Moldable organic silicon resin, composition and semiconductor light-emitting element

A technology of resin composition and molding, which is applied in the field of silicone resin and composition, and can solve problems such as difficulty in compounding and molding, poor processability at low temperature, and no teaching of condensation-type silicone molding compounds. Achieve good low-temperature processability and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

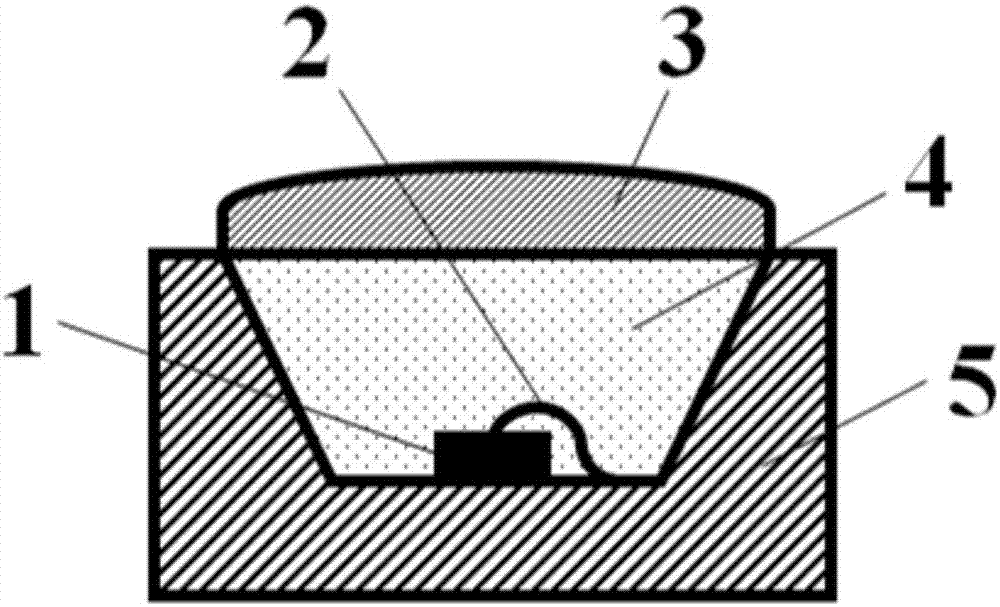

Image

Examples

preparation example Construction

[0047]

[0048] As the preparation method of the silicone resin of the present invention, comprising:

[0049] (a) Hydrolysis step: adding the first mixed solution comprising water, an acid catalyst, and the first organic solvent to the second mixed solution comprising chlorosilane and the second organic solvent, so that the chlorosilane undergoes a hydrolysis reaction, and from Separate the organic phase and the aqueous phase in the hydrolysis reaction product;

[0050] (b) Condensation step: after the pH value of the separated organic phase is neutralized to 7-14, condensation reaction occurs;

[0051] Wherein, the chlorosilane is MeSiCl 3 , PhSiCl 3 and R 2 SiCl 2 and R represents Me or Ph.

[0052] In the hydrolysis step (a), the water is preferably deionized water.

[0053] In the hydrolysis step (a), the type of the acidic catalyst is not particularly limited, and its examples include but are not limited to: inorganic acids such as sulfuric acid, hydrochloric aci...

