Patents

Literature

118 results about "Silicon mold" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

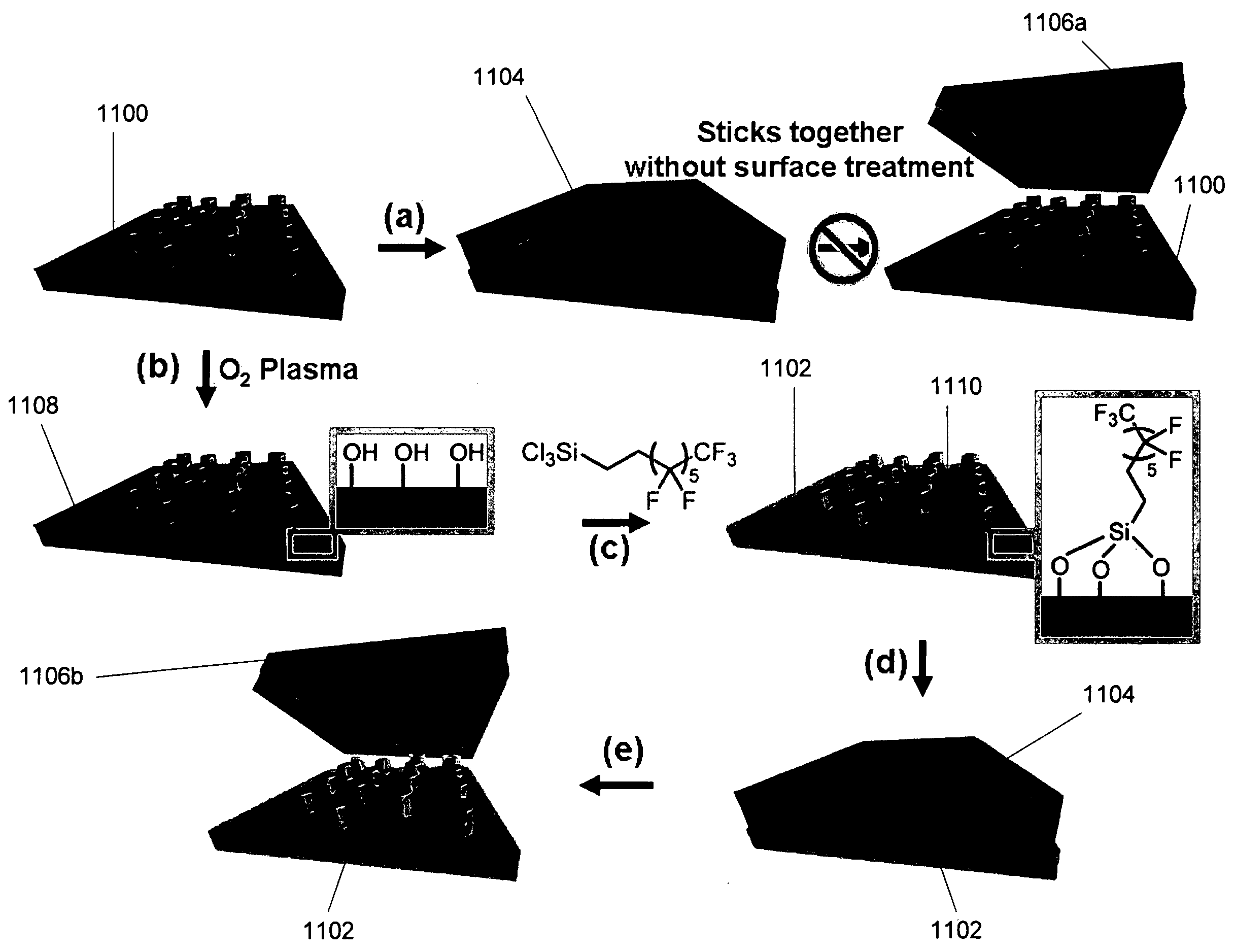

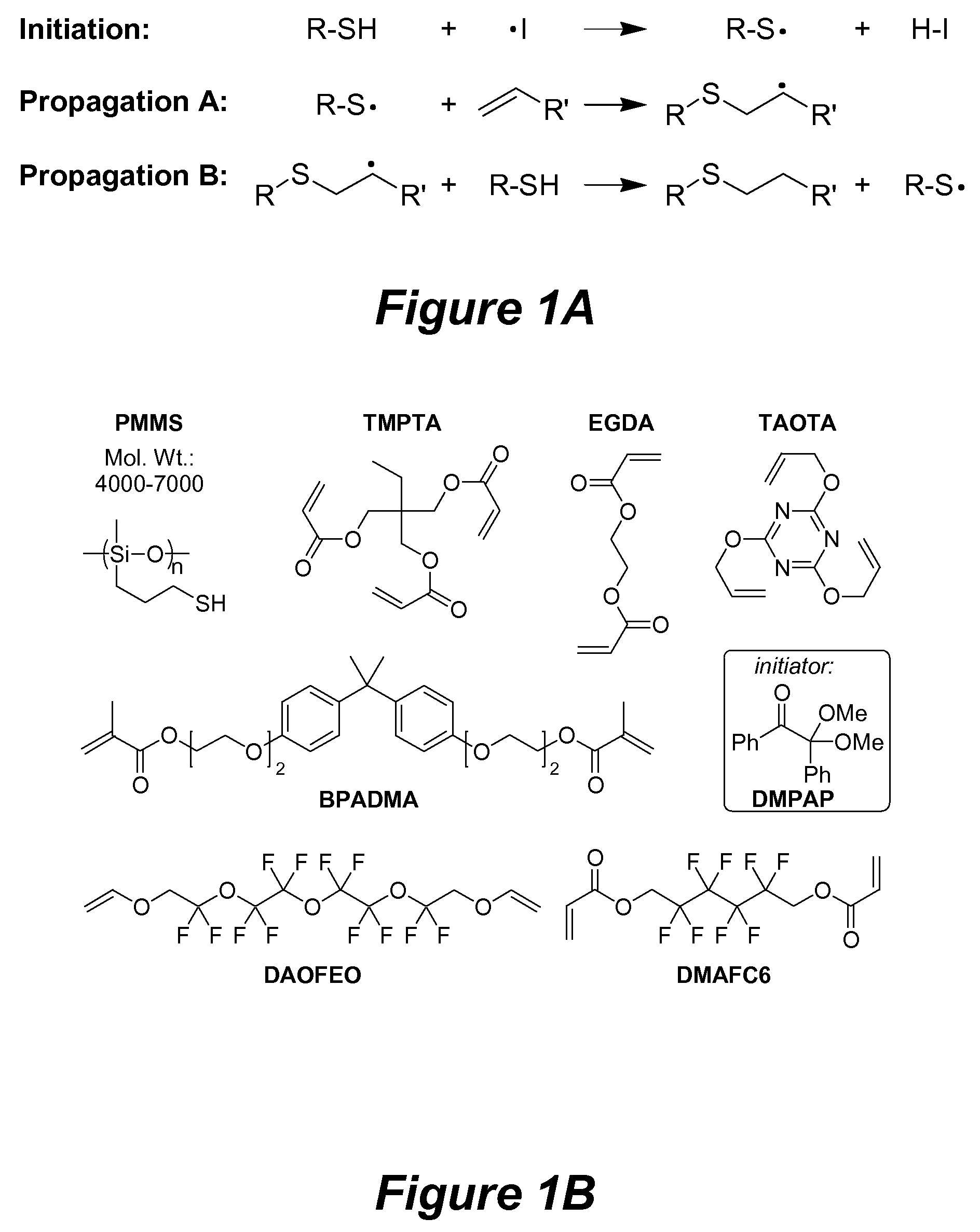

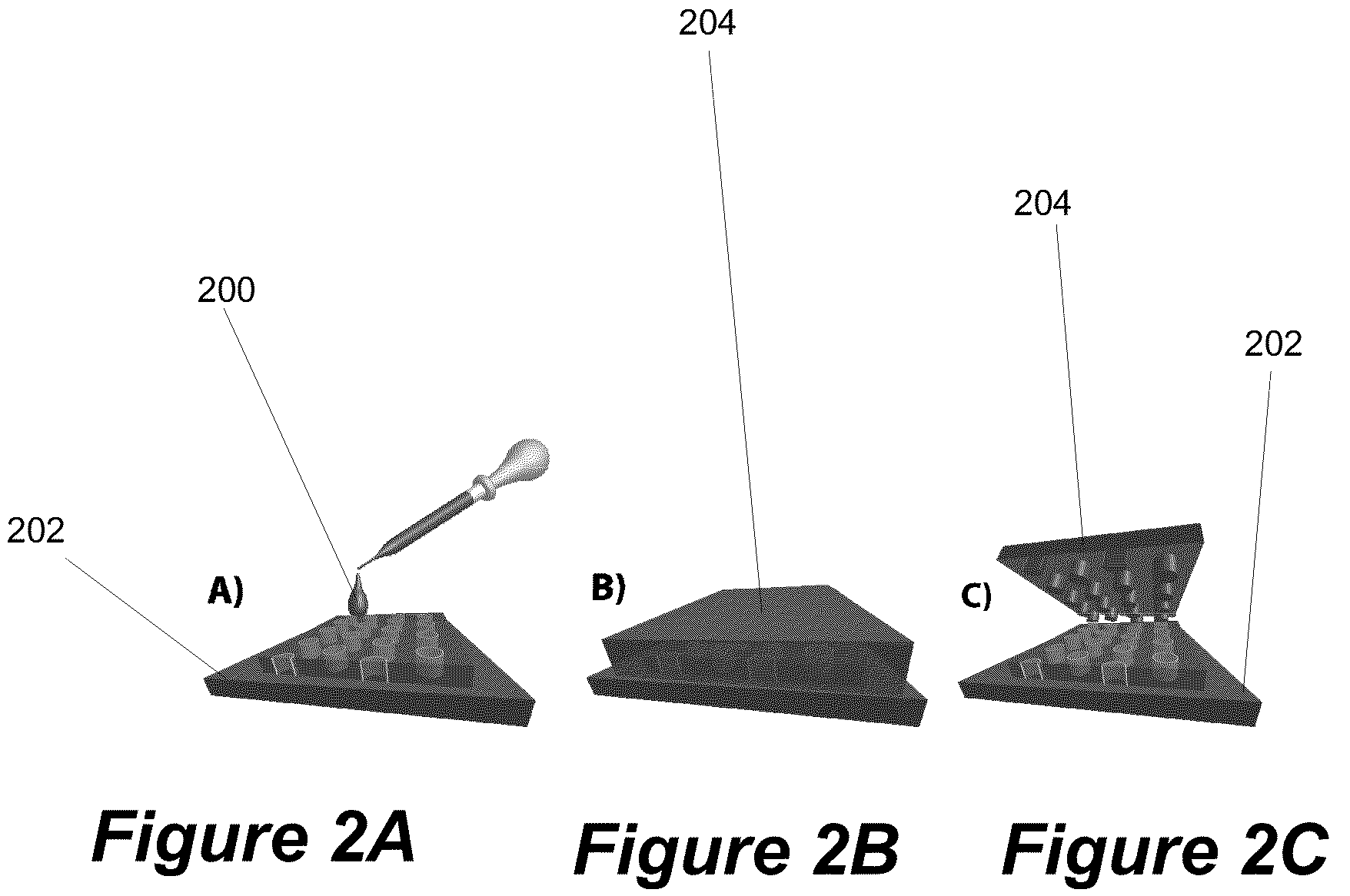

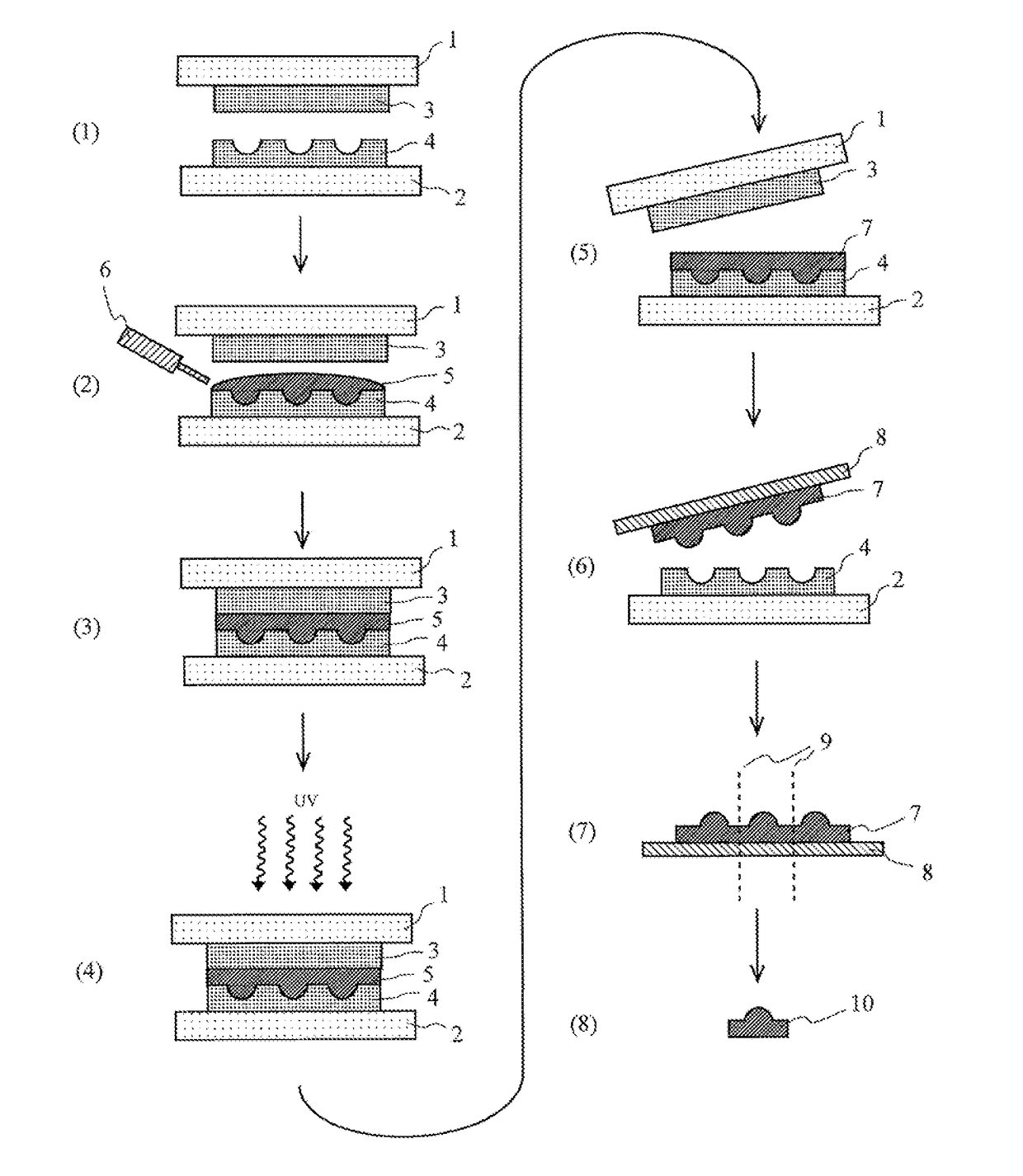

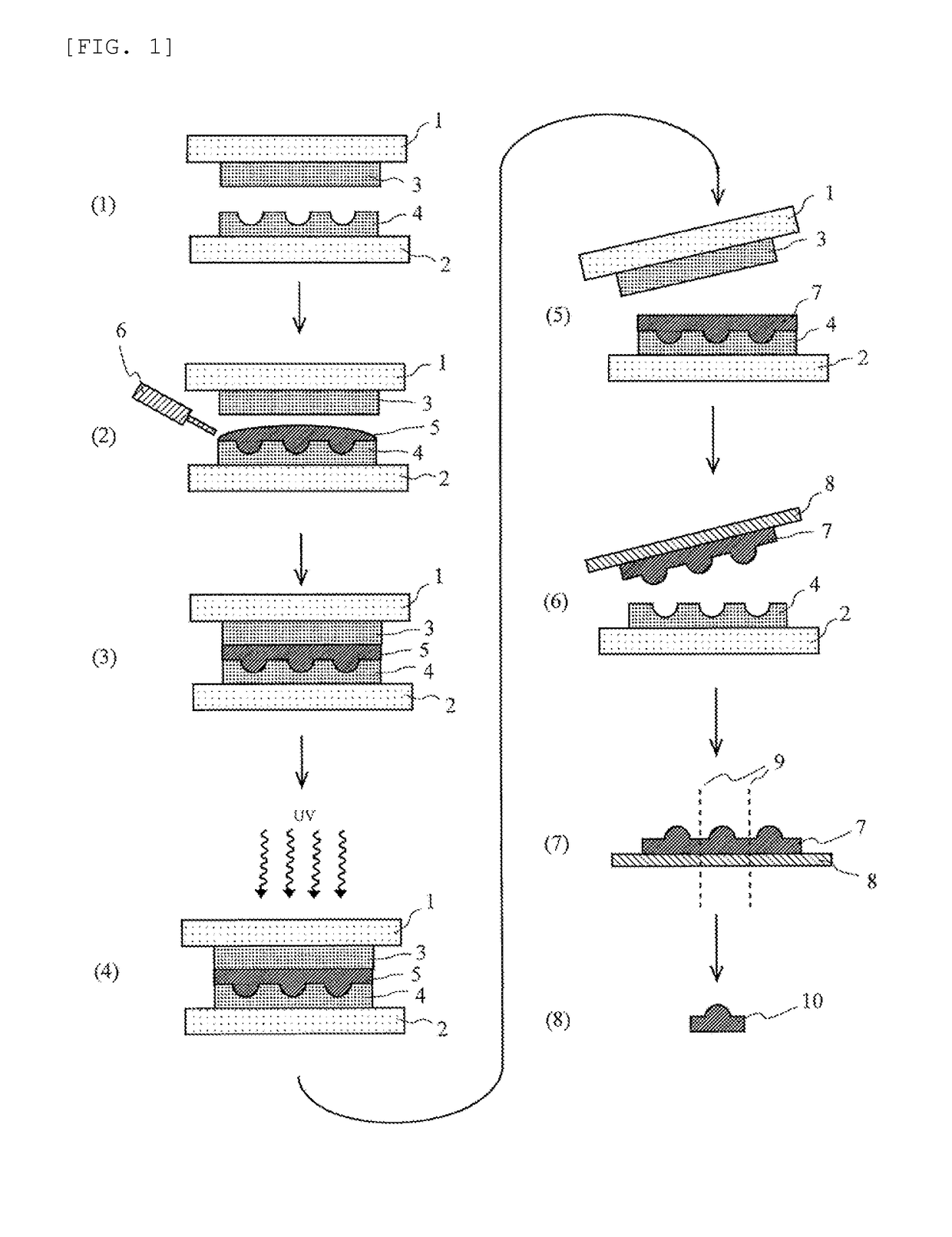

Thiol-ene based poly(alkylsiloxane) materials

A stamp is comprised of a thiol-ene polymer, wherein the thiol-ene polymer allows for creation of micro-scale or nano-scale patterns useful in soft or imprint lithography. A patterned thiol-ene polymer is fabricated by casting a thiol-ene mixture onto a patterned mold, curing the thiol-ene mixture to form the patterned thiol-ene polymer, and peeling off the patterned thiol-ene polymer from the silicon mold. A stamp comprised of a thiol-ene polymer may be replicated by exposing the to oxygen plasma to form a hydrophilic mold, exposing the hydrophilic mold to a fluorinating agent under vacuum conditions to form a functionalized surface of the hydrophilic mold, casting a thiol-ene mixture on top of the functionalized surface, photocuring the thiolene mixture to form a replica thiol-ene polymer, and peeling off the replica thiol-ene polymer.

