includes, by weight, 80-90 parts of aggregate, 5-15 parts of a functional filling material, 4-7 parts of high-viscosity high-elasticity modified asphalt, 0.4-0.7 parts of a warm mixing agent, and 0.2-0.5 parts of mineral fibers. The composite warm-mixed flame-retarding antiskid asphalt tunnel pavement material has a compact framework structure and has reasonable construction depth and high anti-track capability, thereby ensuring antiskid and durable performances of the mixture. The emulsifying-type warm mixing agent is compounded with the functional filling material for comprehensively controlling the mixing temperature of the asphalt mixture. With the composite flame-retarding component, a gradient-temperature flame-retarding effect is achieved. The asphalt tunnel pavement material is antiskid when being spread, is flame-retarding and is low in mixing temperature, and satisfies a special semi-sealed environment.

Owner:广州市市维新材料科技有限公司

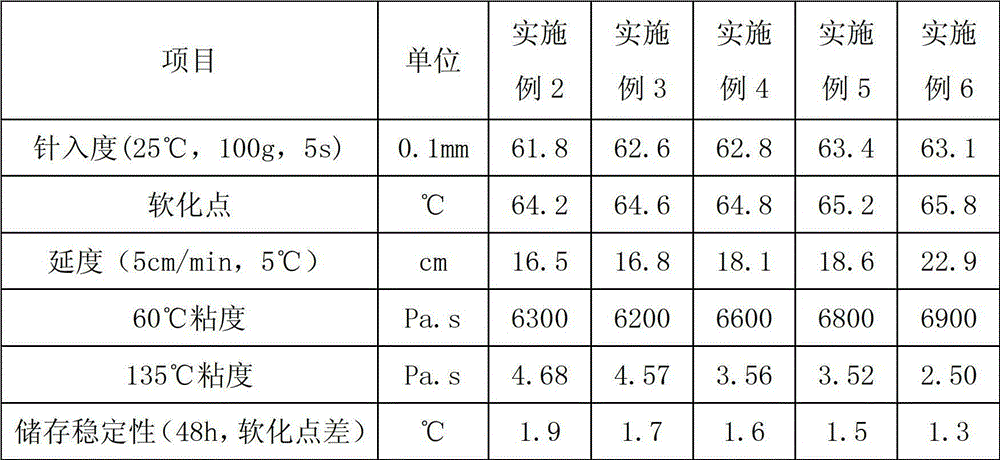

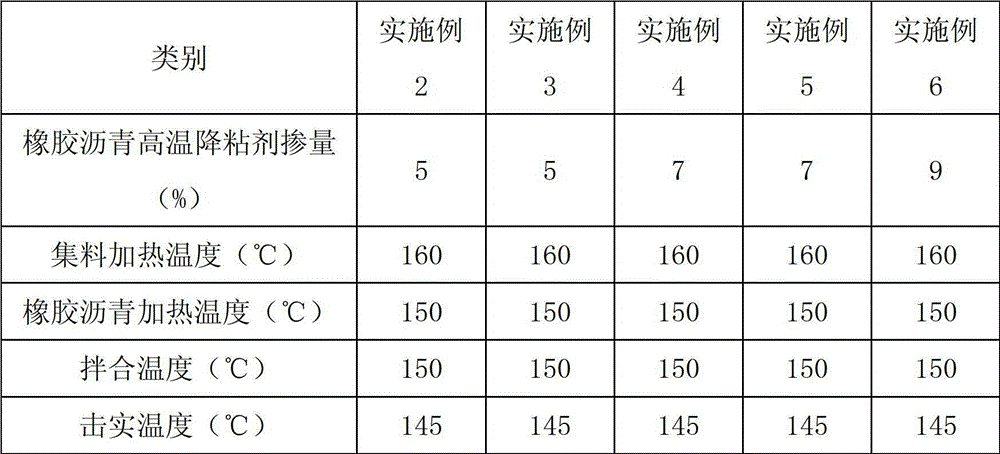

Rubber asphalt high temperature viscosity reducer, preparation method and application thereof

ActiveCN102942794AGood storage stabilityDelay agingClimate change adaptationBuilding insulationsWaxPolymer science

The invention discloses a rubber asphalt high temperature viscosity reducer, a preparation method and an application thereof. The rubber asphalt high temperature viscosity reducer is prepared by raw materials of, by mass, 100 parts of oxidized polyethlene wax, 5-40 parts of higher fatty acid and 10-50 parts of metal hydroxide. The rubber asphalt high temperature viscosity reducer is simple in preparation process, convenient to use and capable of reducing high temperature viscosities of ordinary rubber asphalt and modified rubber asphalt and reducing rubber asphalt intermolecular surface tension so that mixing temperatures of rubber asphalt mixtures are reduced, and purposes of reducing energy consumption and protecting environment are achieved.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

