Microporous polyurethane elastomer compound with excellent dynamic performance and preparation method thereof

A polyurethane elastomer and dynamic performance technology, applied in the field of polyurethane elastomer synthesis, can solve the problems of complex processing technology, high melting point of PPDI, small damping property, etc., and achieve the effect of simple process control conditions, easy mixing and uniform operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

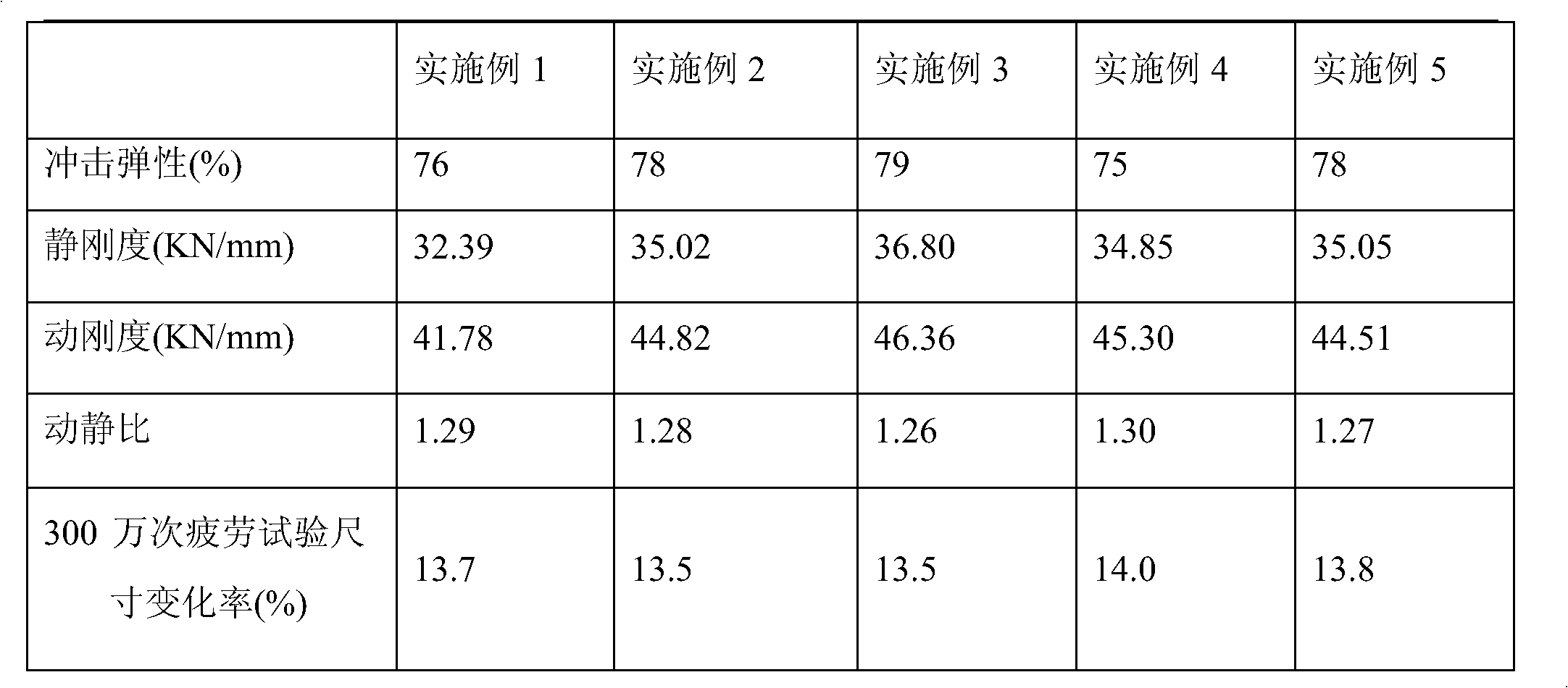

Examples

Embodiment 1

[0022] Component A: Weigh 50 parts of polytetrahydrofuran ether polyol (PTMG2000, BASF product) with average functionality = 2 and number average molecular weight = 2000, and 50 parts of polytetrahydrofuran ether with average functionality = 2 and number average molecular weight = 1000 Polyol (PTMG1000, BASF product), 8 parts of 1,4-butanediol, 0.25g water, 0.5 part of AK-7703, 0.8 part of diethylene glycol solution of triethylenediamine with a solid content of 33%, 0.03 part of diethylene glycol Put dibutyltin laurate and 0.35 parts of BHT264 in a mixer, stir evenly, remove air bubbles in a vacuum, and store in a sealed container.

[0023] Component B: with 80 parts of average functionality=2, polytetrahydrofuran ether polyol (PTMG2000, BASF product) of number average molecular weight=2000 and 20 parts of average functionality=3, polyether polyol of number average molecular weight=6000 ( EP-3600, product of Shandong Bluestar Dongda Chemical Co., Ltd.) dehydrated under vacuum ...

Embodiment 2

[0026] Component A: Weigh 80 parts of polytetrahydrofuran ether polyol (PTMG2000, BASF product) with average functionality = 2 and number average molecular weight = 2000, 20 parts of polyether polyol with average functionality = 3 and number average molecular weight = 6000 Alcohol (EP-3600, product of Shandong Bluestar Dongda Chemical Co., Ltd.), 7 parts of 1,4-butanediol, 0.25g of water, 0.5 part of AK-7703, 1.0 part of triethylenediamine with a solid content of 33%. Ethylene glycol solution, 0.03 parts of dibutyltin dilaurate, and 0.35 parts of BHT264 are placed in a mixer, stirred evenly, vacuumed to remove air bubbles, and sealed for storage.

[0027] Component B: Dehydrate 100 parts of polytetrahydrofuran ether polyol (PTMG2000, BASF product) with an average functionality of 2 and a number average molecular weight of 2000 at 110°C for 2 hours under vacuum (-0.09MPa) to ensure that the moisture content is less than 0.05% , then lower the temperature to 50°C, add 72.5 parts...

Embodiment 3

[0030] Component A: Weigh 80 parts of polytetrahydrofuran ether polyol (PTMG2000, BASF product) with average functionality = 2 and number average molecular weight = 2000, 20 parts of polyether polyol with average functionality = 3 and number average molecular weight = 6000 Alcohol (EP-3600, product of Shandong Bluestar Dongda Chemical Co., Ltd.), 8.0 parts of 1,4-butanediol, 0.25g of water, 0.5 part of DC3043, 1.0 part of diethylenediamine diethylenediamine with a solid content of 33%. Alcohol solution, 0.03 parts of dibutyltin dilaurate, 0.35 parts of BHT264 in a mixer, stir evenly, remove air bubbles in vacuum, and seal them for storage.

[0031] Component B: Dehydrate 100 parts of polytetrahydrofuran ether polyol (PTMG2000, BASF product) with an average functionality of 2 and a number average molecular weight of 2000 at 110°C for 2 hours under vacuum (-0.09MPa) to ensure that the moisture content is less than 0.05% , then lower the temperature to 50°C, add 28.1 parts of pur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com