Owner:RGT UNIV OF CALIFORNIA

Preparation method of high-temperature-resistant anti-cracking MDQ silicon resin

The invention relates to a preparation method of high-temperature-resistant anti-cracking MDQ silicon resin. The method comprises the following steps of adding acid, divinyl tetramethyl disiloxane, hexamethyldisiloxane and dimethyl dialkoxy silane, alcohol and 2 to 5g of water into a four-opening bottle; performing stirring; heating the materials to 25 DEG C; performing reaction for 1 to 2 hours; after the reaction is completed, dripping the rest total amount of water and silicate ester at the same time at the room temperature; controlling the temperature in a system to be between 30 and 40 DEG C; after the dripping completion, performing reaction for 1 to 2 hours at 70 DEG C; then, distilling out alcohol in the system; then, adding methylbenzene and alkali with the same mass as the theoretical synthesis resin to regulate the system pH to be 9 to 10; performing reaction for 1 hour at 90 DEG C; then, raising the temperature to distill out the rest alcohol and water; finally, lowering the temperature; performing neutralization by acid; performing water washing until the system pH is 6 to 7; performing rotary evaporateion at 120 DEG C to remove methylbenzene so as to obtain the silicon resin. The DMQ silicon resin prepared by the method provided by the invention is mainly used for reinforcing agents of encapsulation glue, organic silicon additives and organic silicon mold plastics.

Owner:YANTAI DARBOND TECH

Wood-plastic composite environmentally-friendly decorative paper and production process thereof

InactiveCN101519861AGood finishWaterproofMechanical working/deformationSpecial paperSilicon moldPolyvinyl chloride

The invention relates to wood-plastic composite environmentally-friendly decorative paper. The wood-plastic composite environmentally-friendly decorative paper is produced in such a way that a decorative layer, a protective layer and a organic silicon mold release agent layer are sequentially attached to the surface of base paper, and a pressure-sensitive adhesive layer and a mold release paper layer are sequentially attached to the back surface of the base paper, wherein the protective layer can be an adhesive polythene (PE), polyethylene terephthalate (PET), bi-axially oriented polypropylene (BOPP), o-phenylphenol (OPP) or polyvinyl chloride (PVC) plastic film or sprayed polyethylene film. The wood-plastic composite environmentally-friendly decorative paper has favorable and obvious surface decorating effect, good ductibility and strong intensity of tension and is self-adhesive, waterproof and moistureproof and easy to paste and coat and does not deform, crack and bulge on surface when heated and cooled, thereby the wood-plastic composite environmentally-friendly decorative paper can be widely applied to food packing, decorative material and furniture material; in addition, the wood-plastic composite environmentally-friendly decorative paper is attractive in appearance and convenient to construct and manufacture, has clear patterns and characters and can be widely manufactured on a large scale in a factory with low cost, thereby being an larger improvement on surface decorating material.

Owner:杨建文

Process for making a silicone mold and baking a food product therein

The present invention relates to a process for baking a food product utilizing a confectionery mould made from silicone. The confectionery mould is obtained by mixing and reacting a crosslinkable silicone, especially methyl-vinyl siloxane (VMQ), and a peroxide as a cross-linking agent.

Owner:SAR HLDG INT

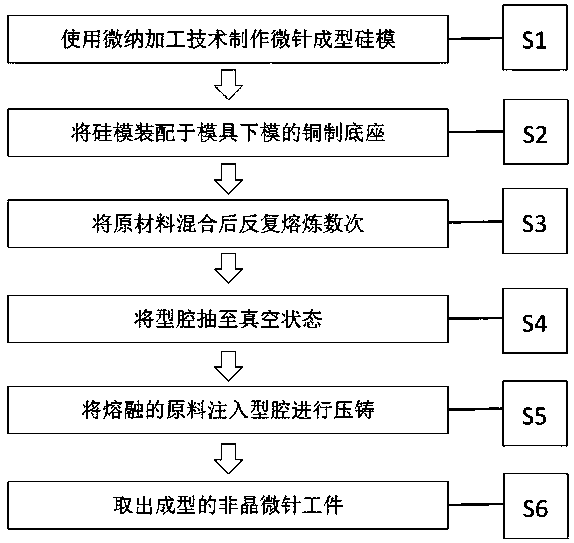

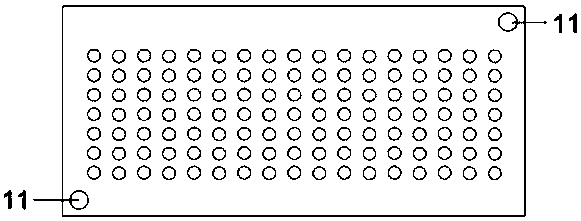

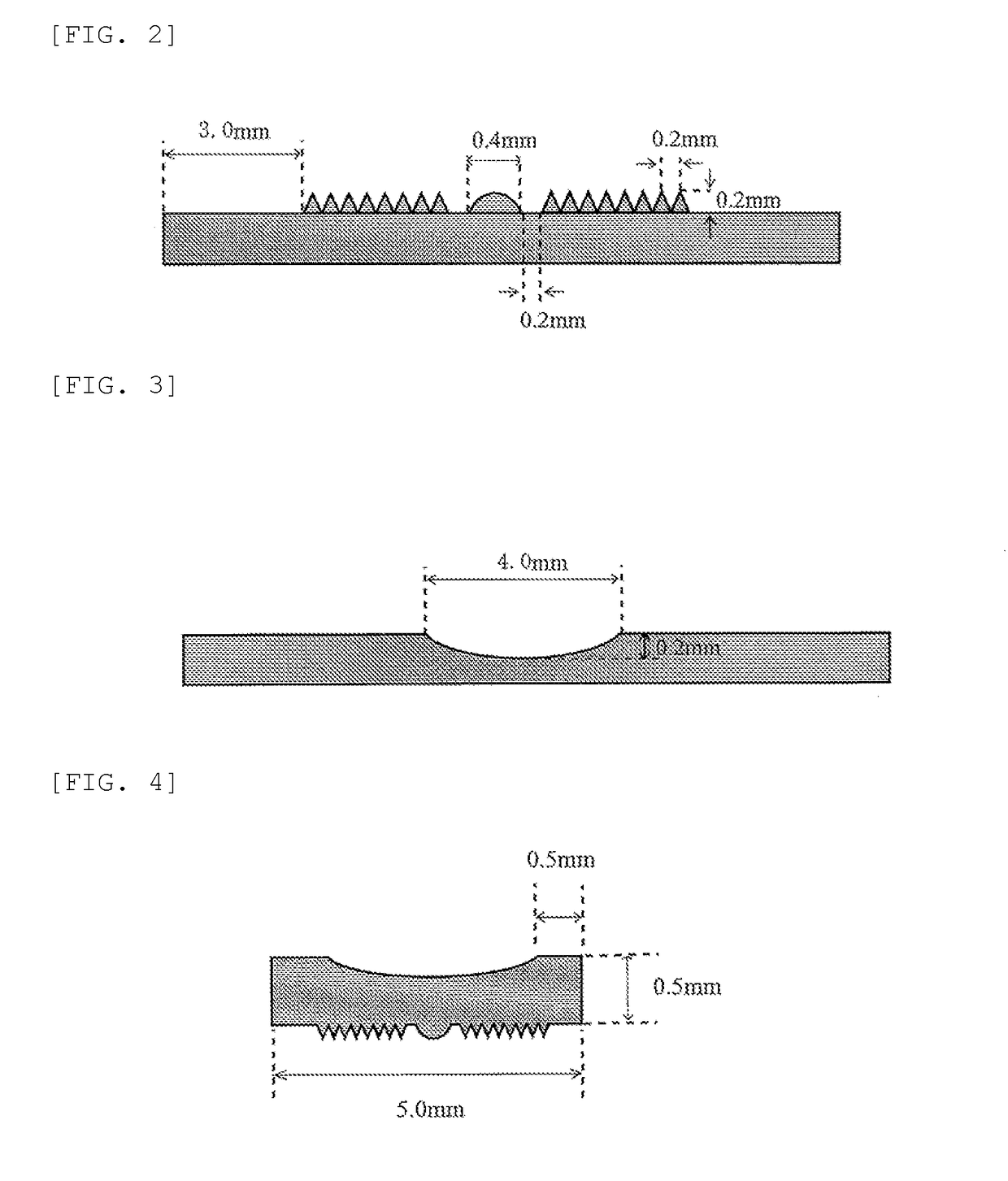

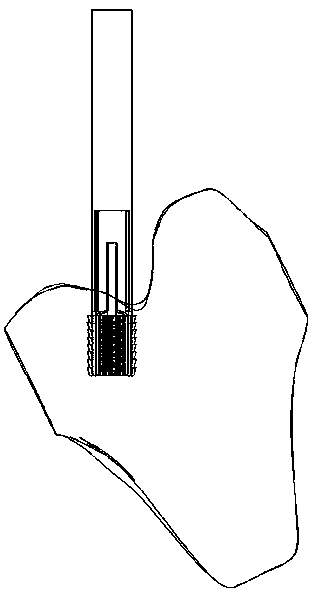

Manufacturing method of amorphous alloy microneedle

The invention provides an amorphous alloy microneedle and a manufacturing method thereof. The manufacturing method comprises the following steps: manufacturing a microneedle forming silicon mold on asilicon wafer by employing a micro-nano machining technology; then assembling the silicon mold on a copper base of a lower mold of the mold; then smelting the mixed raw materials repeatedly; then vacuumizing a cavity to a vacuum state; then injecting the molten raw materials into the cavity for pressure casting; and finally, taking out a formed amorphous alloy microneedle workpiece after a part isformed. Compared with a conventional metal microneedle, the amorphous alloy provided by the invention is high in injection moulding capacity, good in mechanical property and higher in corrosion resistance, has certain antibacterial activity, and has a wide prospect in the biochemical field.

Owner:GUANGDONG UNIV OF TECH

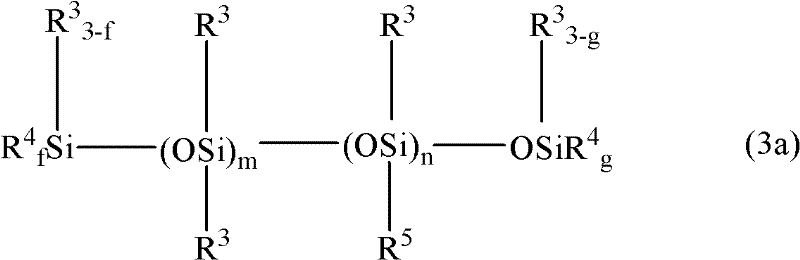

Curable composition and cured product from same

ActiveUS20180237579A1Easy to useHighly accurate shapeOptical articlesOptical elementsSolubilitySilicone

Provided is a curable composition which has excellent curability, less causes silicone molds to swell, and allows the silicone molds to have better durability and a longer service life in repeated use. The curable composition according to the present invention is a curable composition for production of an optical component by molding using silicone molds. The curable composition contains curable compounds and a cationic initiator. The curable compounds include (A) a cycloaliphatic epoxy compound and (B) an oxetane compound. The oxetane compound (B) is present in a content of 10 to 45 weight percent of the totality of all the curable compounds contained in the curable composition. Of the totality of all the curable compounds contained in the curable composition, 90 weight percent or more is a compound or compounds having a solubility parameter of 9.0 (cal / cm3)1 / 2 or more as determined at 25° C. by the Fedors' method.

Owner:DAICEL CHEM IND LTD

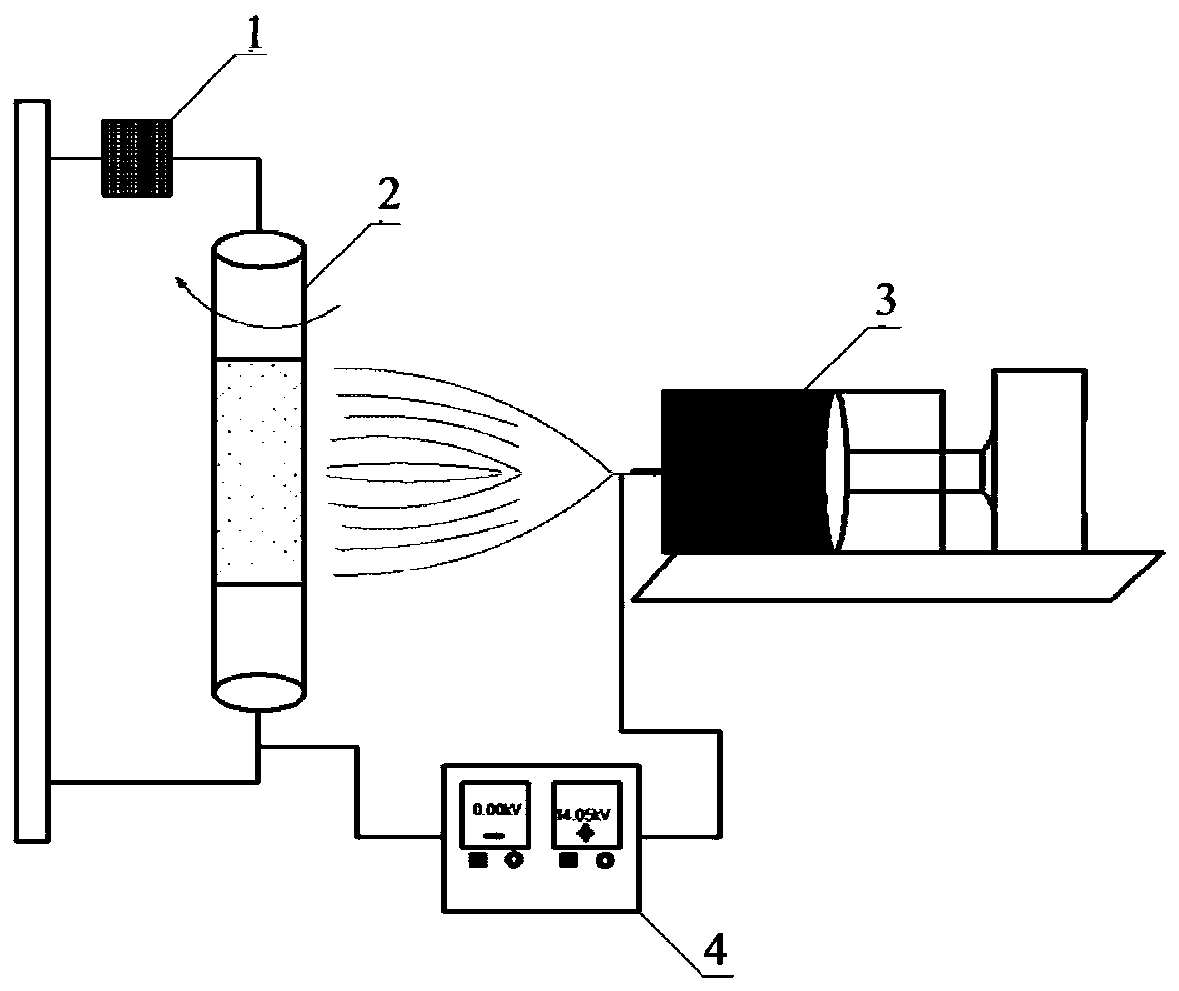

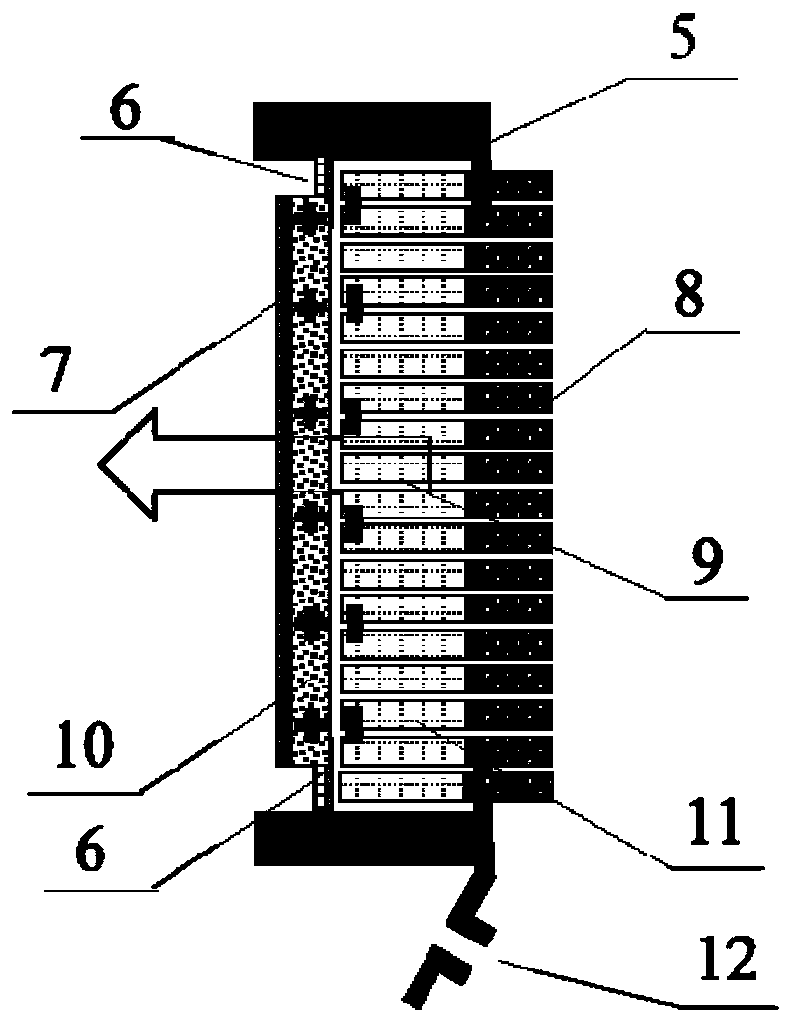

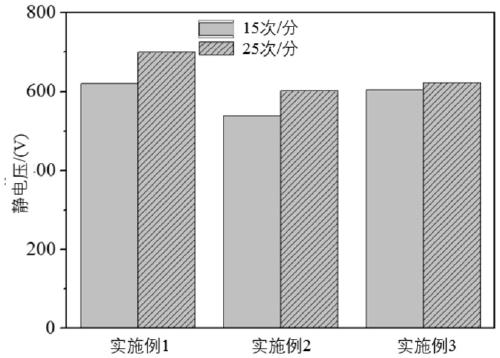

High-efficiency protective mask based on full-fiber electret generator and preparation method thereof

ActiveCN111249638AImprove filtration efficiencyMechanicalBreathing filtersFire rescueSilicon moldEngineering

The invention discloses a high-efficiency protective mask based on a full-fiber electret generator and a preparation method thereof. The high-efficiency protective mask based on the full-fiber electret generator comprises a tightening belt, a silicone mold, a full-fiber electret generator arranged in the silicone mold and a breathing valve. The full-fiber electret generator comprises a filtering layer and a sliding fixed pillar arranged on the filtering layer; the filtering layer comprises a silicone film, a conductive fabric, an electret fiber film and a non-woven fabric which are stacked insequence; and the conductive fabric and the electret fiber film have different electronegativities and are driven by spontaneous breathing so as to produce 200- 1000V of electrostatic pressure. According to the invention, the protective mask based on the full-fiber electret generator has a filtering efficiency greater than or equal to 98% for PM2.5, a filtering efficiency greater than or equal to1.0% for PM1.0, and the filtering pressure drop is 20- 50 Pa, and with good flexibility and breathability, simple preparation process, the protective mask has wide application prospect in the field ofpersonal protection.