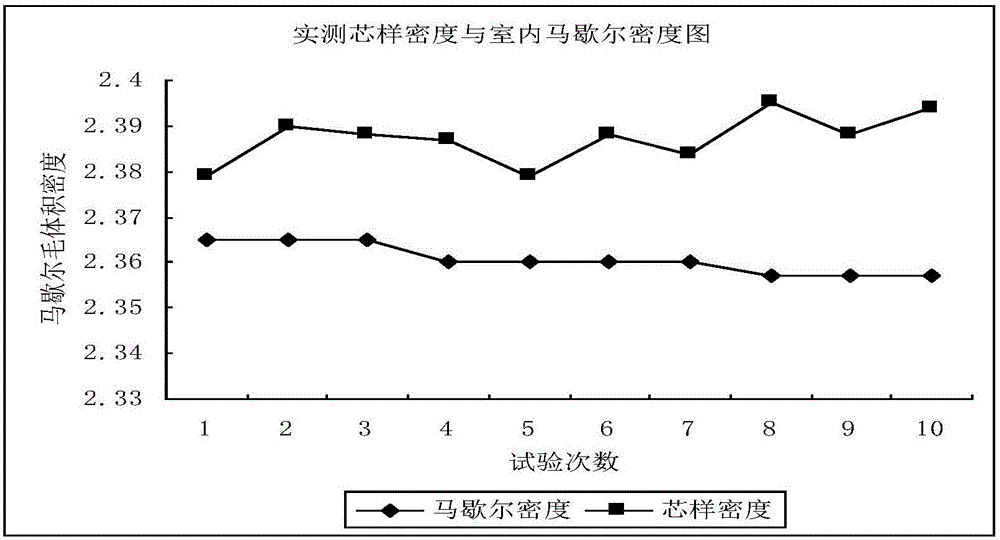

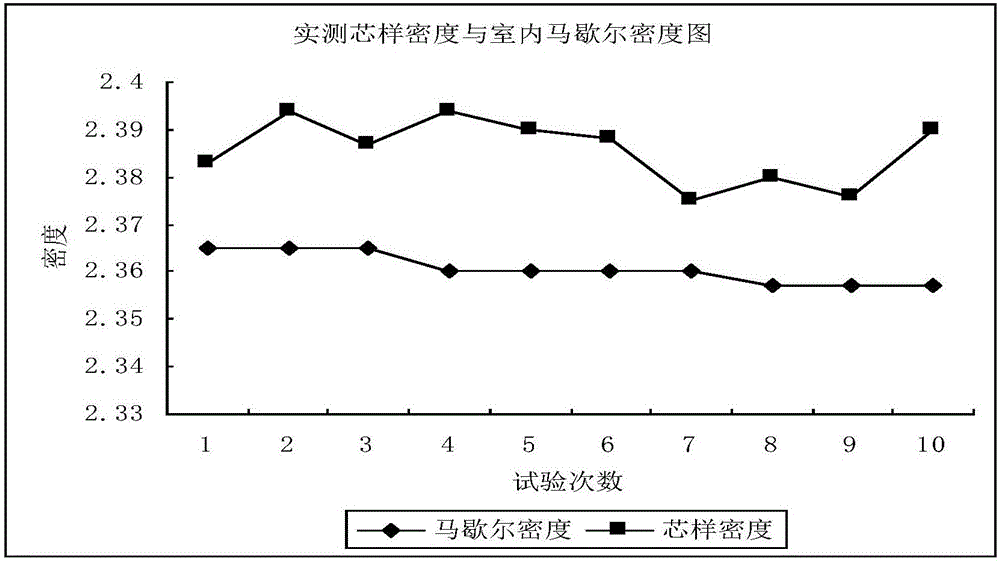

Test detection method for equivalent compaction function of asphalt mixture and application

ActiveCN106442058ALower mixing temperaturePaving temperature reductionPreparing sample for investigationMaterial strength using repeated/pulsating forcesRoad engineeringEngineering

The invention relates to a test detection method for the equivalent compaction function of an asphalt mixture and an application, and belongs to the technical field of road engineering. The method includes the steps that the asphalt mixture is subjected to a mixture proportion design test, the optimal asphalt amount is determined, and the gross volume relative density is calculated; a trial road section is paved, the number of grinding times of a site compaction machine generated when grinding is carried out till density is not increased any more is recorded, and a core sample is taken in site to measure the gross volume relative density; the compaction degree is calculated, and according to the gross volume density and the compaction degree of the obtained sample, by adjusting the number of the compaction times and the compaction temperature, the maximum number of the compaction times and the lowest compaction temperature are finally determined to correct the method of a standard indoor Marshall test; a Marshall correction test piece is prepared, and the compaction degree of a construction site is measured with the gross volume relative density of the Marshall correction test piece as the standard. According to the test detection method, the actual compaction degree of the construction site can be more accurately measured; meanwhile, the lowest compaction temperature of the mixture is determined, the mixing temperature and the paving temperature are reasonably reduced, the construction speed is increased, and energy is saved.

Owner:黑龙江省交通运输信息和规划研究中心

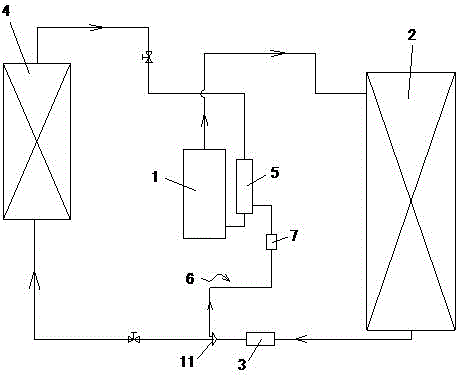

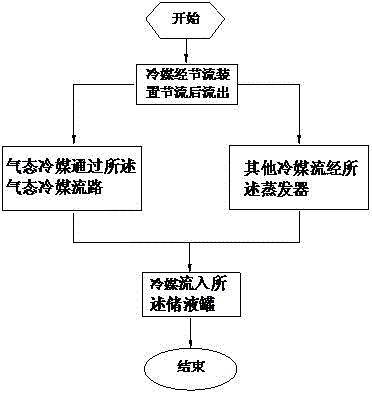

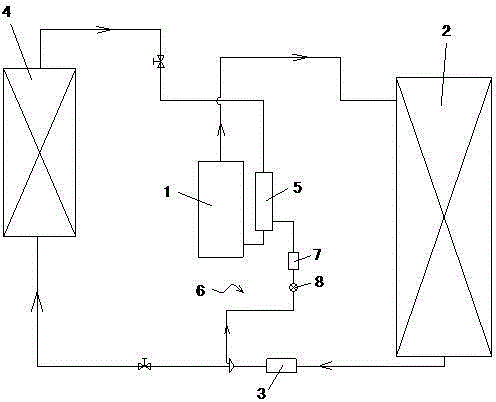

Air conditioner and control method of air conditioning refrigerants

InactiveCN105402958AImprove cooling effectAvoid blowing waterMechanical apparatusFluid circulation arrangementHigh humidityLiquid storage tank

The invention provides an air conditioner and a control method of air conditioning refrigerants. The air conditioner comprises a compressor, a condenser, a throttling device, an evaporator and a liquid storage tank which are connected through a refrigeration pipeline, wherein a gaseous refrigerant flow path is arranged between the throttling device and the liquid storage tank; a part of a gaseous refrigerant or all the gaseous refrigerant flowing out of the throttling device flows into the liquid storage tank through the gaseous refrigerant flow path; and other refrigerants flowing out of the throttling device flow into the liquid storage tank after flowing through the evaporator for heat exchange. According to the air conditioner, the gaseous refrigerant flow path is arranged, so that a part of the gaseous refrigerants or all the gaseous refrigerant flowing out of the throttling device is enabled to flow into the liquid storage tank through the gaseous refrigerant flow path, so that the dryness of the inlet of the evaporator is reduced, the heat exchange efficiency of the evaporator is improved, and the refrigeration performance of the air conditioner is improved; and besides, the dryness of the inlet of the evaporator is low, so that the divided flow of the refrigerants in the evaporator is relatively good, the refrigerant flowing noise generated by a flow divider is greatly reduced, and a water blowing phenomenon of the air conditioner in a high humidity condition is avoided.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

