Warm mixing agent and preparation method thereof

The technology of warm mix agent and modifier is applied in the field of asphalt modifier to achieve the effects of reducing exhaust gas and asphalt smoke emission, reducing mixing temperature and improving asphalt softening point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

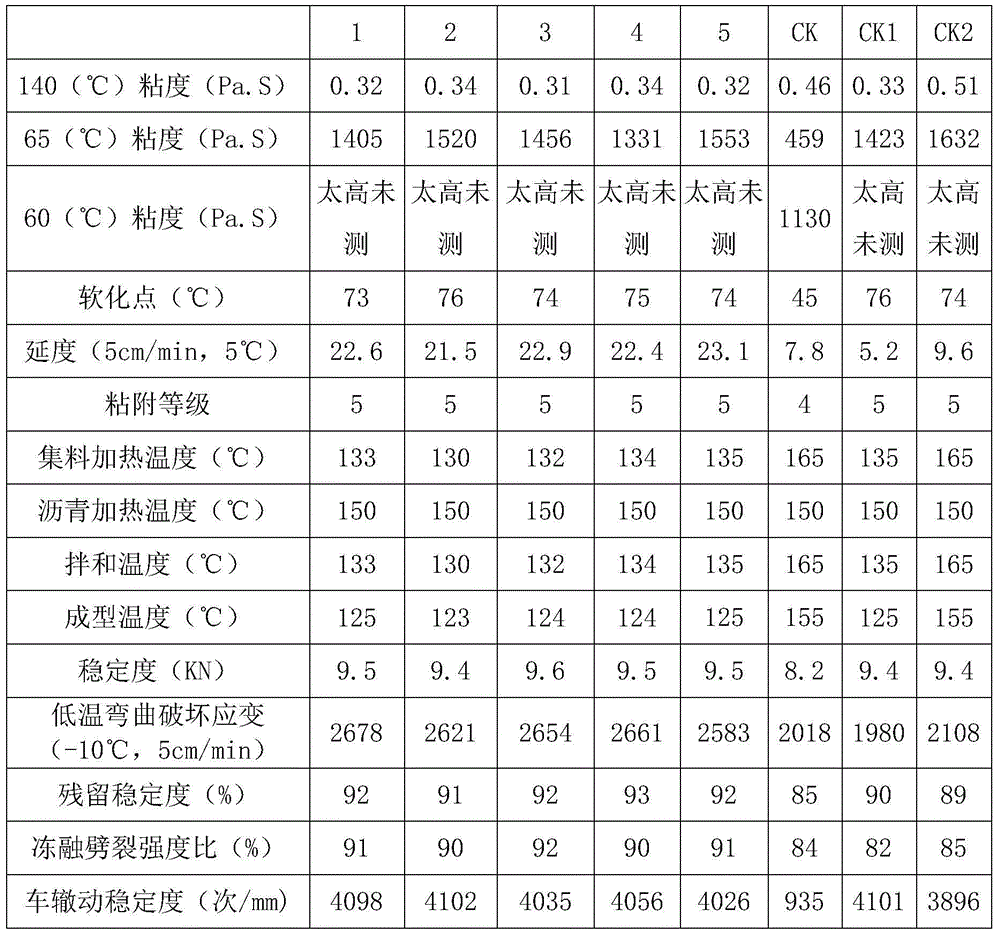

Examples

Embodiment 1

[0024] The warm mixing agent of the present embodiment is prepared according to the following steps:

[0025] 1. Preparation of amide compounds: In a 500mL four-necked flask equipped with a stirrer, thermometer, condenser, and water separator, first replace with nitrogen, then add 120g of oleic acid, 60g of ethylenediamine and 0.54g of phosphoric acid in sequence, Stir evenly, and at the same time pass nitrogen protection, stir at 150°C for 4 hours, and cool to obtain oleic acid amide;

[0026] 2. Add 3g of asphalt anti-stripping agent, 18g of di-(tert-butylperoxyisopropyl)benzene and 60g of EVA to the amide compound prepared in step 1, stir at 150°C for 3h, and cool to normal temperature to obtain warm mix.

Embodiment 2

[0028] 1. Preparation of amide compounds: In a 500mL four-necked flask equipped with a stirrer, thermometer, condenser, and water separator, first replace with nitrogen, and then add 105g of stearic acid, 150g of ethylenediamine and 0.51g of phosphoric acid in sequence , stirred evenly, and at the same time passed nitrogen protection, stirred at 120°C for 6 hours, and cooled to obtain stearic acid amide;

[0029] 2. Add 10 g of asphalt anti-stripping agent, 10 g of dicumyl peroxide and 36 g of EVA to the amide compound obtained in step 1, stir at 100° C. for 1 hour, and cool to room temperature to obtain the warm mixing agent.

Embodiment 3

[0031] 1. Preparation of amide compounds: In a 500mL four-neck flask equipped with a stirrer, thermometer, condenser, and water separator, first replace it with nitrogen, and then add 120g of lauric acid, 120g of ethylenediamine and 0.96g of phosphorous acid in sequence , stirred evenly, and at the same time passed nitrogen protection, stirred at 200°C for 1 hour, and cooled to obtain lauric acid amide;

[0032] 2. Add 26g of asphalt anti-stripping agent, 3g of sulfur and 27g of EVA to the amide compound prepared in step 1, stir at 110°C for 1.5h, and cool to room temperature to prepare the warm mix agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com