Composite warm-mixed flame-retarding antiskid asphalt tunnel pavement material and preparation method thereof

A pavement material and anti-skid technology, applied in the field of building materials, can solve the problems of unfavorable maintenance and renovation, small structure depth, poor anti-rutting performance, etc., to eliminate the damage of water stability, reasonable structure depth, and high anti-rutting ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

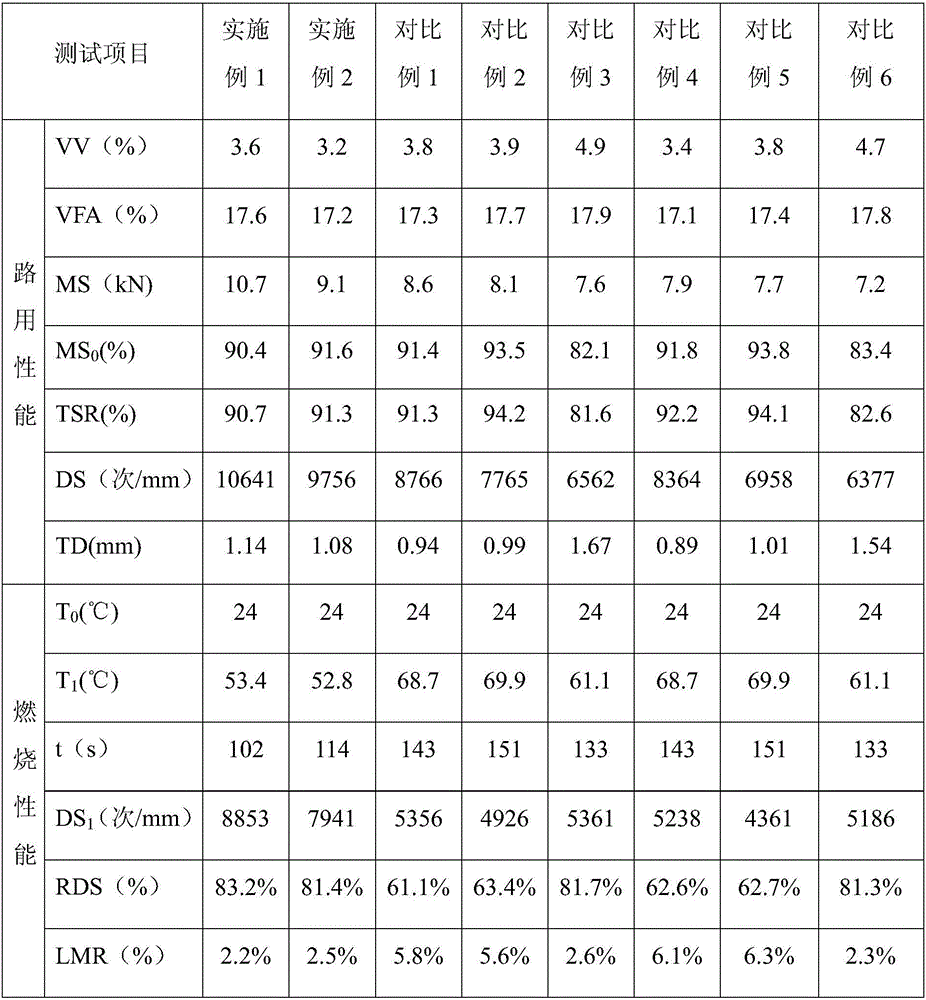

Examples

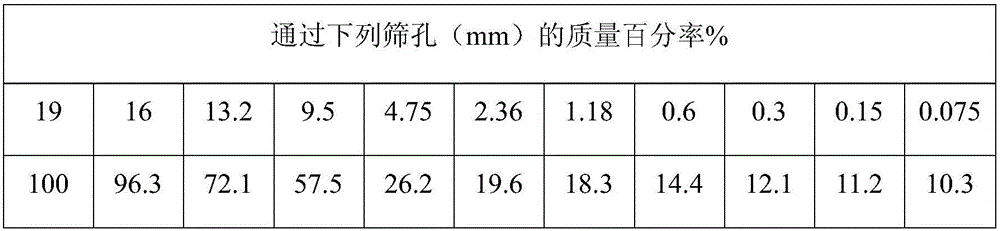

Embodiment 1

[0033] A composite warm-mix flame-retardant anti-slip asphalt tunnel pavement material, the preparation method of which comprises the following steps:

[0034] 1) Preparation of functional filler: Mix 69 parts of mineral powder, 18 parts of aluminum hydroxide powder, 5 parts of magnesium hydroxide powder, 3 parts of 4A zeolite powder, and 5 parts of tin oxide powder into a uniform powder to obtain a functional filler;

[0035] 2) Preparation of high-viscosity and high-elasticity modified asphalt: heat 100 parts of AH-70 heavy traffic asphalt to 150°C, perform high-speed shearing and heat up to 170°C within 10 minutes, and add 5 parts of styrene at a constant speed during the heating process - Butadiene-styrene block copolymer and 3 parts of stabilizer (terpene resin); keep the temperature condition of 165 ℃ and continue high-speed shearing for 10 minutes, and add 20 parts of active rubber powder at a uniform speed during this process; then stop shearing And keep it at 145°C fo...

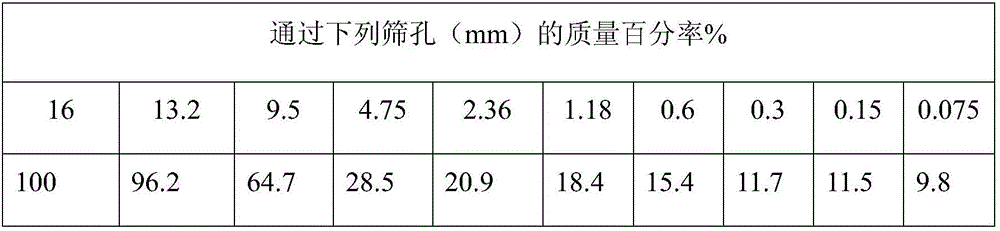

Embodiment 2

[0042] A composite warm-mix flame-retardant anti-slip asphalt tunnel pavement material, the preparation method of which comprises the following steps:

[0043] 1) Preparation of functional filler: Mix 69 parts of mineral powder, 18 parts of aluminum hydroxide powder, 5 parts of magnesium hydroxide powder, 3 parts of 4A zeolite powder, and 5 parts of tin oxide powder into a uniform powder to obtain a functional filler;

[0044] 2) Preparation of high-viscosity and high-elasticity modified asphalt: heat 100 parts of AH-70 heavy traffic asphalt to 150°C, perform high-speed shearing and heat up to 170°C within 10 minutes, and add 5 parts of styrene at a constant speed during the heating process - Butadiene-styrene block copolymer and 3 parts of stabilizer (terpene resin); keep the temperature condition of 165 ℃ and continue high-speed shearing for 10 minutes, and add 20 parts of active rubber powder at a uniform speed during this process; then stop shearing And keep it warm at 145...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com