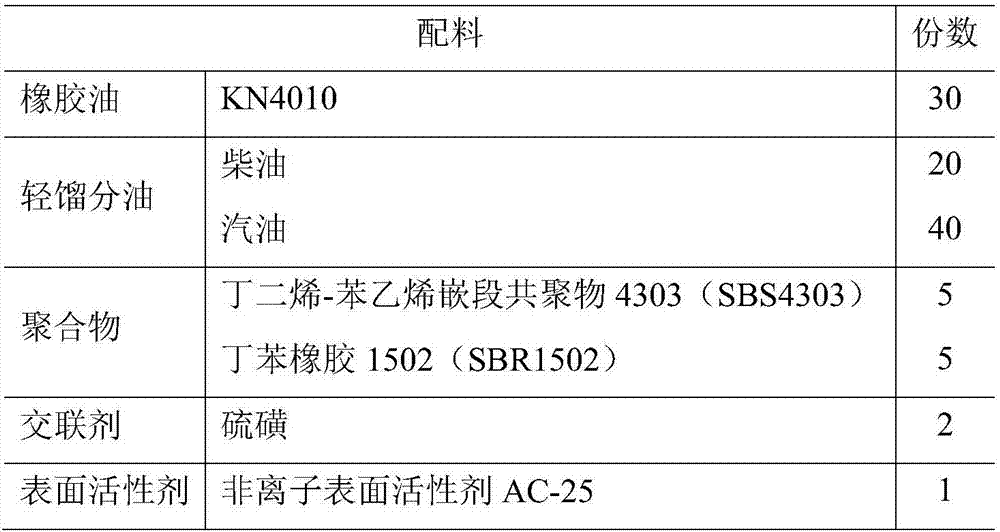

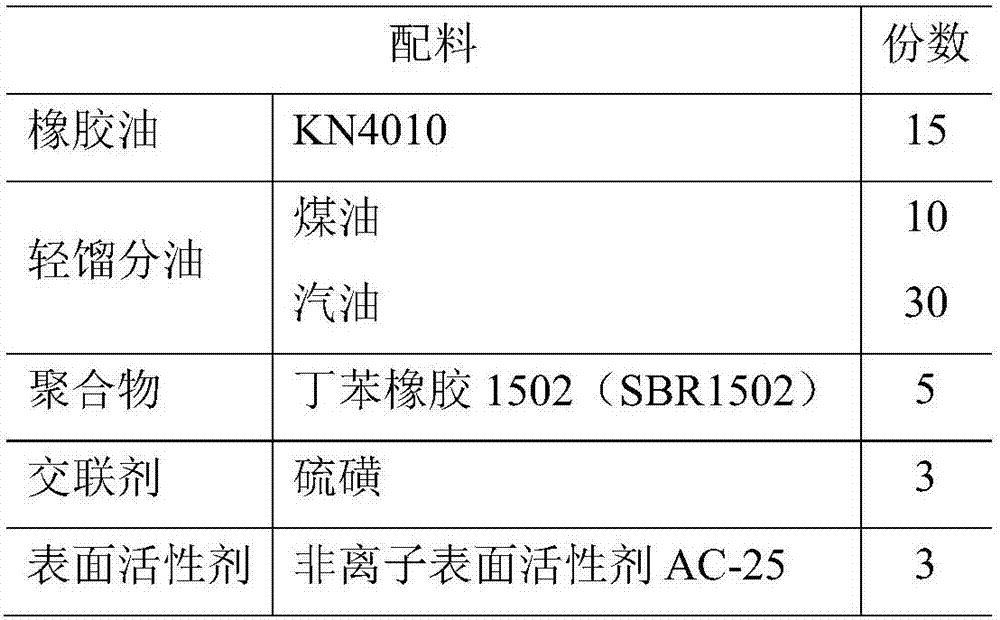

Waste asphalt mixture normal-temperature regeneration modifying agent and preparation method thereof

The invention discloses a waste asphalt mixture normal-temperature regeneration modifying agent and a preparation method thereof. Particularly, the waste asphalt mixture normal-temperature regeneration modifying agent comprises the following components in parts by weight: 0-30 part of rubber oil, 30-60 parts of light distillates, 5-10 parts of a polymer, 2-5 parts of a crosslinking agent and 1-5 parts of a surfactant. The regeneration modifying agent is used for producing a regenerative asphalt mixture; the RAP blending rate is high; the blending temperature is low; and the pavement performance of the regenerative asphalt mixture is good.

Owner:CHINA ACAD OF TRANSPORTATION SCI

Once-formed highly-elastic micro-foaming bouncing ball compound and preparation method thereof

The invention belongs to the technical field of polyurethane and particularly relates to a once-formed highly-elastic micro-foaming bouncing ball compound and a preparation method thereof. The compound is composed of polyol mixture components and modified isocyanate components. The compound can be used to prepare the highly-elastic bouncing ball by once forming. The preparation method has the advantages that a semi-prepolymerization method is used to prepare the bouncing ball, viscosity of two groups of components are close, mixing temperature is low, materials can be evenly mixed easily, control conditions of the process is simple, and operation is easy; compact surface and foam core can be once formed during formation by using the compound to prepare the bouncing ball, and forming process is simple; and rebounding rate of the microporous bouncing ball prepared by the compound can reach a range of 80-85%.

Owner:SHANDONG INOV POLYURETHANE

Thermal processing apparatus and cooling method

ActiveUS20110076632A1Good effectLow heat resistanceAfter-treatment apparatusSemiconductor/solid-state device manufacturingEngineeringCooling methods

A thermal processing apparatus including: a cylindrical processing vessel; a support unit to be loaded into and unloaded from the vessel; and a heating furnace surrounding an outer periphery of the vessel, with a cooling space therebetween. The furnace is connected to a cooling-gas introduction unit, including a gas introduction passage to which a blowing fan is connected, for introducing a cooling gas into the cooling space during a temperature lowering operation after a thermal process. The furnace is connected to a cooling-gas discharge unit, including a heat exchanger, a suction fan, and a gas discharge passage, for discharging the cooling gas of a raised temperature from the cooling space. Connected to the gas discharge passage at a position upstream of the heat exchanger is a temperature-lowering gas introduction unit for introducing a temperature-lowering gas to the cooling gas of a raised temperature so as to lower its temperature.

Owner:TOKYO ELECTRON LTD

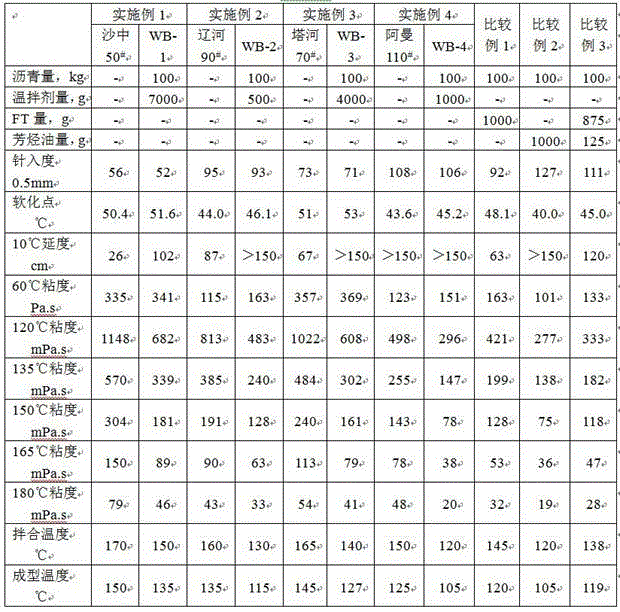

Warm mixing agent and preparation method thereof

InactiveCN104559266ALow viscosityLow heating temperatureClimate change adaptationBuilding insulationsExtensibilityElastomer

