Warm mixed asphalt and preparation method thereof

A technology of warm-mixed asphalt and base asphalt, which is applied in building insulation materials, building components, climate change adaptation, etc. It can solve problems such as inferior chemical plasticization, lack of test methods and example data support, immaturity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

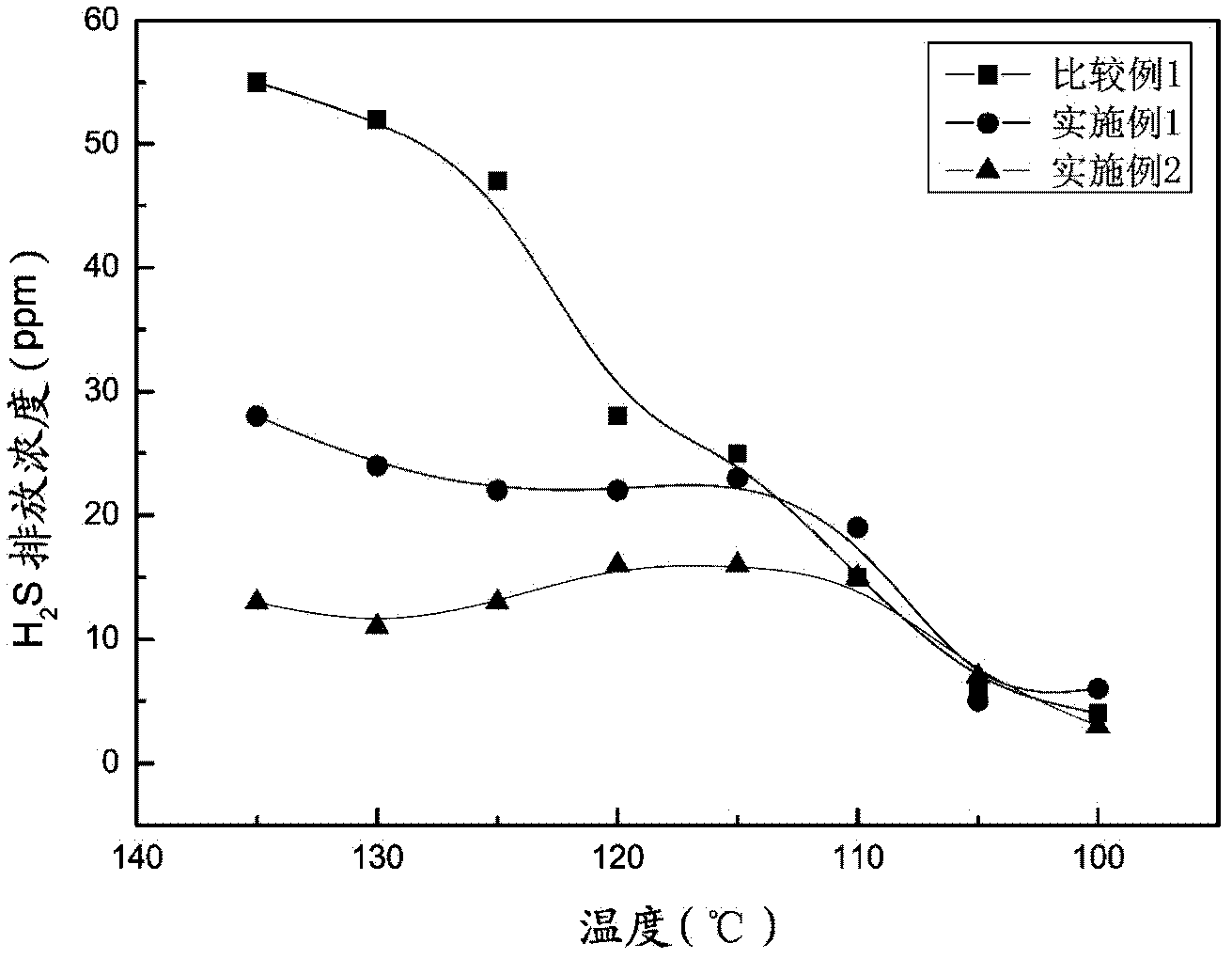

[0048] After the plasticized sulfur warm mix asphalt is prepared, it is necessary to evaluate the volatility of the undesired gases in the formulation of this example. The implementation method is as follows:

[0049] (1) Seal the asphalt sample to be tested and place it in an oven at 135°C.

[0050] (2) After the sample has been kept at constant temperature for a period of time, it is taken out and quickly placed in the annular partition. The annular partition is located in a fume hood with a steady updraft, and the ambient temperature is kept constant at 23 °C.

[0051] (3)H 2 The S detector is placed at a certain height directly above the asphalt sample, the sealing cover of the asphalt sample is opened, and the H 2 The gas concentration of S, and then record the concentration value every time the sample temperature drops by 5°C until the detected concentration approaches zero.