Owner:SOUTH CHINA UNIV OF TECH

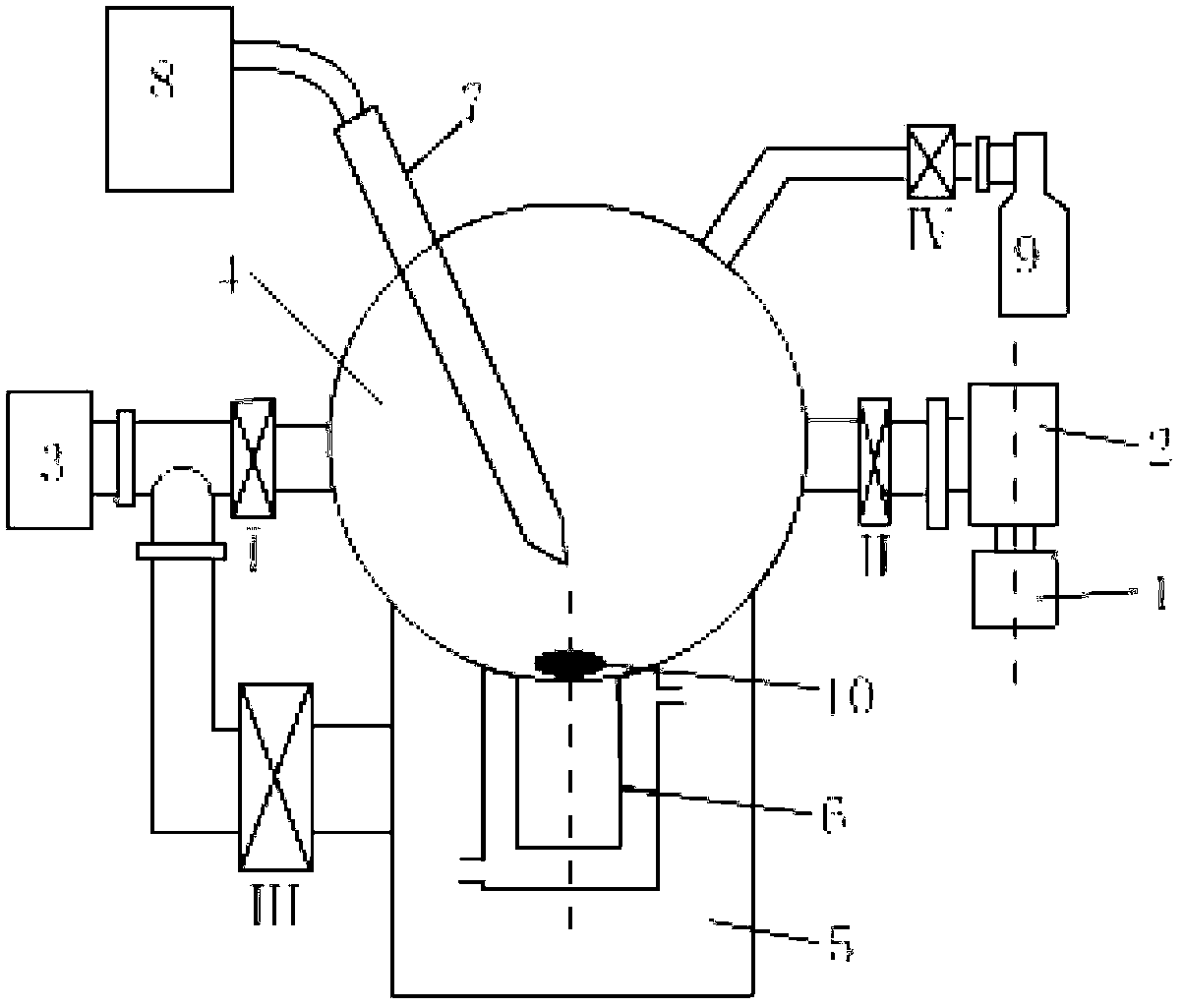

Preparation method and preparation device of amorphous alloy fine part based on vacuum suction casting

The invention discloses a preparation method of an amorphous alloy fine part. The preparation method of the amorphous alloy fine part comprises the following steps: various types of pure metal needed by amorphous alloy is prepared according to a proportion to form raw materials of the amorphous alloy and is arranged in a vacuum melting cavity of a vacuum arc suction casting furnace; a silicon mold used for preparing the amorphous alloy fine part is prepared and arranged into a copper mold, an inner cavity of the copper mold is a through hole, and the copper mold is arranged in a lower cavity of the vacuum arc suction casting furnace; the vacuum melting cavity is pumped to be vacuum and is filled with protective gas, the raw materials of the amorphous alloy are melted, and melted amorphous alloy liquid is sucked into the silicone mold from the vacuum melting cavity through the through hole by lowering the pressure inside the copper mold; and the amorphous alloy fine part is obtained after demolding. The invention further discloses a preparation device of the amorphous alloy fine part. By means of vacuum suction casting, the defects that the amorphous alloy melt is poor in fluidity and difficult in mold filling are overcome, and the prepared amorphous alloy fine part is high in quality, and free of the defects like air holes.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for moulding disc grade glass device by using micro-mould

InactiveCN101475298AReduce roughnessHigh bonding strengthGlass shaping apparatusSilicon moldAtmospheric pressure

The invention provides a method for molding a wafer-level glass device by using a micro mold, which comprises the following steps: etching a polished silicon wafer by a micro-electronic processing technique to form a mold deep cavity with a specific structure, bonding the silicon wafer with a Pyrex7740 glass wafer under the vacuum environment so that the mold deep cavity with the specific structure on the silicon wafer forms a sealed cavity, heating the two bonded wafers under one atmospheric pressure, carrying out hot molding, forming a microstructure corresponding to the mold deep cavity with the specific structure by the softened glass due to internal and external pressure difference of the cavity, cooling the wafers, annealing the wafers and relieving stress, chemically and mechanically polishing the glass back of the thermally annealed bonding sheets, planishing the glass back of the bonding sheets, and removing a silicon mold layer by a single-side corrosion method. The method can prepare the glass microstructure with large height-width ratio (more than 50:1), has low cost, and has important application in the fields of micro-fluid device, MOEMS and the like.

Owner:SOUTHEAST UNIV

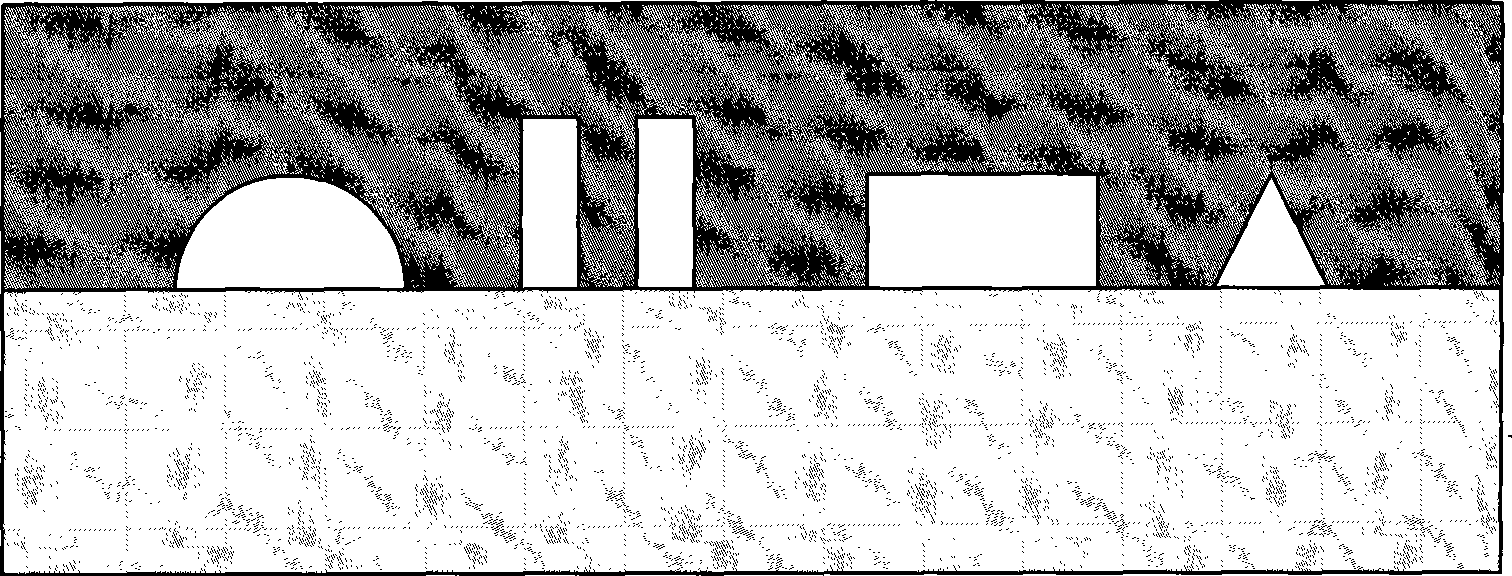

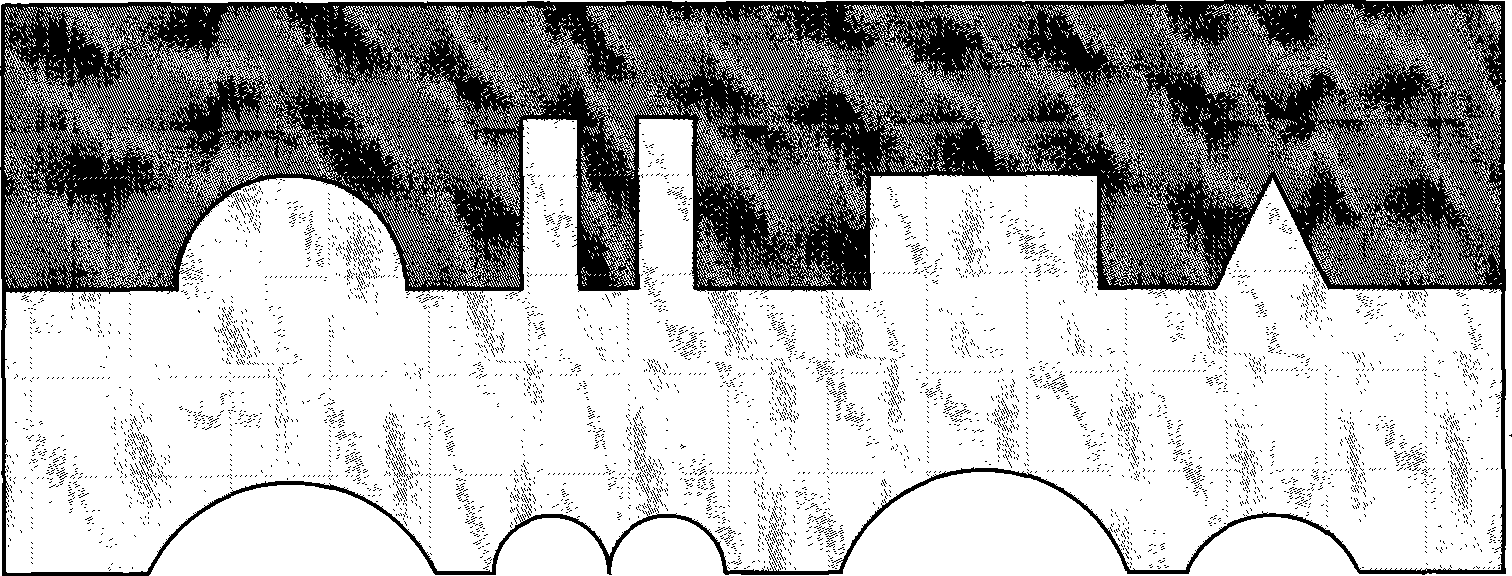

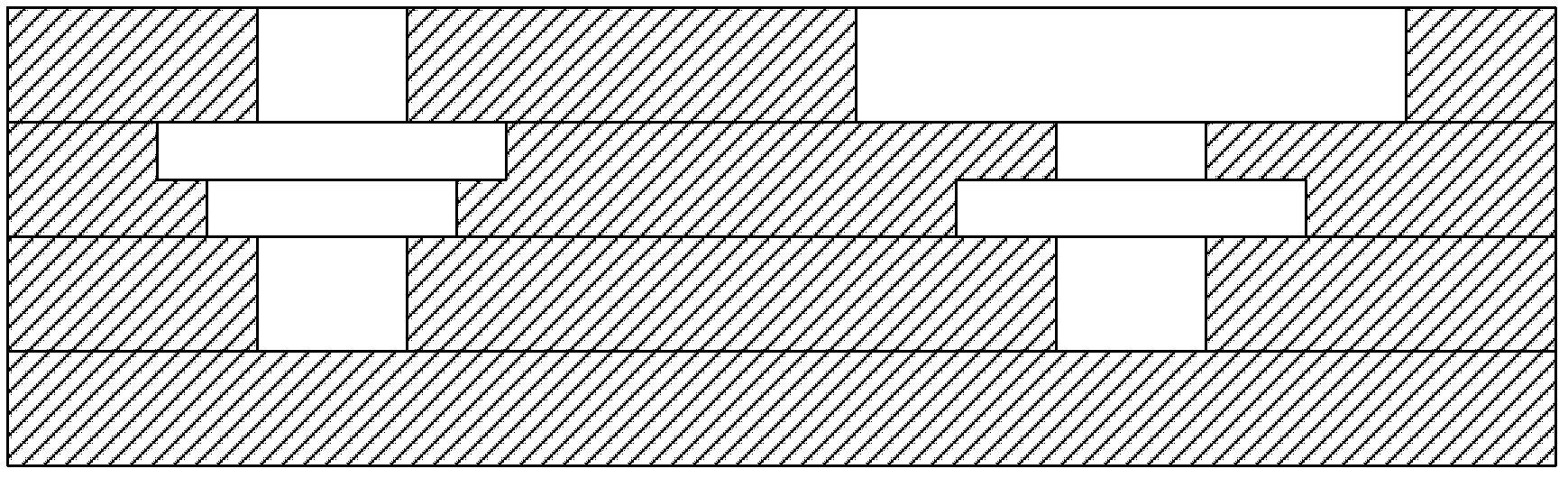

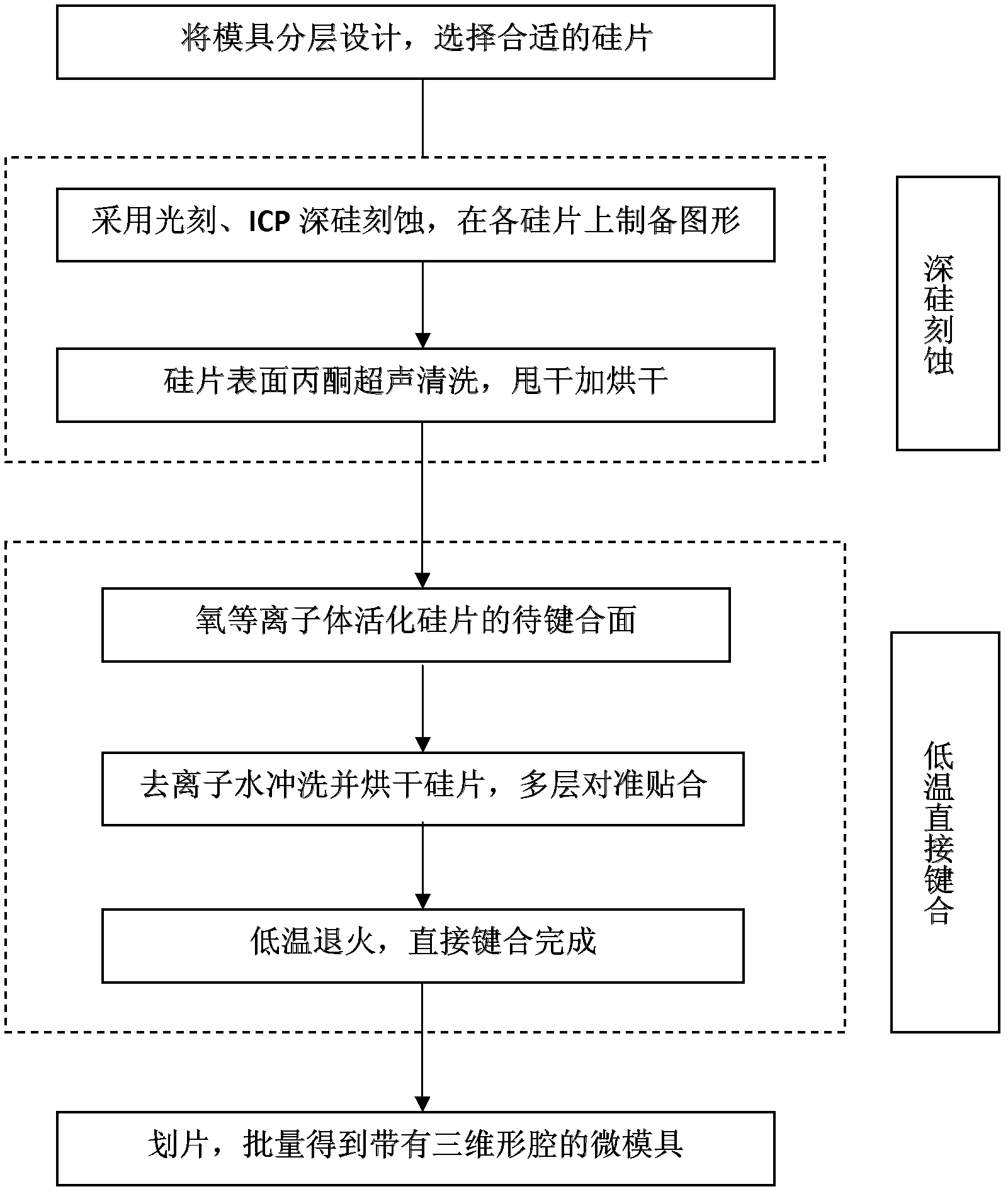

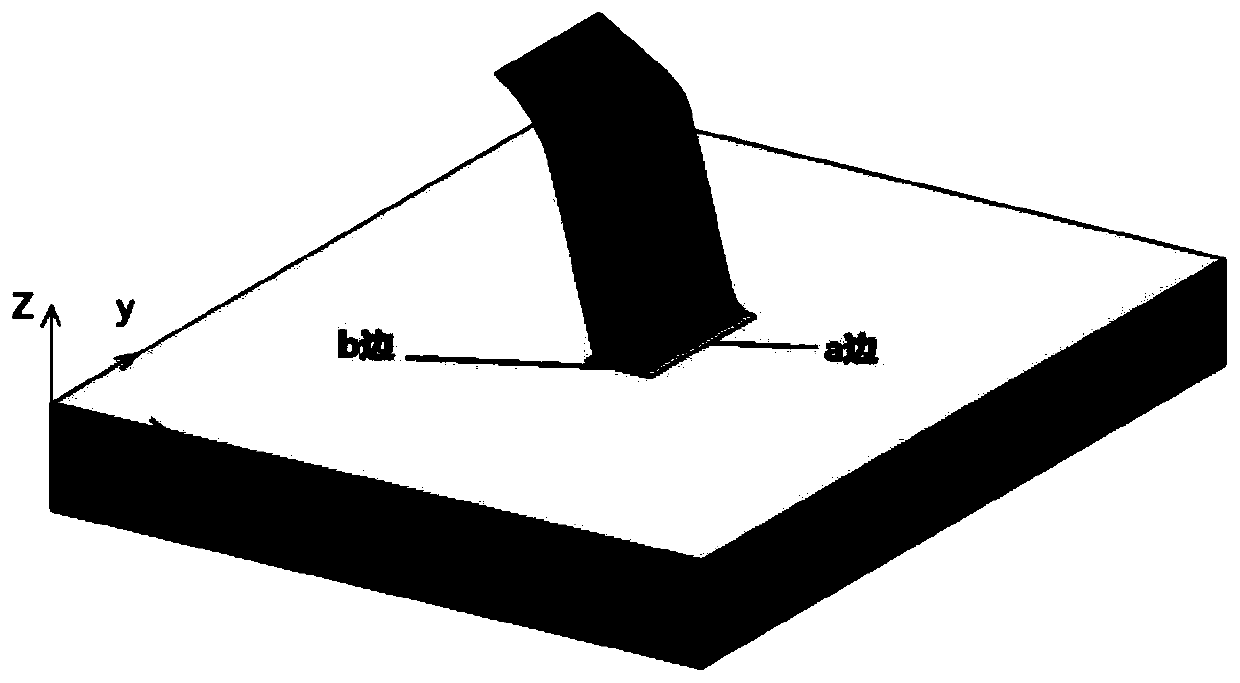

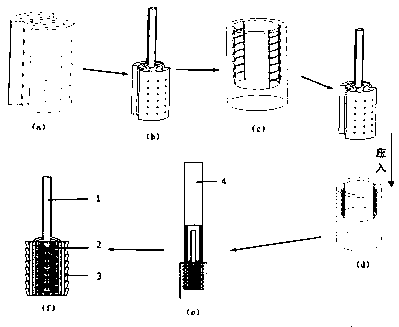

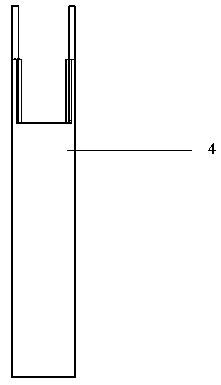

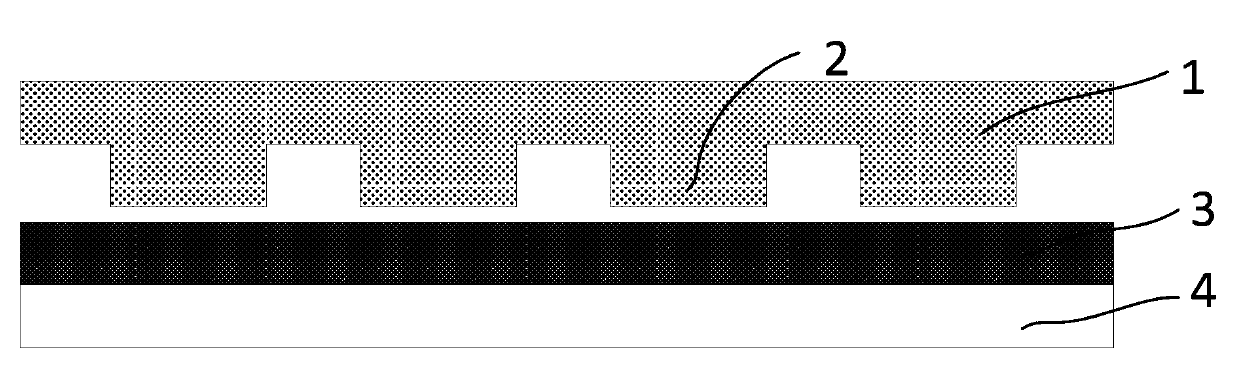

Method for manufacturing three-dimensional silicon mold directly bonded by low-temperature plasma activation