The invention relates to a warm mixing agent and a preparation method thereof and relates to a modifier, and particularly relates to a modifier of asphalt. The warm mixing agent provided by the invention aims to provide the warm mixing agent capable of reducing the mixing temperature of an asphalt mixture and improving the anti-rut capacity and low-temperature bending property of the asphalt mixture and the preparation method thereof. The warm mixing agent comprises 60-90 parts of amide compounds, 1-10 parts of an asphalt anti-stripping agent, 1-10 parts of an asphalt extensibility modifier and 5-20 parts of an elastomer modifier. The warm mixing agent provided by the invention is convenient to use. The warm mixing agent is added into asphalt, so that the mixing temperature of the asphalt mixture can be reduced, and moreover, the anti-rut capacity and low-temperature bending property of the asphalt mixture are improved. The warm mixing agent provided by the invention is used in the field of asphalt modification.

Owner:CHANGZHOU XINTUO PAVEMENT MODIFICATION MATERIALS CO LTD

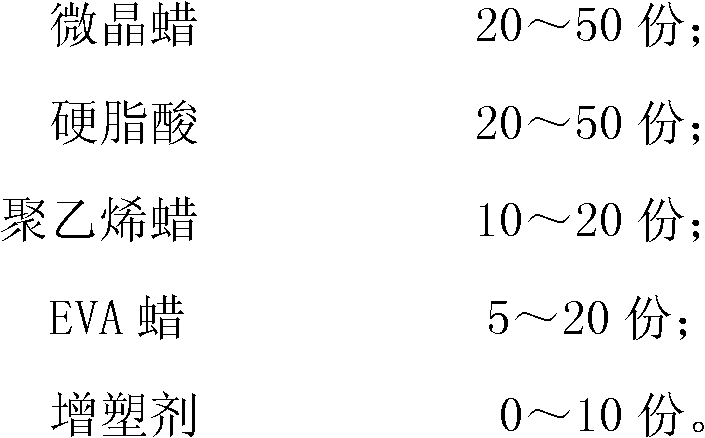

Compound asphalt mixture wet-mixing additive and preparation method thereof

The invention relates to the field of road materials, and discloses a compound asphalt mixture wet-mixing additive and a preparation method thereof. According to the compound asphalt mixture wet-mixing additive, production and construction temperatures of a hot-mix asphalt mixture can be reduced. The compound asphalt mixture wet-mixing additive is characterized by comprising the following components in parts by weight: 20-50 parts of microcrystalline wax, 20-50 parts of stearic acid, 10-20 parts of polyethylene wax, 5-20 parts of EVA (ethyl vinyl acetate) wax and 0-10 parts of plasticizer. The preparation method comprises the following steps of: uniformly mixing the polyethylene wax, the EVA wax, the stearic acid and the plasticizer under the mechanical stirring action, then adding the microcrystalline wax, continuously stirring and uniformly mixing to obtain a mixed dry material; and finally, adding the mixed dry material in a granulating machine melting furnace, heating at a temperature of 120-130 DEG C and melting, then granulating, cooling and drying. According to the compound asphalt mixture wet-mixing additive, the blending temperature of the asphalt mixture can be effectively lowered by about 30 DEG C, and better used road performance can be ensured.

