Anti-rut agent composition for high-performance composite polyolefin asphalt mixture and preparation method thereof

A technology for compounding polyolefin and asphalt mixture, which is applied to building structures, building insulation materials, building components, etc., can solve the problems of incompatibility, insufficient improvement of low temperature performance and water stability, etc., and achieves easy processing and improved rutting resistance. performance and overall performance, and the effect of improving overall performance

Active Publication Date: 2015-05-20

BEIJING ZHONGJIAO JIANYE TECH DEV CO LTD

View PDF2 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the current polymer anti-rutting agents have the disadvantages that high and low temperature performance c

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

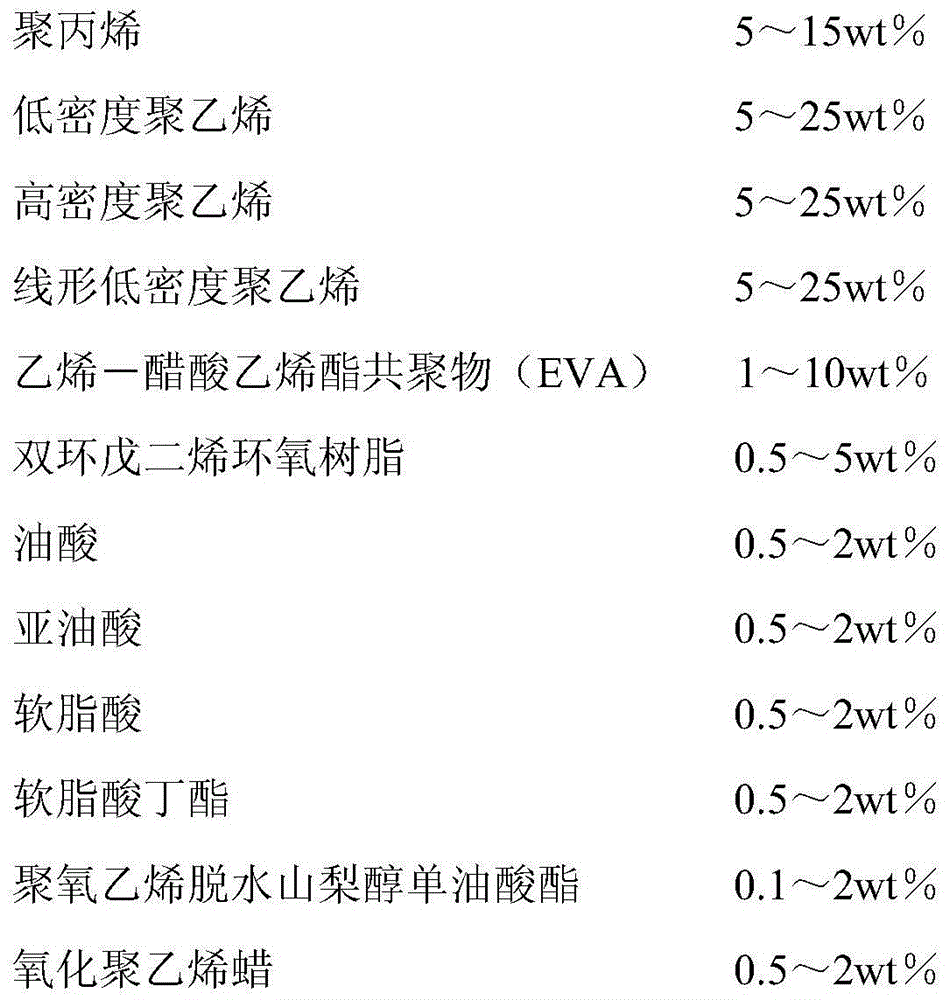

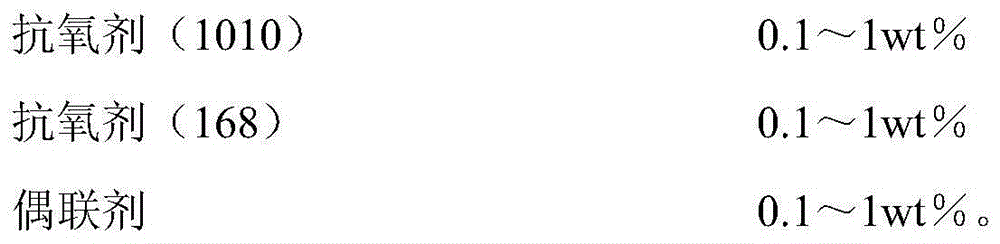

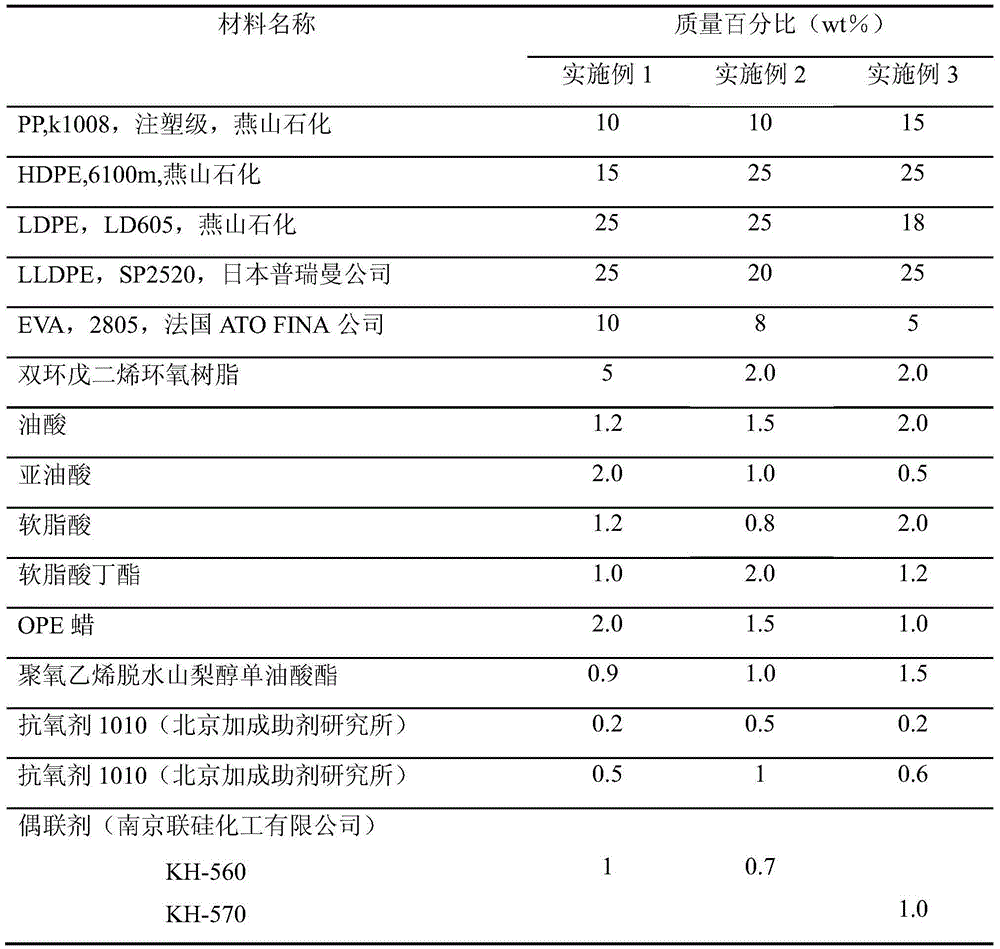

The invention discloses an anti-rut agent composition for a high-performance composite polyolefin asphalt mixture and a preparation method of the anti-rut agent composition. The composition comprises the components in percent by weight: 5-15 percent of polypropylene, 5-25 percent of low-density polyethylene, 5-25 percent of high-density polyethylene, 5-25 percent of linear low-density polyethylene, 1-10 percent of EVA, 0.5-5 percent of dicyclopentadiene epoxy resins, 0.5-2 percent of oleic acid, 0.5-2 percent of linoleic acid, 0.5-2 percent of palmitic acid, 0.5-2 percent of palmitic acid butyl ester, 0.1-2 percent of polyoxyethylene sorbitan monooleate, 0.5-2 percent of oxidized polyethlene wax, 0.1-1 percent of antioxidant (1010), 0.1-1 percent of antioxidant (168) and 0.1-1 percent of coupling agent. The preparation method comprises the steps of uniformly mixing all components by using a high-speed mixing machine and