Method for preparing 3,3'-dimethyl-4,4'-biphenyl diisocyanate (TODI)-based thermoplastic polyurethane elastomer

A thermoplastic polyurethane and elastic technology, applied in the field of polyurethane, can solve the problems of butanediol volatilization, continuous metering of solid TODI and other problems, and achieve the effects of avoiding volatilization of adding materials, easy operation and low mixing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Dehydrate 300g of PCL (PCL-2000) with a number-average molecular weight of 2000 at 100-120°C and vacuum degree of -0.098--0.01MPa for 2h, add 173.7g of TODI, and react at a temperature of 110-120°C for 1h , to obtain a storage-stable prepolymer (component A) with an NCO mass fraction of 9.0%.

[0031] (2) 28.7g PCL-2000, 4.8g 1,4-butanediol, 0.008g catalyst bismuth isooctanoate, 0.1g antioxidant Irgastab PUR68, 0.3g ultraviolet absorber Tinuvin213 and 0.2g light stabilizer UV- 765 mix well (component B), keep the temperature at 60°C, and mix with 66g component A (80°C), where the molar ratio R of NCO groups to OH groups in PCL-2000 and 1,4-BDO is 1.02:1.

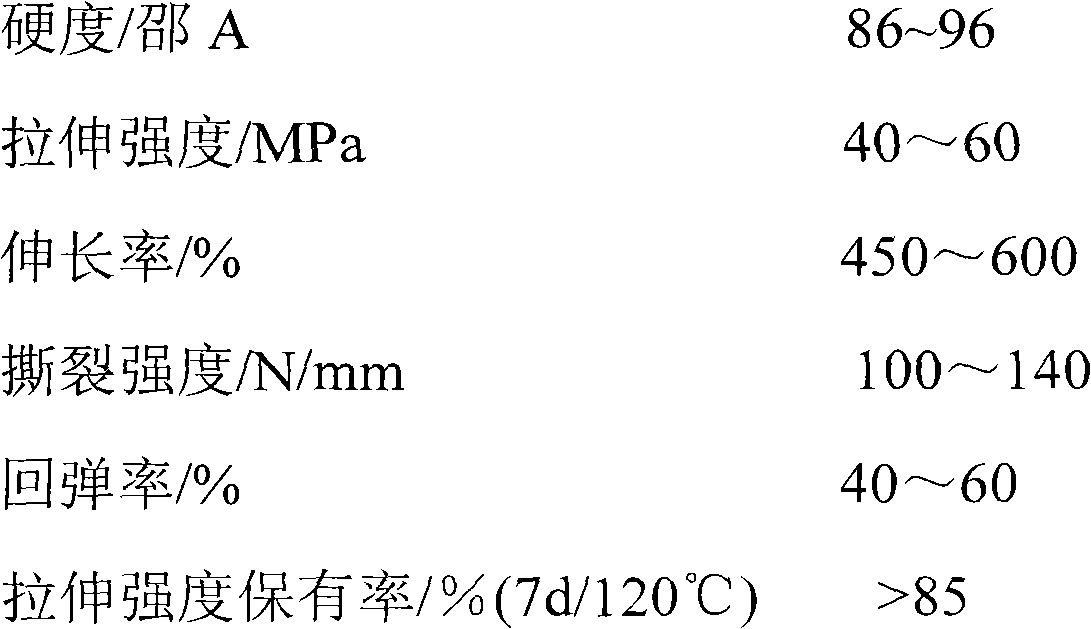

[0032] (3) Pour the mixture into a mold at 180° C. for 15 minutes after vacuum defoaming, and release it from the mold. Put the semi-finished product after demolding into an oven at 120° C. and mature it for 24 hours to obtain the finished product. The main performance indicators are shown in Table 2.

Embodiment 2

[0034] (1) Dehydrate 300g of PCL (PCL-1000) with a number-average molecular weight of 1000 at 100-120°C and a vacuum of -0.098--0.01MPa for 2h, add 230g of TODI, and react at a temperature of 95-110°C for 1h, A storage-stable prepolymer (component A) with an NCO mass fraction of 9.0% was produced.

[0035] (2) 22.5g PCL-1000, 1.4g ethylene glycol, 0.004g catalyst bismuth isooctanoate, 0.3g antioxidant Irgastab PUR68, 0.2g ultraviolet absorber Tinuvin213 and 0.5g light stabilizer UV-765 are mixed in proportion Homogeneous (component B), keep the temperature at 60°C, and mix with 75.5g component A (80°C), where the molar ratio R of NCO groups to OH groups in PCL-2000 and ethylene glycol is 1.02:1 .

[0036] (3) After vacuum defoaming, the mixture is poured into a mold at 160°C for 15 minutes for demoulding, and the semi-finished product after demolding is placed in an oven at 100°C for 24 hours to obtain the finished product. The main performance indicators are shown in Table ...

Embodiment 3

[0038] (1) Dehydrate 300g of PTMG (PTMG-2000) with a number-average molecular weight of 2000 at 100-120°C and a vacuum of -0.098--0.01MPa for 2h, add 260g of TODI, and react at a temperature of 95-100°C for 1h, A storage-stable prepolymer (component A) with an NCO mass fraction of 12.3% was produced.

[0039] (2) 26.0g PTMG-2000, 7.4g 1,4-butanediol, 0.002g catalyst bismuth carboxylate, 0.3g antioxidant Irgastab PUR68, 0.2g ultraviolet absorber Tinuvin571 and 0.5g light stabilizer UV- 765 (component B) mix well, keep the temperature at 55°C, and mix with 66g component A (70°C), where the molar ratio of NCO group to OH group in PCL-2000 and 1,4-butanediol is R It is 0.98:1.

[0040] (3) Pour the mixture into a mold at 160°C for 15 minutes for demoulding after vacuum defoaming, and place the semi-finished product after demoulding in an oven at 110°C for aging for 20 hours to obtain the finished product. The main performance indicators are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com