Rubber asphalt high temperature viscosity reducer, preparation method and application thereof

A high-temperature viscosity reducer and rubber asphalt technology, which is applied in the field of rubber asphalt modification, can solve the problem that the water stability performance and high temperature performance of warm-mix rubber asphalt mixture are reduced, it is difficult to achieve the effect of hot-mix rubber asphalt mixture, and the reduction of rubber asphalt and rubber asphalt. Aggregate adhesion and other problems, to achieve the effect of reducing mixing temperature, improving storage stability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A high-temperature viscosity-reducing agent for rubber asphalt, which is prepared from oxidized polyethylene wax, higher fatty acid, and calcium hydroxide raw materials; the mass ratio of each raw material is: oxidized polyethylene wax: higher fatty acid: calcium hydroxide=100:5: 10.

[0036] Oxidized polyethylene wax is from Nanjing Tianshi Experimental Micro Powder Co., Ltd., model is PEWO-0502; higher fatty acid is stearic acid, from Shijiazhuang Taixin Chemical Co., Ltd., industrial grade; calcium hydroxide is from Chengshi Calcium, Jiande City, Zhejiang Province Industry Co., Ltd., the fineness is 300 mesh.

[0037] The preparation method of above-mentioned rubber asphalt high temperature viscosity reducer is as follows:

[0038] (1) Weigh the oxidized polyethylene wax, higher fatty acid, and calcium hydroxide in proportion, and the total mass is 300g.

[0039] (2) Add oxidized polyethylene wax and higher fatty acid into a three-neck flask equipped with a liquid ...

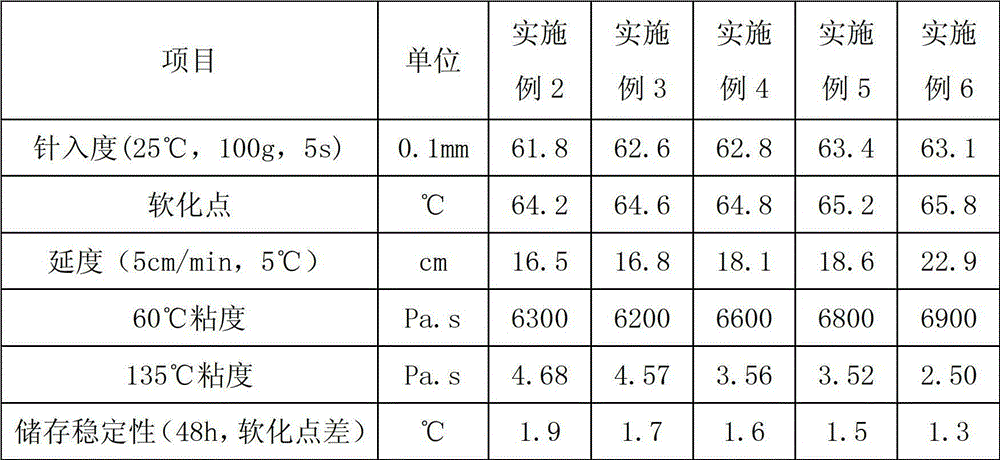

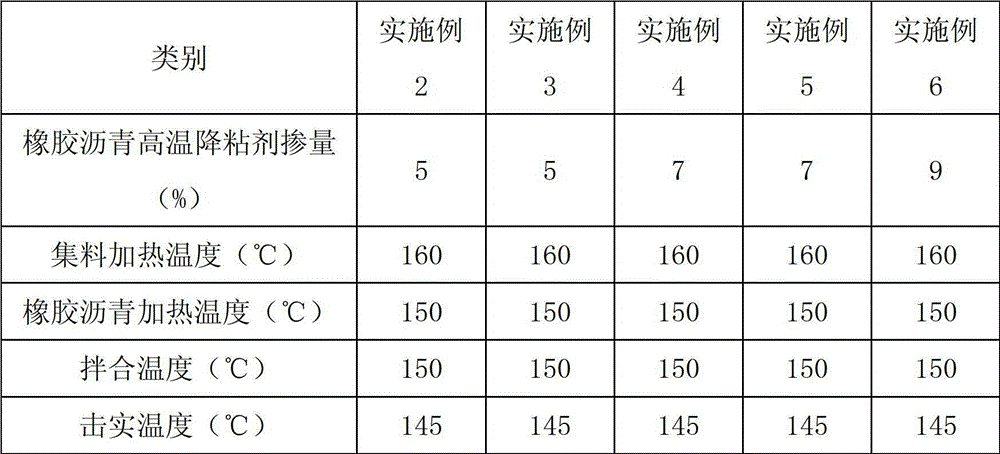

Embodiment 2

[0055] A high-temperature viscosity-reducing agent for rubber asphalt, which is prepared from oxidized polyethylene wax, higher fatty acid, and calcium hydroxide raw materials; the mass ratio of each raw material is: oxidized polyethylene wax: higher fatty acid: calcium hydroxide=100:5: 50.

[0056] Oxidized polyethylene wax is from Nanjing Tianshi Experimental Micropowder Co., Ltd., the model is PEWO-0502; the higher fatty acid is oleic acid, from Jiangsu Jinma Oil Technology Development Co., Ltd., the model is RLYS-I; calcium hydroxide is from Jiande City, Zhejiang Province Chengshi Calcium Industry Co., Ltd., the fineness is 300 mesh.

[0057] The preparation method of above-mentioned rubber asphalt high temperature viscosity reducer is as follows:

[0058] (1) Weigh the oxidized polyethylene wax, higher fatty acid, and calcium hydroxide in proportion, and the total mass is 300g.

[0059] (2) Add oxidized polyethylene wax and higher fatty acid into a three-necked flask eq...

Embodiment 3

[0062] A high-temperature viscosity-reducing agent for rubber asphalt, which is prepared from oxidized polyethylene wax, higher fatty acid, and calcium hydroxide raw materials; the mass ratio of each raw material is: oxidized polyethylene wax: higher fatty acid: calcium hydroxide=100:40: 50; Higher fatty acid is stearic acid, from Shijiazhuang Taixin Chemical Co., Ltd., industrial grade; calcium hydroxide is from Zhejiang Jiande Chengshi Calcium Industry Co., Ltd., with a fineness of 300 mesh.

[0063] The preparation method of above-mentioned rubber asphalt high temperature viscosity reducer is as follows:

[0064] (1) Weigh the oxidized polyethylene wax, higher fatty acid, and calcium hydroxide in proportion, and the total mass is 300g.

[0065] (2) Add oxidized polyethylene wax and higher fatty acid into a three-necked flask equipped with a liquid separator, then add 80ml of toluene and 40g of concentrated sulfuric acid, heat to 70°C to dissolve, turn on the electric stirre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com