InactiveCN102431961AEasy to operateImprove controllabilityDecorative surface effectsChemical vapor deposition coatingMicro structureSilicon mold

The invention provides a method for manufacturing a three-dimensional silicon mold directly bonded by low-temperature plasma activation. The method comprises the following steps of: designing a micro-mold to be manufactured in the Z direction in a laminated manner; selecting silicon chips with appropriate thicknesses as substrates on all layers, and accurately etching the silicon chips on all the layers by a photoetching or inductively-coupled plasma (ICP) deep silicon etching method to form a structural graphic of a mold corresponding layer; cleaning the surfaces of all the silicon chips, performing plasma activation, pre-bonding, and annealing at a low temperature to finish the direct bonding of a plurality of layers of silicon chips; and finally, scribing to acquire three-dimensional micro silicon molds in batches. The method is suitable for efficiently manufacturing the silicon mold with a stepped high depth-to-width ratio three-dimensional micro structure (such as a micro gear shaft, a micro stepped shaft, a micro pump and the like) in a microelectromechanical system (MEMS) device at high accuracy.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for preparing asphalt micro-meso analysis sample by adopting silicone mold

InactiveCN104502168AChemically stableGood elasticityPreparing sample for investigationChemical propertyAnalysis sample

The invention discloses a method for preparing an asphalt micro-meso analysis sample by adopting a silicone mold. According to the technical scheme, the method comprises the steps of preparing a mold; heating and pouring; scraping by utilizing a heat knife; carrying out secondary heating; fixing a mold glass slide; cooling and demolding; testing and observing. The mold is prepared by utilizing the characteristics of no toxicity, no odor, stable chemical property, good elasticity, high tensile strength, high temperature resistance, easiness in forming and demolding, and the like of silicon, the prepared analysis sample has a smooth surface, is high in flatness and uniform in thickness, various analysis samples meeting different requirements can be obtained by adjusting the shape, specification and size of a sample preparation mold, so that the specification requirement of test instruments such as a scanning electron microscope, an atomic force microscope and the like for different analysis samples can be met. According to the method, the operation is convenient, the analysis sample forming efficiency is high, the consumption of asphalt is controllable, and the method is ideal for preparing the asphalt micro-meso analysis sample.

Owner:INNER MONGOLIA UNIV OF TECH

Preparation method of amorphous alloy mold and application thereof in micro-flow groove forming

The invention discloses a preparation method of an amorphous alloy mold. The amorphous alloy mold prepared by the method is used for thermoforming a micro-flow groove. The method is characterized by comprising the following steps of: (1) preparing a silicon mold; (2) preparing an amorphous alloy sample; (3) sequentially placing a spacer, the silicon mold, the amorphous alloy sample and a press head spacer in a clamp body; (4) precisely replicating and forming the amorphous alloy mold; and (5) cooling and de-molding. The invention also discloses a method for forming a high polymer micro-flow groove by utilizing the amorphous alloy mold prepared by the method. The method comprises the following steps of: (1) preparing a high polymer sample; (2) thermoforming a high polymer micro-flow groove; and (3) cooling and de-molding. In the invention, the quick and batch production of the amorphous alloy mold and the high polymer micro-flow groove can be realized through adjusting the sizes of the silicon mold and the clamp body, thereby enhancing processing efficiency, shortening manufacturing cycle and reducing manufacturing cost.

Owner:HUAZHONG UNIV OF SCI & TECH

Mold applied to resin-based cement-based light-transmitting concrete

The invention provides a mold applied to resin-based cement-based light-transmitting concrete. According to the mold, a silicone rubber mold is obtained conveniently, and then a prefabricated resin block can be obtained by using the silicone rubber mold. According to the function of the prefabricated resin block, the prefabricated resin block is inserted into unsolidified concrete, after the concrete is solidified, due to the fact that resin is light-transmitting so that the whole concrete can have the light transmission property. The mold has the beneficial effects that the silicone rubber mold can be conveniently and quickly manufactured by using a mold turning method according to a pre-designed distribution form through the mold, and then the prefabricated resin block can be manufactured; and the silicone rubber mold is divided into an upper part and a lower part, and meanwhile, a preservative film is used for covering so that the prepared silicone rubber mold can be easily separated from a acrylic plate.