Owner:陕西长大博源公路养护科技有限公司

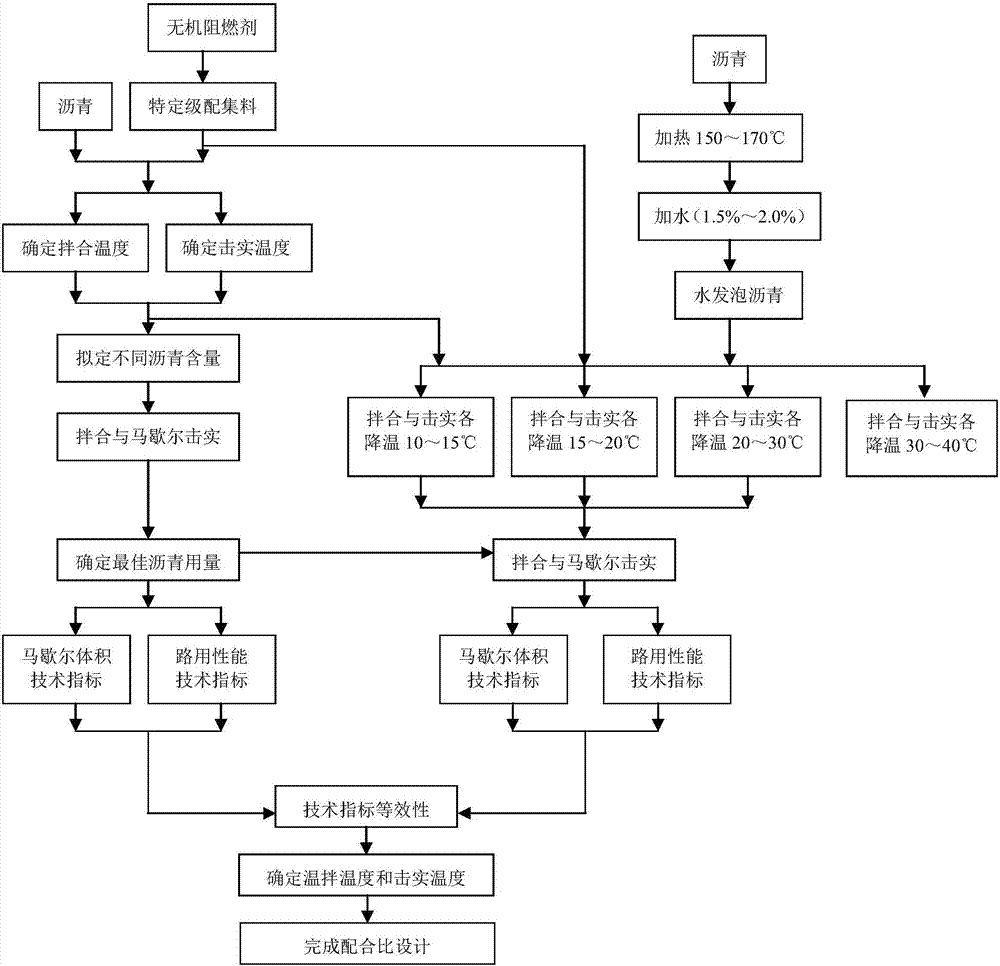

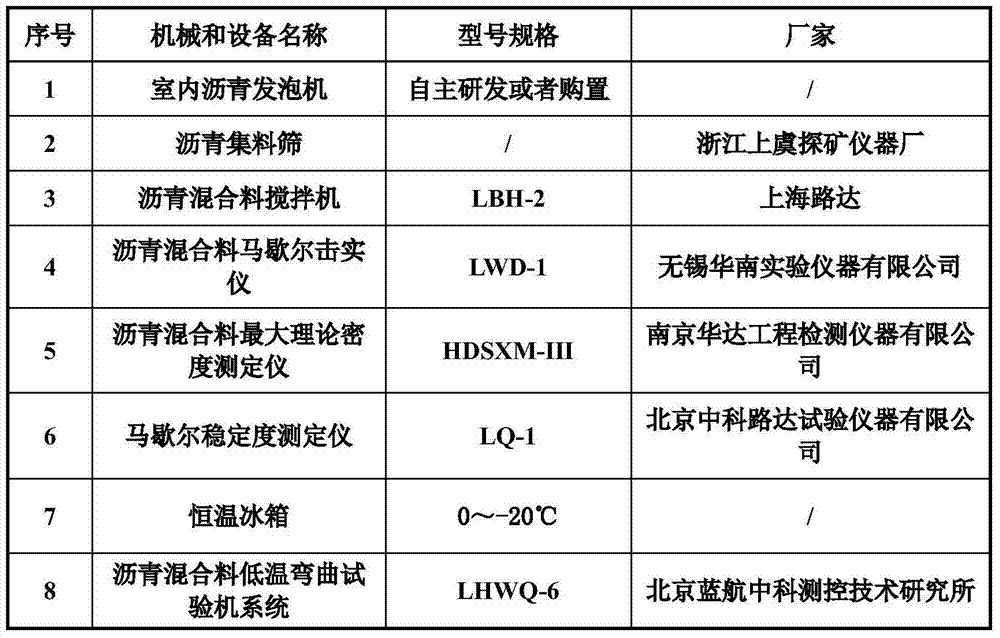

Water-blown warm-mix flame-retardant asphalt mixture, and preparation and design method thereof

The invention discloses a water-blown warm-mix flame-retardant asphalt mixture and a preparation method thereof. According to the invention, through comprehensive utilization of a water-blown asphalt warm-mixing technology and an asphalt flame-retardation technology, construction temperature of an asphalt pavement is effectively reduced, the safety factor of a tunnel asphalt pavement is increased, and the advantages of energy conservation, emission reduction, greenness, environmental protection, reduction in construction cost, improvement of warm-mixing construction technology for tunnel flame-retardant asphalt pavements and the like are obtained. The invention also provides a design method for the water-blown warm-mix flame-retardant asphalt mixture. The method utilizes the concept of equivalent design of basic mix ratios and technique indexes to improve the traditional design method for the warm-mix flame-retardant asphalt mixture, provides bases for the design of the water-blown warm-mix flame-retardant asphalt mixture and fills a gap in the design method for the water-blown warm-mixed flame-retardant asphalt mixture.

Owner:SUZHOU UNIV OF SCI & TECH

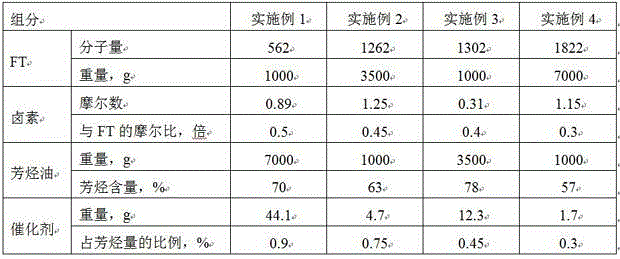

Warm mix agent as well as preparation method and application thereof

ActiveCN105585859AWarming effectImprove adhesionClimate change adaptationBuilding insulationsAlkaneCarbon number

The invention discloses a warm mix agent for reducing high-temperature viscosity of asphalt and a preparation method thereof. Raw materials for preparation of the warm mix agent comprise FT, halogen, aromatic hydrocarbon oil and a catalyst. The FT is high-molecular alkane, whose carbon number is 40-130; molecular weight is 562-1822. The amount of halogen is 0.3-0.5 times the mole number of the FT. Halogen and the catalyst are added, so that a chemical reaction is carried out between aromatic hydrocarbon oil and the FT. The warm mix agent has a warm mixing effect for asphalt, and can improve compatibility between asphalt and the warm mix agent as well as adhesiveness between asphalt and stones. The warm mix agent can effectively reduce high-temperature viscosity of asphalt, reduce mixing and moulding temperatures of an asphalt mixture, enhance softening point and viscosity at 60 DEG C and extension of asphalt, and improve high and low temperature performances of asphalt.