Embodiment

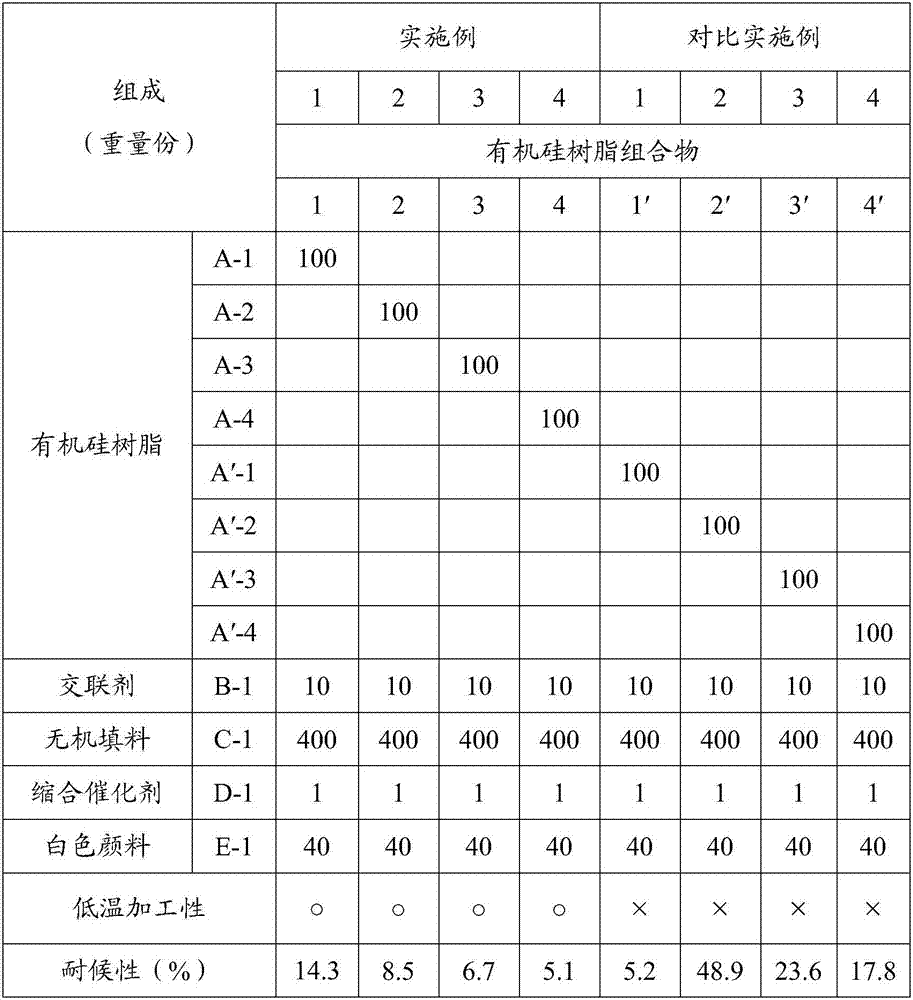

[0117] Hereinafter, the present invention will be further described through examples, but the protection scope of the present invention is not limited by the examples.

[0118]

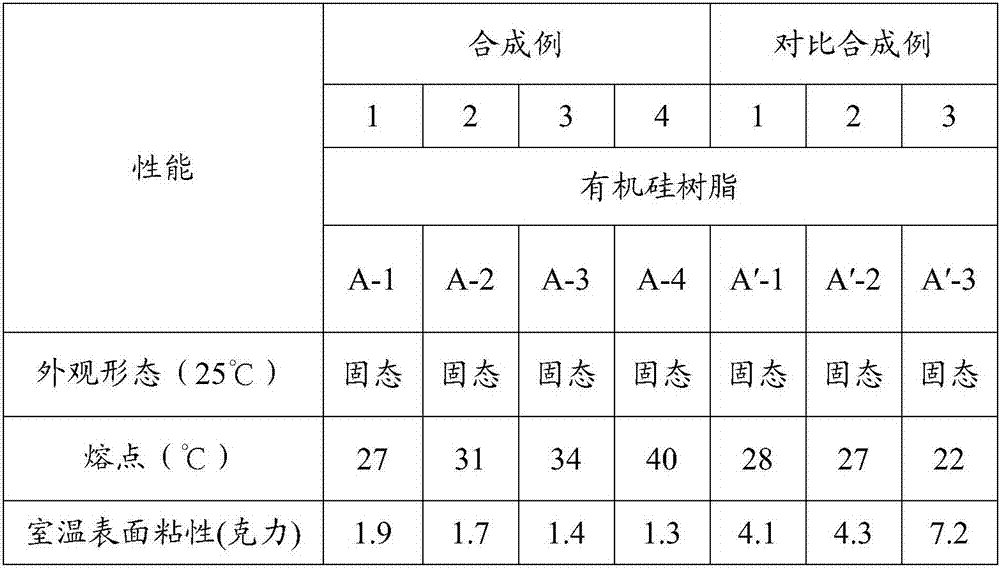

[0119] Utilize the AVANCE II 400MHz type nuclear magnetic resonance instrument that Switzerland Bruker company manufactures, by measuring the proton nuclear magnetic resonance spectrum of organosilicon resin ( 1 H-NMR) and silicon NMR spectra ( 29 Si-NMR), determine the average unit formula of the silicone resin.

[0120]

[0121] The melting point of the silicone resin was determined by measuring the DSC curve of the silicone resin with a DSC 204HP differential scanning calorimeter manufactured by Netzsch, Germany.

[0122]

[0123] After molding the silicone resin into a test sample with a size of 10cm×10cm×2mm, place it on the surface of a steel plate with a size of 15cm×15cm×1mm and a flat surface. Place the steel plate loaded with the test sample in the center of the stage of the TA.TX Pl...

Synthetic example 1

[0129]In the reactor equipped with stirrer, thermometer, and condensing reflux element, open the stirrer, add 504.0 grams (28.0 moles) of deionized water, 9.0 grams of hydrochloric acid with a concentration of 0.05N, and 1000.0 grams of toluene to form the first mixed solution; The reactor was slowly warmed up, and at the same time, 747.5 grams (5.0 moles) of methyltrichlorosilane, 634.5 grams (3.0 moles) of phenyltrichlorosilane, 258.0 grams (2.0 moles) of dimethyl A second mixed solution composed of dichlorosilane and 1000.0 grams of toluene; after the second mixed solution is added dropwise, keep the inner temperature of the reactor at 70°C, and perform a hydrolysis reaction under reflux for 3 hours to obtain a hydrolysis reaction product; The obtained hydrolysis reaction product was cooled and allowed to stand to separate layers, and then the organic phase and the aqueous phase were separated. Adjust the pH value of the separated organic phase to 9 with potassium hydroxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com