Preparation method of foot-shape imitated gecko adhesion material

A strip and sheet technology is applied in the field of preparation of foot-shaped gecko-like adhesive materials, which can solve problems such as difficulty in processing microporous array molds, and achieve the effects of reducing production costs, simple process, and strong controllability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

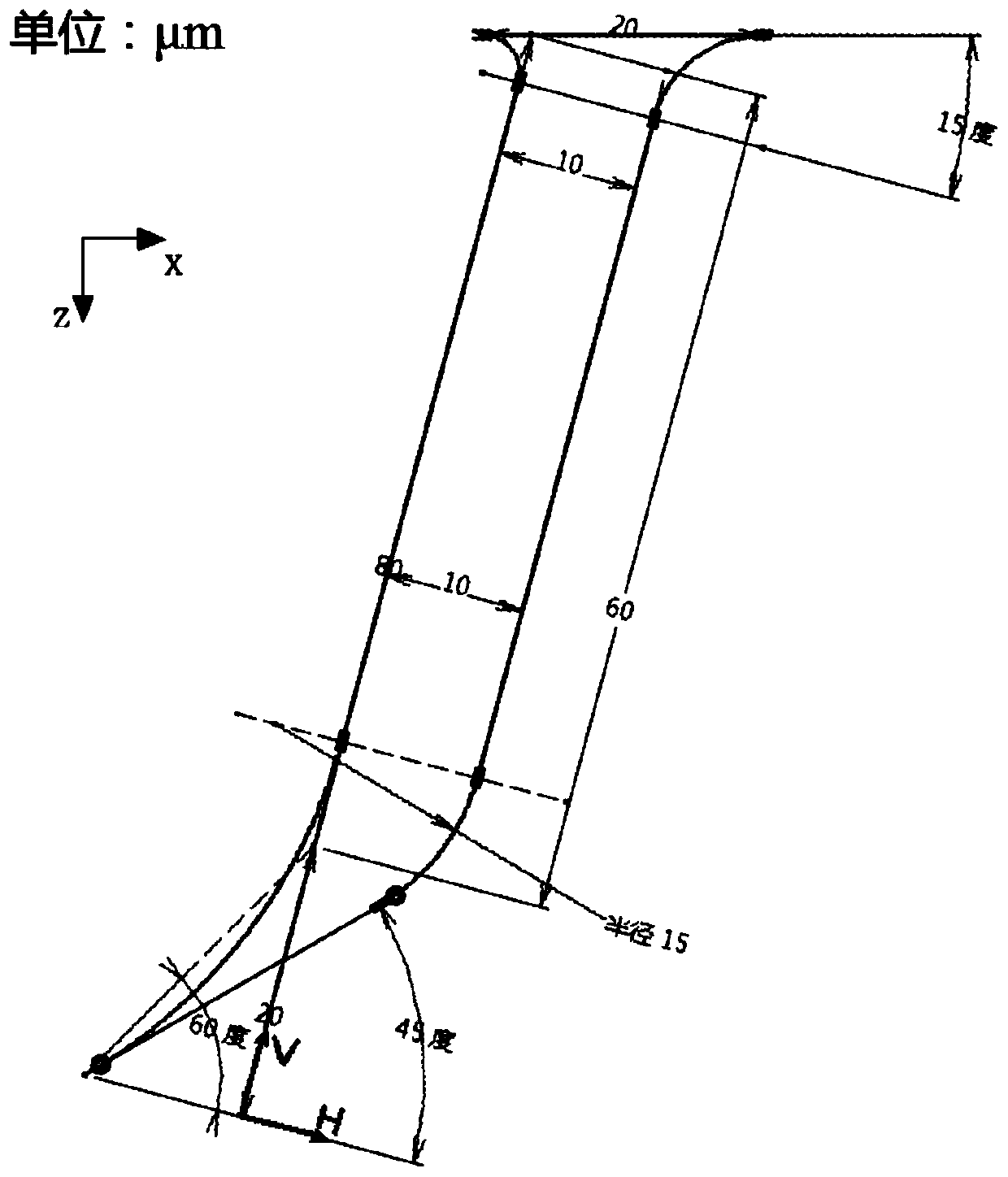

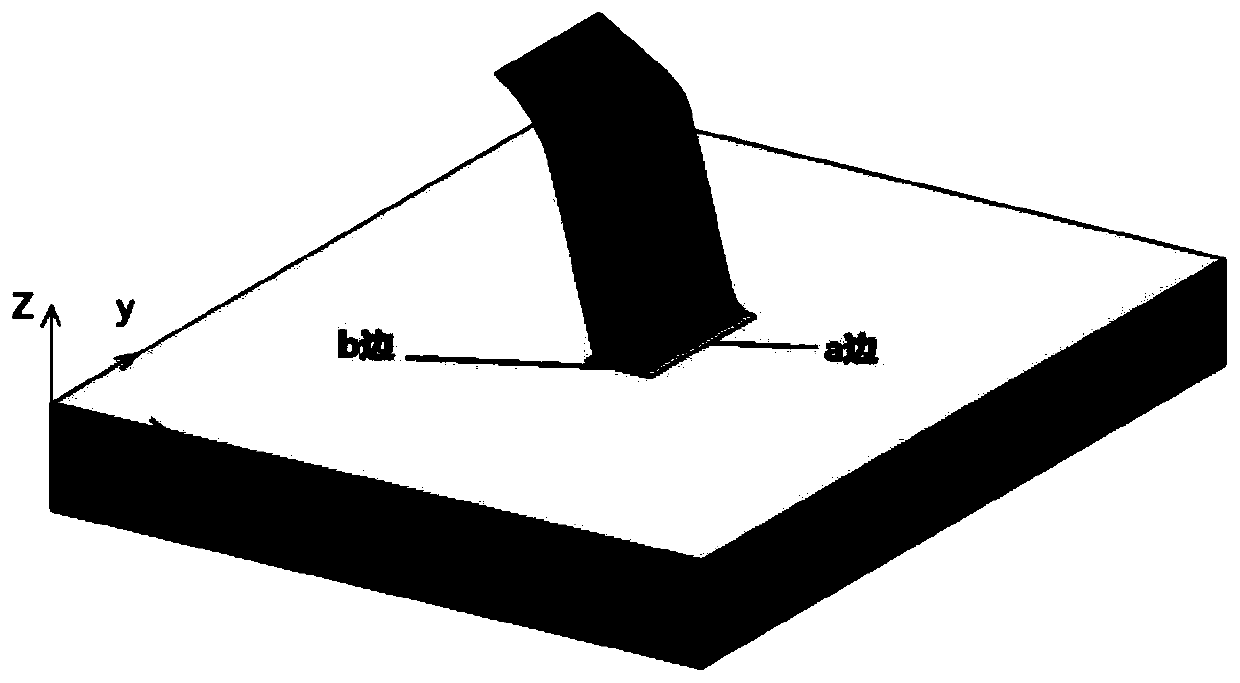

[0028] The cross-sectional view and specific dimensions of the fiber unit of the foot-shaped imitation gecko adhesive material designed in this embodiment are as follows: figure 1 shown. Specifically, the structure of the fiber unit has both a rectangular cross-section and a foot-like longitudinal section, and the simultaneous having a rectangular cross-section and a foot-like longitudinal section refers to the shape of the fiber unit. Such as figure 2 As shown, the transverse section refers to the plane parallel to xy, which is a profile with rectangular features; the longitudinal section refers to the plane parallel to xz, which is the complex shape profile of the fiber that can be designed.

[0029] The lamellar assembly silicon mold used in the preparation method of the foot-shaped imitation gecko adhesive material is formed by directional bonding and assembly of n silicon sheets with corresponding microstructure etching grooves, where n=required mold Overall width / thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com