Method for forming Llight resistance wall molding method by adopting silicon mold

A molding method and technology of silicon molds, which are applied in the direction of photo-plate making process of originals for photomechanical processing, optics, pattern surface, etc., can solve the problem of affecting product quality and service life, low rigidity of photoresist materials, and reliable sensors Sexual problems and other problems, to achieve the effect of improving strength, reducing delamination and detachment, and low moisture absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

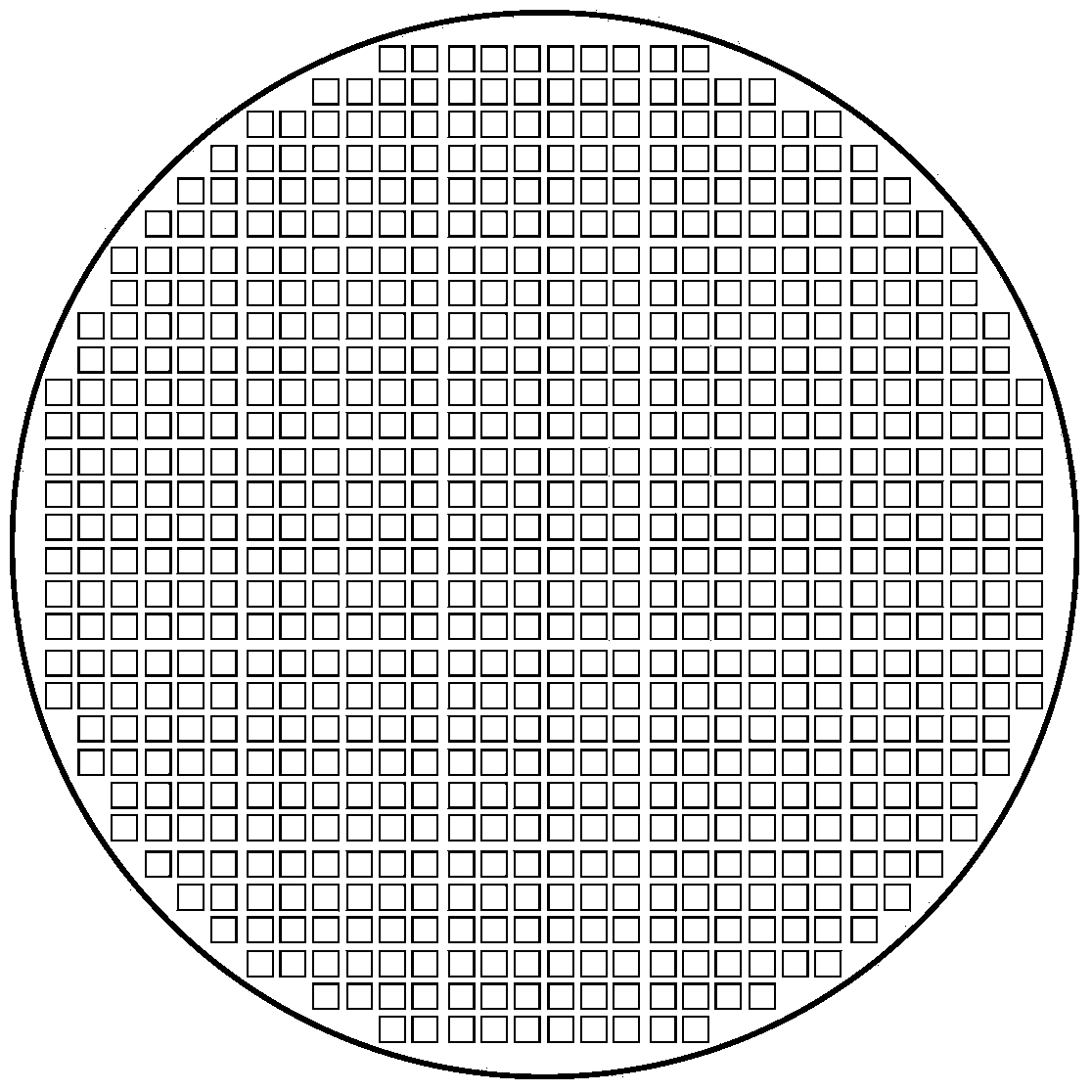

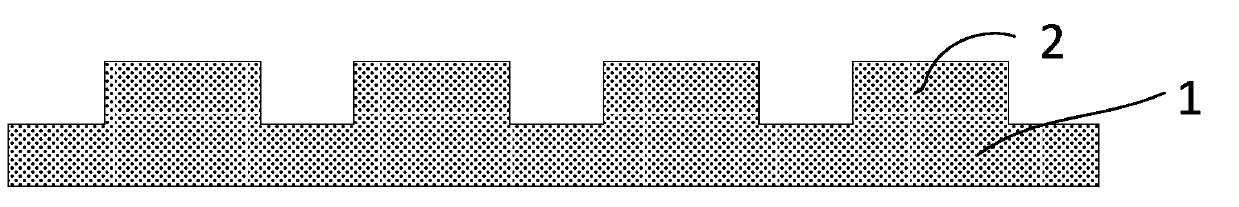

[0025] 1. The present invention first uses wet etching, dry etching, laser cutting or wire cutting to make silicon mold 1, such as figure 2 As shown, the front side of the silicon mold 1 has an array of bosses 2, and the grid-shaped grooves between the bosses form a mold cavity; the depth of the grooves is 50 to 150 microns.

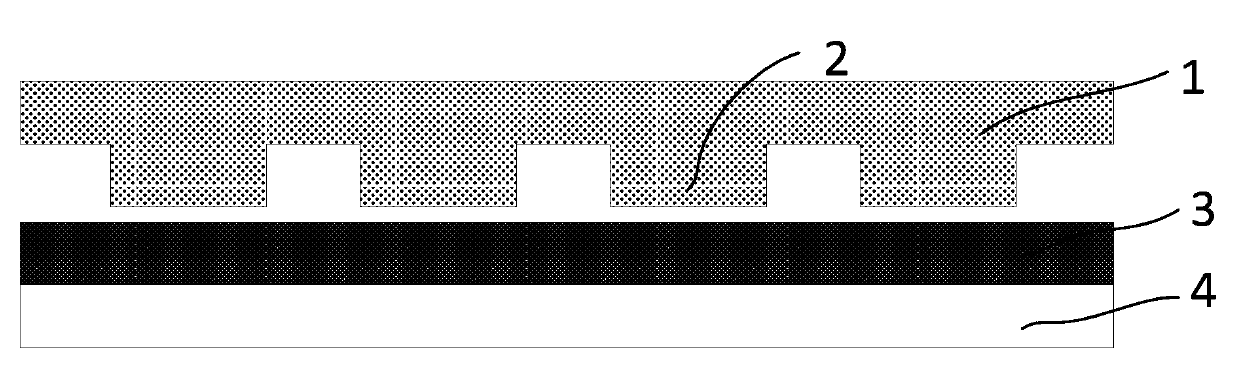

[0026] 2. If image 3 As shown, the thermoplastic material 3 is coated on the first substrate 4 with a thickness of 20 to 100 microns, and heated to the melting temperature of the material, and the front side of the silicon mold 1 is pressed on the first substrate with the thermoplastic material 3 by molding. 4; or the thermoplastic material 3 is filled between the front of the silicon mold 1 and the first substrate 4 by means of pressure injection. The thermoplastic material 3 can be epoxy resin, polytetrafluoroethylene, phenolic resin, benzox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com