Owner:CHINA PETROLEUM & CHEM CORP +1

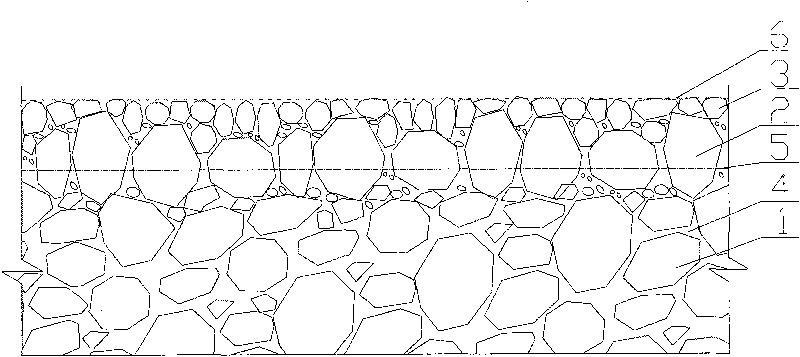

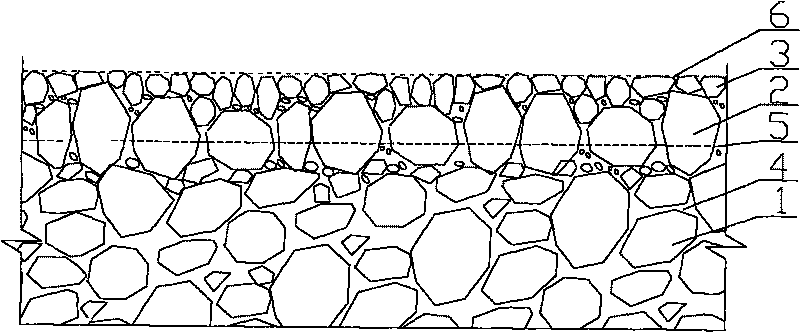

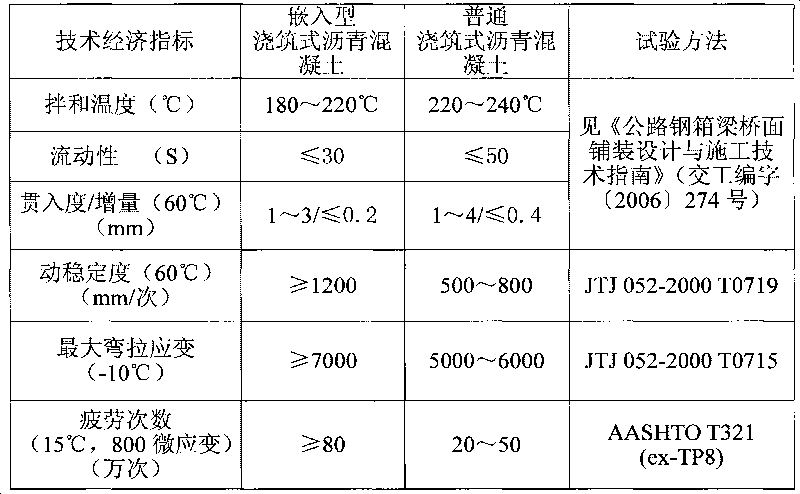

Embedded pouring asphalt concrete

ActiveCN101736672AIncreased durabilityLower mixing temperatureIn situ pavingsRoads maintainencePavement engineeringGranularity

The invention relates to paving structures and materials for pavement engineering, in particular to embedded pouring asphalt concrete. The coarse aggregate dosage of the embedded pouring asphalt concrete is reduced by 10-30 percent than the coarse aggregate dosage in the mixing proportion design of ordinary pouring asphalt concrete, and the embedded pouring asphalt concrete is prepared through the following steps of: mixing the coarse aggregate, uniformly stirring at the temperature of 180-220 DEG C, spreading and leveling by using a spreading machine, then spreading a first layer of aggregate with the granularity of 10-15mm and the dosage accounting for 10-25 percent of the quality of the designed pouring asphalt concrete, then spreading a second layer of aggregate with the granularity of 5-10mm and the dosage accounting for 10-15 percent of the quality of the designed pouring asphalt concrete and rolling once through a combined wheel road roller of which bearing wheel walking railways at both sides are provided with lower limited positions and can vibrate to form the embedded pouring asphalt concrete. The coarse aggregate dosage of the embedded pouring asphalt concrete is reduced before the mixture is spread to improve the fluidity, thereby lowering the construction temperature and improving the fatigue durability; the dosage of spread broken stones is increased, and the compaction process and the power are adjusted and increased, thereby ensuring the embedding ratio of the broken stones and improving the high temperature stability.

Owner:重庆市智翔铺道技术工程有限公司

Red mud-based asphalt mixture warm-mixing agent and preparation method thereof

ActiveCN109336456AReduce the temperatureLow molding temperatureCement productionActive agentGeopolymer

The invention relates to a red mud-based asphalt mixture warm-mixing agent and a preparation method thereof, and belongs to the technical field of asphalt warm-mixing agents. The preparation method comprises the following steps: step 1) calcining red mud powder and then mixing with an active aluminum silicon source in proportion, and allocating the molar ratio of SiO2 / Al2O3 to obtain a geopolymerprecursor; step 2) adding the geopolymer precursor obtained in the step 1) into an alkaline activator solution, and stirring to obtain geopolymer mud; step 3) curing the geopolymer mud obtained in thestep 2) to obtain a geopolymer block, and preparing the geopolymer block into powder; and step 4) adding the geopolymer powder obtained in the step 3) into a surfactant solution, stirring uniformly,and then suction-filtering and drying the obtained slurry to obtain the red mud-based asphalt mixture warm-mixing agent. According to the invention, the asphalt mixture warm-mixing agent is prepared by surface modification of red mud-based geopolymer powder, thereby effectively ensuring mechanical properties of an asphalt mixture while significantly reducing a mixing temperature and a molding temperature of the asphalt mixture.

