Pavement structure for cement concrete bridge deck and pavement method thereof

A cement concrete and bridge deck paving technology, applied in the field of traffic engineering, can solve the problems of insufficient waterproof bonding performance between the pavement layer and the bridge deck, insufficient roughness of the cement concrete bridge deck, and uncleaned impurities and pollutants. Achieve superior compaction performance, reduce smoke and gas generation, and save energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

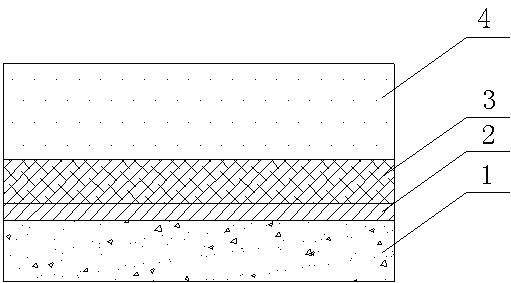

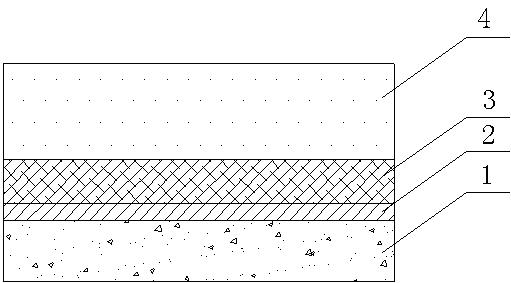

[0046]1) Carry out sandblasting treatment on the cement concrete bridge deck, remove the laitance, oil and sundries on the surface, form a dry, clean and rough interface, and the structure depth reaches 0.5mm;

[0047] 2) Coat a layer of epoxy resin on the cement concrete bridge deck after sand blasting according to the standard of 0.6kg / ㎡; 2.36mm small basalt gravels, so that the small gravels are bonded to the epoxy resin; after the epoxy resin is cured, apply a layer of reactive waterproof adhesive according to the standard of 0.3kg / ㎡ ;

[0048] 3) After the reactive waterproof adhesive is cured, spread a layer of 5mm thick modified asphalt mastic on it as a stress absorbing layer; in the modified asphalt mastic, the weight of SBS modified asphalt and mineral powder The ratio is 22: 100; the SBS modified asphalt is formed by heating and mixing modifier SBS and base asphalt, and the weight ratio of SBS and base asphalt is 6: 100; in order to increase the construction of the...

Embodiment 2

[0051] 1) Carry out sandblasting treatment on the cement concrete bridge deck, remove the laitance, oil and sundries on the surface, form a dry, clean and rough interface, and the structure depth reaches 0.8mm;

[0052] 2) Coat a layer of epoxy resin on the cement concrete bridge deck after sandblasting according to the standard of 0.3kg / ㎡; 2.36mm small basalt gravels, so that the small gravels are bonded to the epoxy resin; after the epoxy resin is cured, apply a layer of reactive waterproof adhesive according to the standard of 0.2kg / ㎡ ;

[0053] 3) After the reactive waterproof adhesive is cured, a layer of 3mm thick modified asphalt mastic is spread on it as a stress absorption layer; the modified asphalt mastic is prepared by hot mixing SBS modified asphalt and mineral powder Form, the weight ratio of SBS modified asphalt and slag powder is 23: 100; Described SBS modified asphalt is formed by heating and mixing of modifier SBS and base asphalt, and the weight ratio of SB...

Embodiment 3

[0056] 1) Carry out sandblasting treatment on the cement concrete bridge deck, remove the laitance, oil and sundries on the surface, form a dry, clean and rough interface, and the structure depth reaches 0.6mm;

[0057] 2) Coat a layer of epoxy resin on the cement concrete bridge deck after sand blasting according to the standard of 0.5kg / ㎡; 2.36mm small basalt gravels, so that the small gravels are bonded to the epoxy resin; after the epoxy resin is cured, apply a layer of reactive waterproof adhesive according to the standard of 0.4kg / ㎡ ;

[0058] 3) After the reactive waterproof adhesive is cured, spread a layer of 4mm thick modified asphalt mastic on it as a stress absorbing layer; the modified asphalt mastic is formed by hot mixing SBS modified asphalt and mineral powder Form, the weight ratio of SBS modified asphalt and slag powder is 20: 100; Described SBS modified asphalt is formed by heating and mixing of modifier SBS and matrix asphalt, and the weight ratio of SBS a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com