Owner:江苏五大洲高铁轨道材料有限公司

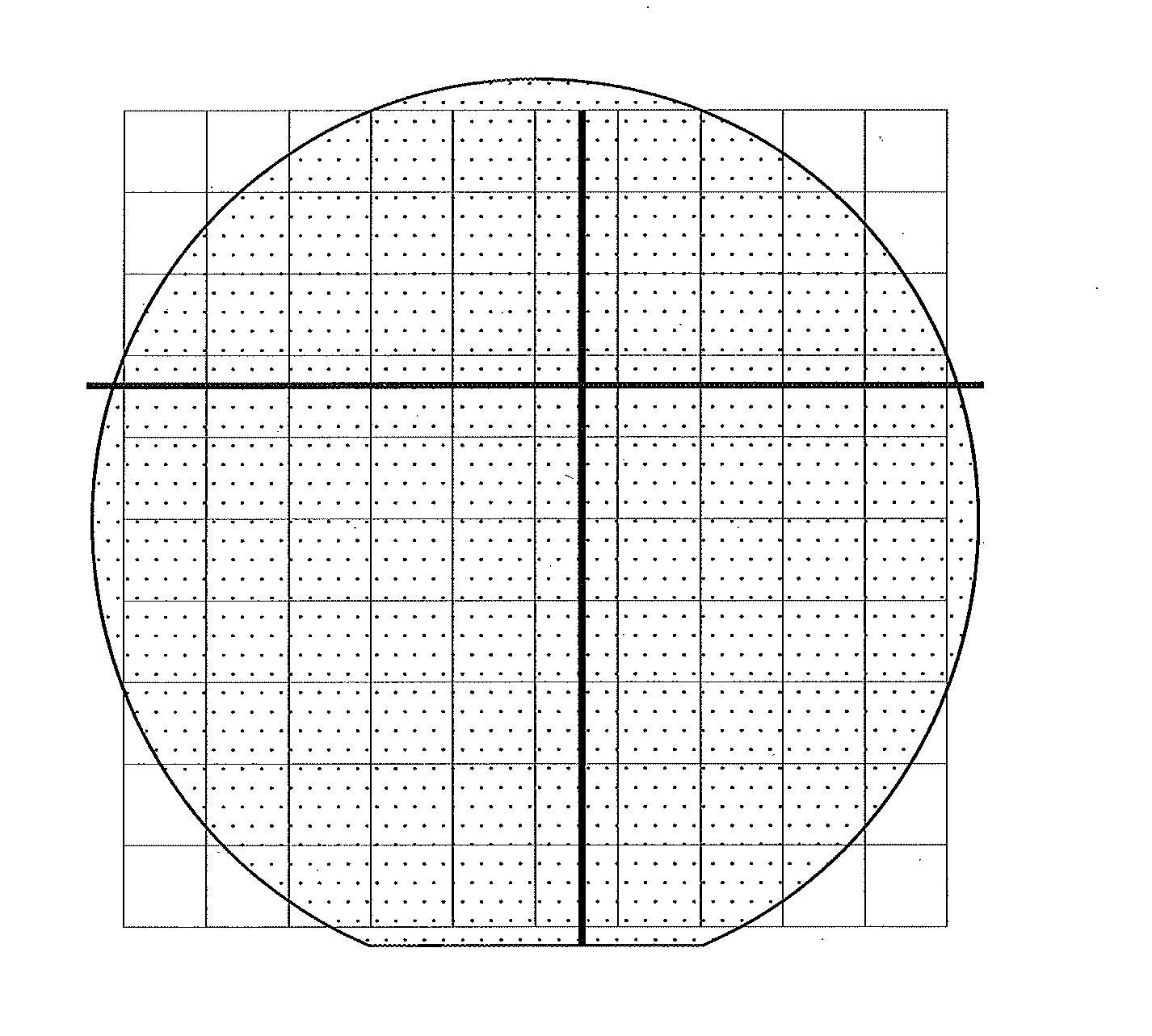

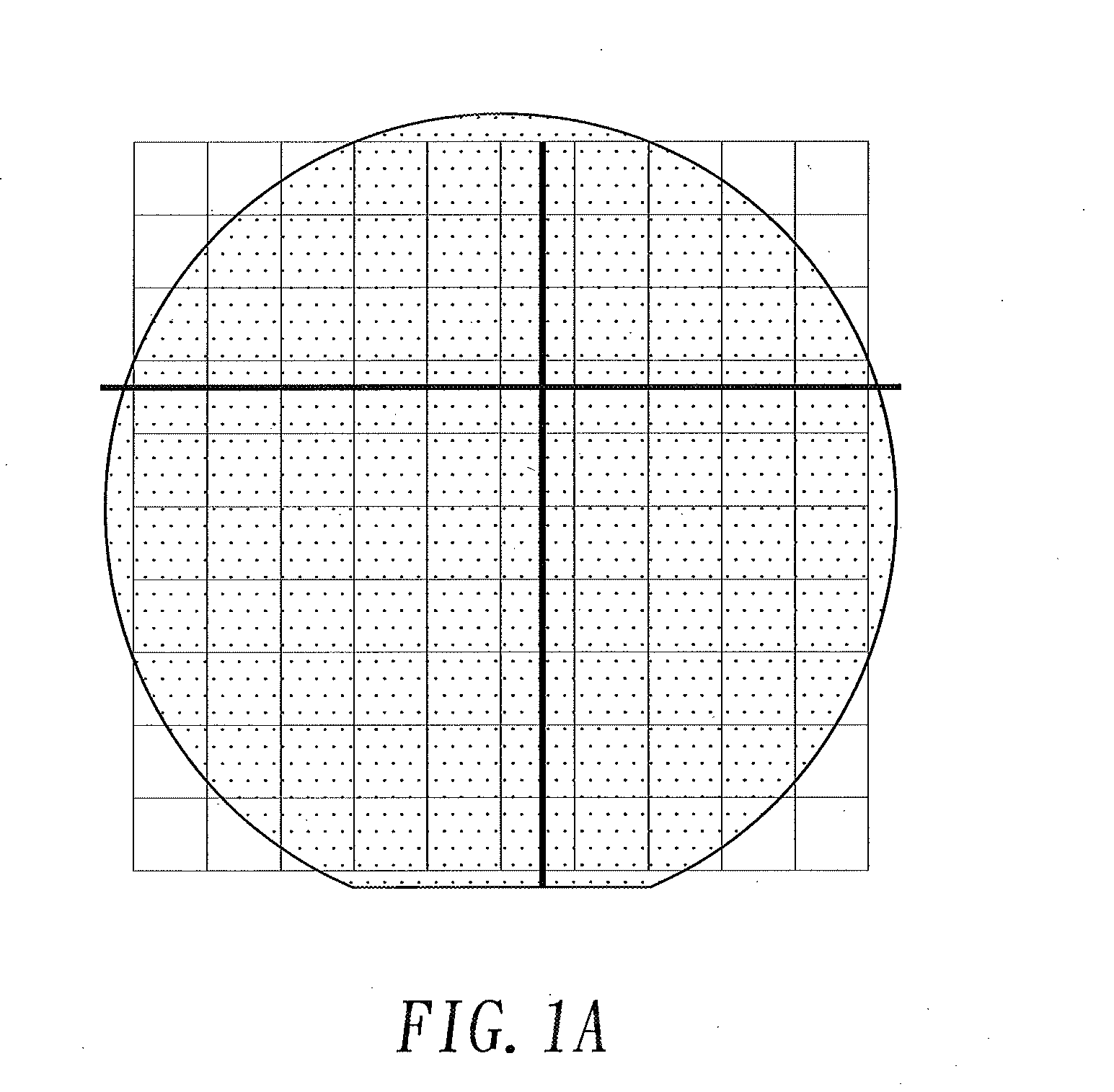

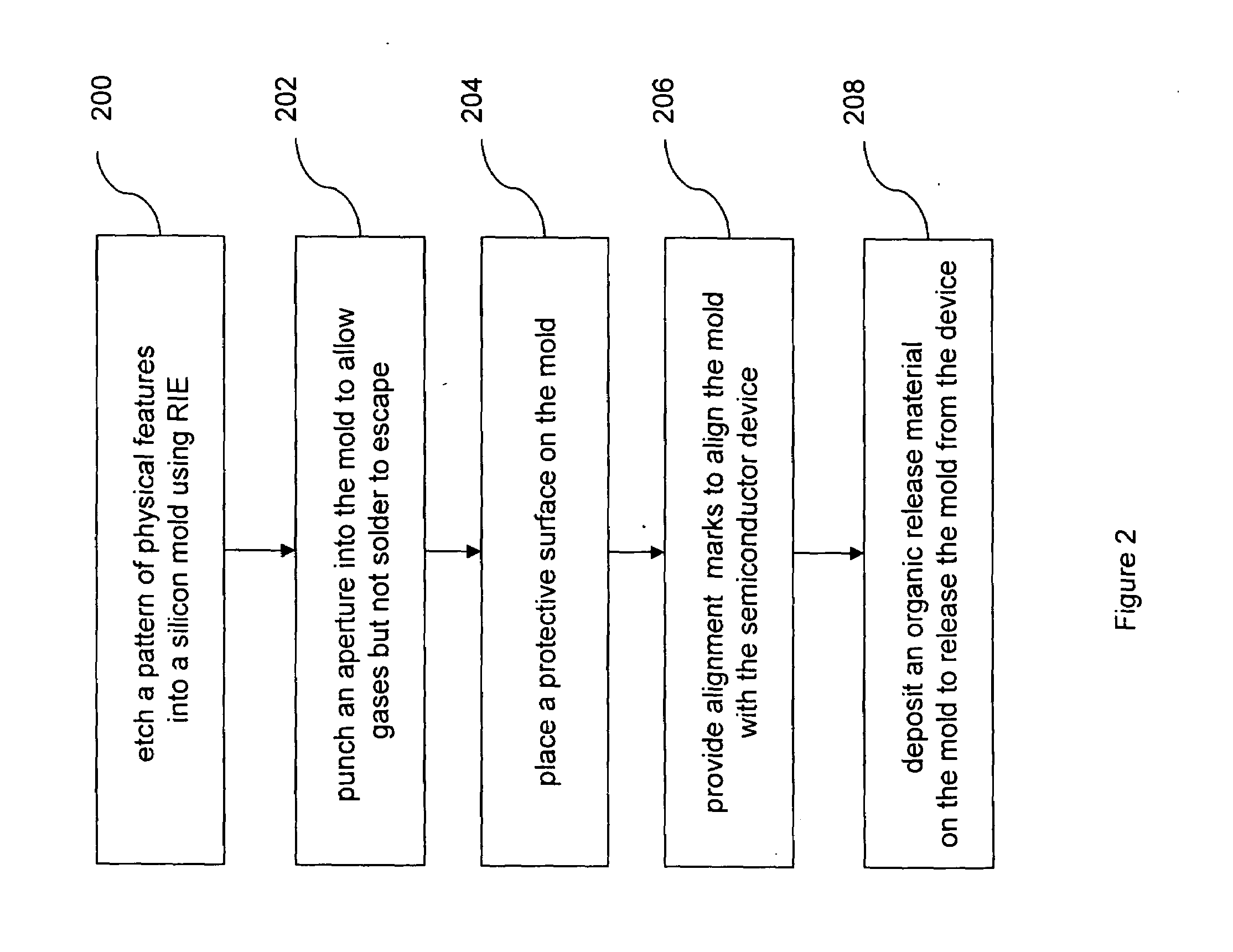

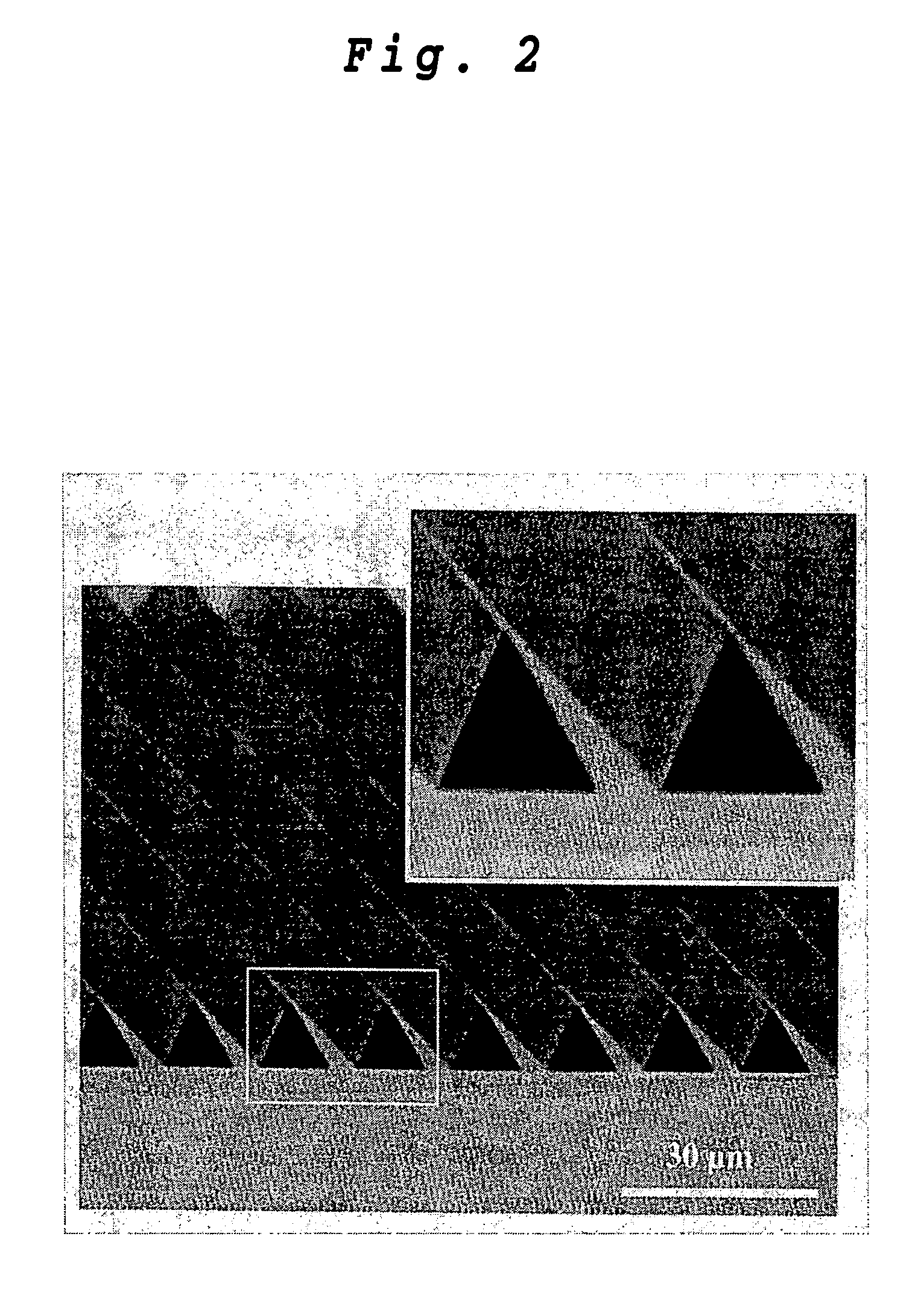

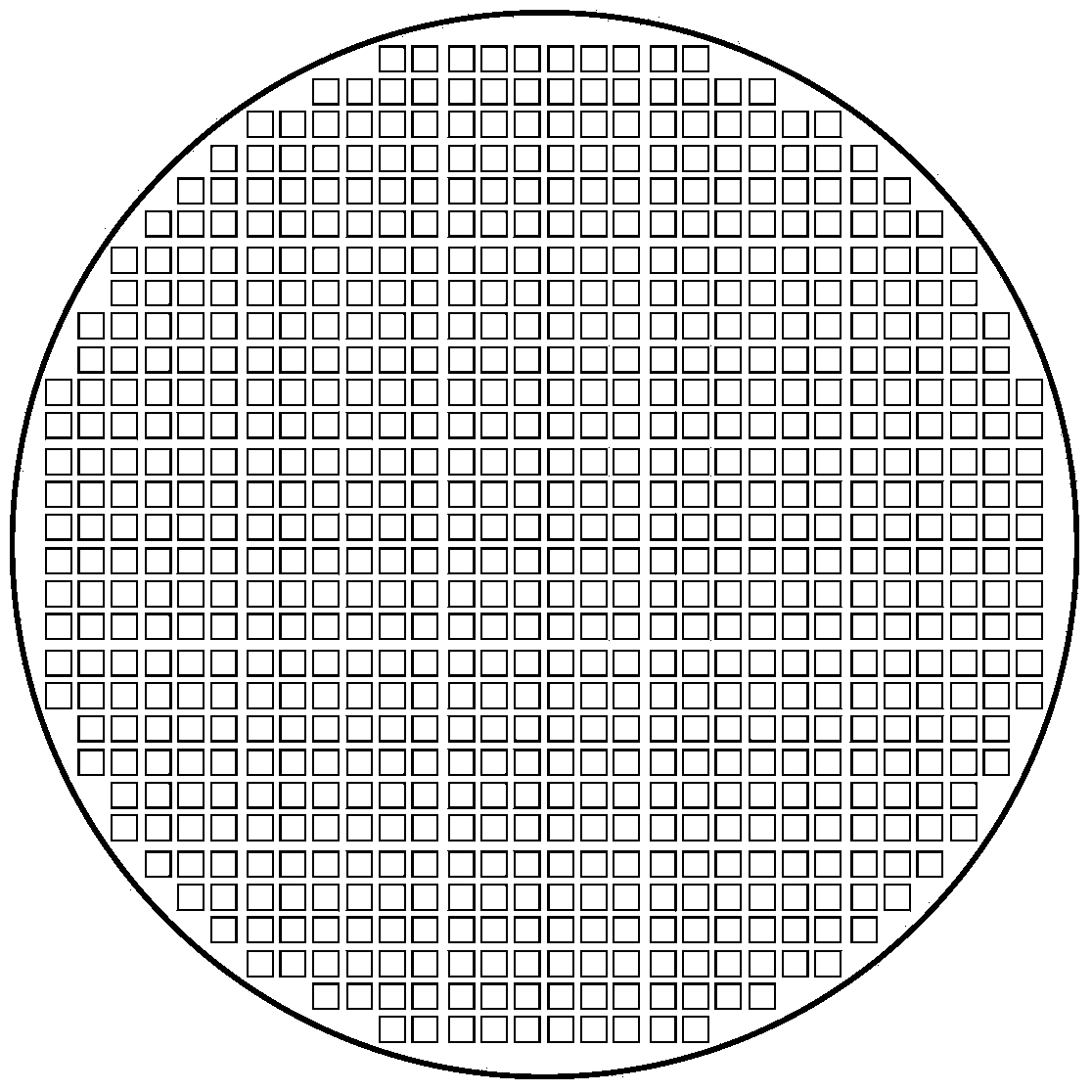

Method for fabricating defect free silicon mold insert

InactiveUS20140353277A1Improve throughputUniform distanceDecorative surface effectsPhotomechanical apparatusSilicon moldNanometre

The present invention discloses a method for fabricating a default free silicon mold insert. The method includes providing a silicon mold insert substrate, producing a photoresist pattern, coating a metal film, removing the photoresist pattern, performing heating and annealing, performing dry etching, and removing the metal balls so as to fabricate the default free silicon mold insert. The default free silicon mold insert produced by the method of the present invention can be applied to the nonoimprint process in manufacturing epitaxy wafers to microscopicly provide uniform distances of patterns on the silicon mold insert, and macroscopicly eliminate the grid lines on the epitaxy wafers, and enormously raise the throughput of epitaxy wafer productions. With the ease of application, cheap and fully reproducible nature of the default free silicon mold insert, nanoimprint technology can really replace the stepper machines used nowadays for producing default free nanoimprint mold insert.

Owner:NANOCRYSTAL ASIA +1

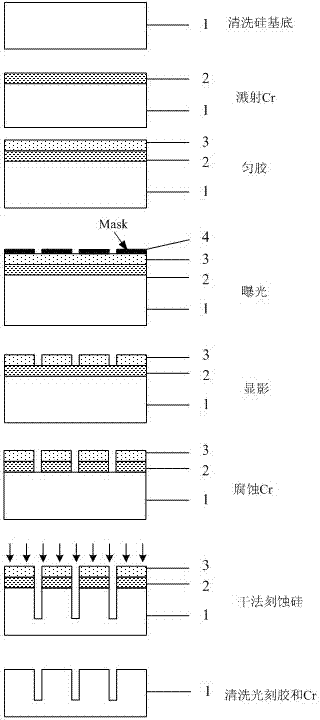

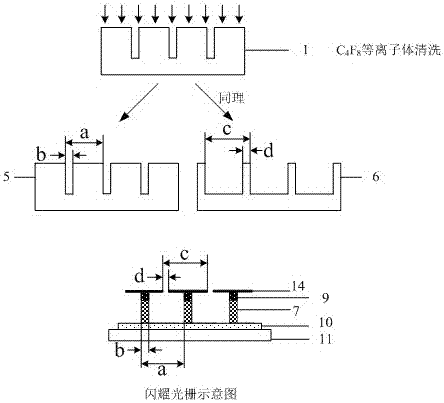

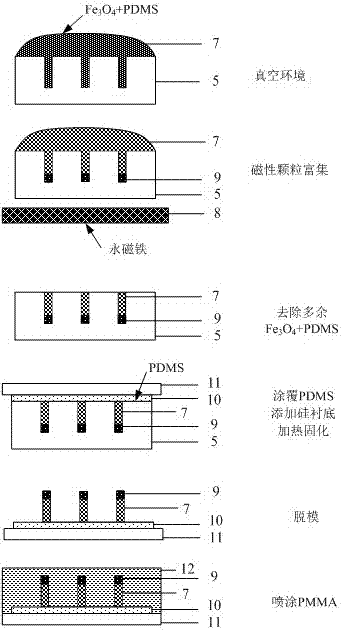

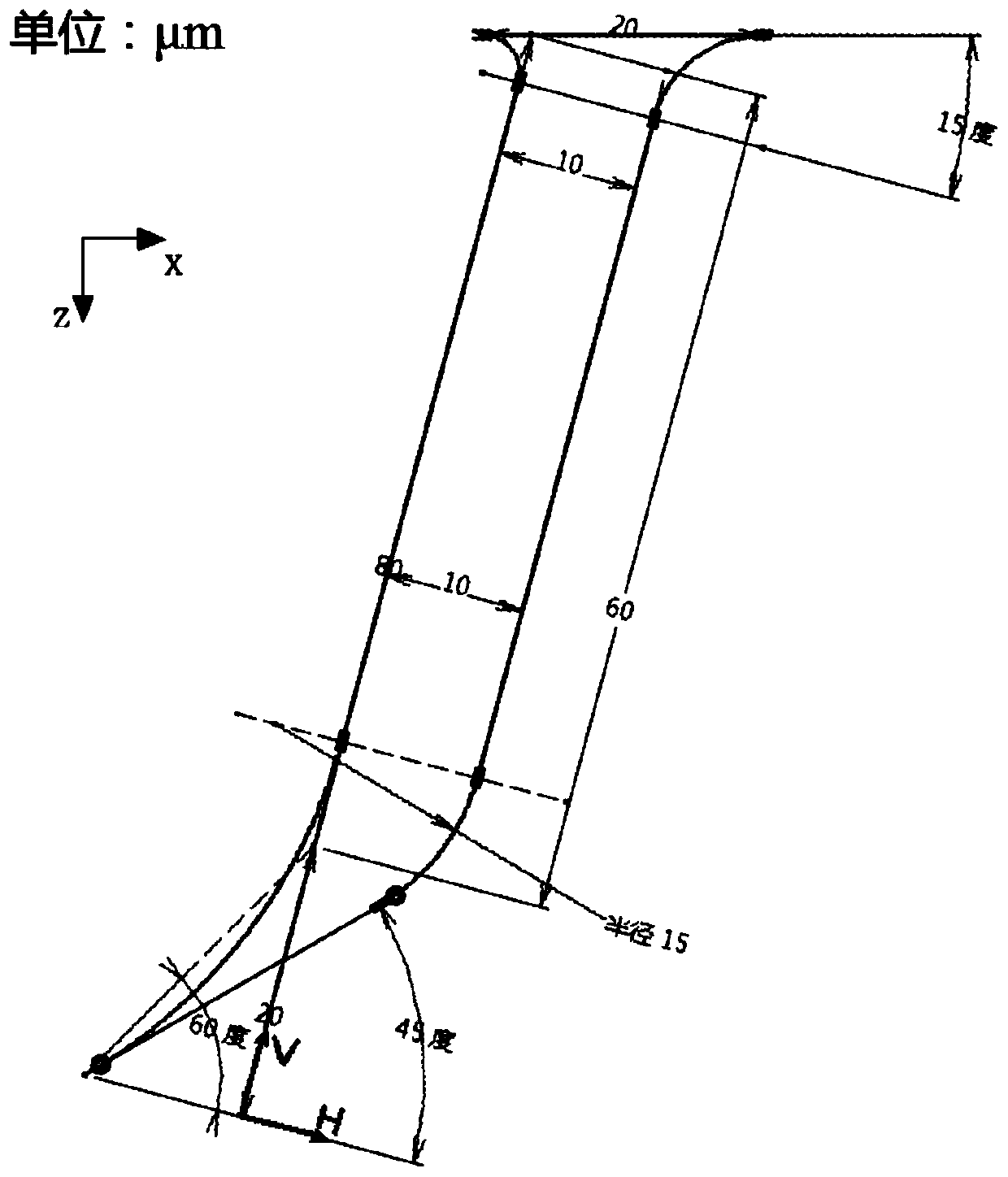

Manufacturing method of adjustable blazed grating based on magnetic field

The invention discloses a manufacturing method of an adjustable blazed grating based on a magnetic field. The manufacturing method comprises the following steps: manufacturing of a silicon mold: sputtering a metal film A on the surface of a cleaned silicon wafer, then gelatinizing, exposing, developing and corroding the metal film A, and preparing the silicon mold A through dry etching silicon; preparing a mold B according to same steps; rolling over the molds to prepare a flexible magnetic polymer grid line; manufacturing of a reflecting surface: coating the surface of the mold B with a configured polymer mixture, then applying a substrate, heating a solidified polymer, demolding to obtain a flexible polymer grid line, sputtering a metal film C with the deposition thickness of 20 to 300 nm on the surface of the flexible polymer grid line to obtain the reflecting surface; and adjusting the transferring of the reflecting surface by using the magnetic field so as to realize the adjustment for an blazing angle of the blazed grating. The blazing angle of the blazed grating is accurately adjusted by using the magnetic field; and the manufacturing method has the advantages that the blazing angle can be accurately adjusted, the response is quick and the cost is low.

Owner:CHANGZHOU RUIFENGTE TECH CO LTD

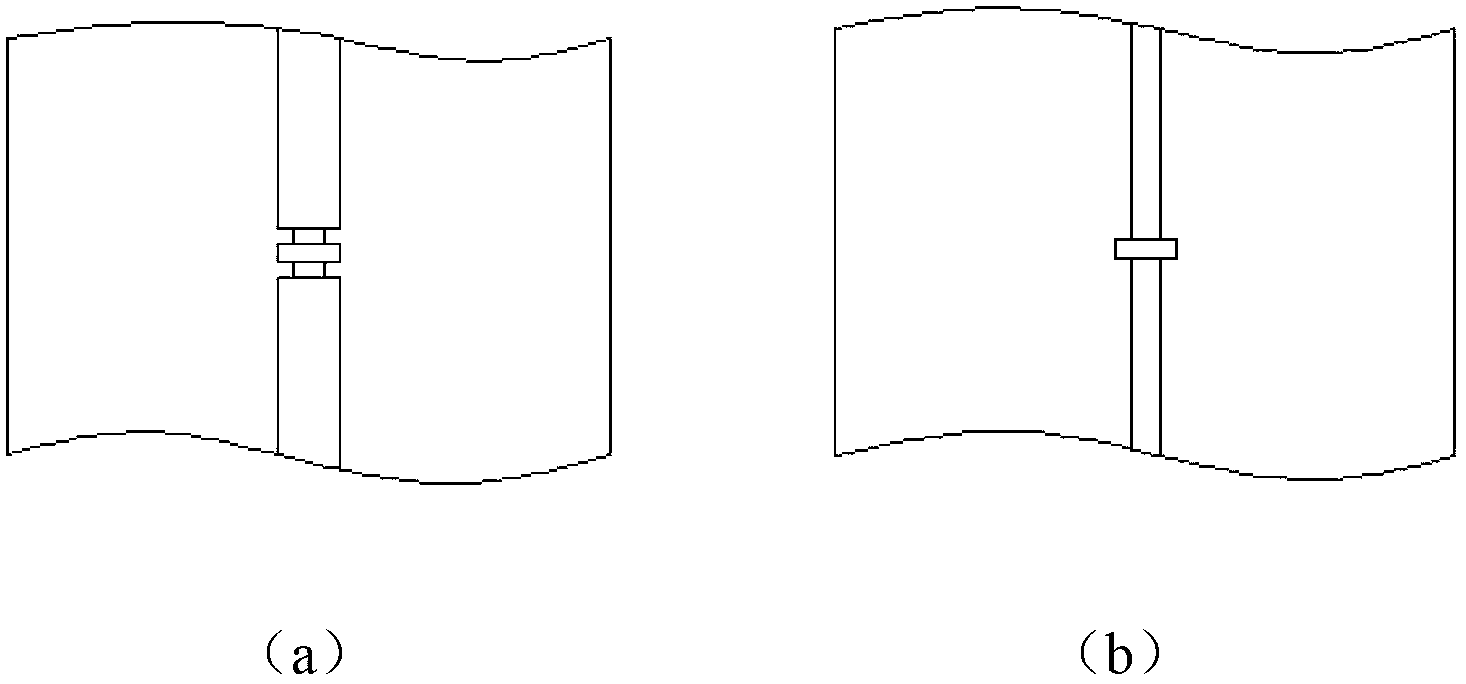

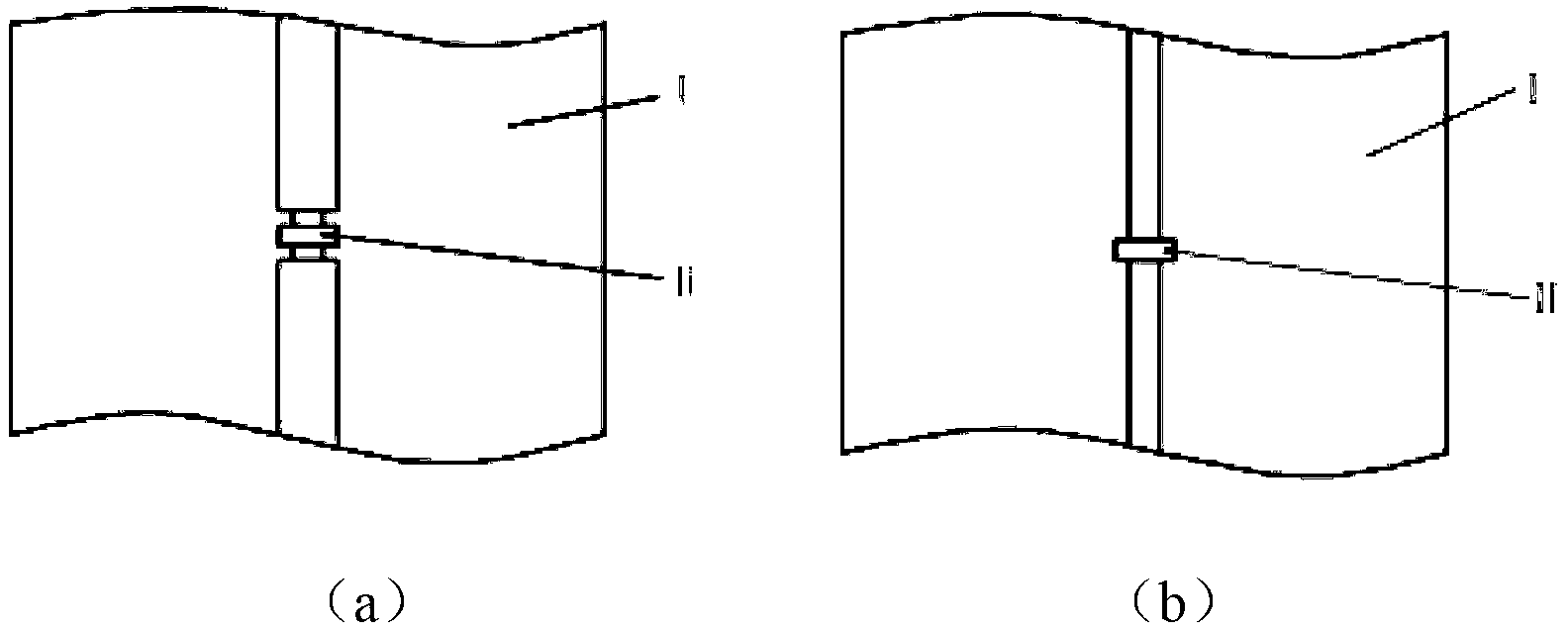

Preparation method of foot-shape imitated gecko adhesion material

The invention discloses a preparation method of a foot-shape imitated gecko adhesion material. The foot-shaped imitated gecko-like adhesion material is obtained by pouring a liquid high-molecular polymer into a sheet-laminated assembled silicon mold, curing, and separating the cured high-molecular polymer from the mold. The sheet-laminated assembled silicon mold is assembled by directionally laminating at least two silicon sheets with corresponding microstructure etching grooves in parallel. The method is directly designed and processed from a side surface contour design of adhesive fibers, the fiber array materials with different adhesion characteristics can be controlled and formed,the manufacturing method is capable of realizing the preparation of an array structure with a complicated morphology, and has the advantages of easiness in demolding and reusability of the mold.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

