Composite modified asphalt mixture of rubber powder with high anti-rutting performance and preparation method thereof

A technology of composite modified asphalt and mixture, which is applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems that the road performance cannot be fully adapted, and achieve the purpose of highlighting the significance of social environmental protection and solving environmental pollution Effects of problems, large social benefits, and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

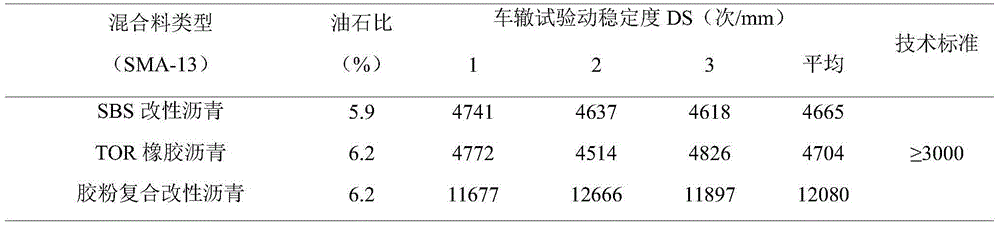

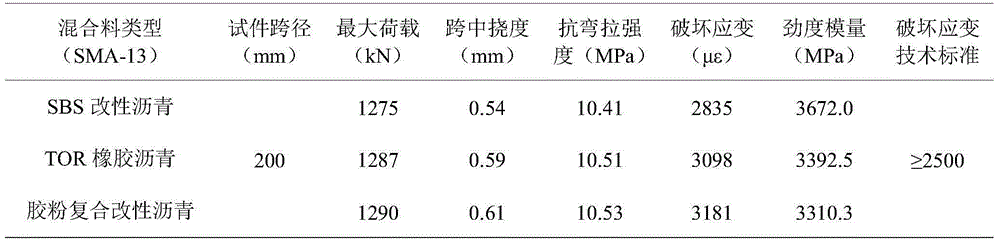

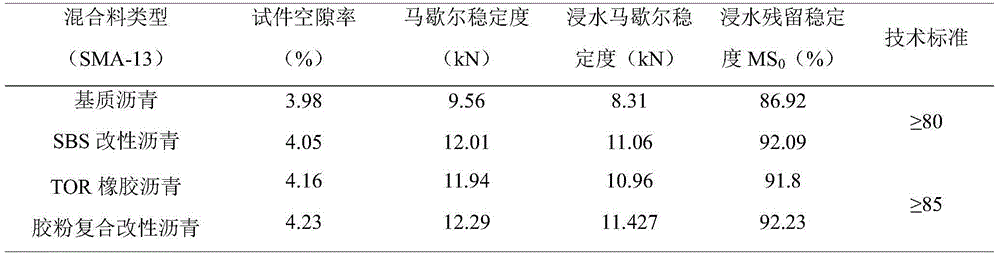

Examples

Embodiment 1

[0029] Example 1 is a dry molding preparation method. First, put 180g of rubber powder and 8.1g of Vita linking agent (TOR) into 1000g of Jinling 70# road petroleum asphalt at 120°C, and then stir at a high speed for 1 hour at 160-170°C. Then put it in a 170°C oven and swell for 1 hour to obtain TOR rubber asphalt; then put 6g of Lufu 8000 and 1335g of aggregate (wherein 1#:2#:3#:4#=42:30:0:17) in Stir in the mixing pot for 30s, add 93g of TOR rubber asphalt and stir for 90s, then add 165g of mineral powder and stir for 90s, then form the test piece and prepare the rubber powder composite modified asphalt mixture. The specific steps are:

[0030] 1) Heating road petroleum asphalt: heating and dehydrating the asphalt, the heating temperature is 120°C.

[0031] 2) The mass of rubber powder is 18% of the mass of asphalt, and TOR is 4.5% of the mass of rubber powder.

[0032] 3) Mix the rubber powder and TOR into the road petroleum asphalt at the same time, and carry out mechani...

Embodiment 2

[0037] Example 2 is the preparation method of wet molding. First put 50g of Lufu 8000 into 1000g of Jinling 70# road petroleum asphalt at 120°C, stir for 2 to 3 minutes, then add 180g of rubber powder and 8.1g of Vita linker (TOR) , stirred at 160-170°C for 1 hour at high speed, and then put it in a 160°C oven to swell for 1 hour to obtain rubber powder composite modified asphalt; 42:30:0:17) was mixed with 93g of rubber powder compound modified asphalt for 90s, then 165g of mineral powder was added and stirred for 90s, the test piece was formed, and the rubber powder compound modified asphalt mixture was prepared.

[0038] 1) Heating road petroleum asphalt: heating and dehydrating the asphalt, the heating temperature is 120°C.

[0039] 2) The quality of Lufu 8000 is 5% to 10% of the asphalt, the rubber powder is 18% of the asphalt, and TOR is 4.5% of the rubber powder.

[0040] 3) Mix Lufu 8000, rubber powder and TOR into the road petroleum asphalt at the same time, and carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com