Compound asphalt mixture wet-mixing additive and preparation method thereof

An asphalt mixture and composite technology, which is applied in the field of road materials, can solve the problems of single type of warm mix additives, high price, and reduce the road performance of asphalt mixture, so as to improve the working environment of workers, improve road performance, and improve road performance. By the effect of performance enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

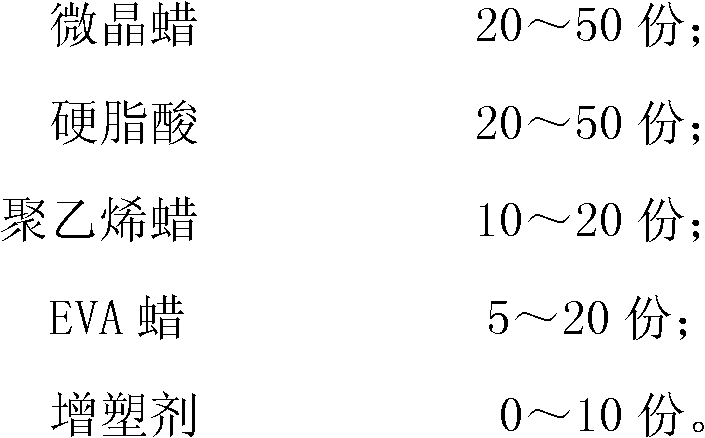

Method used

Image

Examples

Embodiment 1

[0042] According to the parts by weight of each component of Example 1 in Table 1, the warm mixing additive product is prepared, comprising the following steps:

[0043] (1) 40 parts of blocky microcrystalline wax are chopped into fragments below 2cm in particle size, and set aside;

[0044] (2) Add 15 parts of polyethylene wax, 20 parts of EVA wax and 20 parts of stearic acid in powder form to the ribbon mixer, and then add 5 parts of chlorinated paraffin after starting and mix evenly under the action of mechanical stirring; then add micro The crystal wax continues to stir and mix evenly to obtain a mixed dry material;

[0045] (3) Put the mixed dry material into the melting tank of the granulator, heat it at 120°C to 130°C and melt it, and then granulate it through a rotary belt type condensation device, the particle size is less than 5mm, cool and dry.

Embodiment 2

[0047] According to the parts by weight of each component of embodiment 2 in table 1, prepare warm mixing additive product, comprise the following steps:

[0048] (1) 30 parts of blocky microcrystalline wax are chopped into fragments below 2cm in particle size, and set aside;

[0049] (2) Add 20 parts of polyethylene wax, 20 parts of EVA wax and 20 parts of stearic acid into the ribbon mixer in powder form, and then add 10 parts of chlorinated paraffin after starting and mix evenly under the action of mechanical stirring; then add micro The crystal wax continues to stir and mix evenly to obtain a mixed dry material;

[0050] (3) Put the mixed dry material into the melting tank of the granulator, heat it at 120°C to 130°C and melt it, and then granulate it through a rotary belt type condensation device, the particle size is less than 5mm, cool and dry.

Embodiment 3

[0052] According to the parts by weight of each component of Example 3 in Table 1, the warm-mix additive product is prepared, comprising the following steps:

[0053] (1) 40 parts of blocky microcrystalline wax are chopped into fragments below 2cm in particle size, and set aside;

[0054] (2) Add 20 parts of polyethylene wax, 10 parts of EVA wax and 30 parts of stearic acid into the ribbon mixer and mix evenly under the action of mechanical stirring; dry ingredients;

[0055] (3) Put the mixed dry material into the melting tank of the granulator, heat it at 120°C to 130°C and melt it, and then granulate it through a rotary belt type condensation device, the particle size is less than 5mm, cool and dry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com