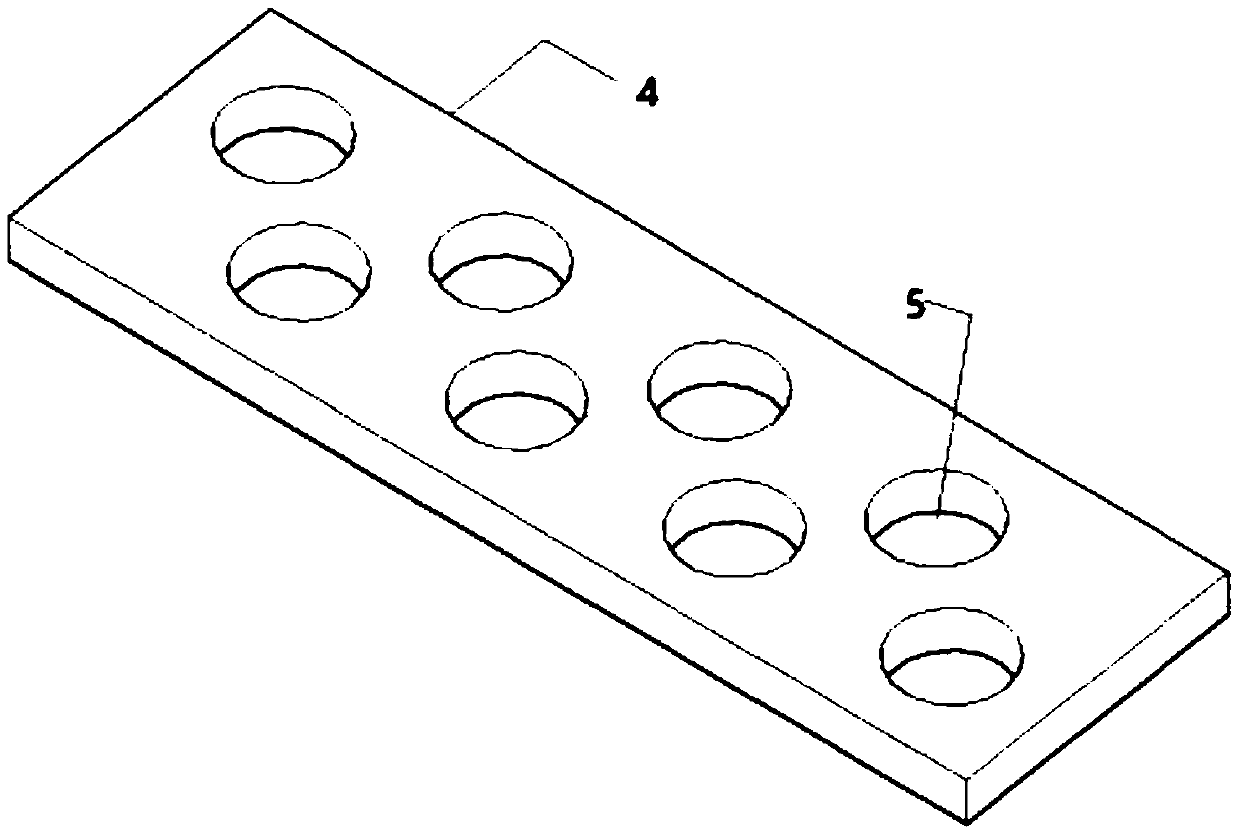

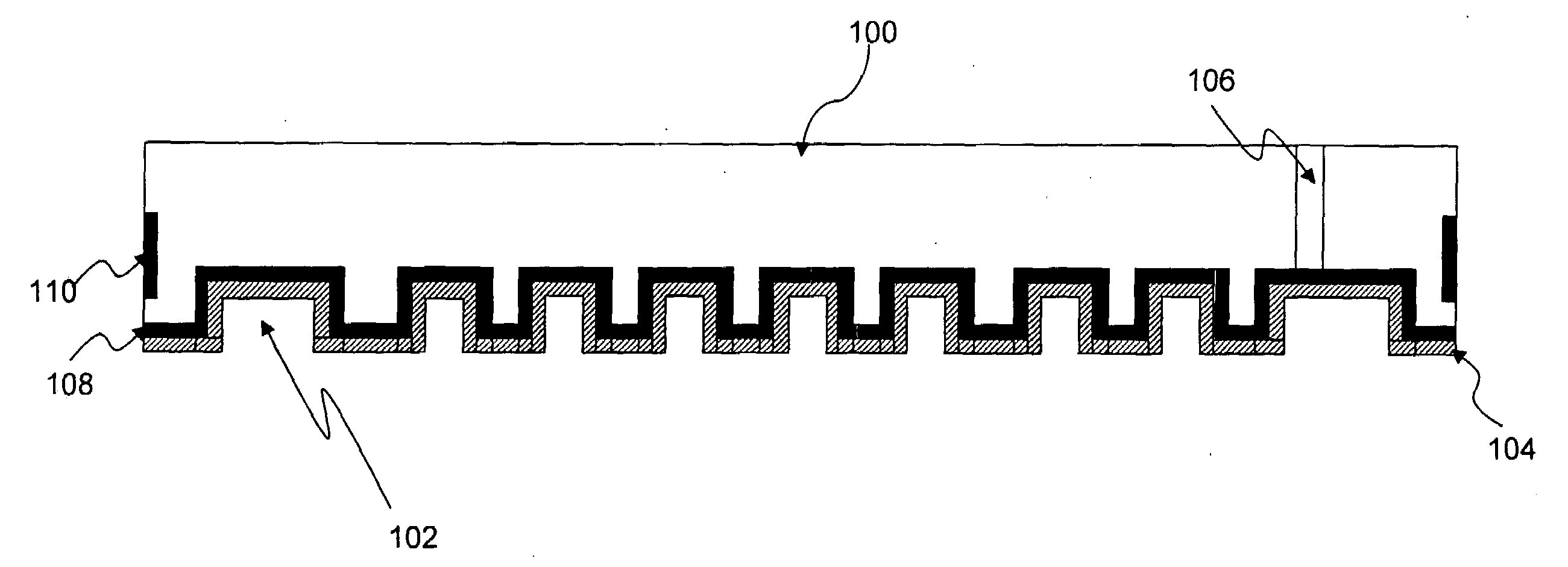

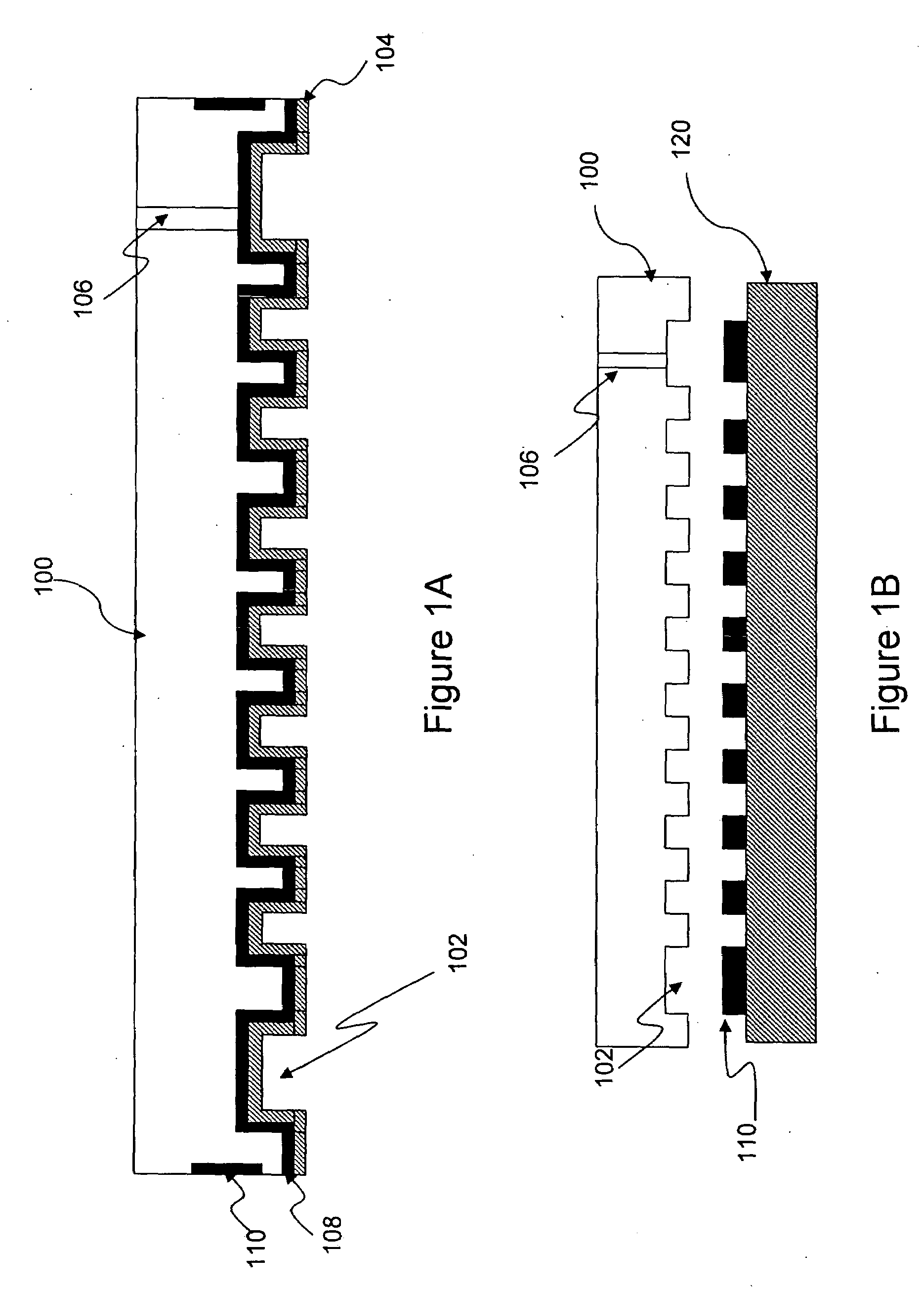

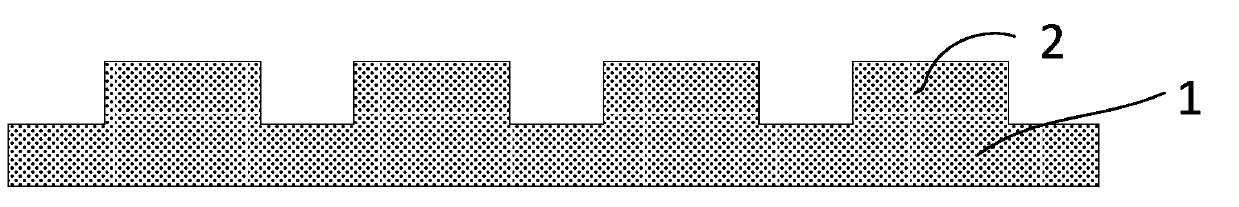

Precision fabricated silicon mold

The invention provides a reusable precision fabricated silicon mold comprising a mold made of silicon which comprises a desired pattern of physical features cavities etched into the mold to transfer a patter on bumps to a semiconductor wafer, e.g., computer chip, semiconductor device, silicon on insulator device, etc.; an aperture etched into the mold adapted to allow gases to escape but does not to allow a solder to escape during the process of transferring solder bumps to a chip; a protective oxide or nitride on the mold; alignment marks adapted to properly align the mold with a semiconductor wafer; an organic release material on the mold adapted to release the mold from the semiconductor wafer, wherein the mold precisely defines a conductive adhesive material volume for interconnects on the semiconductor wafer.

Owner:IBM CORP

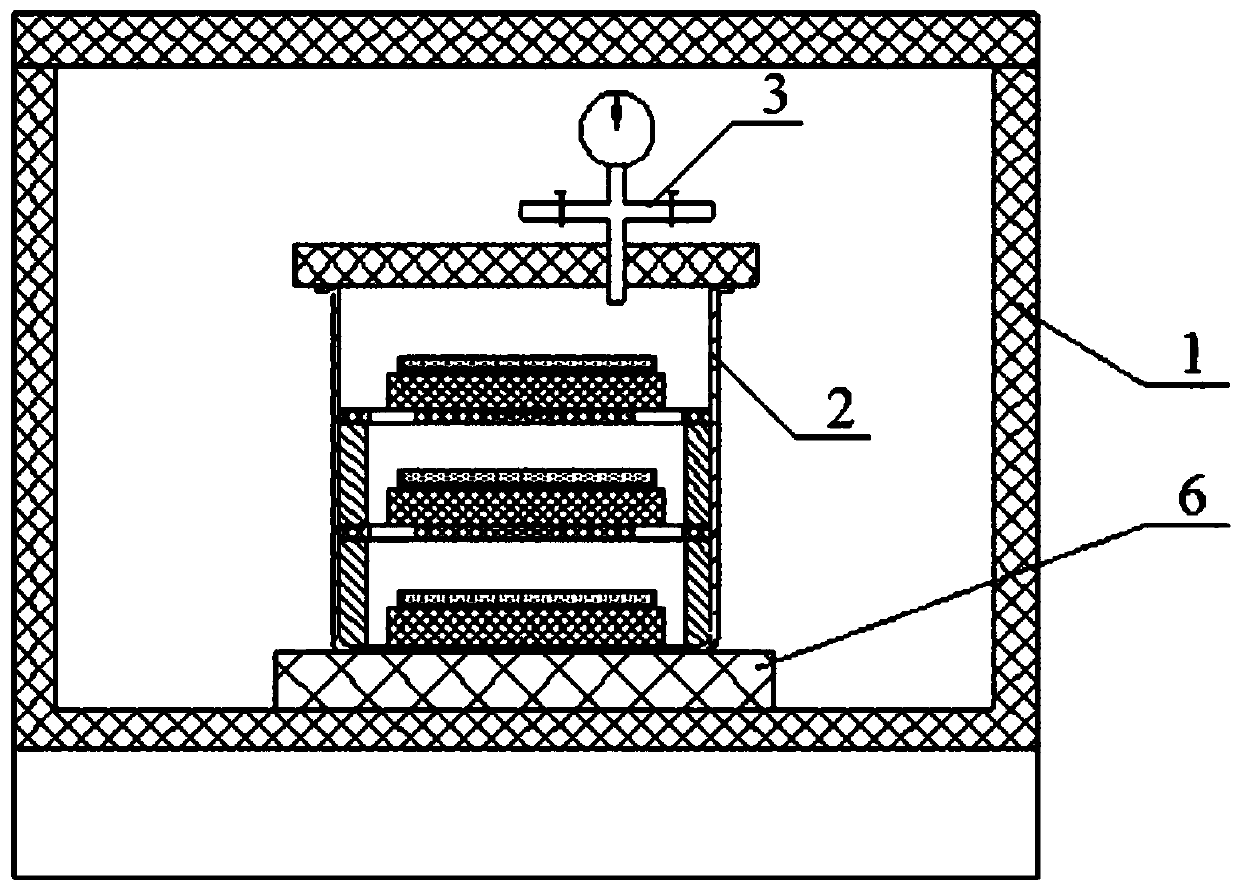

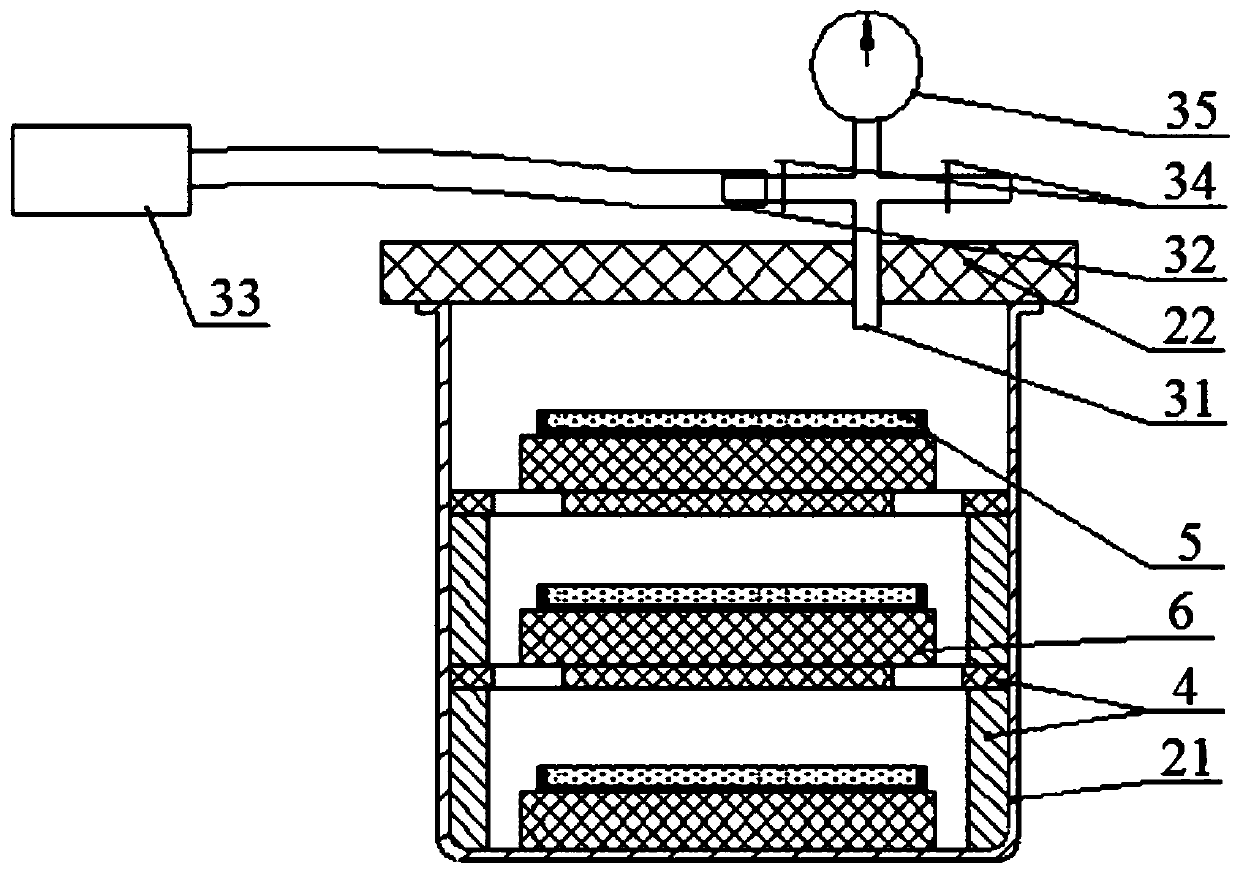

Preparation device and method of ice for complete machine ice swallowing test of aero-engine

ActiveCN111288699AReduce volume lossEasy to demouldLighting and heating apparatusIce productionTemperature controlSilicon mold

The invention belongs to the technical field of aero-engine tests, and particularly relates to a preparation device and method of ice for a complete machine ice swallowing test of an aero-engine. Thedevice comprises a temperature control freezer (1), a vacuum barrel (2) and a silica gel mold (5), wherein the vacuum barrel (2) is arranged in the temperature control freezer (1), the vacuum barrel (2) comprises a vacuum barrel body (21) and a vacuum barrel cover (22), a pressure control assembly (3) is installed on the vacuum barrel cover (22), and a partition plate assembly (4) is arranged in the vacuum barrel (2); and the silica gel mold (5) is arranged on the partition plate assembly (4). According to the preparation device of the ice for the complete machine ice swallowing test of the aero-engine, low-density ice can be prepared, the density requirement of ice for the complete machine ice swallowing test in the national military standard is met, the silica gel mold is easy to demoldand not prone to being broken, and the volume loss of the ice is reduced.

Owner:AECC SHENYANG ENGINE RES INST

Nano organic silicon mold release agent and application method thereof

The invention relates to a nano organic silicon mold release agent which comprises the following substances in parts by weight: 2-8 parts of nano silicon dioxide, 15-25 parts of organic silicon resin, 0.5-3 parts of alcohol ester-12, 0.1-1 part of silicon 69, 0.1-1 part of dispersing agent and 60-80 parts of ethanol. The application method comprises the following steps: uniformly mixing the materials to prepare the nano organic silicon mold release agent for later use; and spraying the nano organic silicon mold release agent onto a clean rubber stopper mold surface, curing at normal temperature for 1.5-3 hours, and putting the mold into use. The product is cured at normal temperature, has the advantages of high durability and low damage to the mold, is easy to clean and prolongs the service life of the mold.

Owner:江阴特洁橡塑有限公司

Method of fabricating mold for glass press

InactiveUS20060130527A1High resolutionImprove accuracyLiquid surface applicatorsDecorative surface effectsSilicon moldSilicon

A method of fabricating a mold for glass press, characterized in that silicon carbide is deposited on the surface of a silicon mold, subsequently the deposited silicon carbide is bonded to a silicon carbide substrate, and thereafter the silicon mold is removed by etching. In this method of fabricating a mold for glass press, the bonding between the silicon carbide deposited on the silicon mold surface and the silicon carbide substrate can be strengthened by interposing a metal thin film.

