Embedded pouring asphalt concrete

An asphalt concrete, pouring technology, which is applied to the coagulation pavement, buildings, roads and other directions of on-site paving, can solve the problems that the performance of the construction fluid concrete cannot be solved, and the anti-fatigue performance of the pouring asphalt concrete cannot be solved. High promotion and application value, the effect of ensuring the embedding rate and reducing the mixing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

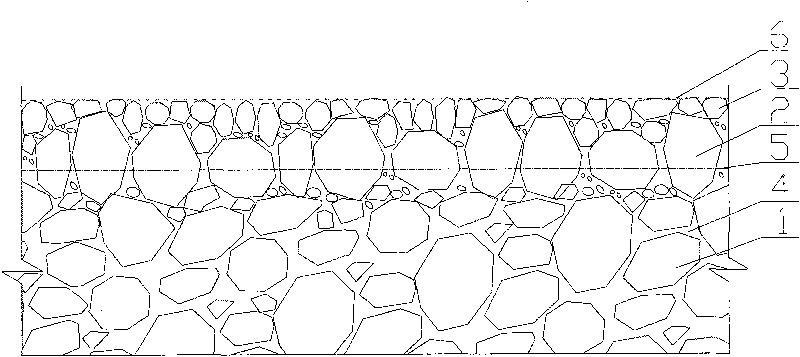

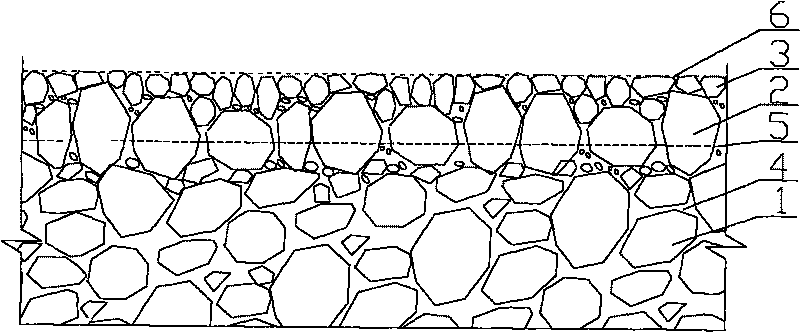

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

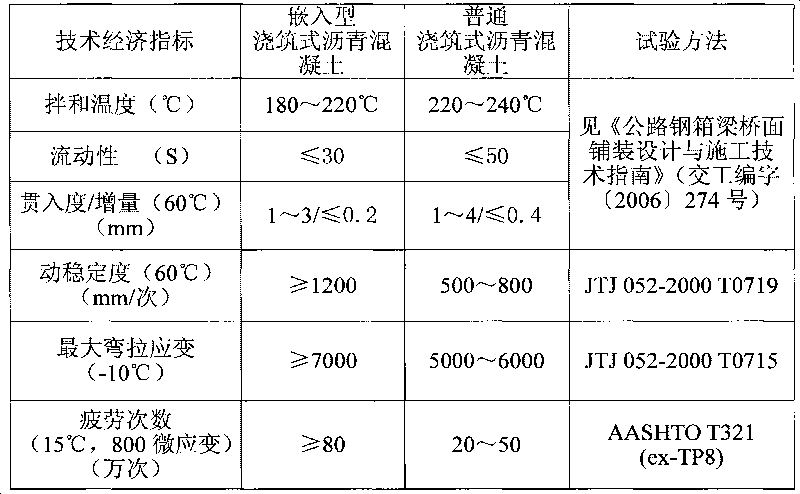

[0019] Reduce the amount of coarse aggregate (≥2.36mm) basalt by adopting the gradation requirement range of poured asphalt concrete (GA10) in the "Technical Guidelines for Design and Construction of Highway Steel Box Girder Bridge Deck Pavement" (Jiaogong Editor [2006] No. 274) 28%, put it into the asphalt mixture mixing building to mix and mix well. The mixing temperature is 203°C. After paving and leveling with a paver, a cast-type asphalt concrete 1 with a reduced amount of coarse aggregate is formed, and spread on its surface A layer of basalt gravel with a particle size of 10-15mm is used in an amount of 22% of the mass of the designed poured asphalt concrete to form the first layer of coarse aggregate 2, and then a second layer of basalt gravel with a particle size of 5-10mm is spread on the surface. The amount used is 14% of the mass of the designed pouring asp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com