Layer-by-layer mixing device with material proportion capable of being adjustable and work method thereof

A mixing device and working method technology, which is applied in the field of layer-by-layer mixing devices, can solve the problems of heavy burden on the mixing device, difficult mixing of materials, and great damage to the mixer, so as to achieve good mixing effect, easy mixing of materials, and good dispersion effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

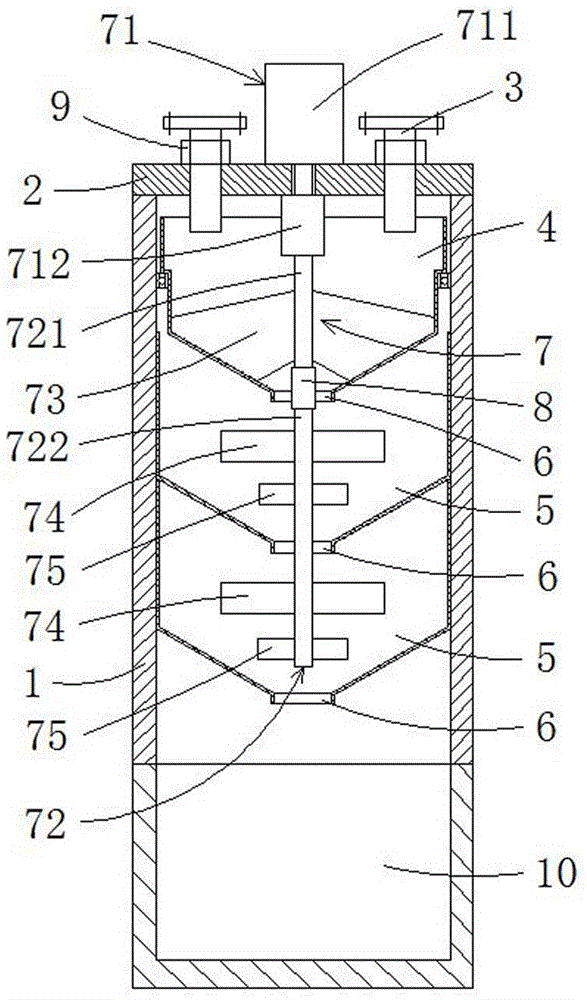

[0018] The layer-by-layer mixing device with adjustable material ratio of the present invention, such as figure 1 As shown, it includes a support 1 and an upper cover 2 arranged on the support 1. The upper cover 2 is provided with a set of feed ports 3, the feed ports 3 are provided with a control valve 9, and the upper cover 2 is provided with first Mixing barrel 4 and a set of second mixing barrels 5, the bottoms of the first mixing barrel 4 and a set of second mixing barrels 5 are tapered and both have a discharge port 6; the upper cover 2 is provided with a mixing device 7, so The mixing device 7 includes a driving device 71, a main shaft 72, and a first fan blade 73, a second fan blade 74 and a third fan blade 75 made of elastic material arranged on the main shaft 72, a group of first fan blades 73, A set of second fan blades 74 and a set of third fan blades 75 are arranged obliquely, and are distributed in an annular array with the main shaft 72 as the center; wherein the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com