Owner:JAPAN SCI & TECH CORP

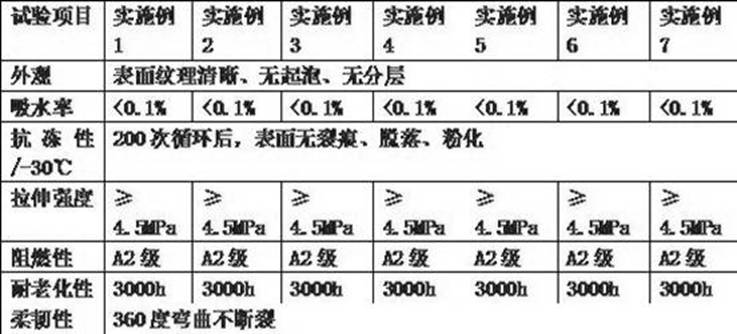

Modified inorganic decorative sheet and preparation method thereof

The invention discloses a modified inorganic decorative sheet which comprises the following components in parts by weight: 30-50 parts of inorganic powder, 10-40 parts of acrylic emulsion, 50-80 parts of stone sand, 0.001-0.01 part of polyvinyl alcohol fiber, 0.002-0.01 part of cellulose, 0.2-1 part of a water repellent, 0.1-2 parts of pigment, 0.1-0.5 part of a dispersing agent, 0.1-0.5 part of a defoaming agent and 10-20 parts of water. The modified inorganic decorative sheet disclosed by the invention has excellent fireproof performance, can reach A2-grade fireproof grade, also has good elasticity and flexibility, and can be bent by 360 degrees without breakage; by means of the silica gel mold, the vivid decorative effect with rich, diverse and natural textures can be specially achieved according to requirements, and the mold is suitable for decoration of inner and outer walls of villas, schools, hospitals, office buildings, parks, high-rise buildings and the like. The manufacturing process of the product is simplified, the cost is reduced, the efficiency is improved, energy conservation and emission reduction are achieved, noise and dust pollution are avoided, and low carbon and environmental protection are achieved.

Owner:东莞爱福旺工业设备有限公司

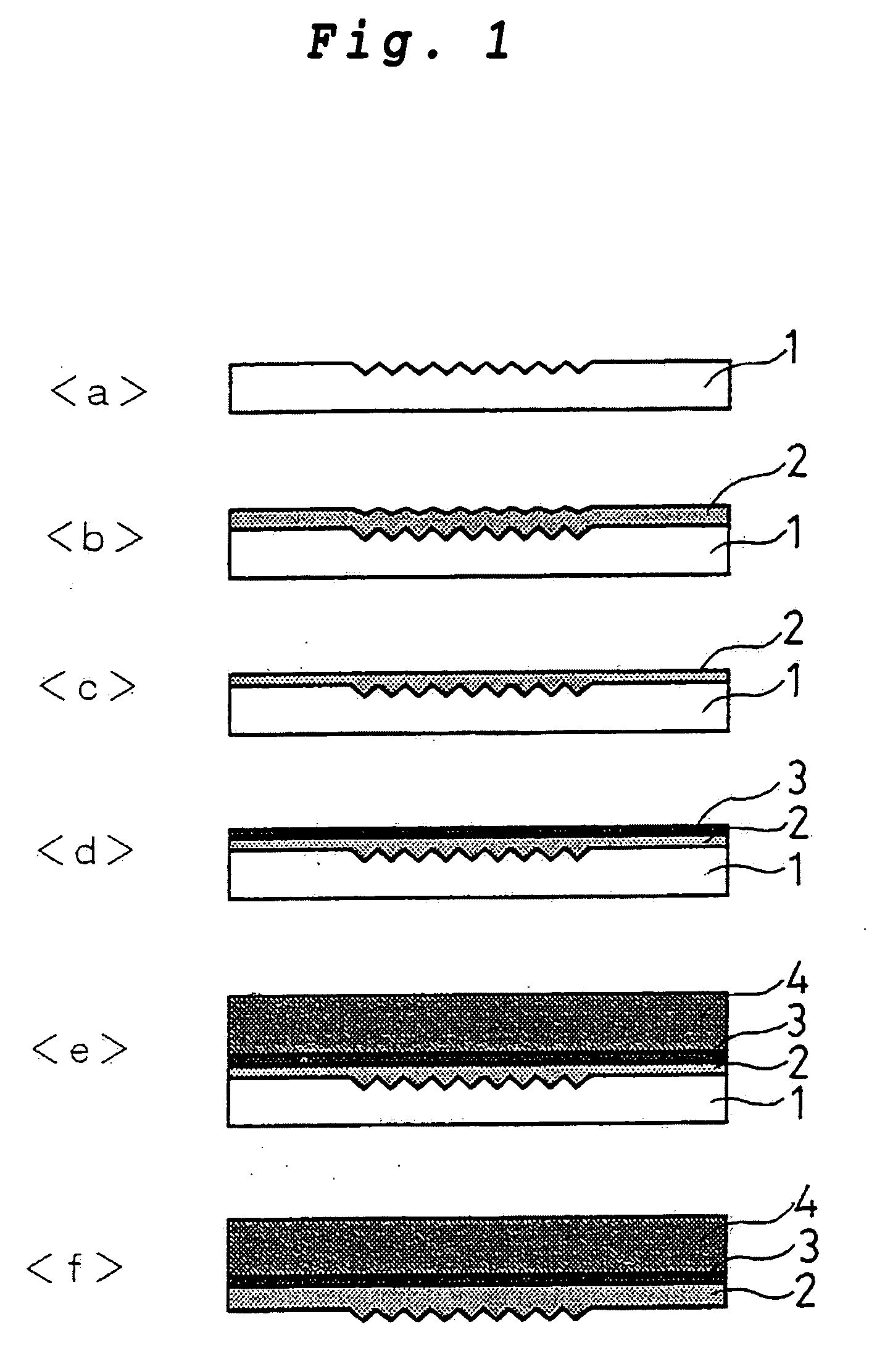

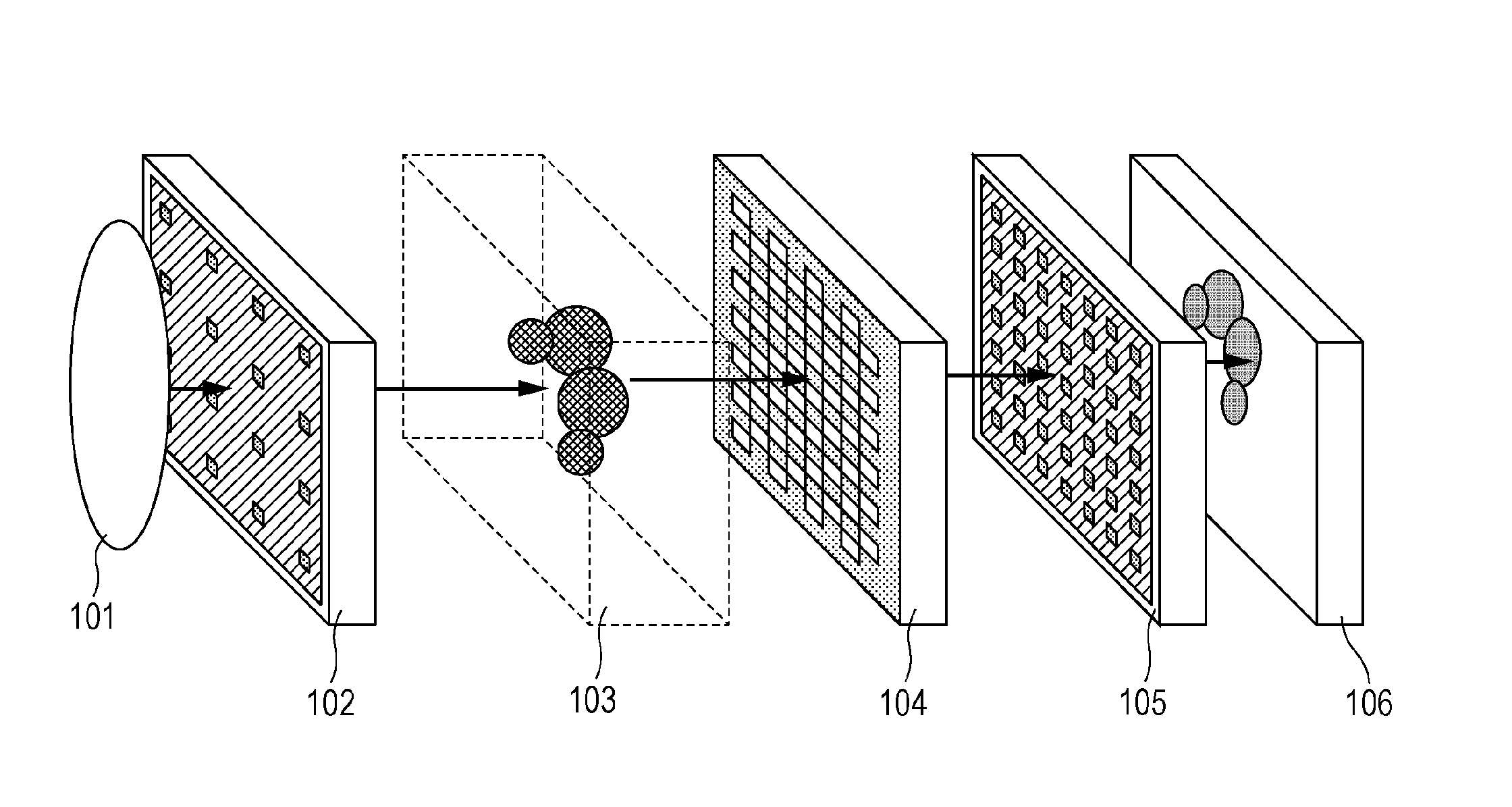

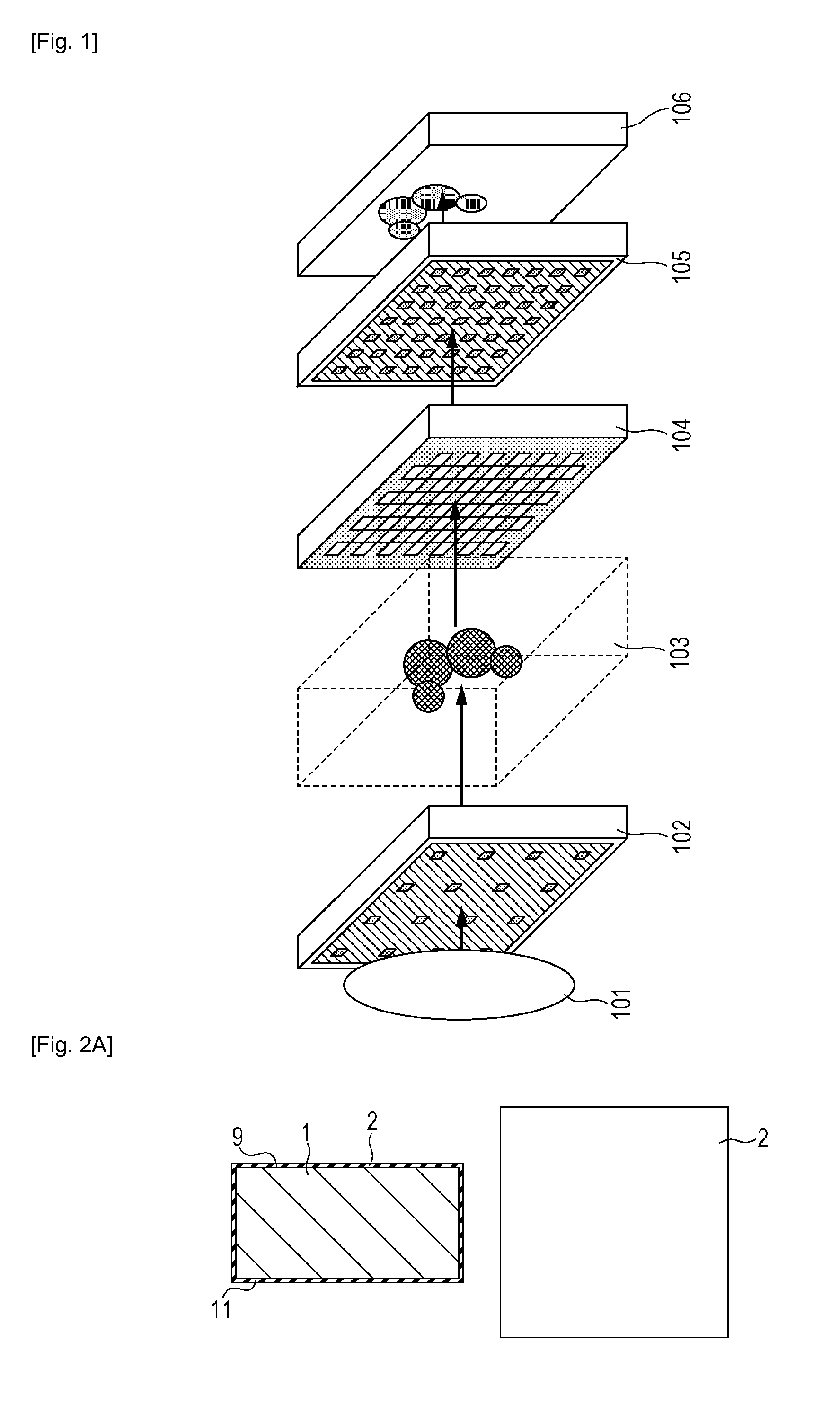

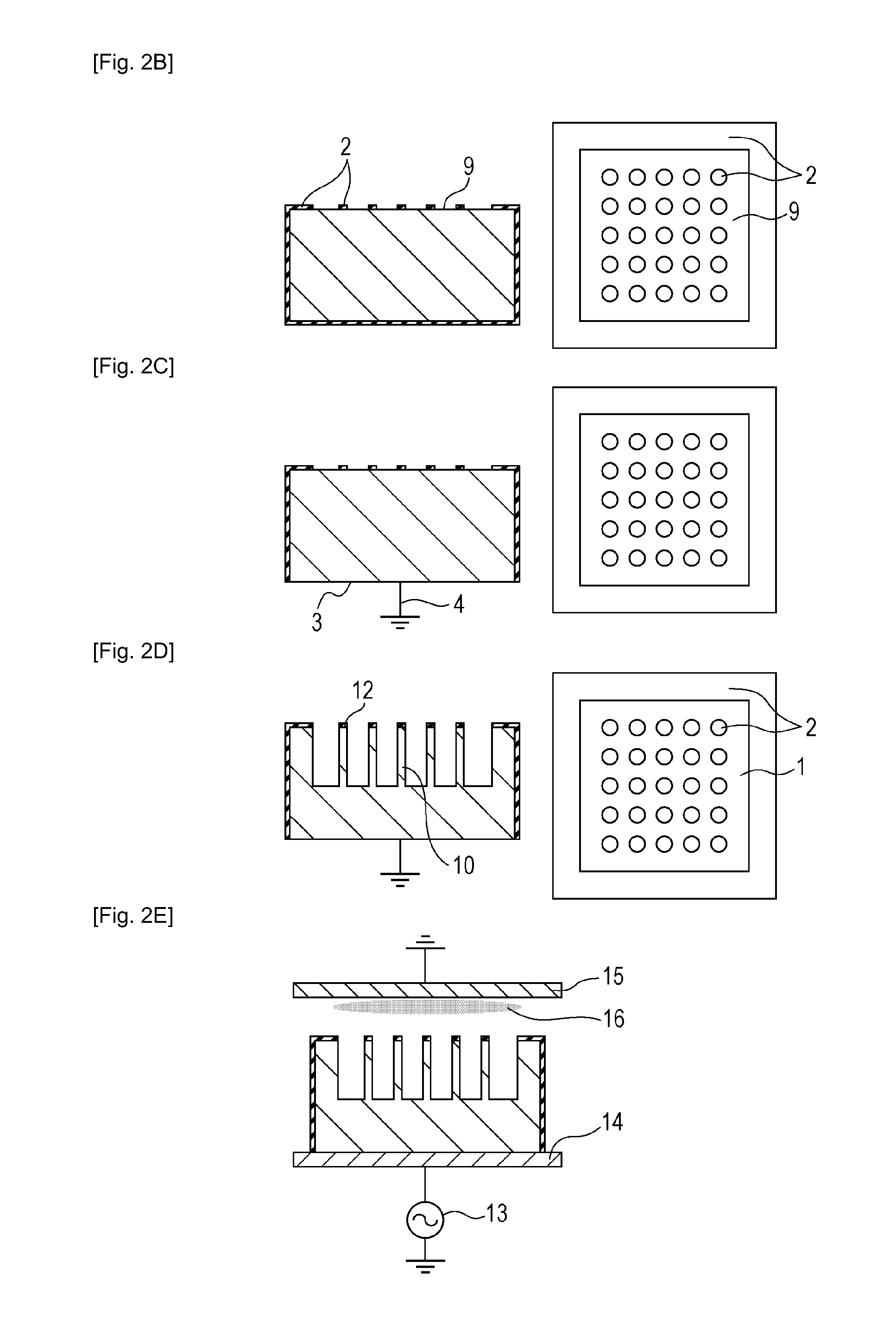

Structure and method for manufacturing the same

InactiveUS20140211920A1Disturbance in arrangement is reducedReduce arrangementCellsImaging devicesSilicon moldSilicon

A method for manufacturing a structure by using a silicon mold, in which disturbances in arrangement due to charges are reduced, can be provided.The method for manufacturing a structure includes the steps of forming a recessed portion in a silicon substrate, cleaning, drying, or conveying the silicon substrate while charges of a plurality of portions sandwiched between the recessed portion are removed, and filling a metal into the recessed portion of the silicon substrate subjected to the cleaning, drying, or conveying.

Owner:CANON KK

High-modulus organic silicon mold glue and preparation method thereof

The invention provides high-modulus organic silicon mold glue which comprises white carbon black, silane coupling agents, catalysts, polymerization inhibitors, hydrogen-containing silicone oil, vinylsilicone oil and release agents. The content of hydrogen in the hydrogen-containing silicone oil is 0.5%, 500CS-50000CS of end vinyl silicone oil is compounded to form the vinyl silicone oil, the release agents are provided with alkyl siloxane with the viscosity of 50CS-1000CS, adding amount of the release agents is 2wt%-4wt%, and the silane coupling agents are selected from one or more of silazane, methyltrimethoxysilane, diethoxy dimethylsilane, vinyl tri-methoxysilane and vinyltriethoxysilane. The prepared organic silicon mold glue is good in contraction rate and wide in applicable range, can adapt to different curing time and conditions and meets different user curing modes, mode compounding frequency is increased, mould burning cannot be easily generated, the service life of the moldis greatly prolonged, demolding is easily achieved, and raw materials are easily acquired and low in cost.

Owner:SHANGHAI JORLE FINE CHEM

Process for production of silicon carbide molded article

InactiveCN102548931AEasy to manufactureHigh puritySemiconductor/solid-state device manufacturingSilicon moldNon oxidative

Disclosed is a process for producing a silicon carbide molded article. The process comprises molding a curable silicon composition comprising a silicon carbide powder or a combination of a silicon carbide powder and a carbon powder into a desired shape, curing a molded product, and thermally decomposing the cured silicon molded article in a non-oxidative atmosphere. The process can produce a silicon carbide molded article having high purity and desired shape and size.