Owner:SHANDONG UNIV

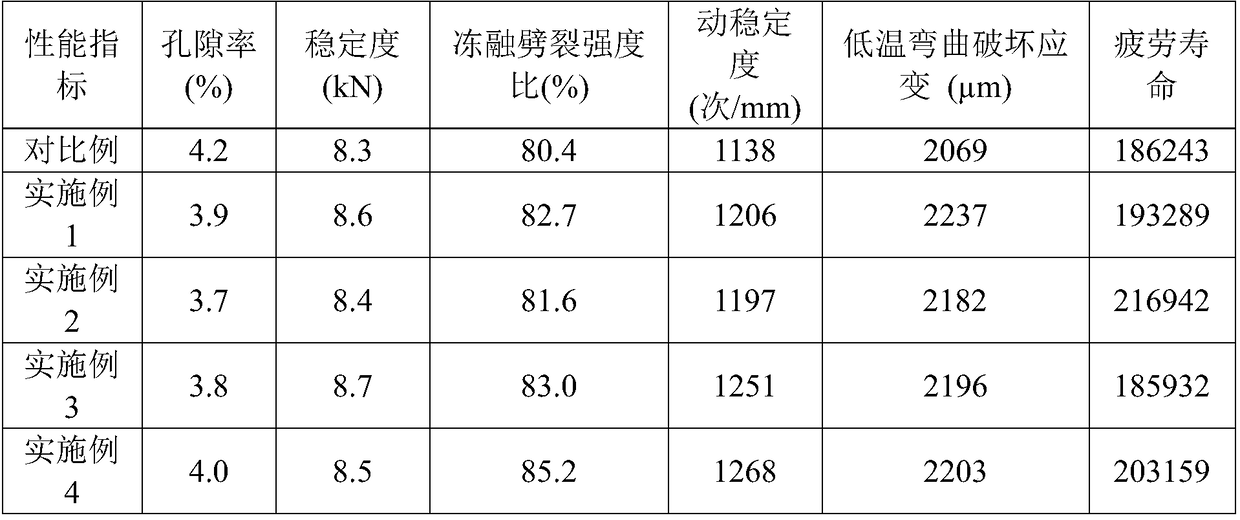

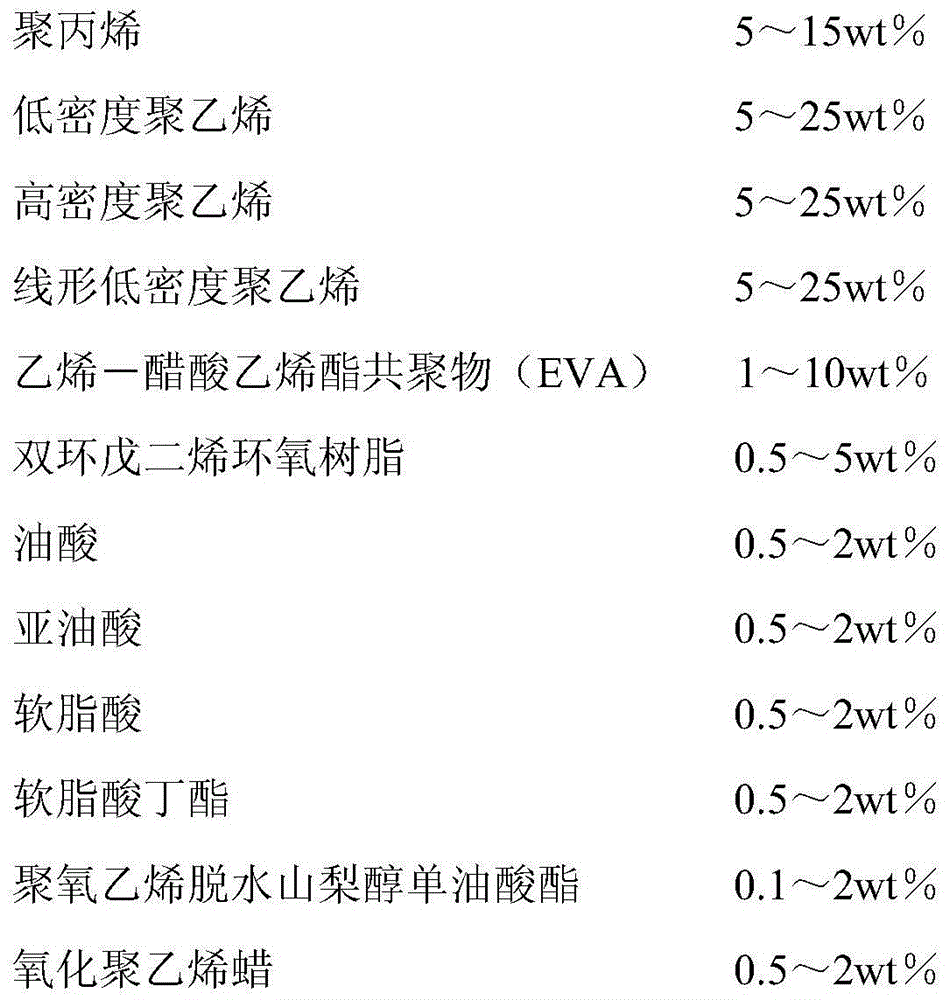

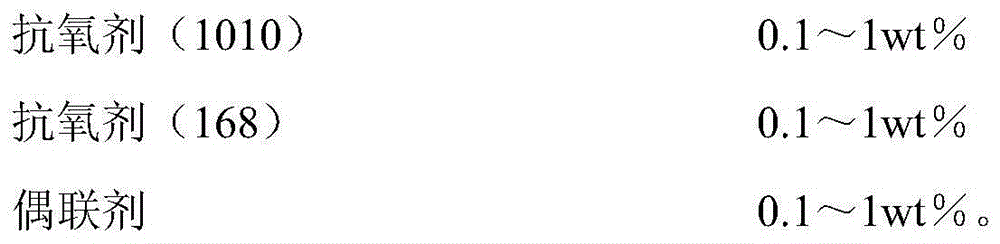

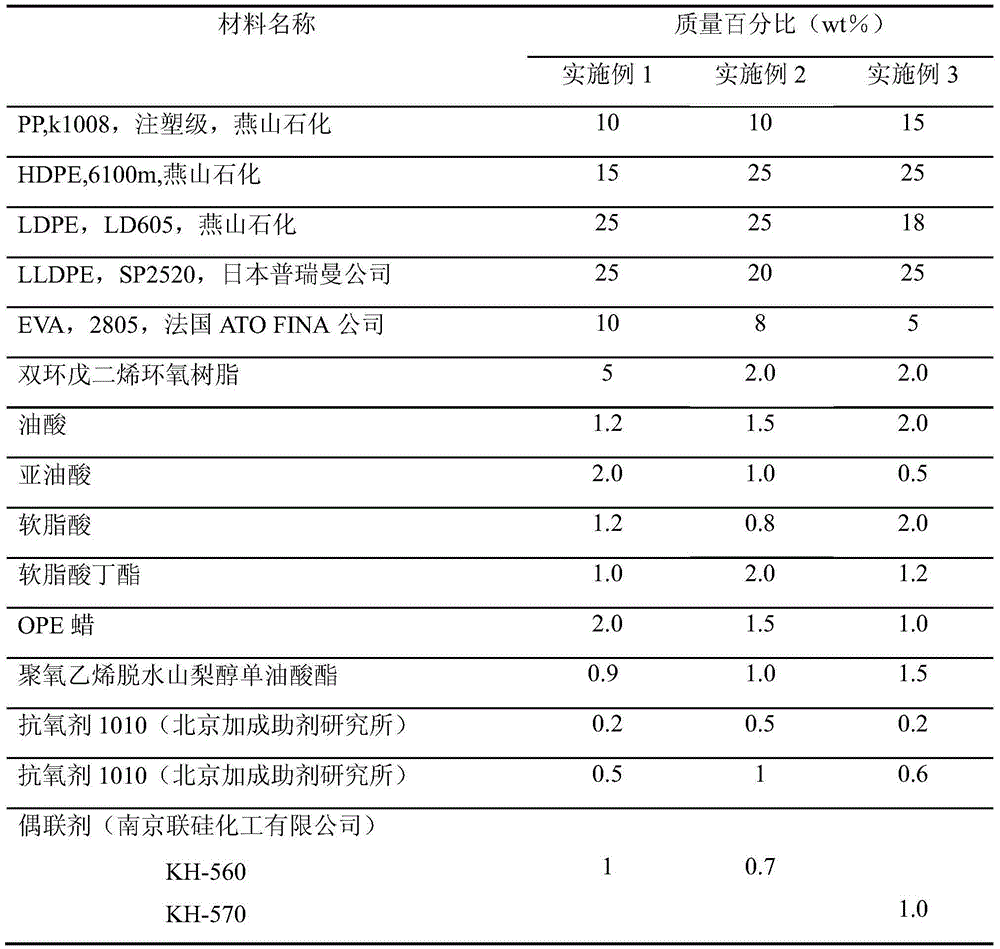

Anti-rut agent composition for high-performance composite polyolefin asphalt mixture and preparation method thereof

ActiveCN104629150AImprove low temperature performanceLow viscosityBuilding insulationsLow-density polyethyleneEpoxy