[0052] (4) with H 2 S concentration / temperature as coordinates, draw H 2 The curve of the...

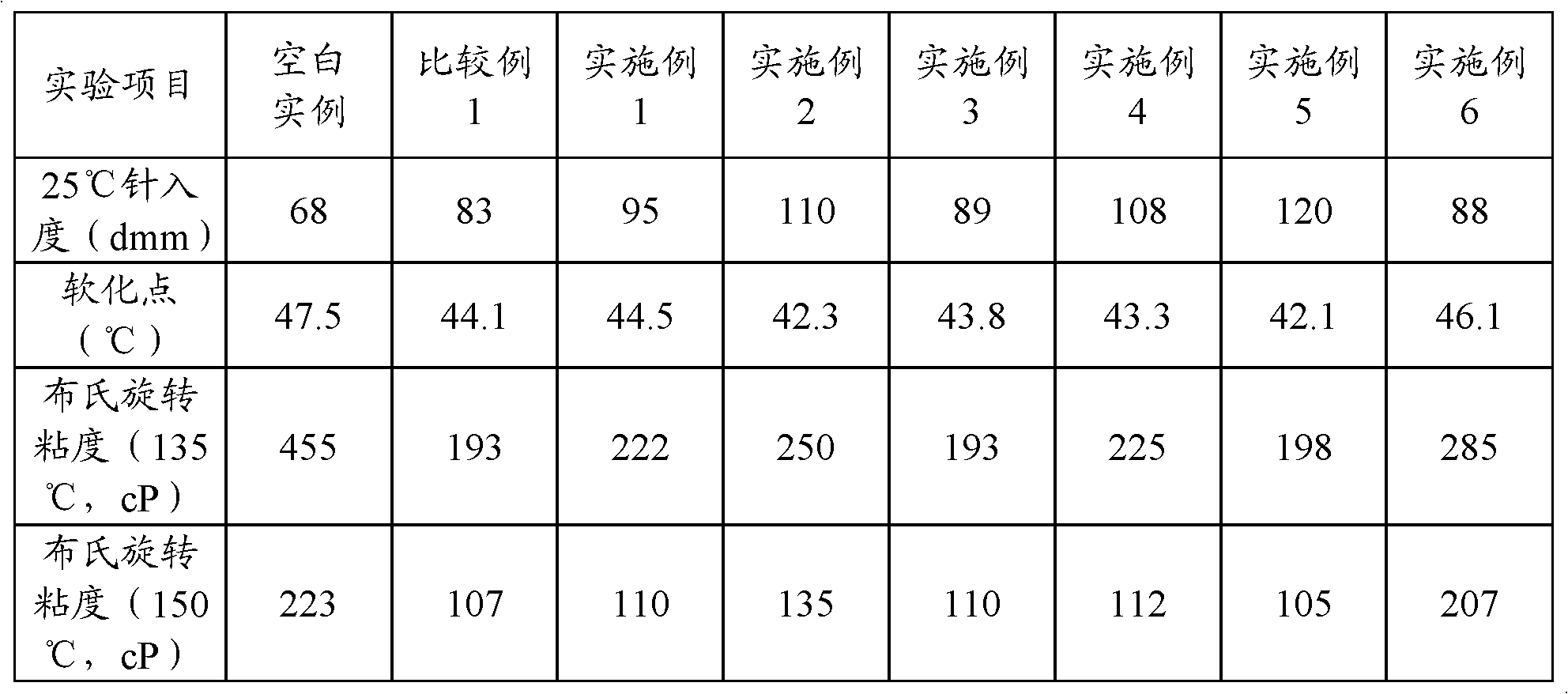

Embodiment 1

[0055] 100 parts of elemental sulfur, 20 parts of dicyclopentadiene and 5 parts of pyridine were mixed and stirred at 130° C. for 3 hours. Then at 135°C, add 20 parts of the prepared plasticized sulfur to 100 parts of general-purpose petroleum-based asphalt (base asphalt) with a penetration of 68dmm at 25°C, add 1 part of calcium oxide and 0.1 part of amyl acetate in sequence, and stir for 0.5 hours to get the product.

Embodiment 2

[0057] 100 parts of elemental sulfur and 20 parts of liquid polyolefin polysulfide (Mw≈4000) were mixed and stirred at 130° C. for 1.5 hours. Then at 135°C, add 20 parts of the prepared plasticized sulfur to 100 parts of general-purpose petroleum-based asphalt (base asphalt) with a penetration of 68dmm at 25°C, add 0.05 parts of hydrogen peroxide, 0.02 parts of 1,6-hexane Dithiol was stirred for 1 hour to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com