Owner:SHIN ETSU CHEM CO LTD

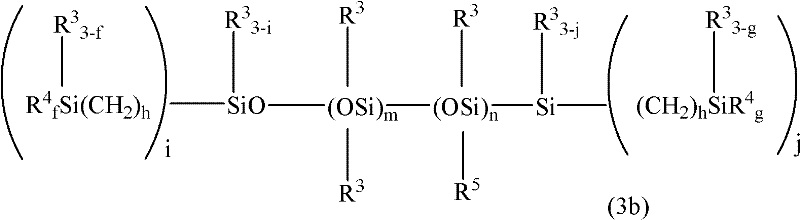

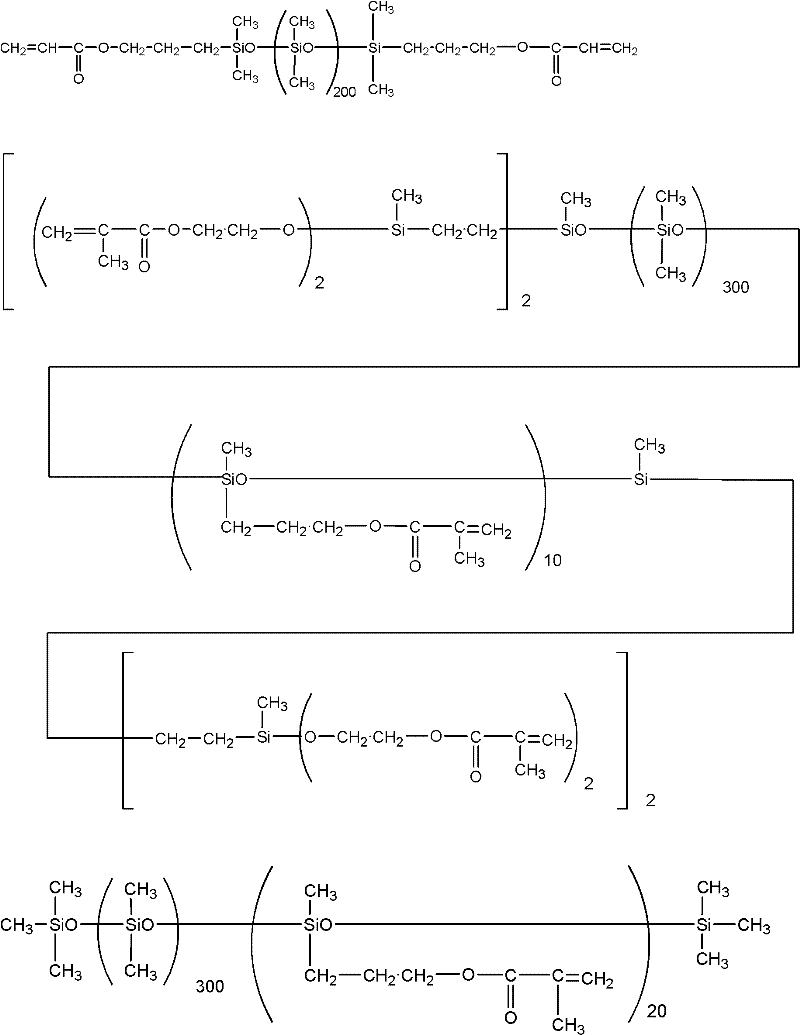

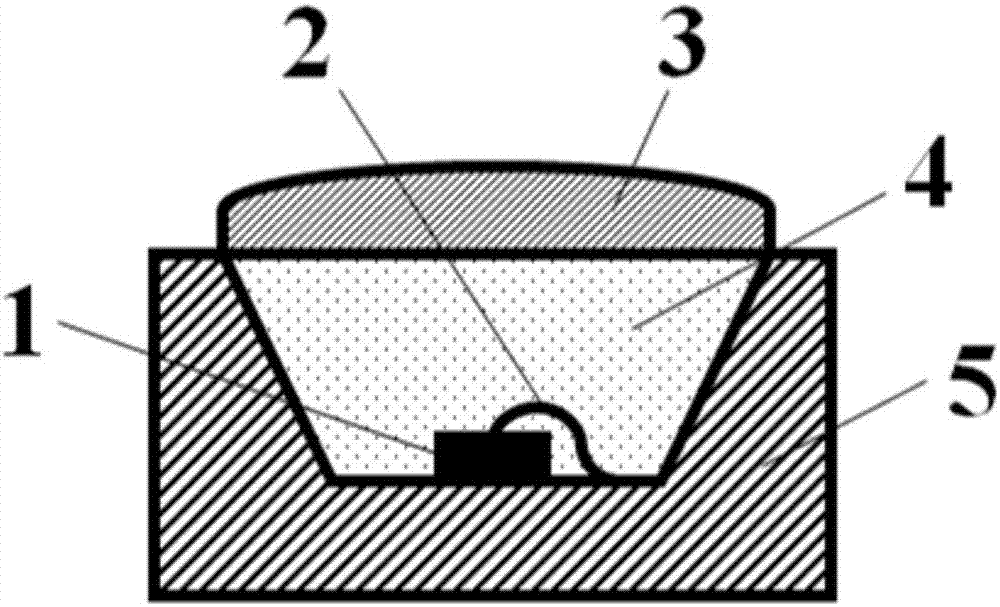

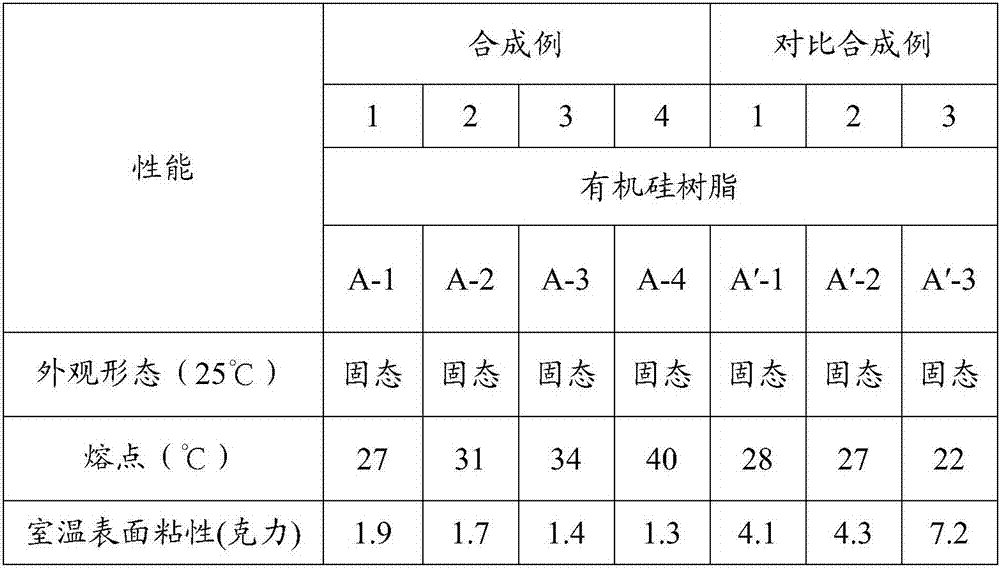

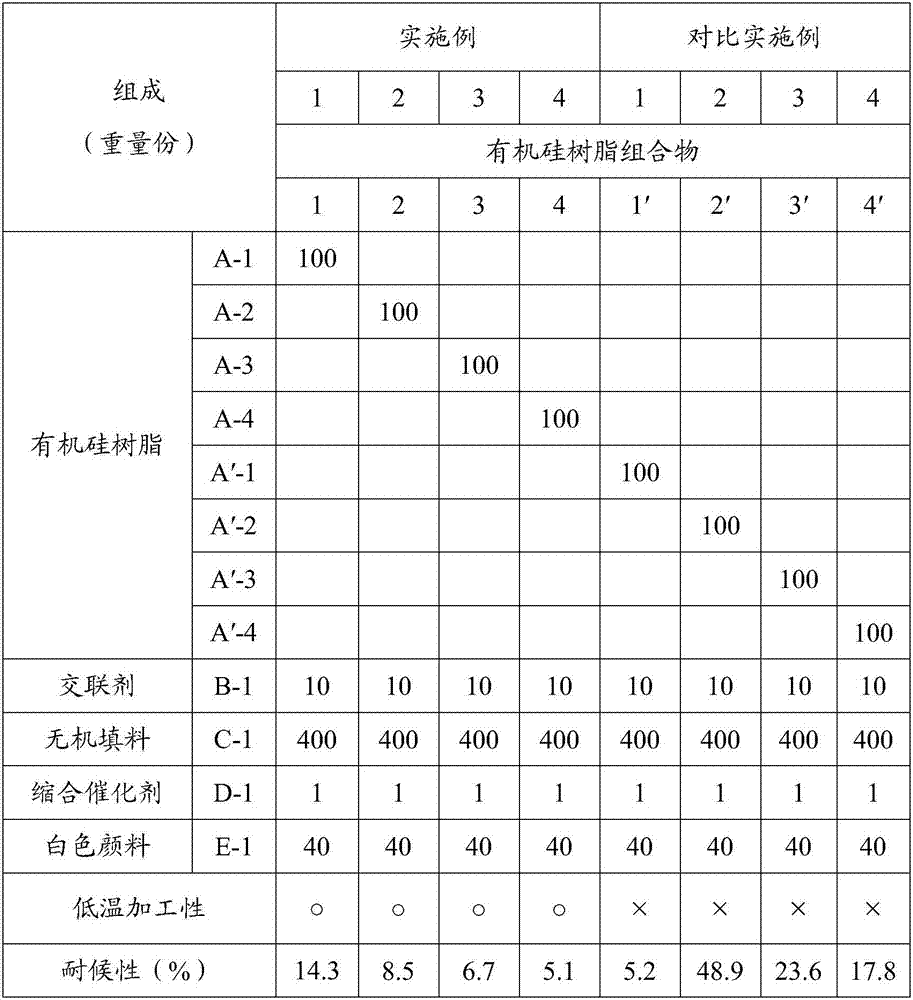

Moldable organic silicon resin, composition and semiconductor light-emitting element

ActiveCN107501942ALow melting pointEasy to processSemiconductor devicesWeather resistanceSilicon mold

The invention relates to moldable organic silicon resin, a composition and a semiconductor light-emitting element. The moldable organic silicon resin and a preparation method thereof are firstly provided. The organic silicon resin is in a solid state at 25 DEG C by controlling a molar ratio of a [MeSiO3 / 2] unit, a [PhSiO3 / 2] unit, a [R2SiO2 / 2] unit and hydroxyl in the organic silicon resin within a specific value range, and the melting point is lower than 50 DEG C, so that the moldable organic silicon resin which is applicable to condensed type organic silicon mold plastic and has the relatively low melting point can be obtained. The invention further provides a moldable organic silicon resin composition. By at least mixing the organic silicon resin with a crosslinking agent, an inorganic filler and a condensed catalyst, the condensed type organic silicon mold plastic which is high in low-temperature processibility and weather resistance is obtained. Furthermore, the invention further provides a molded body and a manufacturing method thereof, an LED shell and the semiconductor light-emitting element.

Owner:BEIJING KMT TECH

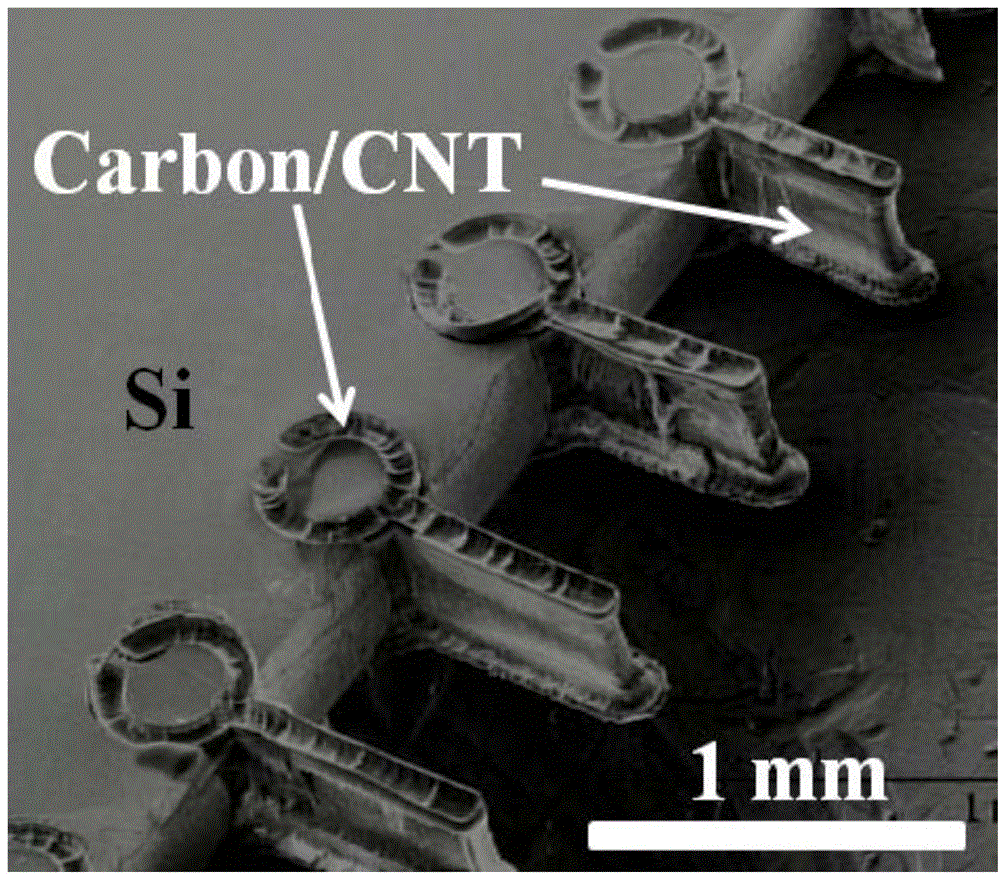

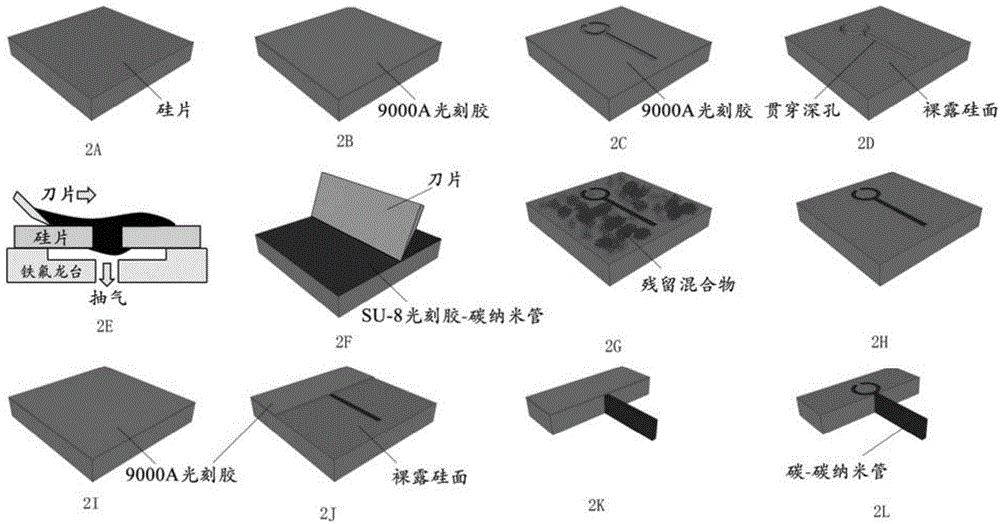

Manufacturing method of high aspect ratio micro structure of novel carbon-carbon nano tube composite material

InactiveCN104609366AImprove mechanical propertiesHigh Young's modulusMicrostructural devicesMicro structureSilicon mold

The invention provides a manufacturing method of a high aspect ratio micro structure of a novel carbon-carbon nano tube composite material. The manufacturing method comprises the following steps of manufacturing a micro silicon mold and manufacturing the carbon-carbon nano tube composite material and the high aspect ratio micro structure, wherein the micro silicon mold is prepared by an ultraviolet photoetching and silicon deep etching technique; the novel carbon-carbon nano tube composite material is obtained by carbonizing a photoetching-carbon nano tube composite material obtained by mixing a multi-wall carbon nano tube and SU-8 photoresist; the high aspect ratio micro structure can be prepared in a micro silicon mold by a background vacuumizing method. According to the invention, relevant techniques in the field of semiconductors are fused; the technology is simple, and the relevant techniques are developed, and the manufacturing method can be applied to the large-scale production; the micro structure of the obtained carbon-carbon nano tube composite material has good mechanical property and relatively high chemical stability; the micro structure with the width range of 5-100 microns and the depth range of 200-500 microns can be obtained; the highest depth-to-width ratio can reach 100.

Owner:WUHAN UNIV OF TECH

Integrated manufacturing method of novel composite ligament-bone scaffold

ActiveCN103750921AStable Physiological FixationPhysiological fixation is goodStentsLigamentsSilicon moldBone tissue

The invention discloses an integrated manufacturing method of a novel composite ligament-bone scaffold. After a ligament scaffold, a bone scaffold and a fastening nail silicon mold are manufactured, the ligament scaffold and the bone scaffold are connected, a molten fastening nail material is poured into the fastening nail silicon mold, the bone scaffold is pressed into the fastening nail silicon mold, an auxiliary implantation device is placed in a fastening nail material molten liquid which is not solidified and is pulled out after being solidified, and then the ligament-bone scaffold is acquired. The ligament-bone scaffold and an autogenous bone channel are initially fixed through fastening nails, at the later period, an autogenous bone grows into a bone scaffold hole and the bone scaffold is degraded to grow bone tissue, stable physiological fixation is achieved, and the auxiliary implanting device guides the ligament-bone scaffold into the bone channel. The whole ligament-bone scaffold is biodegradable and does not need to be taken out, and the good physiological fixation can be achieved.

Owner:SUSHENG BIOTECH (HAINAN) CO LTD

Ingot mold coating for industrial silicon production and preparation method of ingot mold coating

ActiveCN110184650AImprove molding qualityCan't solvePolycrystalline material growthCoatingsCalcium silicateSilicon mold

The invention discloses an ingot mold coating for industrial silicon production and a preparation method of the ingot mold coating. The ingot mold coating consists of the following raw materials in parts by weight: 50 parts of silicon carbide, 25-30 parts of silicon nitride, 10-12 parts of calcium silicate, 15-20 parts of bentonite, 8-10 parts of sodium tripolyphosphate, 3-5 parts of acrylamide and / or polyacrylamide, 6-8 parts of an adhesive, 1-2 parts of graphite powder and 20-30 parts of a solvent. The ingot mold coating is specifically applied to an industrial silicon molding mold which ismade of polycrystalline silicon as a raw material, is capable of solving the problem that in the prior art a coating matched with a polycrystalline silicon mold is not available, and ensures that thepolycrystalline silicon mold maintains advantages of rapid heat conduction and no contamination of self; and a mode that a conventional mold coating takes carbon or a carbon-containing organic matteras a main coating agent is abandoned, a silicon-based main agent is adopted to match with the polycrystalline silicon mold for industrial silicon production, and silicon carbide and silicon nitride are capable of ensuring that no impurity contamination is caused for silicon molding, meanwhile have very good adaptability with the polycrystalline silicon, and ensure that industrial silicon is not contaminated by the coating while the industrial silicon is not contaminated by the polycrystalline silicon.

Owner:新疆泰宇达环保科技有限公司

Method for forming Llight resistance wall molding method by adopting silicon mold

InactiveCN103728831AIncrease costReduce manufacturing costOriginals for photomechanical treatmentRadiation controlled devicesSilicon moldPressure casting

The invention provides a method for forming a light resistance wall molding method by adopting a silicon mold. The method comprises the following steps: the silicon mold, the front side of which the front side is provided with boss arrays, is manufactured, and mold cavities are formed by latticed grooves among the bosses; the front side of the silicon mold is pressed on a first baseplate with thermoplastic material through a mould pressing method; or the gap between the front side of the silicon mold and the first baseplate is fully filled with the thermoplastic material through a pressure casting method; the silicon mold is separated from the first baseplate after the mold cavities are fully filled with the thermoplastic material; a light resistance wall structure is formed on the first baseplate; the first baseplate is cleaned to removeso that residues on the first baseplate and the light resistance wall structure are removed. The silicon mold can be manufactured through the method of wet etching, dry etching, laser cutting or line cutting; the molding method has the advantages that the silicon is adopted to manufacture the mold, so that the cost of the mold manufacturing is reduced greatly; meanwhile, the etching method can be used for manufacturing the light resistance wall structures with different patterns conveniently and flexibly; compared with the conventional photoetching technology, the molding method adopts the silicon mold, so that more flexible choices on the requirements of materials of the light resistance wall are achieved.

Owner:NAT CENT FOR ADVANCED PACKAGING

Preparation method of polydimethylsiloxane porous film

The invention relates to the technical field of microfluidic chips, in particular to a preparation method of a polydimethylsiloxane porous film. The preparation method of the polydimethylsiloxane porous film can overcome the weaknesses that a silicon mold is relatively crisp, short in service life, relatively long in preparation process time and the like, and also can overcome the defects of a metal mold prepared by a UV-LIGA process that the process is long, and the cost is high. A process for preparing the polydimethylsiloxane porous film is simple, the cost is low, the operation is easy, the prepared polydimethylsiloxane porous film is high in elasticity, gas permeability and hydrophobicity and particularly suitable for researching the microfluidic chips; and moreover, and the polydimethylsiloxane porous film prepared by the method has a porous structure of a micro-nano size, so that the application range of the plydimethylsiloxane prous film can be greatly increased.

Owner:苏州锐材半导体有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com