Owner:BEIJING ZHONGJIAO JIANYE TECH DEV CO LTD

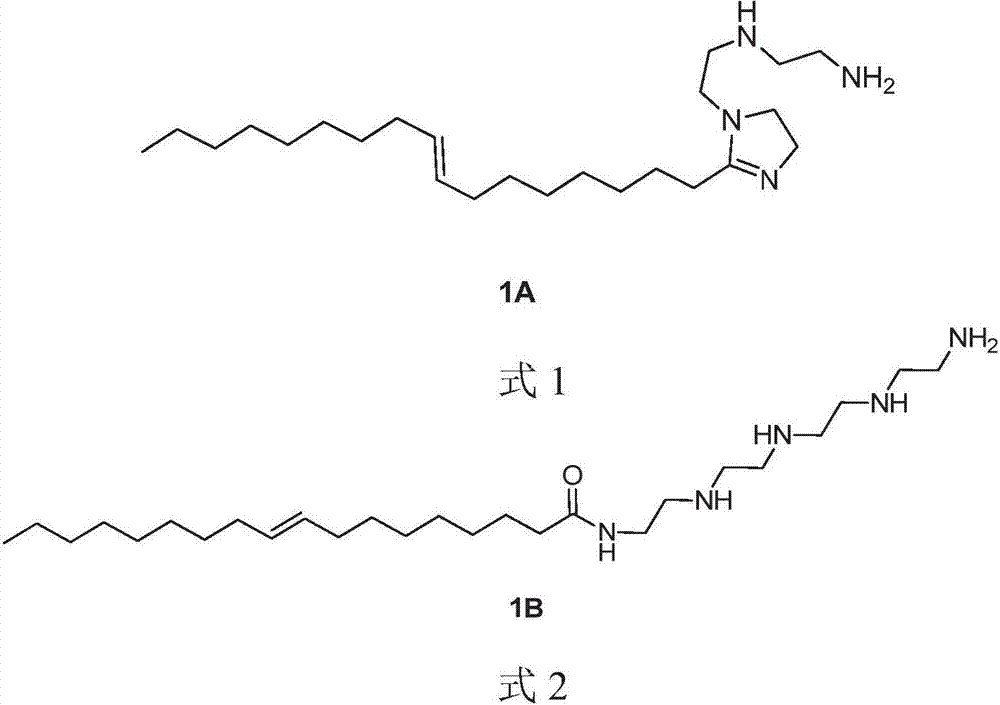

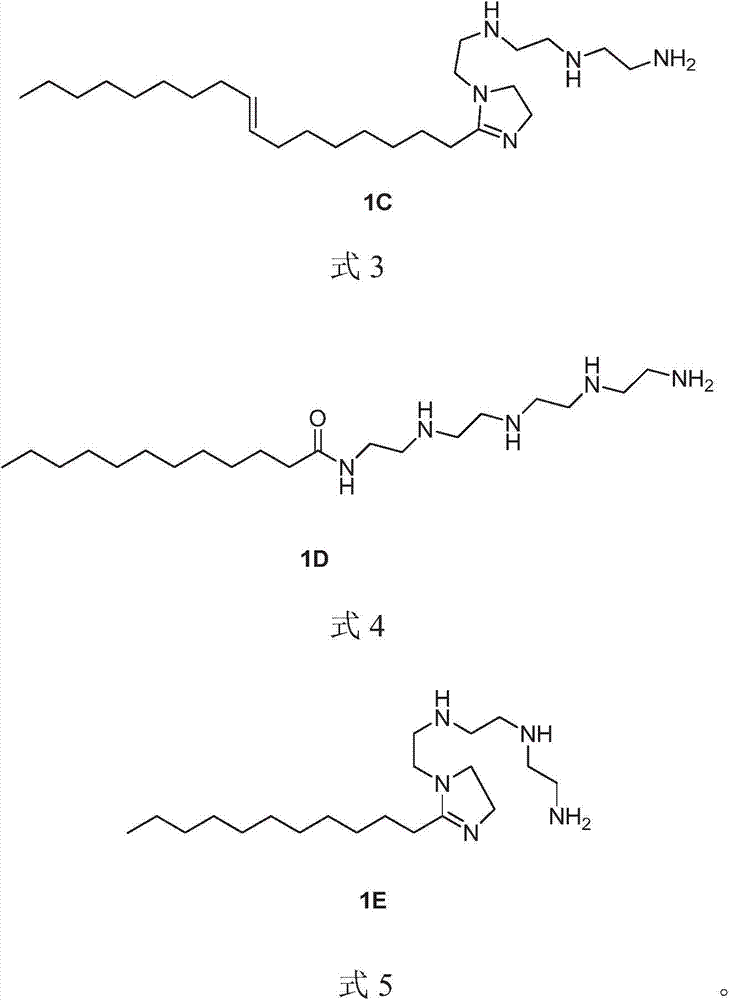

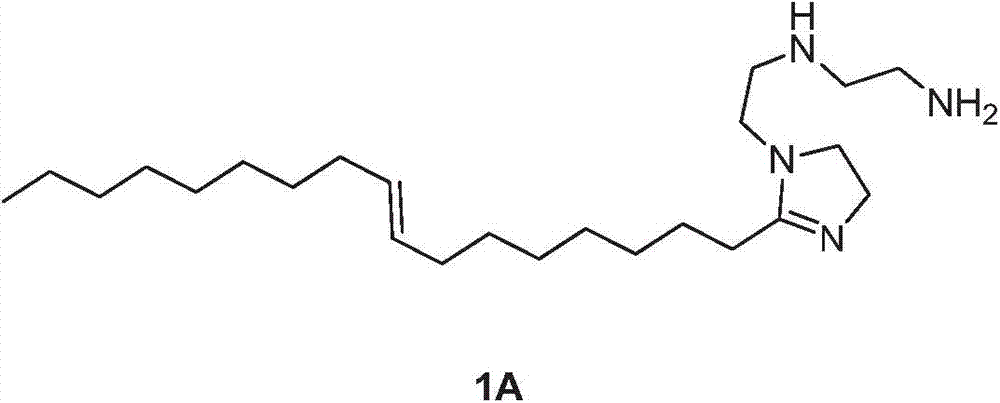

Warm mix asphalt additive, warm mix asphalt, preparation method and application

InactiveCN107163592AReduce agingLower mixing temperatureClimate change adaptationBuilding insulationsAsphaltWorking temperature

The invention discloses a warm mix asphalt additive, warm mix asphalt, warm mix asphalt mixture, a preparation method and an application. The warm mix asphalt additive comprises 30%-70% of fatty acid amide polyamine or fatty imidazoline polyamine, 20%-55% of aliphatic polyamine ethylene oxide adducts and 10%-15% of vinyl-amine, and the percent is weight percent relative to the total weight of the warm mix asphalt additive. The warm mix asphalt additive can be directly added into the asphalt to prepare the anhydrous warm mix asphalt, the working temperature of the asphalt mixture is effectively reduced, and the warm mix asphalt additive is applicable to different asphalt mixture types. Compared with hot-mixed asphalt mixture of the same type, the temperature can be reduced by 20-50 DEG C, the warm mix asphalt mixture has the advantages of simple process, energy conservation, environmental protection, low cost and the like, the moisture damage resistance of the warm mix asphalt is improved, and the service life of a road is prolonged.

Owner:上海龙孚材料技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com