Preparation method of high-performance warm-mix regenerated asphalt mixture

A technology for asphalt mixture and recycled asphalt, which is used in climate change adaptation, roads, road repair, etc., can solve the problems of low strength of recycled mixture, reduced water stability of mixture, and high cost, saving fuel and exhaust emissions, The effect of saving stone and asphalt, saving resources and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

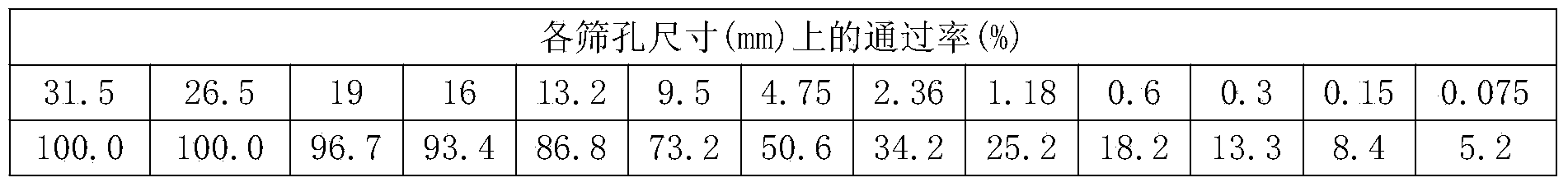

[0028] 1) Extract and screen the old asphalt mixture, determine the gradation and asphalt content of the mixture, and conduct three index tests on the asphalt to evaluate the performance indicators of the old asphalt in RAP.

[0029]

[0030] Three major indicators of asphalt:

[0031] Asphalt penetration: 22 (0.1mm), softening point: 58°C, ductility 7cm at 15°C.

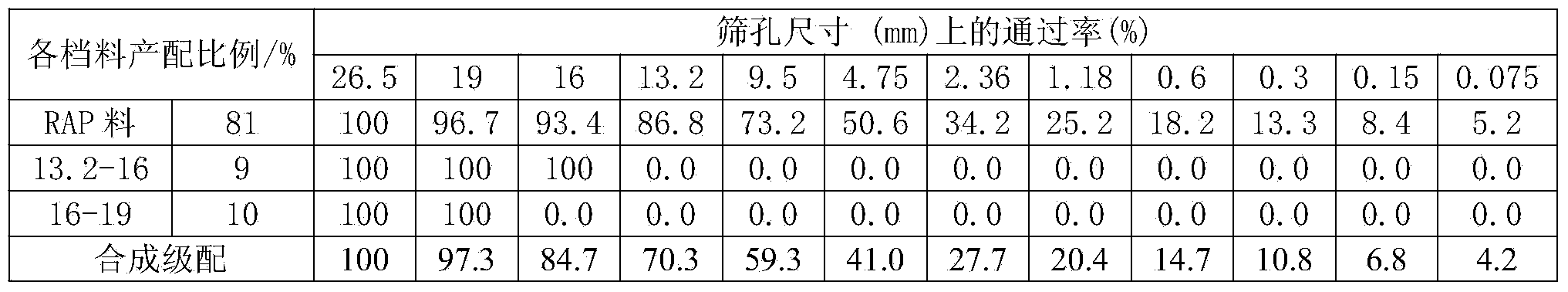

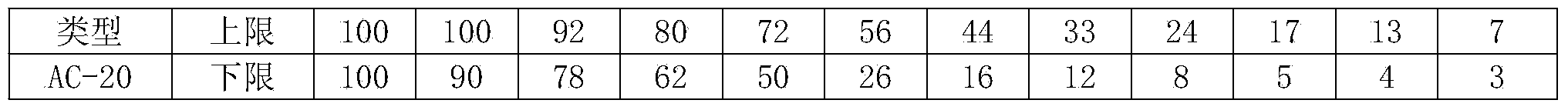

[0032] 2) Adjust the mixture gradation

[0033] The target mixture gradation prepared with AC-20 gradation requires 9% of 13.2-16mm aggregate and 10% of 16-19mm aggregate. The blending results are shown in the table below:

[0034]

[0035]

[0036] 3) According to the economic index analysis of the project, the ratio of RAP dosage is determined to be 60%.

[0037] 4) According to Marshall's "5-point method" of conventional asphalt mixture, determine the optimal amount of new asphalt added to the asphalt mixture (OAC n ) is 2.0%.

[0038] 5) The amount of sulfur additive added is 1% of the mass of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Modulus of resilience | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com