performing mixed granulation by using a high-shear type double-screw extrusion machine. The anti-rut agent composition is used in the asphalt mixture, so that the anti-rut property, the constant water temperature property and the low-temperature anti-cracking performance of the asphalt mixture can be improved, the mixing of the original asphalt mixture is maintained, and the comprehensive performance of the asphalt mixture is improved.

Description

technical field [0001] The invention relates to a polymer material for modified asphalt, in particular to a composite polyolefin asphalt anti-rutting agent composition and a preparation method thereof, which is mainly used in road asphalt. Background technique [0002] With the rapid development of my country's economy and the increasing traffic flow, the performance requirements of roads are getting higher and higher. Usually, ordinary asphalt mixture is used to pave the road surface. Brittle cracks will occur, rutting is prone to occur at high temperatures, and poor water stability is likely to cause water damage to the road surface. In order to improve these properties of asphalt, save resources and protect the environment, prolong the service life of the pavement, improve the high-temperature rutting resistance and low-temperature crack resistance of the pavement, improve the water stability of the pavement, reduce maintenance costs, and improve driving comfort, domestic ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L23/06C08L23/08C08L23/12C08L23/14C08L63/00C08L23/30C08L71/02C08K5/00C08K5/09C08K5/101C08K5/134C08K5/526C08L95/00C04B26/26

CPCC04B24/2611C04B40/0039C08L23/06C08L23/0815C08L95/00C08L2205/025C08L2205/035C08L2207/062C08L2207/066C08L23/12C08L23/0853C08L63/00C08L23/30C08L71/02C08K5/00C08K5/09C08K5/101C04B24/281C04B24/04

Inventor 王珏张奎元徐柏康杨明山张晓霞

Owner BEIJING ZHONGJIAO JIANYE TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com