High-addition-amount plant-mixed warm regenerated asphalt mixture and preparation method thereof

A technology of recycled asphalt and mixture, which is applied in the field of asphalt mixture, which can solve the problems of temperature increase, increase of mixture production cost, serious aging of asphalt, etc., achieve high temperature stability, solve serious aging of asphalt, and improve comprehensive road performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation method of the high-volume factory-mixed temperature recycled asphalt mixture proposed by the present invention has the following steps:

[0037] (1) Analysis and selection of materials

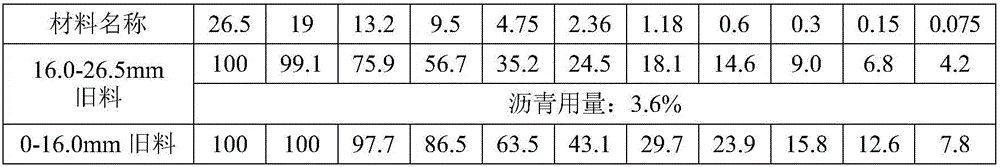

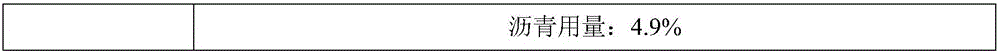

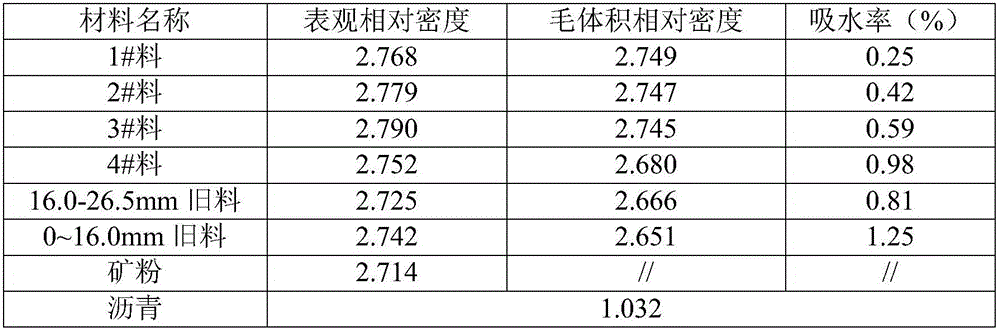

[0038] a. The aggregate is limestone aggregate, the asphalt is No. 70 A-grade road petroleum asphalt, and the mineral powder is limestone mineral powder. Extraction and screening of waste asphalt mixture: the milling material is first divided into 0-16.0mm and 16.0- The two sieve sizes of 26.5mm are divided into two categories: coarse material and fine material. The coarse material and fine material are sampled respectively, and the waste asphalt mixture is extracted by the Abson method asphalt recovery instrument or the rotary evaporator method. Aggregate and asphalt analysis, calculation of asphalt content in coarse and fine materials; the results of extraction and screening of waste asphalt mixture are shown in Table 1, and the densities of various mineral materials a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| residual stability | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com